ASTM C965-96

(Practice)Standard Practice for Measuring Viscosity of Glass Above the Softening Point

Standard Practice for Measuring Viscosity of Glass Above the Softening Point

SCOPE

1.1 This practice covers the determination of the viscosity of glass above the softening point through the use of a platinum alloy spindle immersed in a crucible of molten glass. Spindle torque, developed by differential angular velocity between crucible and spindle, is measured and used to calculate viscosity. Generally, data are taken as a function of temperature to describe the viscosity curve for the glass, usually in the range from 1 to 10 6 Pa·s.

1.2 Two procedures with comparable precision and accuracy are described and differ in the manner for developing spindle torque. Procedure A employs a stationary crucible and a rotated spindle. Procedure B uses a rotating crucible in combination with a fixed spindle.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 965 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Measuring Viscosity of Glass Above the Softening Point

This standard is issued under the fixed designation C 965; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.1.1 Procedure A employs an electrically heated tube-type

furnace with a fixed support for the crucible as shown in Fig.

1.1 This practice covers the determination of the viscosity

1. A platinum alloy resistance-heated crucible also may be

of glass above the softening point through the use of a platinum

used.

alloy spindle immersed in a crucible of molten glass. Spindle

4.1.2 Procedure B employs a similar furnace but with a

torque, developed by differential angular velocity between

removable, rotatable crucible support as shown in Fig. 2.

crucible and spindle, is measured and used to calculate

4.1.3 Furnaces other than resistance-wound muffle types

viscosity. Generally, data are taken as a function of temperature

may be used provided they give uniform and stable tempera-

to describe the viscosity curve for the glass, usually in the

ture conditions. Temperature differences greater than 3°C

range from 1 to 10 Pa·s.

within the crucible (in glass) are excessive for high precision

1.2 Two procedures with comparable precision and accu-

measurements.

racy are described and differ in the manner for developing

4.1.4 A temperature controller shall be provided for main-

spindle torque. Procedure A employs a stationary crucible and

taining the glass temperature within 62°C of a specified

a rotated spindle. Procedure B uses a rotating crucible in

temperature.

combination with a fixed spindle.

4.1.5 Temperatures shall be measured with Type R or S

1.3 This standard does not purport to address all of the

thermocouples calibrated in accordance with Method E 220 in

safety concerns, if any, associated with its use. It is the

conjunction with a calibrated potentiometer or solid state

responsibility of the user of this standard to establish appro-

instrumentation capable of 0.5°C accuracy. An immersion

priate safety and health practices and determine the applica-

thermocouple is recommended but a thermocouple in air may

bility of regulatory limitations prior to use.

be used provided measurements show equivalency.

2. Referenced Documents

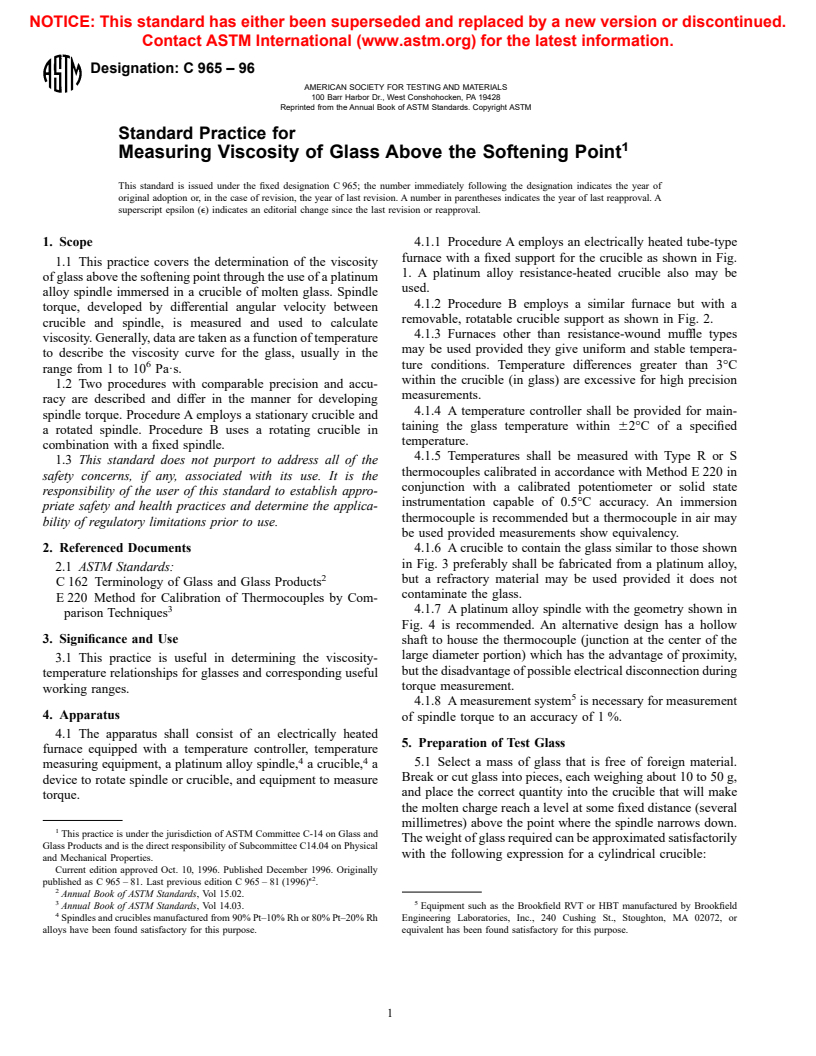

4.1.6 A crucible to contain the glass similar to those shown

in Fig. 3 preferably shall be fabricated from a platinum alloy,

2.1 ASTM Standards:

but a refractory material may be used provided it does not

C 162 Terminology of Glass and Glass Products

contaminate the glass.

E 220 Method for Calibration of Thermocouples by Com-

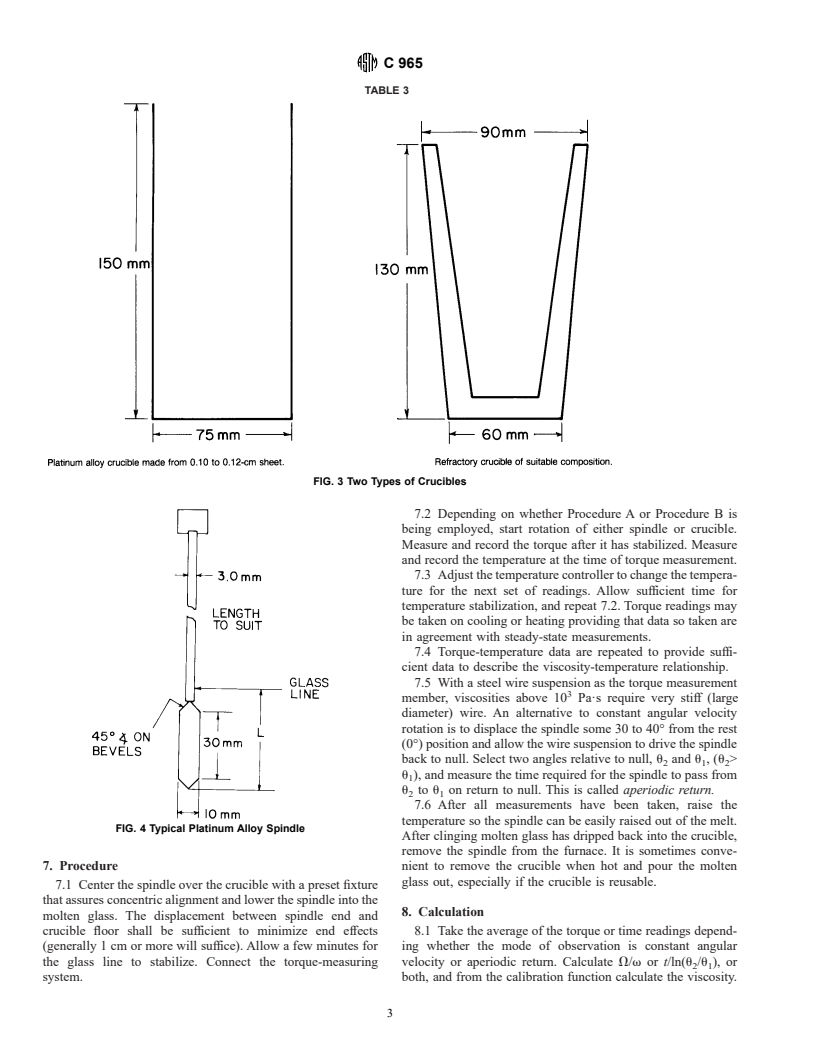

4.1.7 A platinum alloy spindle with the geometry shown in

parison Techniques

Fig. 4 is recommended. An alternative design has a hollow

3. Significance and Use

shaft to house the thermocouple (junction at the center of the

large diameter portion) which has the advantage of proximity,

3.1 This practice is useful in determining the viscosity-

but the disadvantage of possible electrical disconnection during

temperature relationships for glasses and corresponding useful

torque measurement.

working ranges.

4.1.8 A measurement system is necessary for measurement

4. Apparatus

of spindle torque to an accuracy of 1 %.

4.1 The apparatus shall consist of an electrically heated

5. Preparation of Test Glass

furnace equipped with a temperature controller, temperature

4 4

5.1 Select a mass of glass that is free of foreign material.

measuring equipment, a platinum alloy spindle, a crucible, a

Break or cut glass into pieces, each weighing about 10 to 50 g,

device to rotate spindle or crucible, and equipment to measure

and place the correct quantity into the crucible that will make

torque.

the molten charge reach a level at some fixed distance (several

millimetres) above the point where the spindle narrows down.

This practice is under the jurisdiction of ASTM Committee C-14 on Glass and

The weight of glass required can be approximated satisfactorily

Glass Products and is the direct responsibility of Subcommittee C14.04 on Physical

with the following expression for a cylindrical crucible:

and Mechanical Properties.

Current edition approved Oct. 10, 1996. Published December 1996. Originally

e2

published as C 965 – 81. Last previous edition C 965 – 81 (1996) .

Annual Book of ASTM Standards, Vol 15.02.

3 5

Annual Book of ASTM Standards, Vol 14.03. Equipment such as the Brookfield RVT or HBT manufactured by Brookfield

Spindles and crucibles manufactured from 90% Pt–10% Rh or 80% Pt–20% Rh Engineering Laboratories, Inc., 240 Cushing St., Stoughton, MA 02072, or

alloys have been found satisfactory for this purpose. equivalent has been found satisfactory for this purpose.

C 965

1—Furnace Winding

2—Crucible

3—Spindle

4—Shaft

5—Viscometer (providing both rotation and torque measurement)

6—Thermocouple

FIG. 1 General Arrangement for Rotating Spindle, Fixed Crucible

Scheme (Procedure A)

NOTE 1—Details are the same as in Fig. 1 except that the viscometer is

W 5 @pd ~L 1 h!/4 2 V #r ~1 2 0.0007a! (1)

T s

replaced by a torque measuring device, and the crucible is mounted on a

where: removable rotatable stand.

h 5 distance between crucible floor and spindle tip, mm FIG. 2 General Apparatus Arrangement for Rotating Crucible

Scheme (Procedure B)

(generally greater than 10 mm to avoid end effects)

W 5 glass charge weight at room temperature, g,

T

dards and Technology, is recommended. These provide a wide

d 5 inside diameter of crucible, mm,

range of temperatures and viscosities for calibration.

L 5 immersed portion of spindle, mm,

6.2 For constant angular velocity rotation:

V 5 volume of immersed portion of spindle, mm ,

s

r5 density of glass at room temperature, g/cm , and

h}V/v (2)

a5 0 to 300°C thermal expansion coefficient, cm/cm·°C

where:

(3 10 ).

h5 viscosity,

Avoid very small pieces of glass in the charge as they tend

V5 torque, and

to make the molten glass seedy.

v5 angular velocity

5.2 Place the filled crucible in proper position in the furnace

For aperiodic return:

and heat to a temperature that lowers the viscosity of glass

h} t/ln ~u /u ! (3)

sufficiently to allow trapped air bubbles to be released. This

2 1

temperature sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.