ASTM A937/A937M-12(2019)

(Test Method)Standard Test Method for Determining Interlaminar Resistance of Insulating Coatings Using Two Adjacent Test Surfaces

Standard Test Method for Determining Interlaminar Resistance of Insulating Coatings Using Two Adjacent Test Surfaces

SIGNIFICANCE AND USE

5.1 This test method is particularly suitable for quality control in the application of insulating coatings. This test method measures the interlaminar resistance of insulating coatings, as defined in 3.1.4. Interlaminar resistance is the measure of the insulating quality of the coating. Interlaminar resistance is reported in units of kΩ.

5.2 The interlaminar resistance determined in accordance with this test method is not the same quantity determined by Test Method A717/A717M.

5.3 This test method is particularly useful for electrical steels coated with inorganic insulating coatings having surface insulation resistivities in excess of 0.3 kΩ·cm2 [30 kΩ·mm2] when tested using Test Method A717/A717M (a Franklin current less than 0.02 A). This test method can readily be extended to any range of insulation resistivity that the equipment comprising the two-surface tester allows. For the equipment specified herein, the maximum measurable resistance is 1200 kΩ for the 10-μA current setting and 12 000 kΩ for the 1-μA current setting; the maximum voltage for the test system is 12 V.

5.4 Repeat readings on the same set of two electrical steel laminations using different contact positions, as well as the testing of multiple laminations from the same lot of electrical steel, are recommended. Several readings are suggested because the coating thickness may vary across the surface of a given electrical steel lamination. Additionally, the coating thickness may vary across several laminations taken from the same lot of electrical steel. Such variations in coating thickness are likely to yield variations in the measured interlaminar resistance. The required number of readings depends on the nature of the coating and the accuracy required.

SCOPE

1.1 This test method covers a means of testing the interlaminar resistance of electrically insulating coatings as applied to adjacent laminations of flat-rolled electrical steel, under predetermined conditions of voltage, pressure and temperature. It indicates the effectiveness of surface coatings on electrical sheet steels for limiting interlaminar losses in electrical machinery. The interlaminar resistance is measured directly in units of resistance (kΩ).

1.2 This test method is particularly useful for, but not limited to, electrical steels coated with inorganic insulating coatings.

1.3 The values and equations stated in customary (cgs-emu and inch-pound) or SI units are to be regarded separately as standard. Within this standard, SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A937/A937M −12 (Reapproved 2019)

Standard Test Method for

Determining Interlaminar Resistance of Insulating Coatings

Using Two Adjacent Test Surfaces

This standard is issued under the fixed designationA937/A937M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers a means of testing the inter- 2.1 ASTM Standards:

laminar resistance of electrically insulating coatings as applied A34/A34MPractice for Sampling and Procurement Testing

to adjacent laminations of flat-rolled electrical steel, under of Magnetic Materials

predeterminedconditionsofvoltage,pressureandtemperature. A717/A717MTestMethodforSurfaceInsulationResistivity

It indicates the effectiveness of surface coatings on electrical of Single-Strip Specimens

sheet steels for limiting interlaminar losses in electrical ma-

3. Terminology

chinery. The interlaminar resistance is measured directly in

units of resistance (kΩ). 3.1 Definitions of Terms Specific to This Standard:

3.1.1 bad contact—acontactwhichresultsinavoltagedrop

1.2 This test method is particularly useful for, but not

in excess of 0.6 V as described in 6.1.3.

limited to, electrical steels coated with inorganic insulating

coatings. 3.1.2 exposed test surface—the insulating top surface of the

top lamination or the insulating bottom surface of the bottom

1.3 The values and equations stated in customary (cgs-emu

lamination of the test specimen.

and inch-pound) or SI units are to be regarded separately as

3.1.3 four-terminal measuring technique, often referred to

standard. Within this standard, SI units are shown in brackets.

as four-probe measuring technique—a common method to

Thevaluesstatedineachsystemmaynotbeexactequivalents;

measure resistance when a high degree of accuracy is re-

therefore,eachsystemshallbeusedindependentlyoftheother.

quired. In this standard, the circuit configuration for this

Combining values from the two systems may result in noncon-

technique is referred to as a four-probe configuration.Inthe

formance with this standard.

two-surface tester, this configuration features two probes con-

1.4 This standard does not purport to address all of the

nected to the top lamination test surface and two probes

safety concerns, if any, associated with its use. It is the

connected to the bottom lamination test surface. One of the

responsibility of the user of this standard to establish appro-

probesineachpaircarriesthemeasuringcurrent,andtheother

priate safety, health, and environmental practices and deter-

providesacontactforthevoltagemeasurement.Becauseofthe

mine the applicability of regulatory limitations prior to use.

extremely high impedance of the measuring circuit, very little

1.5 This international standard was developed in accor-

current flows through the voltage contacts, and thus very little

dance with internationally recognized principles on standard-

voltage is produced across the contacts to influence the true

ization established in the Decision on Principles for the

reading,thatis,anyeffectfromcontactresistanceisavoidedor

Development of International Standards, Guides and Recom-

reduced to a negligible amount. The two-surface tester has

mendations issued by the World Trade Organization Technical

provision to check the integrity of the contacts made between

Barriers to Trade (TBT) Committee.

the probes and the test surfaces.

1 2

This test method is under the jurisdiction of ASTM Committee A06 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Methods. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2019. Published April 2019. Originally the ASTM website.

approved in 1995. Last previous edition approved in 2012 as A937/A937M–12. Harris,F.K., Electrical Measurements,RobertE.KriegerPublishingCompany,

DOI: 10.1520/A0937_A0937M-12R19. Huntington, New York, 1975, pp. 220–224.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A937/A937M − 12 (2019)

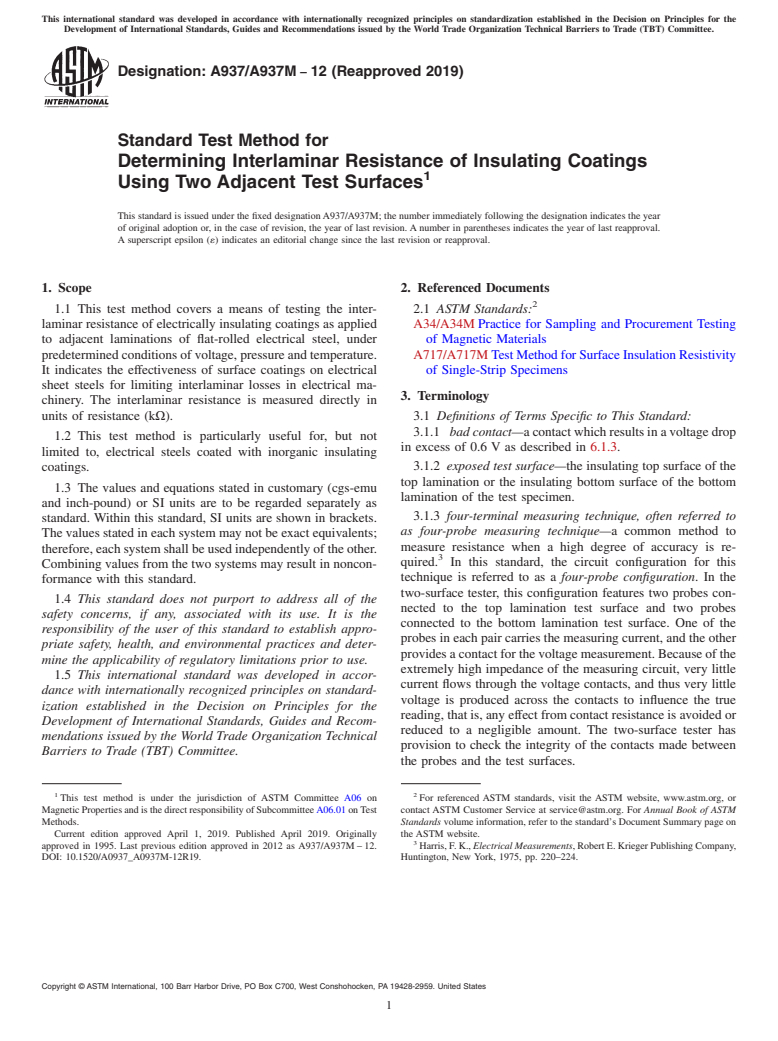

3.1.4 interlaminar resistance—theaverageresistanceoftwo current source using metallic contacts (drill bits). The tester

adjacent insulating surfaces in contact with each other, under utilizes two sets of metallic contacts which penetrate the

conditions specified in this standard.

exposed test surfaces into the base metal, to form a four-probe

configuration, Fig. 1. A continuous electrical path is formed

3.1.5 surface insulation resistivity—the effective resistivity

between the contacts and constant current source when the

of a single insulating layer tested between applied bare metal

metallic contacts penetrate through the coating on the exposed

contacts and the base metal of the insulated test specimen, as

test surfaces to the underlying base metal, and the insulating

per Test Method A717/A717M.

surfaces are held in intimate contact by the test head. When

3.1.6 test specimen—two electrical steel laminations, each

current flows in the circuit, the dc voltage developed in the

having a minimum size of 25×25 cm [250×250 mm] and

circuitmaybeeasilymeasuredbymeansofadigitalvoltmeter.

each having an electrically insulating coating on both sides.

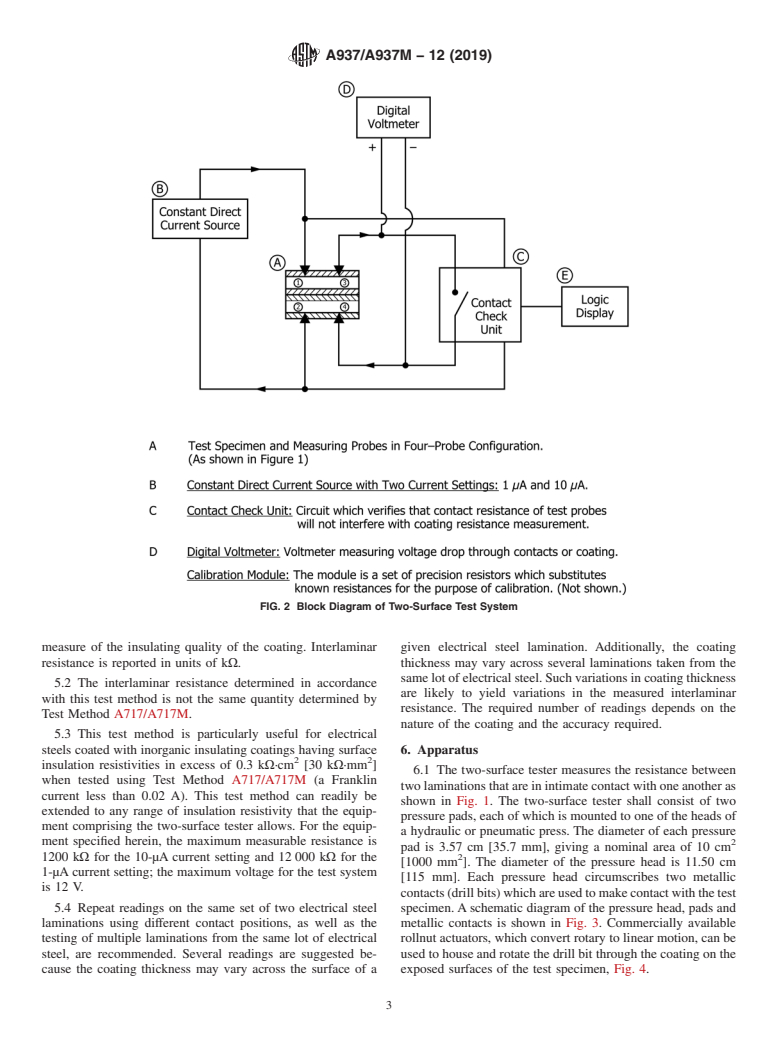

Ablock diagram of the two-surface test system is illustrated in

The two electrical steel laminations are placed one on top of

Fig. 2.

the other for the interlaminar resistance measurement, Fig. 1.

3.1.7 two-surface tester—the apparatus used in this test NOTE 1—The current range settings for the two-surface tester are 1-µA

dc and 10-µAdc, thus enabling the resistance to be read directly from the

method.

voltmeter. The current select switch is designed to shift the decimal point

appropriately so as to provide a resistance reading in units of kΩ.

4. Summary of Test Method

4.1 The test method measures the average resistance of two

5. Significance and Use

adjacent insulating surfaces. Intimate physical contact of these

5.1 This test method is particularly suitable for quality

surfaces is achieved via test heads which force a defined

surface area into contact under a specified pressure. For the control in the application of insulating coatings. This test

interlaminar resistance measurement, electrical contact is es- method measures the interlaminar resistance of insulating

tablished between the test specimen and a constant direct coatings, as defined in 3.1.4. Interlaminar resistance is the

FIG. 1 Schematic Illustration of Four-Probe Configuration

A937/A937M − 12 (2019)

FIG. 2 Block Diagram of Two-Surface Test System

measure of the insulating quality of the coating. Interlaminar given electrical steel lamination. Additionally, the coating

resistance is reported in units of kΩ. thickness may vary across several laminations taken from the

samelotofelectricalsteel.Suchvariationsincoatingthickness

5.2 The interlaminar resistance determined in accordance

are likely to yield variations in the measured interlaminar

with this test method is not the same quantity determined by

resistance. The required number of readings depends on the

Test Method A717/A717M.

nature of the coating and the accuracy required.

5.3 This test method is particularly useful for electrical

steels coated with inorganic insulating coatings having surface 6. Apparatus

2 2

insulation resistivities in excess of 0.3 kΩ·cm [30 kΩ·mm ]

6.1 The two-surface tester measures the resistance between

when tested using Test Method A717/A717M (a Franklin

twolaminationsthatareinintimatecontactwithoneanotheras

current less than 0.02 A). This test method can readily be

shown in Fig. 1. The two-surface tester shall consist of two

extended to any range of insulation resistivity that the equip-

pressure pads, each of which is mounted to one of the heads of

ment comprising the two-surface tester allows. For the equip-

a hydraulic or pneumatic press. The diameter of each pressure

ment specified herein, the maximum measurable resistance is 2

pad is 3.57 cm [35.7 mm], giving a nominal area of 10 cm

1200 kΩ for the 10-µA current setting and 12000 kΩ for the

[1000 mm ]. The diameter of the pressure head is 11.50 cm

1-µAcurrent setting; the maximum voltage for the test system

[115 mm]. Each pressure head circumscribes two metallic

is 12 V.

contacts(drillbits)whichareusedtomakecontactwiththetest

5.4 Repeat readings on the same set of two electrical steel specimen.Aschematic diagram of the pressure head, pads and

laminations using different contact positions, as well as the metallic contacts is shown in Fig. 3. Commercially available

testing of multiple laminations from the same lot of electrical rollnut actuators, which convert rotary to linear motion, can be

steel, are recommended. Several readings are suggested be- used to house and rotate the drill bit through the coating on the

cause the coating thickness may vary across the surface of a exposed surfaces of the test specimen, Fig. 4.

A937/A937M − 12 (2019)

FIG. 3 Diagram of Pressure Head Assembly

6.1.1 The associated measuring equipment, which may be operational amplifier. Current is set by means of an adjustable

remotely located, includes an electronic voltmeter with a resistor. Once set, the current is held constant by means of the

digital readout, a source of constant current, a contact check feedback control circuit. The test system is configured such

unit, a calibration module and a display unit.Ablock diagram that an indicator light will turn on if the current goes out of

of the electronic system for the two-surface tester is shown in regulation.

Fig. 2. A computer compatible interface, although not 6.1.2.2 Furthermore, the test system described herein is

mandatory, is recommended for data collection and analysis. equipped with two constant current range settings, 10 and

This function is a standard feature on many commercial 1µA.Forinterlaminarresistancevalueslessthan1200kΩ,the

electronic voltmeters. 10-µA range is suitable. For interlaminar resistance values

6.1.1.1 The two-surface tester measures the interlaminar greater than 1200 kΩ, the 1-µA range is recommended to

resistance as follows: The constant current source of the tester optimize the accuracy of the measurement. This system is

forces a constant current through the insulation. The voltage equipped with an indicator light that warns the operator if the

which results is measured by a suitable voltmeter. The resis- current range is not appropriate for a given specimen (because

tance of the insulation is then determined by Ohm’s law. The the current goes out of regulation).

results are communicated to the operator via a display. 6.1.2.3 Because the current source setting is an exact

6.1.2 Constant Direct Current Source—The use of a source multiple of ten, the resistance of the test specimen is numeri-

which supplies constant measuring current, independent of cally equal to the voltage reading to within a multiple of ten.

surface resistance, is recommended. The use of a properly Therefore, the resistance, in kΩ, may be directly read on the

adjusted dc constant current source enables resistance to be voltmeter. The decimal point is properly positioned by the

read directly in units of resistance (kΩ). current range select switch.

6.1.2.1 In the two-surface tester, constant direct current is 6.1.3 Contact Check Unit—The contact check unit serves to

supplied using a feedback circuit incorporating a high gain verify the integrity of the contacts and to ensure that bad

A937/A937M − 12 (2019)

FIG. 4 Schematic Diagram of Metallic Contact/Rollnut Actuator Assembly

contacts do not interfere with the coating resistance measure- 5% of the product of the maximum measurable resistance for

ment. The contact resistance is measured using the four-probe the selected current and the selected current, that is, an

configuration shown in Fig. 1. Note that there are two current associated voltage drop of 0.6 V for either current range.

probes and two voltage probes. The contact resistance is (Specifically, V=i×R. For a current setting of 1 µA and a

measured at the start of a test by temporarily connecting the maximum measurable resistance of 12000 kΩ; 0.05×(1

voltage contacts together with a switch. This causes current to µA×12000 kΩ)=0.6 V. Similarly, 0.05×(10 µA×1200

be diverted as shown in Fig. 5. The contacts are considered kΩ)=0.6 V.) If either contact shows a voltage drop in excess

acceptableifthevoltageacrosseitherpairofprobesislessthan of 0.6 V, a bad contact indicator light is lit and the measure-

ment of interlaminar resistance is inhibited. The penetrations

may be reestablished until satisfactory results are obtained. If

the measurable voltage drop is less than 0.6 V, subsequent

interlaminar resistance measurement is enabled.

6.1.3.1 Oncesuitablecontactresistancevaluesareobtained,

the switch connecting the voltage contacts is opened, and

current is redirected to flow through the insulation instead of

the switch, Fig. 6. The interlaminar resistance can then be

measured.

6.1.4 Calibration Module—The calibration module is pro-

videdtoallowprecisecalibrationofthetwo-surfacetester.The

moduleissimplyasetofprecisionresistors,andsomevariable

resistors which may be connected to the two-surface tester by

NOTE 1—When the switch of the Contact Check Unit (Item C–Fig. 2)

means of cables. The calibration module substitutes precisely

isinthe“closed”position,thevoltagecontactsaretemporarilyconnected.

known values of resistance for the insulation under test. It also

The voltage drop across contacts between 1 and 3, and between 2 and 4

substitutes a variable contact resistance for each of the upper

is evaluated. A “bad contact” indicator light is triggered if this voltage

and lower contacts, allowing the operation of the contact

drop is in excess of 0.6 V. The measurement of the coating’s interlaminar

resistancesystemtobeindependentlyverified.Byselectingthe

resistance is inhibited under “bad contact” conditions.

FIG. 5 Current Path During the Contact Check Process appropriate jumper, a precision resistor is substituted for the

----------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.