ASTM F682-82a(1988)e1

(Specification)Standard Specification for Wrought Carbon Steel Sleeve-Type Pipe Couplings

Standard Specification for Wrought Carbon Steel Sleeve-Type Pipe Couplings

SCOPE

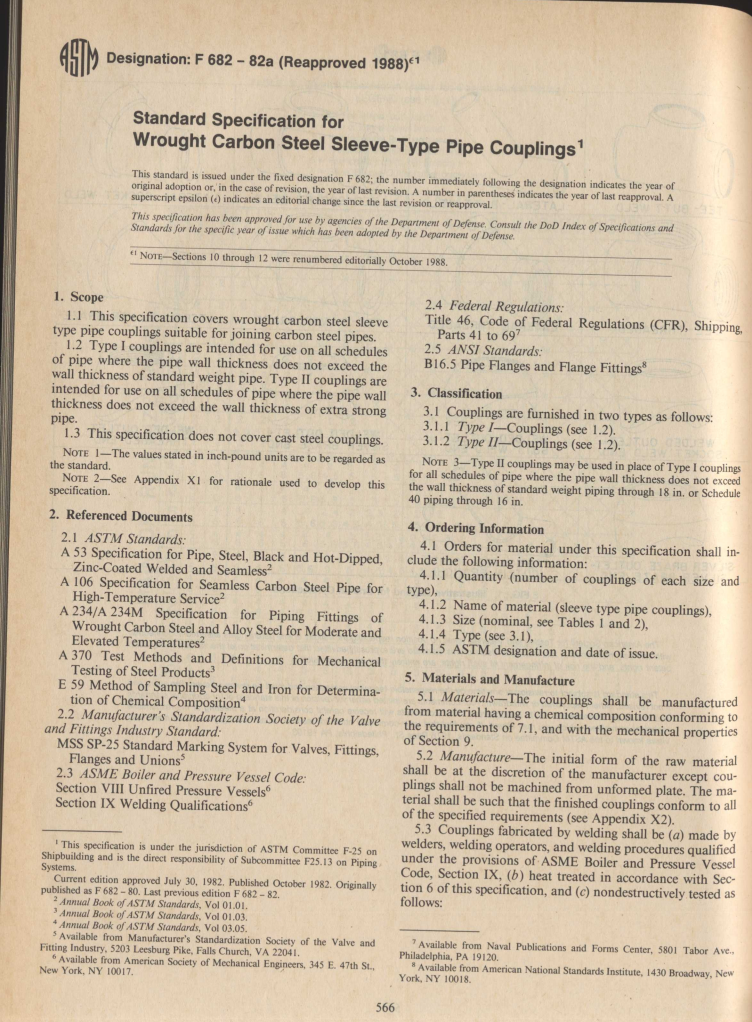

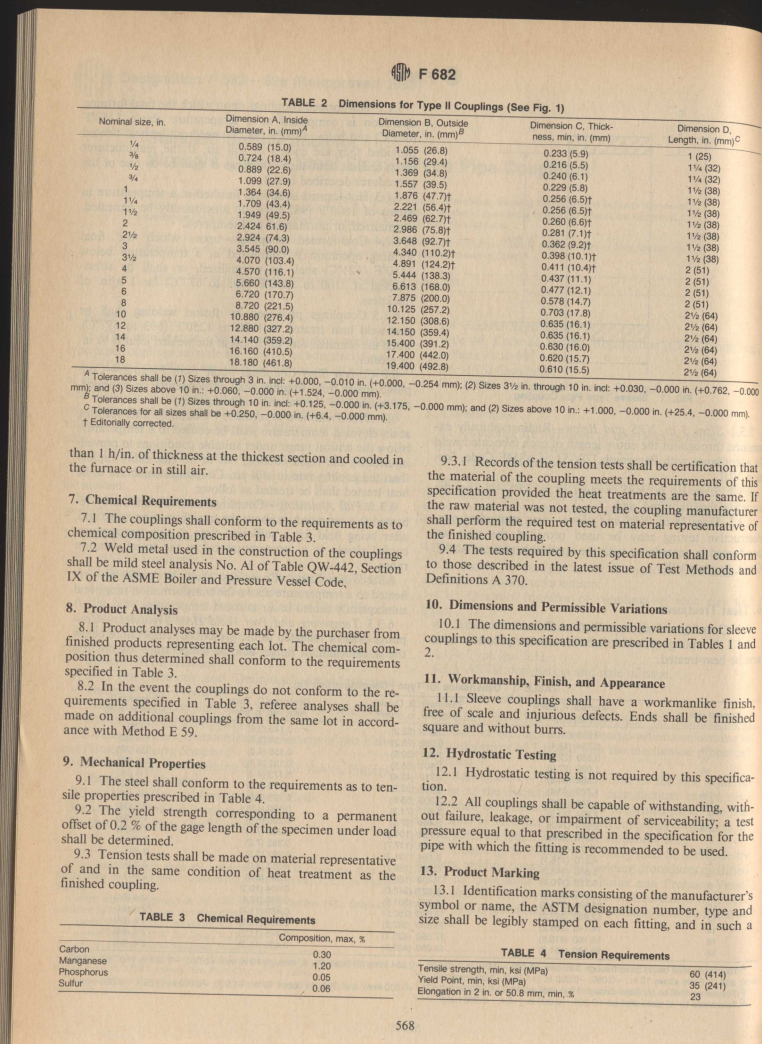

1.1 This specification covers wrought carbon steel sleeve type pipe couplings suitable for joining carbon steel pipes.

1.2 Type I couplings are intended for use on all schedules of pipe where the pipe wall thickness does not exceed the wall thickness of standard weight pipe. Type II couplings are intended for use on all schedules of pipe where the pipe wall thickness does not exceed the wall thickness of extra strong pipe.

1.3 This specification does not cover cast steel couplings. Note 1-The values stated in inch-pound units are to be regarded as the standard. Note 2-See Appendix X1 for rationale used to develop this specification.

General Information

This May Also Interest You

ABSTRACT

This specification covers wrought carbon steel sleeve type pipe couplings suitable for joining carbon steel pipes. Couplings are furnished in two types as follows: Type I couplings are intended for use on all schedules of pipe in which the pipe wall thickness does not exceed the wall thickness of standard weight pipe. Type II couplings are intended for use on all schedules of pipe in which the pipe wall thickness does not exceed the wall thickness of extra strong pipe. The couplings shall be manufactured from material having a chemical composition conforming to the requirements specified. Couplings made from plate or tubular products need not to be heat treated. Hot-formed couplings finished at a temperature in excess of a certain value shall subsequently be annealed, normalized, or normalized and tempered. Cold-formed couplings upon which the final forming operation is completed at a temperature below a certain quantity shall be normalized or shall be stress-relieved. Carbon steel couplings made from forgings shall subsequently be annealed, normalized, or normalized and tempered. Mechanical properties of steel such as tensile strength, yield strength, yield point, and elongation shall be determined.

SCOPE

1.1 This specification covers wrought carbon steel sleeve-type pipe couplings suitable for joining carbon steel pipes.

1.2 Type I couplings are intended for use on all schedules of pipe in which the pipe wall thickness does not exceed the wall thickness of standard weight pipe. Type II couplings are intended for use on all schedules of pipe in which the pipe wall thickness does not exceed the wall thickness of extra strong pipe.

1.3 This specification does not cover cast steel couplings.

Note 1: See Appendix X1 for rationale used to develop this specification.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification5 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers standard requirements for grades of nominal wall thickness, stainless steel tubing for services requiring general corrosion resistance, with particular emphasis on resistance to stress corrosion cracking. These steels are susceptible to embrittlement if used for prolonged periods at elevated temperatures. Heat and product analyses shall be performed wherein the steel shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, nitrogen, copper, and others. All tubes shall be furnished in the heat-treated condition in accordance with the specified temperature and quench conditions. When the final heat treatment is in a continuous furnace, or when heat treated condition is obtained directly by quenching after hot forming, the number of tubes of the same size and from the same heat in a lot shall be determined from the prescribed sizes of the tubes. The material shall conform to the prescribed tensile and hardness properties. Mechanical tests such as tension test, flaring test (for seamless tubes), flange test (for welded tubes), hardness test, and reverse flattening test shall be performed on the steel tubing. Each tube shall also be subjected to the nondestructive electric test or the hydrostatic test.

SCOPE

1.1 This specification2 covers grades of average wall thickness, or, if specified on the order, minimum wall thickness, of stainless steel tubing for services requiring general corrosion resistance, with particular emphasis on resistance to stress corrosion cracking. These steels are susceptible to embrittlement if used for prolonged periods at elevated temperatures.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. Within the text, the SI units are shown in brackets. The inch-pound units shall apply unless the M designation of this specification is specified in the order.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification7 pagesEnglish languagesale 15% off

- Technical specification7 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers straight seam and spiral butt seam welded unannealed austenitic stainless steel tubular products intended for low and moderate temperatures and corrosive service where treatment is not necessary for corrosion resistance. The tubular products shall be made from flat-rolled steel sheet, coil, or plate by a shielded arc-welding process. The welds shall be made by the manual or automatic electric-welding process. Injurious weld defects shall be repaired by removal to sound metal and rewelding. Transverse tension test and transverse-guided bend test shall be done to the welded joints. Finished products shall have smooth ends free or burrs and shall be free of injurious defects.

SCOPE

1.1 This specification covers straight seam and spiral butt seam welded unannealed austenitic stainless steel tubular products intended for low and moderate temperatures and corrosive service where heat treatment is not necessary for corrosion resistance. Table 1 lists the five grades covered by this specification. The user of this specification should be aware that a minimum amount of testing and examination is required of the basic product. The user requiring additional testing or examination is referred to the supplemental requirements or Ordering Information, or both. Users requiring a tubular product with post-weld heat treatment or with radiographic examination are referred to Specification A312/A312M, A358/A358M, or A409/A409M, as applicable.

1.2 This specification covers welded unannealed tubular products 3 in. [75 mm] through 48 in. [1200 mm] in outside diameter and in nominal wall thicknesses of 0.062 in. [1.57 mm] through 0.500 in. [12.70 mm] produced to this specification. Tubular products having other diameters or wall thickness, or both, may be furnished provided it complies with all other requirements of this specification.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining the values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification5 pagesEnglish languagesale 15% off

- Technical specification5 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers several grades of carbon and low alloy steel forged or ring-rolled flanges, forged fittings and valves for low-temperature service. The steel specimens shall be melt processed using open-hearth, basic oxygen, electric furnace or vacuum-induction melting. A sufficient discard shall be made to secure freedom from injurious piping and undue segregation. The materials shall be forged and shall undergo heat treatment such as normalizing, tempering, quenching and precipitation heat treatment. Heat analysis and product analysis shall be performed wherein the steel materials shall conform to the required chemical compositions of carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, copper, columbium, vanadium, and nitrogen. The materials shall also undergo tension tests and shall conform to the required values of tensile strength, yield strength and elongation. Impact tests shall also be performed and the steel materials shall conform to the required values of minimum impact energy, temperature, and minimum equivalent absorbed energy. Hardness and hydrostatic tests shall also be performed.

SCOPE

1.1 This specification2 covers several grades of carbon and low-alloy steel forged or ring-rolled flanges, forged fittings and valves intended primarily for low-temperature service and requiring notch toughness testing. They are made to specified dimensions, or to dimensional standards, such as the ASME and API Specifications referenced in Section 2. Although this specification covers some piping components machined from rolled bar and seamless tubular materials (see 5.3.3), it does not cover raw material produced in these product forms.

1.2 No limitation on size is intended beyond the ability of the manufacturer to obtain the specified requirements. However, Class 3 of Grade LF787 is only available in the quenched-and-precipitation heat treated condition.

1.3 Supplementary requirements are provided for use when additional testing or inspection is desired. These shall apply only when specified by the purchaser in the order.

1.4 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable “M” specification designation (SI units), the material shall be furnished to inch-pound units.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification10 pagesEnglish languagesale 15% off

- Technical specification10 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers two general classes, WP and CR, of wrought ferritic, ferritic/austenitic, and martensitic stainless steel fittings of seamless and welded construction. Class WP fittings are subdivided into four subclasses: Classes WP-S, WP-W, WP-WX, and WP-WU. The material for fittings shall consist of forgings, bars, plates, or seamless or welded tubular products. The steel shall be melted by electric furnace, vacuum furnace, or electric furnace followed by vacuum or electroslag-consumable remelting. Forging or shaping operations shall be performed by hammering, pressing, piercing, extruding, upsetting, rolling, bending, fusion welding, machining or by combination of two or more of these operations. The materials shall undergo heat treatment and shall follow the required cooling process and tempering temperature. Chemical and product analyses shall be performed and shall conform to the required chemical composition in carbon, manganese, phosphorus, silicon, sulfur, nickel, chromium, molybdenum, copper, nitrogen, and titanium. The mechanical properties of the fitting material shall conform to the required values in yield strength, tensile strength, elongation, and hardness.

SCOPE

1.1 This specification covers two general classes, WP and CR, of wrought ferritic, ferritic/austenitic, and martensitic stainless steel fittings of seamless and welded construction covered by the latest revision of Specification A960/A960M. Fittings differing from these standards may be furnished in accordance with Supplementary Requirement S58 of Specification A960/A960M.

1.1.1 Class WP fittings are subdivided into four subclasses: Classes WP-S, WP-W, WP-WX, and WP-WU. They are manufactured to the requirements of Specification A960/A960M, and they shall have pressure ratings compatible with 13.2. Class WP-S fittings are those manufactured from seamless product by a seamless method of manufacture (marked with class symbol WP-S); Class WP-W fittings are those which contain welds where the fitting fabrication or construction welds have been radiographed (marked with class symbol WP-W); and Class WP-WX fittings are those which contain welds where all welds have been radiographed (marked with class symbol WP-WX); and Class WP-WU fittings are those which contain welds where all welds have been ultrasonically tested (marked with class symbol WP-WU).

1.1.2 Class CR fittings are those manufactured to the requirements of MSS SP-43, and they shall have pressure ratings compatible with 13.3.

1.2 This specification does not apply to cast fittings.

1.3 Optional supplementary requirements are provided. When desired, one or more of these may be specified in the order.

1.4 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable “M” specification designation [SI units], the material shall be furnished to inch-pound units.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification8 pagesEnglish languagesale 15% off

- Technical specification8 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves and parts for high-temperature service. After hot working, forgings shall be cooled to a specific temperature prior to heat treatment, which shall be performed in accordance with certain requirements such as heat treatment type, austenitizing/solution temperature, cooling media, and quenching. The materials shall conform to the required chemical composition for carbon, manganese, phosphorus, silicon, nickel, chromium, molybdenum, columbium, titanium. The material shall conform to the requirements as to mechanical properties for the grade ordered such as tensile strength, yield strength, elongation, Brinell hardness. All H grades and grade F 63 shall be tested for average grain size.

SCOPE

1.1 This specification2 covers forged low alloy and stainless steel piping components for use in pressure systems. Included are flanges, fittings, valves, and similar parts to specified dimensions or to dimensional standards, such as the ASME specifications that are referenced in Section 2.

1.2 For bars and products machined directly from bar or hollow bar (other than those directly addressed by this specification; see 6.4), refer to Specifications A479/A479M, A739, or A511/A511M for the similar grades available in those specifications.

1.3 Products made to this specification are limited to a maximum weight of 10 000 lb [4540 kg]. For larger products and products for other applications, refer to Specifications A336/A336M and A965/A965M for the similar ferritic and austenitic grades, respectively, available in those specifications.

1.4 Several grades of low alloy steels and ferritic, martensitic, austenitic, and ferritic-austenitic stainless steels are included in this specification. Selection will depend upon design and service requirements. Several of the ferritic/austenitic (duplex) grades are also found in Specification A1049/A1049M.

1.5 Supplementary requirements are provided for use when additional testing or inspection is desired. These shall apply only when specified individually by the purchaser in the order.

1.6 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable “M” specification designation (SI units), the material shall be furnished to inch-pound units.

1.7 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification17 pagesEnglish languagesale 15% off

- Technical specification17 pagesEnglish languagesale 15% off

ABSTRACT

This guide covers standard specification for three classes of gray iron for castings intended for use as valve pressure retaining parts, pipe fittings, and flanges. Chemical analysis shall be performed in each lot and shall conform to the required chemical composition for phosphorous and sulfur. Tension test shall be conducted on each class of gray iron castings and shall conform to the specified values of tensile strength. Tension test specimens shall have threaded ends and shall conform to the prescribed dimensions.

SCOPE

1.1 This specification covers three classes of gray iron for castings intended for use as valve pressure-retaining parts, pipe fittings, and flanges.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

Note 1: The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers cold-formed welded and seamless carbon steel round, square, rectangular, or special shape structural tubing for welded, riveted, or bolted construction of bridges and buildings, and for general structural purposes. This tubing shall be produced in both welded and seamless sizes and must have the chemical requirements of carbon, manganese, phosphorus, sulfur, and copper. The steel shall be produced by either open-hearth, basic-oxygen, or electric-furnace melting process. When steels of different grades are sequentially strand cast, the steel producer shall identify the resultant transition material and remove it using an established procedure that positively separates the grades. The tubing shall then be made by a seamless or welding process. Welded tubing shall be made from flat-rolled steel by the electric-resistance-welding process. The longitudinal butt joint of welded tubing shall be welded across its thickness in such a manner that the structural design strength of the tubing section is assured. Tension test and flattening test shall be conducted to the specimens. All tubing shall be inspected at the place of manufacture to ensure conformance to the requirements of this specification and must have a workmanlike finish that is free from defects.

SCOPE

1.1 This specification covers cold-formed welded and seamless carbon steel round, square, rectangular, or special structural tubular shapes for welded, riveted, or bolted construction of bridges and buildings, and for general structural purposes.

1.2 This tubing is produced in both welded and seamless sizes with a periphery of 88 in. [2235 mm] or less, and a specified wall thickness of 1.000 in. [25.4 mm] or less. Grade D requires heat treatment.

Note 1: Products manufactured to this specification may not be suitable for those applications such as dynamically loaded elements in welded structures, etc., where low-temperature notch-toughness properties, which are typically measured by Charpy Impact testing, may be important. There are other ASTM standards that do have CVN requirements and may be more suitable for those applications.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

1.4 The text of this specification contains notes and footnotes that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any mandatory requirements.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification6 pagesEnglish languagesale 15% off

- Technical specification6 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers the materials, coating requirements, and inspection of the following fence accessories that are used for chain-link fences: post and line caps; rail and brace ends; top rail sleeves; tie wires, clips, and fasteners; tension and brace bands; tension bars; truss rod assembly; barbed wire arms; color coating of fittings; and fitting size terminology.

SCOPE

1.1 This specification covers the materials, coating requirements, and inspection of fence accessories for chain-link fence for the following:

1.1.1 Post and line caps,

1.1.2 Rail and brace ends,

1.1.3 Top rail sleeves,

1.1.4 Tie wires, clips, and fasteners,

1.1.5 Tension and brace bands,

1.1.6 Tension bars,

1.1.7 Truss rod assembly,

1.1.8 Barbed wire arms,

1.1.9 Color coating of fittings, and

1.1.10 Fitting size terminology.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification5 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers for several grades of carbon and alloy steel mechanical tubing, either hot-finished or cold-finished. The steel used in the mechanical tubing may be cast in ingots or may be strand cast. When steel of different grades is sequentially strand cast, identification of the resultant transition material is required. The seamless tubing is a tubular product made without a welded seam. It is usually manufactured by hot working steel, and if necessary, by subsequently cold finishing the hot-worked tubular product to produce the desired shape, dimensions and properties. The tubes shall be furnished in the following shapes: round, square, rectangular and special sections. Heat analysis shall be made to determine the percentages of the elements specified. If secondary melting processes are used, the heat analysis shall be obtained from one remelted ingot or the product of one remelted ingot of each primary melt. The tubing shall be coated with a film of oil before shaping to retard rust when specified

SCOPE

1.1 This specification covers several grades of carbon and alloy steel seamless mechanical tubing. The grades are listed in Tables 1-3. When welding is used for joining the weldable mechanical tube grades, the welding procedure shall be suitable for the grade, the condition of the components, and the intended service.

1.2 This specification covers both seamless hot-finished mechanical tubing and seamless cold-finished mechanical tubing in sizes up to and including 12 3/4 in. [325 mm] outside diameter for round tubes with wall thicknesses as required.

1.3 The tubes shall be furnished in the following shapes, as specified by the purchaser: round, square, rectangular, and special sections.

1.4 Supplementary requirements of an optional nature are provided and when desired shall be so stated in the order.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets or parentheses. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order. In this specification hard or rationalized conversions apply to diameter, lengths and tensile properties. Soft conversion applies to other SI measurements.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification14 pagesEnglish languagesale 15% off

- Technical specification14 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.