ASTM E768-99

(Practice)Standard Practice for Preparing and Evaluating Specimens for Automatic Inclusion Assessment of Steel

Standard Practice for Preparing and Evaluating Specimens for Automatic Inclusion Assessment of Steel

SCOPE

1.1 This practice covers recognized methods for preparing metallographic specimens for automatic nonmetallic inclusion assessment of steel and includes a test for adequacy of preparation.

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 768 – 99

Standard Guide for

Preparing and Evaluating Specimens for Automatic

Inclusion Assessment of Steel

This standard is issued under the fixed designation E 768; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This guide covers two preparation methods for steel 4.1 Inclusion ratings done either manually using Test Meth-

metallographic specimens that will be analyzed for nonmetallic ods E 45 or automatically using Practice E 1122 or E 1245 are

inclusions with automatic image analysis (AIA) equipment. influenced by the quality of specimen preparation. This guide

The two methods of preparation are offered as accepted provides examples of proven specimen preparation methods

methods used to retain nonmetallic inclusions in steel. This that retain inclusions in polished steel specimens.

guide does not limit the user to these methods. 4.2 This guide provides a procedure to determine if the

1.2 A procedure to test the suitability of the prepared prepared specimens are of suitable quality for subsequent

specimen for AIA inclusion work, using differential interfer- rating of inclusions. None of these methods should be con-

ence contrast (DIC), is presented. strued as defining or establishing specific procedures or limits

of acceptability for any steel grade.

2. Referenced Documents

5. Preparation Methods

2.1 ASTM Standards:

E 3 Methods of Preparation of Metallographic Specimens 5.1 Background:

E 7 Terminology Relating to Metallography 5.1.1 The inclusions in the plane of polish must be fully

E 45 Test Methods for Determining the Inclusion Content preserved and clearly visible. Preparation should not produce

of Steel excessive relief around the perimeter of the inclusions that

E 883 Guide for Reflected-Light Photomicrography would exaggerate the size and number of inclusions on the

E 1122 Practice for Obtaining JK Inclusion Ratings Using plane of polish. In many cases, the preparation of specimens

Automatic Image Analysis for inclusion rating is more readily performed after the

E 1245 Practice for Determining the Inclusion or Second- specimens have been hardened by a suitable heat treatment

Phase Constituent Content of Metals by Automatic Image procedure (austenize, quench to fully martensitic structure,

Analysis temper at a relatively low temperature).

5.1.2 Cleanliness is an important consideration in all stages

3. Terminology

of specimen preparation.

3.1 Definitions: 5.1.2.1 Heat-treated specimens should be wire brushed or

3.1.1 For definitions used in this practice, refer to Termi-

shot blasted or have the surface ground to remove adherent

nology E 7. scale.

3.1.2 differential interference contrast microscopy—a com-

5.1.2.2 After completing the grinding steps and before

prehensive definition appears in Guide E 883, paragraph 11.8. performing the polishing steps, the specimens and specimen

3.2 Definitions of Terms Specific to This Standard:

holders must be cleaned to prevent contamination of the next

3.2.1 rigid grinding disk—a non-fabric support surface, preparation step. Cleaning the specimens and specimen holders

such as a composite of metal/ceramic or metal/polymer,

between each grinding step can eliminate contamination of

charged with an abrasive (usually 6 to 15-μm diamond par- coarse abrasives to the following finer preparation step.

ticles), and used as the fine grinding operation in a metallo-

5.1.2.3 After the preparation is complete, swab the surface

graphic preparation procedure. carefully with cotton and a water/soap solution containing a

corrosion inhibitor such as a machine coolant or ethyl alcohol

solution to remove any films or other debris that would

This test method is under the jurisdiction of ASTM Committee E-4 on

interfere with the inclusion rating.

Metallography and is the direct responsibility of Subcommittee E04.01 on Sampling

Specimen Preparation, and Photography.

5.1.2.4 It is advisable to perform the inclusion analysis as

Current edition approved April 10, 1999. Published July 1999.

soon as possible after preparation to minimize staining or other

Supporting data available from ASTM Headquarters. Request E04.1002.

3 problems that can affect the analysis.

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 768

5.1.3 The two methods that follow have been found to be of steel grades. The relatively low pressures suggested in this

reliable procedures for retaining inclusions in steel and achiev- procedure will not necessarily result in a satisfactory polish for

ing the desired results when evaluated by DIC. There are other etching and the further evaluation of the specimen’s general

methods that will result in a quality specimen as revealed by microstructure. The pressures used in the following rigid disk

DIC. Each laboratory should develop preparation procedures procedure are more likely to result in a surface more satisfac-

for their materials so that the prepared surfaces meet the tory for revealing general microstructures.

requirements presented in 6 of this guide.

5.2.3 Grind the specimens on ANSI 80 grit (P80 FEPA)

5.1.4 As described in Methods E 3, the specimens may be

silicon carbide paper to ensure all sectioning artifacts and

sectioned and mounted to ease handling during preparation. It

deformation damage have been removed and the entire speci-

is advisable to use a mounting medium that is hard enough to

men surface is co-planar to the grinding surface.

preserve edges and maintain flatness.

NOTE 2—If the sectioning method resulted in a smooth face and little

5.1.5 Abrasive grit size designations in this guide are

deformation damage, and if after securing the specimens in a fixture for

expressed in the American National Standards Institute (ANSI)

polishing, the entire surface of interest is co-planar to the grinding surface,

or Coated Abrasives Manufacturers Institute (CAMI) system

then finer grit papers, such as ANSI 180 to 240 (P180 to P240 FEPA) can

units with the corresponding Federation of European Abrasive

be used for the initial grinding step.

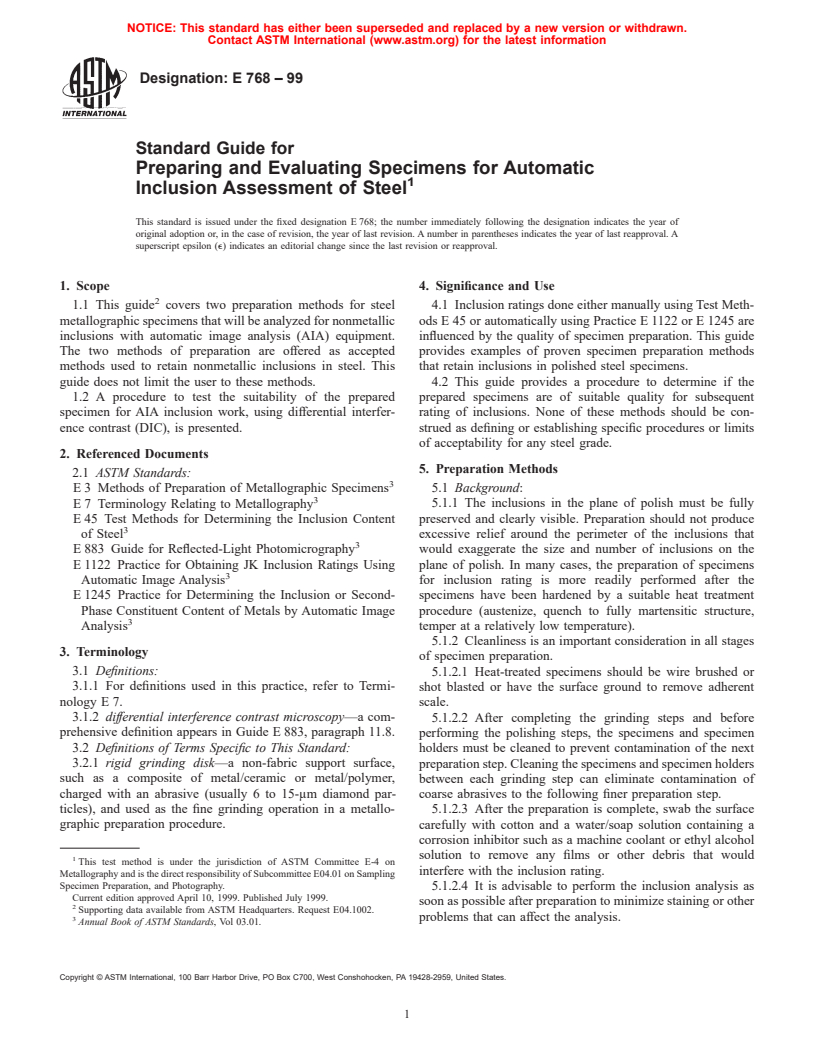

Procedure (FEPA) numbers in parentheses. Table 1 provides a

5.2.3.1 An adequate flow of water should remove all loos-

correlation between these two systems and the approximate

ened abrasive and grinding debris from the paper during the

median particle diameter for a given grit size in micrometres.

grinding procedure. The flow of water should ensure the

5.1.6 Most preparation systems apply pressure on the speci-

specimen is kept cool during grinding.

mens being processed. The best pressure to be used for each

5.2.4 Continue grinding through the sequence of silicon

preparation step should be determined experimentally. Conver-

carbide papers listed in Table 2. It may be necessary to clean

sions between applied force and pressure are discussed in the

the samples between every grinding step to prevent contami-

Appendix X1.

nation of the next preparation step.

NOTE 1—Care must be taken to protect the polished specimen surface

5.2.5 After completing the entire grinding operation, clean

from scratches or contaminants when using a specimen leveling device.

the specimens thoroughly, using ethyl alcohol and cotton, then

5.2 Silicon Carbide Procedure:

rinse and dry. Ultrasonic cleaning can be used.

5.2.1 A summary of the silicon carbide procedure can be

5.2.5.1 The use of a soap and water solution in an ultrasonic

found in Table 2.

cleaner can attack non-metallic inclusions in some carbon and

5.2.2 When using a semi-automatic polishing equipment,

low alloy steels, leading to an exaggeration in the inclusion’s

grinding and polishing should be performed using approxi-

apparent size. Adding an inhibitor (such as that used as a

mately 18 kPa pressure per specimen. (For a specimen holder

machining coolant) may reduce this size exaggeration.

containing six 32-mm mounts, a force of approximately 87 N

5.2.6 Polish the specimens using 3-μm diamond abrasive on

must be applied (see X1.4.2).

a low nap cloth, such as woven wool, for 50 s. Clean and dry

5.2.2.1 Low pressures are recommended to ensure the

the specimens as described in 5.2.5.

retention of an assortment of inclusion types found in a variety

5.2.7 Polish the specimens using a 1-μm diamond abrasive

on a high nap cloth for 50 s. Clean and dry the specimens as

TABLE 1 Comparison of ANSI (CAMI) versus FEPA versus

Median Diameter of Grit Size in Micrometers described in 5.2.5.

A B C

ANSI (CAMI) FEPA Approximate Median 5.2.8 A final manual polishing step may be added, using

Diameter

0.25-μm diamond abrasive on a low nap cloth for 10 to 20 s,

(μm)

using relatively high pressure. Clean and dry the specimens as

60 P60 250

described in 5.2.5.

80 P80 180

100 P100 150

5.2.8.1 Ultrasonic cleaning is not recommended after the

120 P120 125

final manual or automatic polishing step. Ultrasonic cleaning

150 P150 90

can cause cavitation damage, ultimately distorting the inclu-

180 P180 75

220 P220 63

sion sizes.

240 P240 58.5

P280 52.2

NOTE 3—Depending on the material, it may be advisable to avoid water

280 P320 46.2

after polishing.

320 P360 40.5

P400 35.0

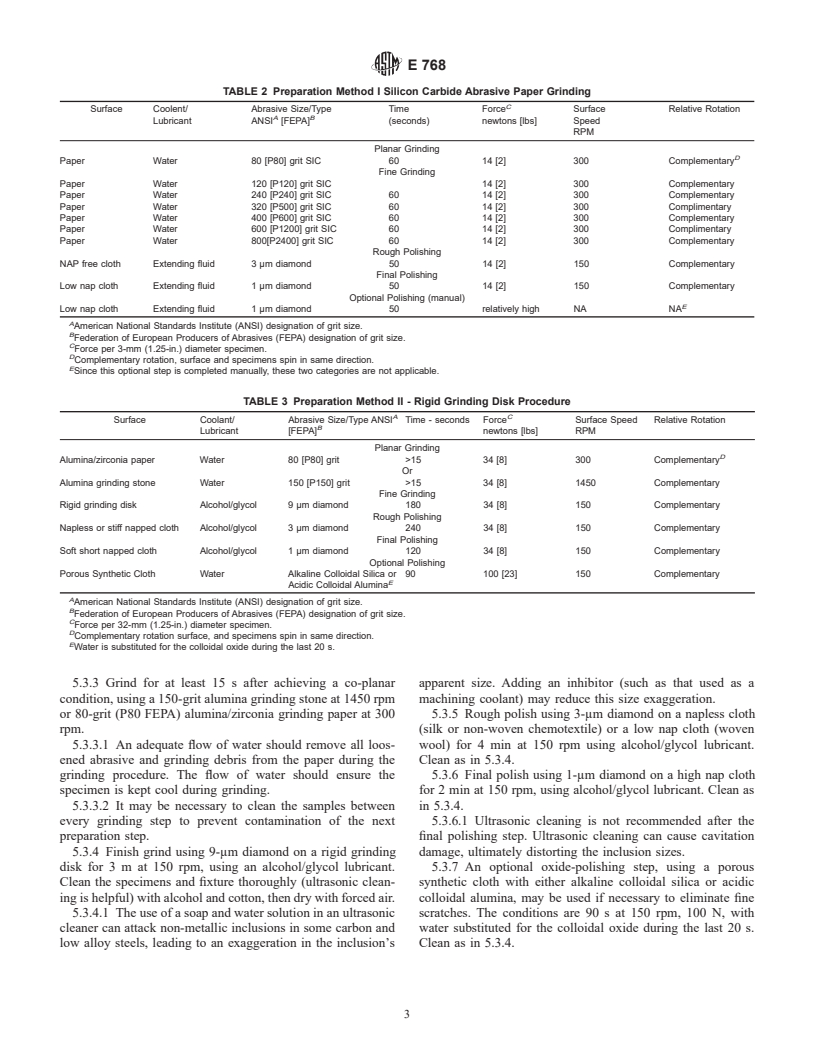

5.3 Rigid Grinding Disk Procedure:

360 P500 30.2

5.3.1 A summary of the rigid grinding disk procedure can be

400 P600 25.8

P800 21.8

found in Table 3.

500 P1000 18.3

5.3.2 Semi-automatic grinding equipment is required, with

600 P1200 15.3

800 P2400 8.4

specimens contained in a circular fixture for the entire proce-

D

1200 P4000 3.0

dure. For 5.3.2-5.3.5, a pressure of 42 kPa should be applied

A

ANSI - American National Standards Institute

per specimen. (For a specimen holder containing six 32-mm

B

CAMI - Coated Abrasives Manufacturers Institute

C circular mounts, a force of approximately 203 N must be

FEPA - Federation of European Abrasive Producers

D

Not a FEPA designation applied (see X1.4.3).

---------------------- Page

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.