ASTM B910/B910M-06

(Specification)Standard Specification for Annealed Copper-Clad Steel Wire

Standard Specification for Annealed Copper-Clad Steel Wire

SCOPE

1.1 This specification covers bare round copper-clad steel for the following applications: electrical, electronic, grounding, telecommunications, and other applications.

1.2 Four conductivities are covered as follows: 21, 30, 40, and 70 %.

1.3 Temper is designated as annealed.

1.4 The values stated in inch-pound or SI units are to be regarded separately as the standard. Each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. For conductor sizes designated by AWG, the requirements in SI units have been numerically converted from corresponding values stated or derived in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.5 The following precautionary statement pertains to the test method portion only, Section , of this specification: This standard does not purport to address all of the safety concerns, if any associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 910/B 910M – 06

Standard Specification for

1

Annealed Copper-Clad Steel Wire

This standard is issued under the fixed designation B 910/B 910M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

3

1. Scope NBS Handbook 100 - Copper Wire Tables

1.1 This specification covers bare round copper-clad steel

3. Ordering Information

forthefollowingapplications:electrical,electronic,grounding,

3.1 Orders for material under this specification shall include

telecommunications, and other applications.

the following information:

1.2 Four conductivities are covered as follows: 21, 30, 40,

3.1.1 Quantity of each size;

and 70 %.

3.1.2 Wire size: diameter in inches (see 5.2);

1.3 Temper is designated as annealed.

3.1.3 Conductivity (see Table 1);

1.4 The values stated in inch-pound or SI units are to be

3.1.4 Wire to be used for redraw or not;

regarded separately as the standard. Each system shall be used

3.1.5 Packaging and shipping (see 10); and

independently of the other. Combining values from the two

3.1.6 Place of inspection (see 6.1).

systems may result in nonconformance with the specification.

ForconductorsizesdesignatedbyAWG,therequirementsinSI

4. Material

units have been numerically converted from corresponding

4.1 The wire shall consist of a core of homogeneous

values stated or derived in inch-pound units. For conductor

open-hearth, electric-furnace, or basic-oxygen steel with a

sizesdesignatedbySI units only, the requirements arestatedor

continuous outer cladding of copper thoroughly bonded to the

derived in SI units.

core throughout and shall be of such quality as to meet the

1.5 The following precautionary statement pertains to the

requirements of this specification.

test method portion only, Section 7, of this specification: This

standard does not purport to address all of the safety concerns,

5. General Requirements

if any associated with its use. It is the responsibility of the user

5.1 Tensile Strength and Elongation—The copper-clad steel

of this standard to establish appropriate safety and health

wireshallconformtothetensilestrengthrequirementsofTable

practices and determine the applicability of regulatory limita-

2. Because there are many carbon steel and copper thickness

tions prior to use.

combinations available, the desired tensile strength should be

agreed upon between the purchaser and manufacturer prior to

2. Referenced Documents

placing an order. The elongation shall be 15.0 % minimum for

2.1 The following documents of the issue in effect on the

all diameters listed in 5.2.

date of material purchase form a part of this specification to the

5.2 Dimensions—The wire size range for this specification

extent referenced herein:

2 shall be from 0.0253 (0.643 mm) to 0.2294 in. (5.827 mm)

2.2 ASTM Standards:

diameter (see Note 1).

B 193 Test Method for Resistivity of Electrical Conductor

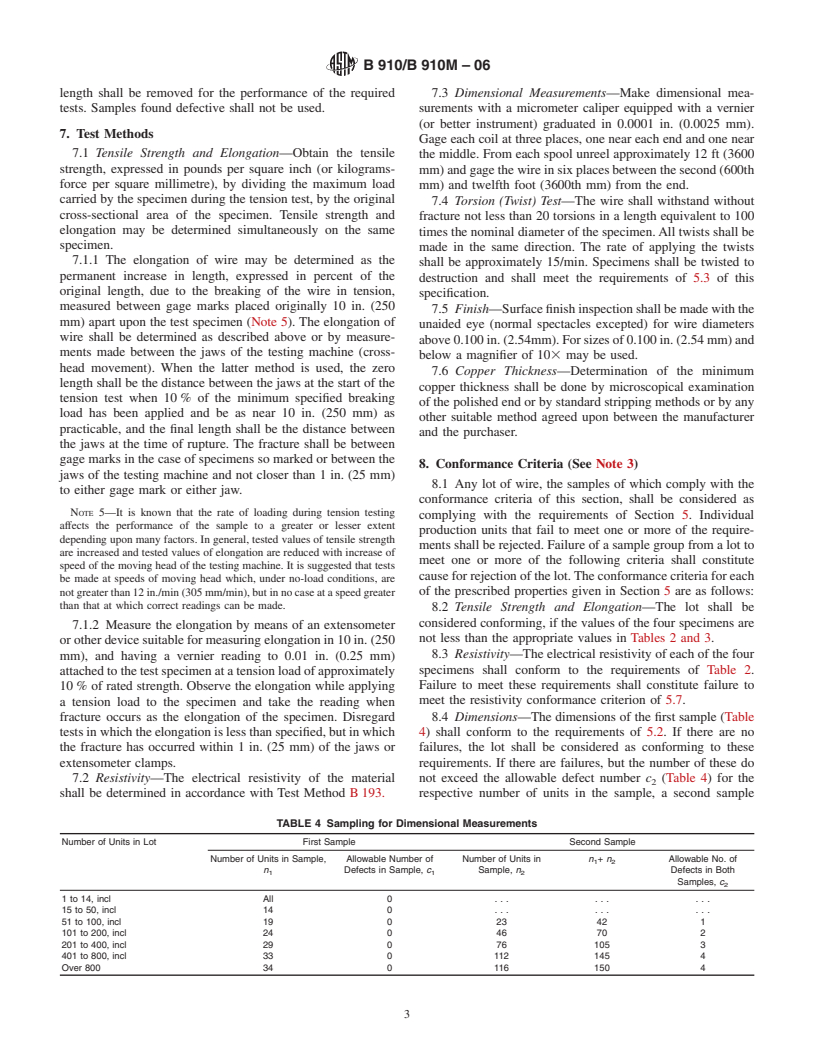

5.2.1 Permissible Variations—The wire sizes shall meet the

Materials

following tolerances:

B 258 Specification for Standard Nominal Diameters and

5.2.1.1 For diameters 0.1000 in. (2.54 mm) and over, the

Cross-SectionalAreasofAWGSizesofSolidRoundWires

wire shall not vary from the specified diameter by more than 6

Used as Electrical Conductors

1

1 ⁄2 %, expressed to the nearest 0.0001 in. (0.003 mm).

2.3 NIST Document:

5.2.1.2 Fordiametersunder0.1000in.(2.54mm)andabove

0.0253 in. (0.643 mm), the wire shall not vary from the

specified diameter by more than 61 %, expressed to the

1

This specification is under the jurisdiction of ASTM Committee B01 on

nearest 0.0001 in. (0.003 mm).

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on

Composite Conductors.

NOTE 1—The values of the wire diameters in 5.2 are given to the

Current edition approved March 1, 2006. Published March 2006. Originally

nearest 0.0001 in. (0.003 mm) and correspond to the standard sizes given

approved in 2000. Last previous edition approved in 2004 as B 910/B 910M - 04.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 910/B 910M – 06

TABLE 1 Density (nom.) and Resistivity, (max.), at 20°C (Nominal figures is required for complete r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.