ASTM E2584-14

(Practice)Standard Practice for Thermal Conductivity of Materials Using a Thermal Capacitance (Slug) Calorimeter

Standard Practice for Thermal Conductivity of Materials Using a Thermal Capacitance (Slug) Calorimeter

SIGNIFICANCE AND USE

5.1 This practice is useful for testing materials in general, including composites and layered types.

5.2 The practice is especially useful for materials which undergo significant reactions or local dimensional changes, or both, during exposure to elevated temperatures and thus are difficult to evaluate using existing standard test methods such as Test Method C1113.

5.3 Performing the test over multiple heating/cooling cycles allows an assessment of the influence of reactions, phase changes, and mass transfer of reactions gases (for example, steam) on the thermal performance.Note 3—This method has been found to be especially applicable to testing fire resistive materials.

SCOPE

1.1 This practice describes a technique for the determination of the apparent thermal conductivity, λa, of materials. It is for solid materials with apparent thermal conductivities in the approximate range 0.02 a Note 1—While the practice should also be applicable to determining the thermal conductivity of non-reactive materials, it has been found specifically useful in testing fire resistive materials that are both reactive and undergo significant dimensional changes during a high temperature exposure.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2584 − 14

Standard Practice for

Thermal Conductivity of Materials Using a Thermal

1

Capacitance (Slug) Calorimeter

This standard is issued under the fixed designation E2584; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Comparison Techniques

E230Specification and Temperature-Electromotive Force

1.1 Thispracticedescribesatechniqueforthedetermination

(EMF) Tables for Standardized Thermocouples

of the apparent thermal conductivity, λ , of materials. It is for

a

E457Test Method for Measuring Heat-Transfer Rate Using

solid materials with apparent thermal conductivities in the

a Thermal Capacitance (Slug) Calorimeter

approximate range 0.02<λ <2 W/(m·K) over the approxi-

a

E691Practice for Conducting an Interlaboratory Study to

mate temperature range between 300K and 1100K.

Determine the Precision of a Test Method

NOTE 1—While the practice should also be applicable to determining

the thermal conductivity of non-reactive materials, it has been found

specifically useful in testing fire resistive materials that are both reactive

3. Terminology

and undergo significant dimensional changes during a high temperature

3.1 Definitions:

exposure.

3.1.1 thermal conductivity, λ—the time rate of heat flow,

1.2 The values stated in SI units are to be regarded as

understeadyconditions,throughunitarea,perunittemperature

standard. No other units of measurement are included in this

gradient in the direction perpendicular to the area.

standard.

3.1.2 apparent thermal conductivity, λ —when other modes

a

1.3 This standard does not purport to address all of the

of heat transfer (and mass transfer) through a material are

safety concerns, if any, associated with its use. It is the

present in addition to thermal conduction, the results of the

responsibility of the user of this standard to establish appro-

measurements performed according to this practice will repre-

priate safety and health practices and determine the applica-

sent the apparent or effective thermal conductivity for the

bility of regulatory limitations prior to use.

material tested.

2. Referenced Documents

3.2 Symbols:

2

2.1 ASTM Standards: 2

A = specimen area normal to heat flux direction, m

C1113Test Method for Thermal Conductivity of Refracto-

C = specific heat capacity, J/(kg·K)

p

ries by Hot Wire (Platinum Resistance Thermometer

F = heating or cooling rate, (K/s)

Technique)

L = thickness of a specimen (slab) in heat transfer

D2214Test Method for Estimating the Thermal Conductiv-

direction,m

ityofLeatherwiththeCenco-FitchApparatus(Withdrawn

M = mass, kg

3

2008)

Q = heat flow, W

E177Practice for Use of the Terms Precision and Bias in T = absolute temperature, K

SSS

T = mean temperature of the stainless steel slug, K

ASTM Test Methods

inner

SPEC

T = mean temperature of outer (exposed) specimen

E220Test Method for Calibration of Thermocouples By

outer

surfaces, K

SPEC

T = mean temperature of specimen, K

mean

1 ∆T = temperature difference across the specimen,

This practice is under the jurisdiction of ASTM Committee E37 on Thermal

SPEC SSS

Measurements and is the direct responsibility of Subcommittee E37.05 on Thermo- given by (T – T ), K

outer inner

physical Properties.

λ = thermal conductivity, W/(m·K)

Current edition approved Feb. 15, 2014. Published March 2014. Originally

λ = apparent thermal conductivity, W/(m·K)

a

approved in 2007. Last previous edition approved in 2010 as E2584–10. DOI:

SPEC 3

ρ = bulk density of specimen being tested, kg/m

10.1520/E2584-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.3 Subscripts/Superscripts:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

SPEC = material specimen being evaluated

the ASTM website.

3 SSS = stainless steel slug (thermal capacitance transducer)

The last approved version of this historical standard is referenced on

www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

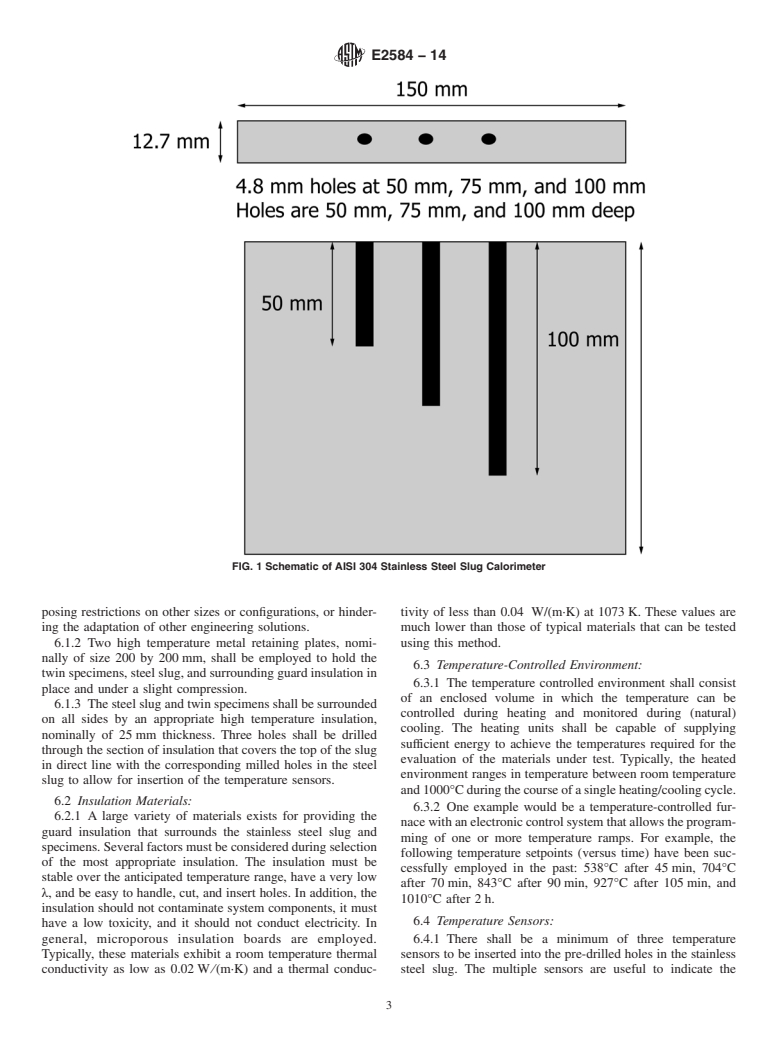

---------------------- Page: 1 ----------------------

E2584 − 14

4. Summary of Practice material, of known mass and known and nominally identical

thickness, between which is sandwiched a stainless steel

4.1 Principle of Operation—Inprinciple,aslugofthermally

thermal capacitance transducer (slug) of known mass. The

conductive metal, capable of withstanding elevated

entire sandwich is placed between two (high temperature)

temperatures, is surroundedwithanothermaterialofauniform

metal retaining plates, and the bolts hold

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2584 − 10 E2584 − 14

Standard Practice for

Thermal Conductivity of Materials Using a Thermal

1

Capacitance (Slug) Calorimeter

This standard is issued under the fixed designation E2584; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes a technique for the determination of the apparent thermal conductivity, λ , of materials. It is for solid

a

materials with apparent thermal conductivities in the approximate range 0.02 < λ < 2 W/(m·K) over the approximate temperature

a

range between 300 K and 1100 K.

NOTE 1—While the practice should also be applicable to determining the thermal conductivity of non-reactive materials, it has been found specifically

useful in testing fire resistive materials that are both reactive and undergo significant dimensional changes during a high temperature exposure.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C1113 Test Method for Thermal Conductivity of Refractories by Hot Wire (Platinum Resistance Thermometer Technique)

3

D2214 Test Method for Estimating the Thermal Conductivity of Leather with the Cenco-Fitch Apparatus (Withdrawn 2008)

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E220 Test Method for Calibration of Thermocouples By Comparison Techniques

E230 Specification and Temperature-Electromotive Force (EMF) Tables for Standardized Thermocouples

E457 Test Method for Measuring Heat-Transfer Rate Using a Thermal Capacitance (Slug) Calorimeter

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 thermal conductivity, λ—the time rate of heat flow, under steady conditions, through unit area, per unit temperature

gradient in the direction perpendicular to the area.

3.1.2 apparent thermal conductivity, λ —when other modes of heat transfer (and mass transfer) through a material are present

a

in addition to thermal conduction, the results of the measurements performed according to this practice will represent the apparent

or effective thermal conductivity for the material tested.

3.2 Symbols:

2

A = specimen area normal to heat flux direction, m

C = specific heat capacity, J/(kg·K)

p

F = heating or cooling rate, (K/s)

L = thickness of a specimen (slab) in heat transfer direction, m

M = mass, kg

Q = heat flow, W

1

This practice is under the jurisdiction of ASTM Committee E37 on Thermal Measurements and is the direct responsibility of Subcommittee E37.05 on Thermophysical

Properties.

Current edition approved March 1, 2010Feb. 15, 2014. Published May 2010March 2014. Originally approved in 2007. Last previous edition approved in 20072010 as

E2584 – 07.E2584 – 10. DOI: 10.1520/E2584-10.10.1520/E2584-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

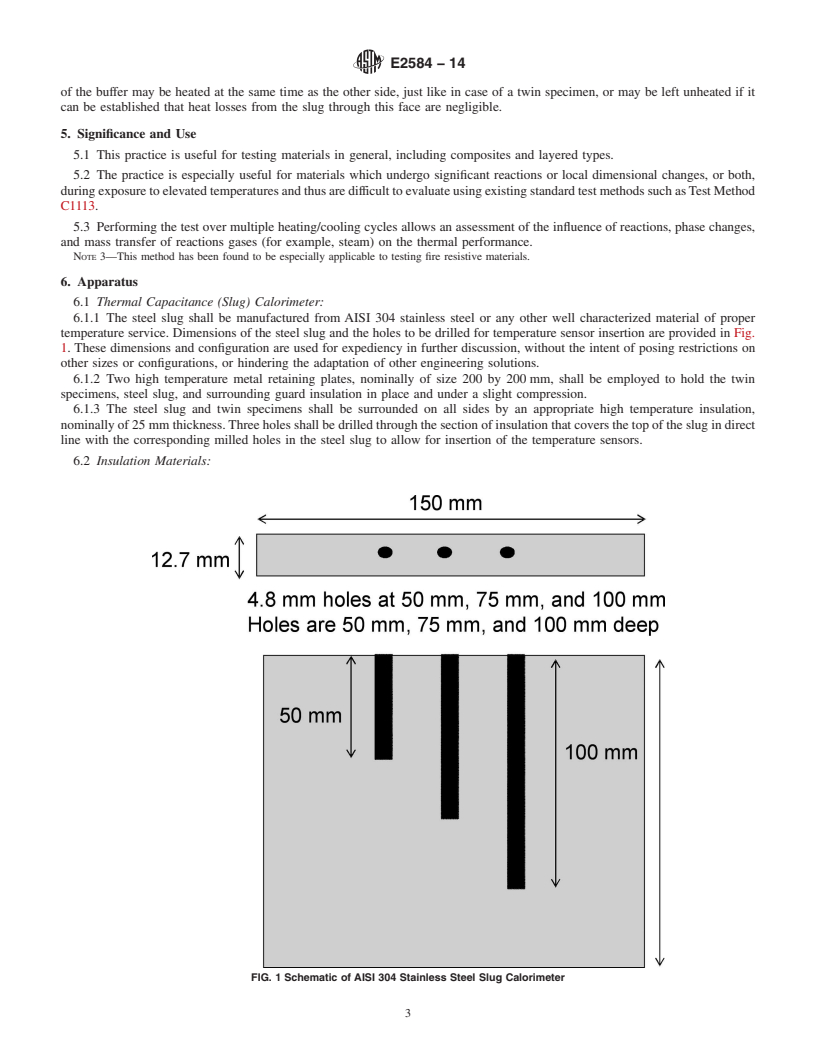

---------------------- Page: 1 ----------------------

E2584 − 14

T = absolute temperature, K

SSS

T = mean temperature of the stainless steel slug, K

inner

SPEC

T = mean temperature of outer (exposed) specimen surfaces, K

outer

SPEC

T = mean temperature of specimen, K

mean

SPEC SSS

ΔT = temperature difference across the specimen, given by (T – T ), K

outer inner

λ = thermal conductivity, W/(m·K)

λ = apparent thermal conductivity, W/(m·K)

a

SPEC 3

ρ = bulk density of specimen being tested, kg/m

3.3 Subscripts/Superscripts:

SPEC = material specimen being evaluated

SSS = stainless steel slug (thermal capacitance transducer)

4. Summary of Practice

4.1 Principle of Operation—In principle, a slug of thermally condu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.