ASTM D6767-08

(Test Method)Standard Test Method for Pore Size Characteristics of Geotextiles by Capillary Flow Test

Standard Test Method for Pore Size Characteristics of Geotextiles by Capillary Flow Test

SIGNIFICANCE AND USE

This test method may be used to:

Determine the pore size distribution of a geotextile,

Determine the maximum pore size of a geotextile,

Determine the mean flow pore size of a geotextile,

Determine the effect of processes such as calendering or needle punching upon the pore size distribution,

Determine the effect of compression upon the pore size distribution of a geotextile, and

Determine the gas flow rate of a geotextile, and thereby its gas flow capability.

The pore size distribution test is significant not only for indicating pore sizes, but may also indicate a damaged, contaminated, or clogged geotextile.

SCOPE

1.1 This test method covers the determination of the pore size distribution of geotextile filters with pore sizes ranging from 1 to 500 μm.

Note 1—The accuracy of this procedure has been verified up to a maximum pore size of 200 μm. Above this value accuracy has been found to be equipment dependent and should be verified by the user through checks on materials with known opening sizes.

1.2 The test method measures the entire pore size distribution in terms of a surface analysis of specified pore sizes in a geotextile, defined in terms of the limiting diameters.

1.3 The analyst should be aware that adequate collaborative data for bias statements as required by Practice D 2777 is not provided. See the precision and bias section for details.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6767–08

Standard Test Method for

Pore Size Characteristics of Geotextiles by Capillary Flow

1

Test

This standard is issued under the fixed designation D6767; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4439 Terminology for Geosynthetics

1.1 This test method covers the determination of the pore

3. Terminology

size distribution of geotextile filters with pore sizes ranging

3.1 Definitions—For definitions of other terms used in these

from 1 to 500 µm.

test methods, refer to Definitions D4439 and D1129.

NOTE 1—The accuracy of this procedure has been verified up to a

3.2 Definitions of Terms Specific to This Standard:

maximum pore size of 200 µm.Above this value accuracy has been found

3.2.1 bubble point pore size (O ), n—the largest effective

98

to be equipment dependent and should be verified by the user through

pore diameter detected by the sudden increase of flow rate at

checks on materials with known opening sizes.

the beginning of the wet test.

1.2 The test method measures the entire pore size distribu-

3.2.2 pore constriction (O), n—diameter of a circle having

tion in terms of a surface analysis of specified pore sizes in a

the same area as the smallest section of a given pore.

geotextile, defined in terms of the limiting diameters.

3.2.3 pore size (O), n—capillary equivalent pore diameter

i

1.3 The analyst should be aware that adequate collaborative

for which the percent of total pore diameters i in a given

data for bias statements as required by Practice D2777 is not

geotextile based on the surface occupied by the pores are

provided. See the precision and bias section for details.

smaller than or equal to that diameter.

1.4 The values stated in SI units are to be regarded as

3.2.4 pore size distribution (PSD), n—percent cumulative

standard. No other units of measurement are included in this

distribution of the complete range of pore sizes with in a given

standard.

geotextile based on the surface occupied by the pores.

1.5 This standard may involve hazardous materials, opera-

3.2.5 wetting liquid, n—liquid used to submerge the geo-

tions, and equipment. This standard does not purport to

textile specimen prior to beginning the test.

address all of the safety concerns, if any, associated with its

use. It is the responsibility of the user of this standard to

4. Summary of Test Method

establish appropriate safety and health practices and deter-

4.1 Geotextile filters have discrete pores from one side to

mine the applicability of regulatory limitations prior to use.

theotherofthegeotextile.Thebubblepointtestisbasedonthe

principle that a wetting liquid is held in these continuous pores

2. Referenced Documents

by capillary attraction and surface tension, and the minimum

2

2.1 ASTM Standards:

pressure required to force liquid from these pores is a function

D1129 Terminology Relating to Water

of pore diameter.

D2777 Practice for Determination of Precision and Bias of

4.2 Afluid-wet geotextile will pass air when the applied air

Applicable Test Methods of Committee D19 on Water

pressure exceeds the capillary attraction of the fluid in the pore

D4354 Practice for Sampling of Geosynthetics for Testing

constriction. Smaller pore constrictions will exhibit similar

behavior at higher pressures. The relationship between pore

1

size and pressure has been established for water.

This test method is under the jurisdiction of ASTM Committee D35 on

Geosynthetics and is the direct responsibility of Subcommittee D35.03 on Perme-

4.3 By comparing the gas flow rates of both a wet and dry

ability and Filtration.

geotextile at the same pressures, the percentage of the flow

Current edition approved April 1, 2008. Published April 2008. Originally

passing through the filter pores larger than or equal to the

approved in 2002. Last previous edition approved in 2002 as D6767–02. DOI:

specified size may be calculated from the pressure-size rela-

10.1520/D6767-08.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tionship. By increasing pressure in small steps, it is possible to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

determine the flow contribution of very small pore size

Standards volume information, refer to the standard’s Document Summary page on

increments by difference.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

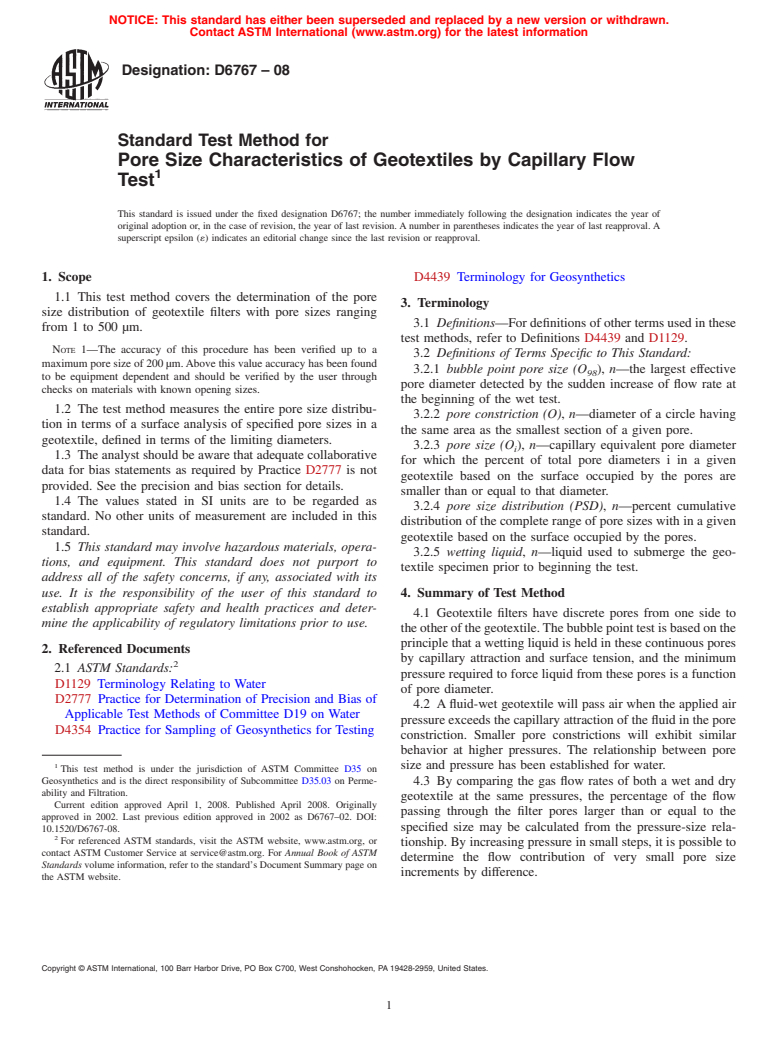

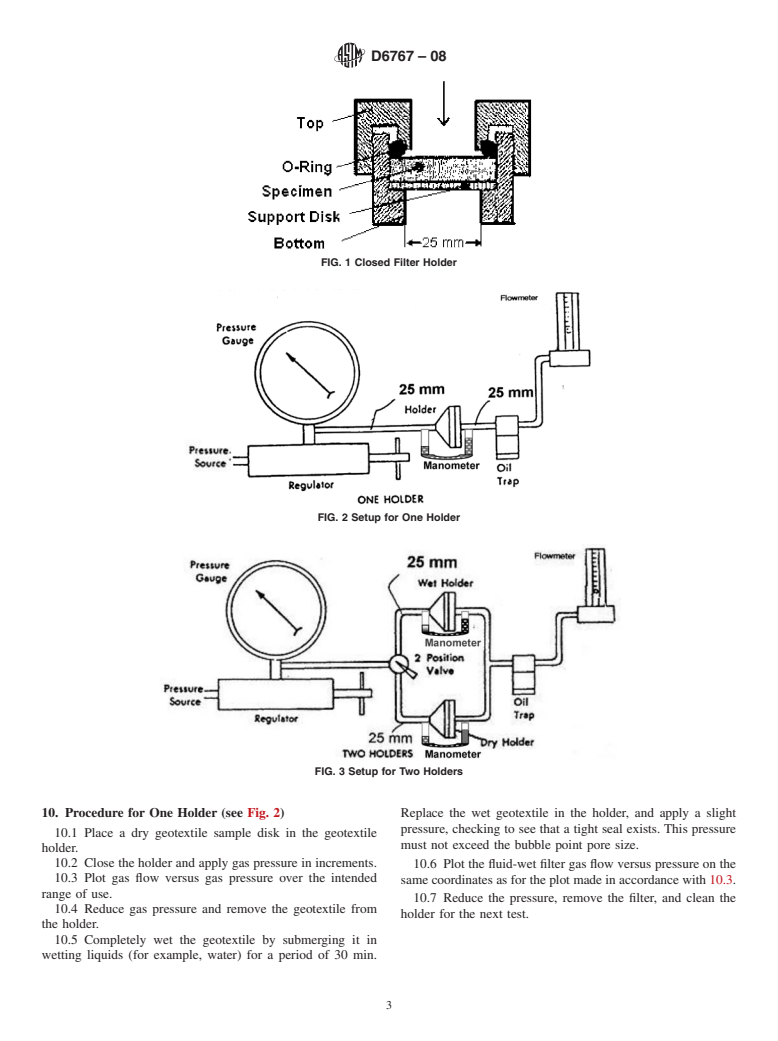

---------------------- Page: 1 ----------------------

D6767–08

5. Significance and Use 6.8 x-y Recorder, to assist in graphing results of mean flow

pore tes

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6767–02 Designation:D6767–08

Standard Test Method for

Pore Size Characteristics of Geotextiles by Capillary Flow

1

Test

This standard is issued under the fixed designation D 6767; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the pore size distribution of geotextile filters with pore sizes ranging from 1

to 500 µm.

NOTE 1—The accuracy of this procedure has been verified up to a maximum pore size of 200 µm. Above this value accuracy has been found to be

equipment dependent and should be verified by the user through checks on materials with known opening sizes.

1.2 The test method measures the entire pore size distribution in terms of a surface analysis of specified pore sizes in a

geotextile, defined in terms of the limiting diameters.

1.3 The analyst should be aware that adequate collaborative data for bias statements as required by Practice D 2777 is not

provided. See the precision and bias section for details.

1.4

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all

of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate

safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 1129 Definition of Terms Relating to Water Terminology Relating to Water

D 2777 Practice for Determination of Precision and Bias of Applicable Test Methods of Committee D-19D19 on Water

D 4354 Practice for Sampling Geosynthetics (for Testing) Practice for Sampling of Geosynthetics for Testing

3

D 4439 Terminology Relating to Geosynthetics

E128Test Method for Maximum Pore Diameter and Permeability of Rigid Porous Filters for Laboratory Use

4

F316Pore Size Characteristics of Membrane Filter by Bubble Point and Mean Flow Pore Test Terminology for Geosynthetics

3. Terminology

3.1 Definitions—For definitions of other terms used in these test methods, refer to Definitions D 4439 and D 1129.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 bubble point pore size (O ), n—the largest effective pore diameter detected by the sudden increase of flow rate at the

98

beginning of the wet test.

3.2.2 pore constriction (O), n—diameter of a circle having the same area as the smallest section of a given pore.

3.2.3 pore size (O), n—capillary equivalent pore diameter for which the percent of total pore diameters i in a given geotextile

i

based on the surface occupied by the pores are smaller than or equal to that diameter.

3.2.4 pore size distribution (PSD), n—percent cumulative distribution of the complete range of pore sizes with in a given

geotextile based on the surface occupied by the pores.

3.2.5 wetting liquid, n—liquid used to submerge the geotextile specimen prior to beginning the test.

1

This test method is under the jurisdiction ofASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.03 on Hydraulic Properties.

Current edition approved Feb 10, 2002. Published August 2002.

1

This test method is under the jurisdiction of ASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.03 on Permeability and

Filtration.

Current edition approved April 1, 2008. Published April 2008. Originally approved in 2002. Last previous edition approved in 2002 as D 6767–02.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 11.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

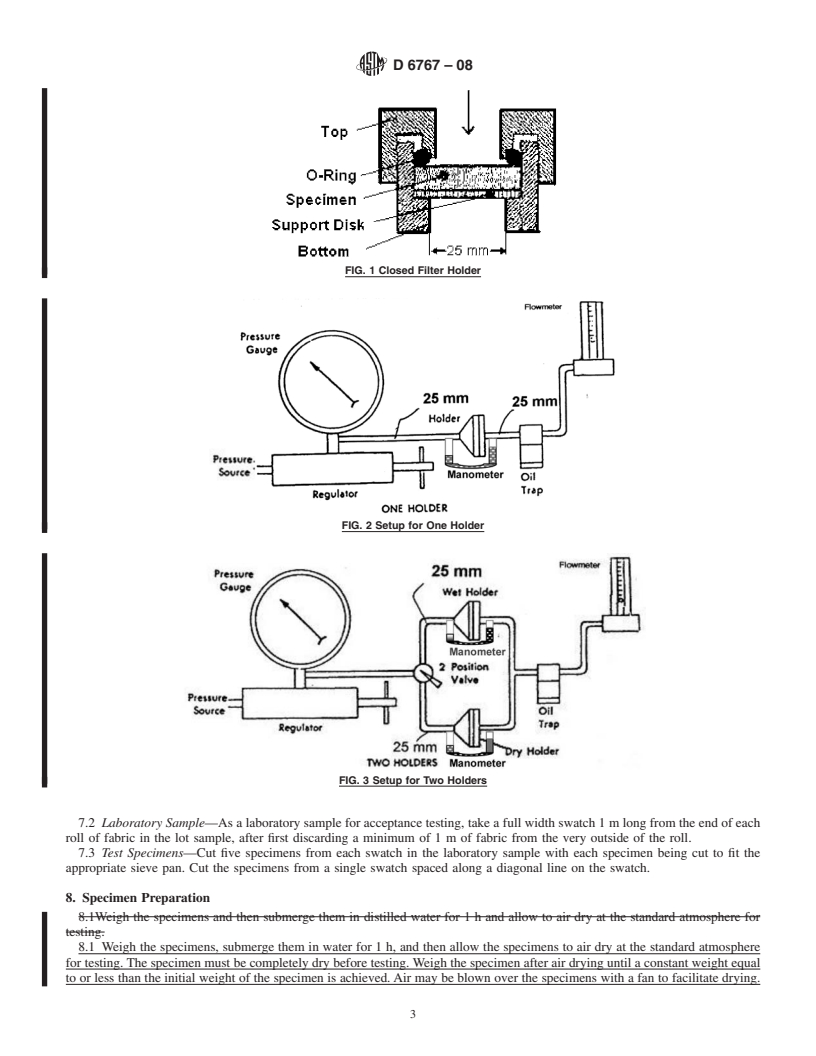

D6767–08

4. Summary of Test Method

4.1 Geotextile filters have discrete pores from one side to the other of the geotextile. The bubble point test is based on the

principle that a wetting liquid is held in these continuous pores by capillary attraction and surface tension, and the minimum

pressure

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.