ASTM D7667-10e2

(Test Method)Standard Test Method for Determination of Corrosiveness to Silver by Automotive Spark-Ignition Engine Fuel—Thin Silver Strip Method

Standard Test Method for Determination of Corrosiveness to Silver by Automotive Spark-Ignition Engine Fuel—Thin Silver Strip Method

SIGNIFICANCE AND USE

5.1 Crude petroleum contains sulfur compounds, most of which are removed during refining. However, of the sulfur compounds remaining in the petroleum product or introduced into the fuel during storage and distribution, some can have a corroding action on various metals and this corrosivity is not necessarily related directly to the total sulfur content. The effect can vary according to the chemical types of sulfur compounds present. The silver strip corrosion test is designed to assess the relative degree of corrosivity of a petroleum product towards silver and silver alloys.

5.2 Under some circumstances, reactive sulfur compounds present in automotive spark-ignition engine fuels can tarnish or even corrode silver alloy fuel gauge in-tank sender units or silver-plated bearings (in 2-stroke cycle engines). To minimize or prevent the failure of silver alloy in-tank sender units by tarnish or corrosion, Specification D4814 requires that fuels shall pass a silver strip corrosion test.

SCOPE

1.1 This test method covers the determination of the corrosiveness to silver by automotive spark-ignition engine fuel (for example, gasoline), as defined by Specification D4814 or similar specifications in other jurisdictions, having a vapor pressure no greater than 124 kPa (18 psi) at 37.8°C (100°F) by one of two procedures.

1.1.1 Procedure A—Involves the use of a pressure vessel.

1.1.2 Procedure B—Involves the use of a vented test tube.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´2

Designation: D7667 − 10

StandardTest Method for

Determination of Corrosiveness to Silver by Automotive

1

Spark-Ignition Engine Fuel—Thin Silver Strip Method

This standard is issued under the fixed designation D7667; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Added legend to Fig. 1 editorially in July 2012.

2

ε NOTE—Subsection 7.4 was revised editorially in March 2014.

1. Scope D130 Test Method for Corrosiveness to Copper from Petro-

leum Products by Copper Strip Test

1.1 This test method covers the determination of the corro-

D3241 Test Method for Thermal Oxidation Stability of

siveness to silver by automotive spark-ignition engine fuel (for

Aviation Turbine Fuels

example, gasoline), as defined by Specification D4814 or

D4057 Practice for Manual Sampling of Petroleum and

similar specifications in other jurisdictions, having a vapor

Petroleum Products

pressure no greater than 124 kPa (18 psi) at 37.8°C (100°F) by

D4177 Practice for Automatic Sampling of Petroleum and

one of two procedures.

Petroleum Products

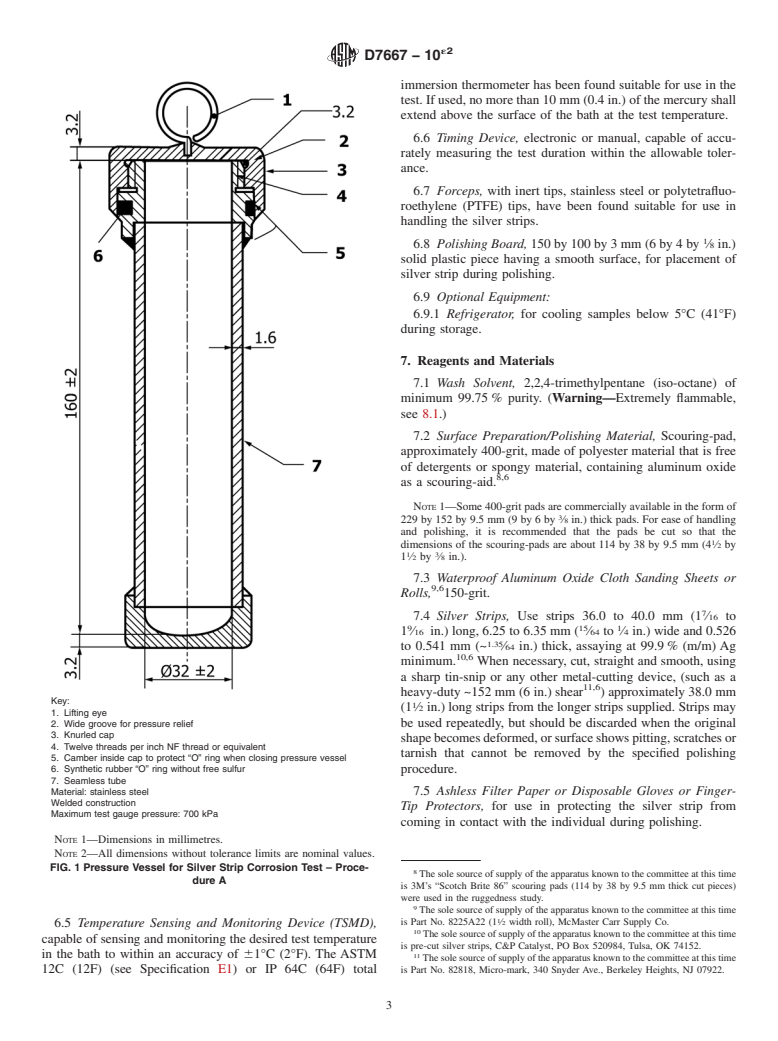

1.1.1 Procedure A—Involves the use of a pressure vessel.

D4814 Specification for Automotive Spark-Ignition Engine

1.1.2 Procedure B—Involves the use of a vented test tube.

Fuel

1.2 The values stated in SI units are to be regarded as the

E1 Specification for ASTM Liquid-in-Glass Thermometers

standard. The values in parentheses are for information only.

3

2.2 Energy Institute Standards:

1.3 WARNING—Mercury has been designated by many

IP 227 Determination of Corrosiveness to Silver ofAviation

regulatory agencies as a hazardous material that can cause

Turbine Fuels - Silver Strip Method

central nervous system, kidney and liver damage. Mercury, or

4

2.3 ASTM Adjuncts:

its vapor, may be hazardous to health and corrosive to

Color standard for tube deposit rating (5 aluminum strips)

materials.Cautionshouldbetakenwhenhandlingmercuryand

mercury containing products. See the applicable product Ma-

3. Terminology

terial Safety Data Sheet (MSDS) for details and EPA’s

website—http://www.epa.gov/mercury/faq.htm—for addi- 3.1 Abbreviations:

tional information. Users should be aware that selling mercury

and/or mercury containing products into your state or country

PTFE = polytetrafluoroethylene

may be prohibited by law.

PV = pressure vessel

1.4 This standard does not purport to address all of the

PVP = pressure vessel procedure

safety concerns, if any, associated with its use. It is the

SSCD = silver strip centering device

responsibility of the user of this standard to establish appro-

TSMD = temperature sensing and monitoring device

priate safety and health practices and determine the applica- VTTP = vented test tube procedure

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents

4.1 Apolished, thin silver strip is immersed in 30 mLof the

2

2.1 ASTM Standards:

sample being tested, and heated at 50°C (122°F) for 2 h.At the

end of the heating period, the silver strip is removed, washed,

and the color and tarnish level assessed against the Silver Strip

1

This test method is under the jurisdiction of ASTM Committee D02 on

Classifications in Table 1.

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.05.0C on Color and Reactivity.

Current edition approved Oct. 1, 2010. Published December 2010. DOI:

10.1520/D7667–10E02.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM U.K., http://www.energyinst.org.uk.

4

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM International Headquarters. Order Adjunct No.

the ASTM website. ADJD3241. Original adjunct produced in 1986.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´2

D7667 − 10

TABLE 1 Silver Strip Classifications

NOTE 1—Acknowledgement—This table has been reproduced from Standard IP 227.

Classification Designation Description

0 No Tarnish Identical to a freshly-polished strip but may have

some very slight loss of luster

1 Slight Tarnish Faint brown or white discoloration of strip (see 12.2)

2 Moderate Tarnish Peacock colors such as blue or mauve or medium/

dark straw or brown coloration (see 12.2)

3 Slight blackening Spots and patches of black or gray on surface or uni-

form thin film of black deposit

4 Blackening Uniform heavy b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.