ASTM D3151-88(1998)

(Test Method)Standard Test Method for Thermal Failure of Solid Electrical Insulating Materials Under Electric Stress (Withdrawn 2007)

Standard Test Method for Thermal Failure of Solid Electrical Insulating Materials Under Electric Stress (Withdrawn 2007)

SCOPE

1.1 This test method covers the determination of the thermal failure of solid electrical insulating materials subjected to electric stress at commercial power frequencies. This test method has been developed for testing materials such as certain glasses and ceramics, that exhibit large increases in dielectric loss with increasing temperature.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. A specific hazard statement is given in 10.1.

WITHDRAWN RATIONALE

This test method covers the determination of the thermal failure of solid electrical insulating materials subjected to electric stress at commercial power frequencies. This test method has been developed for testing materials such as certain glasses and ceramics that exhibit large increases in dielectric loss with increasing temperature.

Formerly under the jurisdiction of Committee D09 on Electrical and Electronic Insulating Materials, this test method was withdrawn in 2007 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3151–88 (Reapproved 1998)

Standard Test Method for

Thermal Failure of Solid Electrical Insulating Materials

Under Electric Stress

This standard is issued under the fixed designation D 3151; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 thermal dielectric breakdown, n—an increase in the

dissipation factor or conductance in the test material which

1.1 Thistestmethodcoversthedeterminationofthethermal

leads to failure by thermal runaway.The time to failure and the

failure of solid electrical insulating materials subjected to

voltage stress at which thermal breakdown occurs is influenced

electric stress at commercial power frequencies. This test

by the ambient test temperature, the test voltage, the dimen-

methodhasbeendevelopedfortestingmaterialssuchascertain

sions of the test specimen, the specific heat of the material, and

glasses and ceramics, that exhibit large increases in dielectric

its thermal conductivity.

loss with increasing temperature.

3.2.2 thermal dielectric breakdown voltage, n—the voltage

1.2 This standard does not purport to address all of the

at which thermal dielectric breakdown takes place at a speci-

safety problems, if any, associated with its use. It is the

fied ambient temperature and thermal transfer condition.

responsibility of the user of this standard to establish appro-

3.2.3 thermal runaway, n—a mode of response exhibited by

priate safety and health practices and determine the applica-

certain materials which, when subjected to electric stress

bility of regulatory limitations prior to use. A specific hazard

exceeding a critical value, undergo a rise in temperature which

statement is given in 10.1.

itselfincreasestheconductanceofthematerial,furtherincreas-

2. Referenced Documents

ing the temperature, and so on in a self-escalating manner.

2.1 ASTM Standards:

4. Significance and Use

D 149 Test Method for Dielectric Breakdown Voltage and

4.1 This test method is intended to supplement the standard

Dielectric Strength of Solid Electrical Insulating Materials

dielectric strength test procedure (Test Method D 149) for tests

at Commercial Power Frequencies

at elevated temperatures, particularly of glasses and ceramics.

D 374 Test Methods for Thickness of Solid Electrical Insu-

The method determines at elevated temperature the potential

lation

2 difference at which the current becomes so great due to

D 1711 Terminology Relating to Electrical Insulation

increased conductance that dielectric heating causes the tem-

E 145 Specification for Gravity-Convection and Forced-

3 perature in the material to rise and ultimately cause thermal

Ventilation Ovens

electric breakdown to occur.

2.2 Other Standards:

4.2 This test method is intended for use as a control and

IEEEStandard No.4 MeasurementsofVoltageinDielectric

acceptance test. It may be used also in the partial evaluation of

Tests

materials for specific end uses and as a means for detecting

3. Terminology

changes in materials due to specific deteriorating causes. A

more complete discussion of the significance of thermal

3.1 Definition:

dielectric breakdown tests is given in Annex A1.

3.1.1 dielectric breakdown voltage—see Terminology

D 1711.

5. Apparatus

3.2 Definitions of Terms Specific to This Standard:

5.1 High-Voltage Test Equipment—Suitable equipment is

described inTest Method D 149.The transformer rating should

This test method is under the jurisdiction of ASTM Committee D-9 on

beadequatetomaintainasinewaveatfull-loadcurrent.Higher

Electrical and Electronic Insulating Materials and is the direct responsibility of

ratings than specified in Test Method D 149 are usually

Subcommittee D09.12 on Electrical Tests.

required.

Current edition approved Aug. 26, 1988. Published October 1988. Originally

5.2 Voltmeter—The voltage shall be measured in accor-

published as D 3151–73. Last previous edition D 3151–79.

Annual Book of ASTM Standards, Vol 10.01.

dance with IEEE Standard No. 4. The response time of the

Annual Book of ASTM Standards, Vol 14.02.

voltmeter shall be such that its time lag does not introduce an

Available from the Institute of Electrical and Electronics Engineers, Inc., 345

E. 47th St., New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3151–88 (1998)

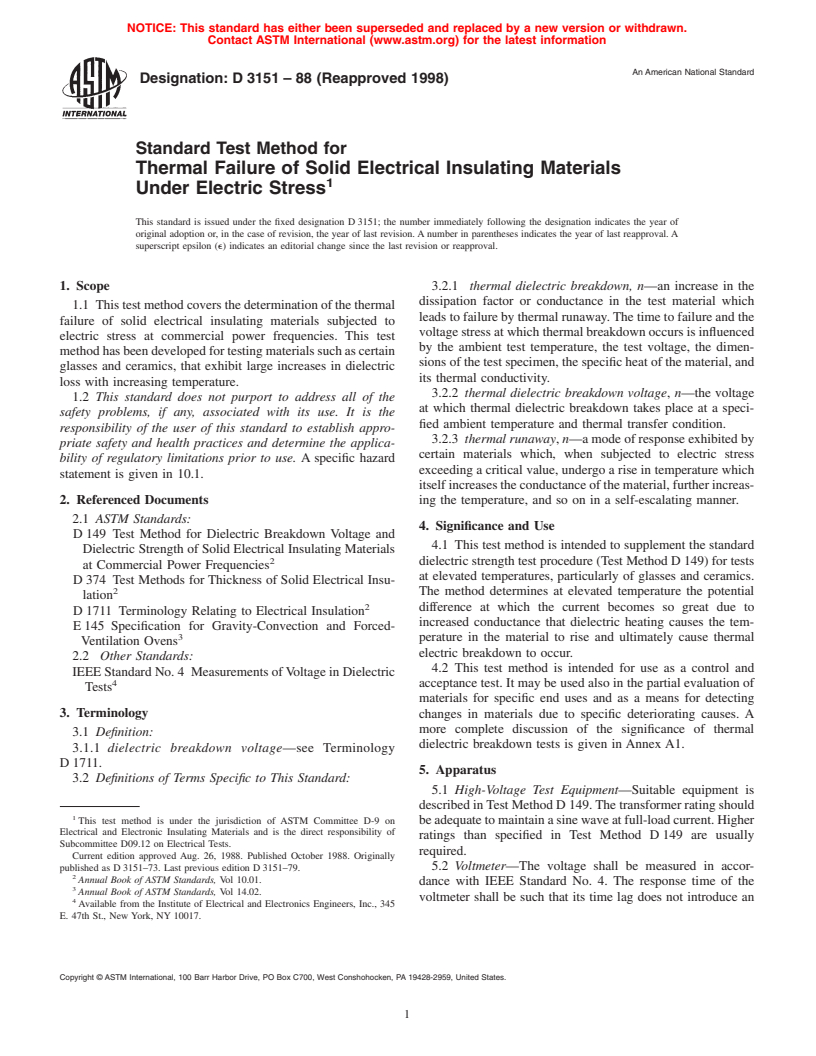

FIG. 1 General Arrangement in Test Chamber

error greater than 1% of full scale at the rate of rise used. The 5.4.6 Fig. 1 shows the general arrangment of the items cited

overall accuracy of the voltmeter and the voltage-measuring in 5.4.3-5.4.5.

device used shall be such that the measurement error will not 5.5 Temperature Recorder—Temperature of the specimen

exceed 5%. shall be measured with a No. 40 Awg (0.080-mm) Chromel-

5.3 Test Area, containing the test chamber and high-voltage Alumel thermocouple.The thermocouple shall be connected to

transformer shall be contained in a suitably grounded metal an adjustable-zero, multirange temperature recorder.

enclosure with a door provided with an interlock that interrupts

the high voltage when opened. 6. Surrounding Medium

5.4 Test Chamber:

6.1 Ingeneralitispreferabletotestmaterialsinthemedium

5.4.1 Thetestchambershallconsistofanelectricallyheated

in which they are to be used. However in this test the

furnace and an auxiliary temperature controller. A high-

surrounding medium is usually restricted to air or other gas or

temperature gravity-convection oven with controller conform-

liquid that is stable at the test temperature.

ing to Specification E 145, Type 1, is suitable.

5.4.2 The size of the chamber shall be such that the highest

7. Electrodes

test voltage anticipated, when applied to the test electrodes,

7.1 The specimens shall have circular gold electrodes 31.75

will not flash over to the walls of the chamber at the highest

6 3.05 mm (1.25 6 0.12 in.) in diameter applied to the center

temperature.

of each face. The gold may be applied with a brush or silk

5.4.3 The chamber shall be provided with holes for three

screen, and then fired in a furnace.

leads. A ceramic or fused-silica glass tube capable of with-

7.2 Electrical contact to the gold electrodes on the specimen

standing the anticipated test voltage shall be inserted through

shall be made by means of two gold-plated hollow stainless

one hole in the floor. The high-voltage lead shall be brought

steel cylinders having the same diameter as the gold electrodes

through this insulating tube. The ground lead and the thermo-

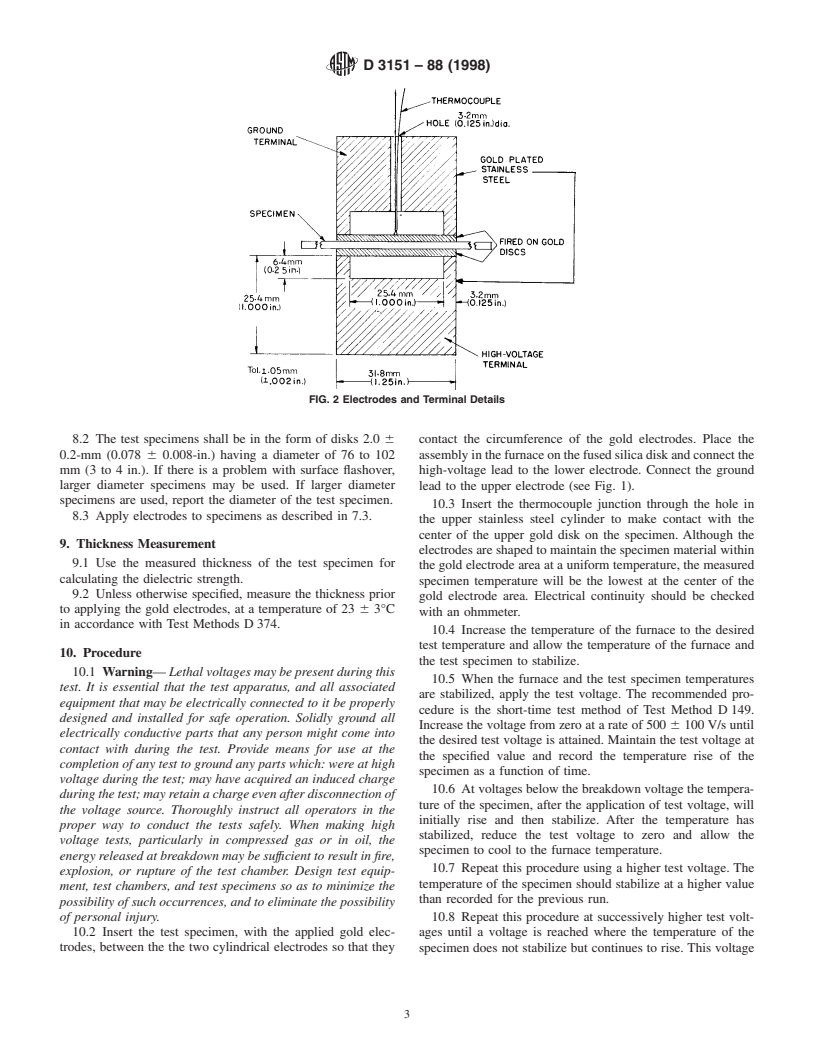

as shown in Fig. 2.

couple lead shall be brought through holes in the walls.

7.3 The high-voltage connection shall be made to the

NOTE 1—Some investigators have found that a conductive coating on bottom electrode. The top electrode shall be grounded.

the inside surface of the insulating tube reduces corona.

8. Test Specimens

5.4.4 Aceramic or fused-silica glass disk with a hole for the

insulating tube of 5.4.3 to fit through should be placed at the

8.1 The test specimens shall be representative of the mate-

bottom of the test chamber to prevent the high-voltage (bot- rialstobetested.Sufficientmaterialshallbeavailabletopermit

tom) electrode from shorting to the bottom of the chamber.

making ten tests.

NOTE 2—Unless the disk fits the tube very closely, or is cemented to it,

voltage breakdown may take place along the interface between the disk

and the tube. For this reason, it may be necessary in some cases to use a

Goldelectrodesthathavebeenfoundsatisfactoryforthispurposewhenapplied

one-piece insulator with an integral flange, or other appropriate shape to

in accordance with the manufacturer’s recommendations are:

prevent breakdown in this location.

(1) Liquid Bright Gold No. MM, Engelhard Industries, Inc., Hanovia Liquid

Gold Div., East Newark, NJ and

5.4.5 The glass tube and disk should be fastened to supports

(2) Vacuum-evaporated gold with suitable masks during application.

outside the furnace and should not touch the inside walls or

(Caution—Significant errors may be produced if the thermocouple removes

other parts of the furnace. electrode material.)

D3151–88 (1998)

FIG. 2 Electrodes and Terminal Details

8.2 The test specimens shall be in the form of disks 2.0 6 contact the circumference of the gold electrodes. Place the

0.2-mm (0.078 6 0.008-in.) having a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.