ASTM A1067/A1067M-12a(2018)

(Specification)Standard Specification for Test Coupons for Steel Castings

Standard Specification for Test Coupons for Steel Castings

ABSTRACT

This specification defines the geometries of several separately-cast and integrally-cast test coupons for use as specified in the applicable casting product or common requirements standard. Procedures for molding, casting, heat treating, machining, or testing are not covered in the standard, and are instead addressed as needed and appropriate by the applicable product or common requirements standard. The applicable casting product standard or common requirements standard or both provide information regarding the number of coupons, molding materials to be used, heat treatment concerns, and other processing issues. The primary function of the test coupon is to provide sound specimens usable for the determination of mechanical, physical, corrosion, or other properties of the metal used to produce the castings. If the test results conform to the stated requirements, then the test coupon may be considered to have functioned acceptably.

SCOPE

1.1 This specification defines the geometries of several separately cast and integrally cast test coupons for use as specified in the applicable casting product or common requirements standard. This standard does not address procedures for molding, casting, heat treating, machining, or testing; these items are addressed as needed and appropriate by the applicable product or common requirements standard.

Note 1: The test coupons described herein were formerly defined in multiple casting specifications. Those standards now reference this document when test coupons are required and should be consulted for applicable manufacturing and processing requirements.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A1067/A1067M −12a (Reapproved 2018)

Standard Specification for

Test Coupons for Steel Castings

This standard is issued under the fixed designation A1067/A1067M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Materials and Manufacture

3.1 Unless otherwise specified by the purchaser, test cou-

1.1 This specification defines the geometries of several

pons shall be poured from the same heat, or from the same

separately cast and integrally cast test coupons for use as

master heat, or from a sub-heat from the same master heat as

specified in the applicable casting product or common require-

the castings they are to represent.

ments standard. This standard does not address procedures for

molding, casting, heat treating, machining, or testing; these

3.2 Except where specified herein or in the applicable

items are addressed as needed and appropriate by the appli-

product or common requirements standard, the details of the

cable product or common requirements standard.

gating and risering of the coupons are left to the discretion of

the producer.

NOTE 1—The test coupons described herein were formerly defined in

multiple casting specifications. Those standards now reference this docu-

3.3 The test coupons shall be processed and heat treated as

ment when test coupons are required and should be consulted for

specified in the applicable product or common requirements

applicable manufacturing and processing requirements.

specification. Except when specified otherwise, the portion of

1.2 Units—The values stated in either SI units or inch-

the test coupon from which the test specimen or specimens are

pound units are to be regarded separately as standard. The

to be machined may be cut from the riser or feeder prior to heat

values stated in each system may not be exact equivalents;

treatment.

therefore, each system shall be used independently of the other.

Combining values from the two systems may result in noncon- 4. Performance Requirements

formance with the standard.

4.1 The primary function of the test coupon is to provide

sound specimens useable for the determination of mechanical,

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the physical, corrosion, or other properties of the metal used to

produce the castings. If the test results conform to the stated

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- requirements, then the test coupon may be considered to have

functioned acceptably.

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

5. Other Requirements

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 5.1 The casting producer shall establish procedures for the

Development of International Standards, Guides and Recom-

identification and traceability of the coupons from pouring

mendations issued by the World Trade Organization Technical through testing.

Barriers to Trade (TBT) Committee.

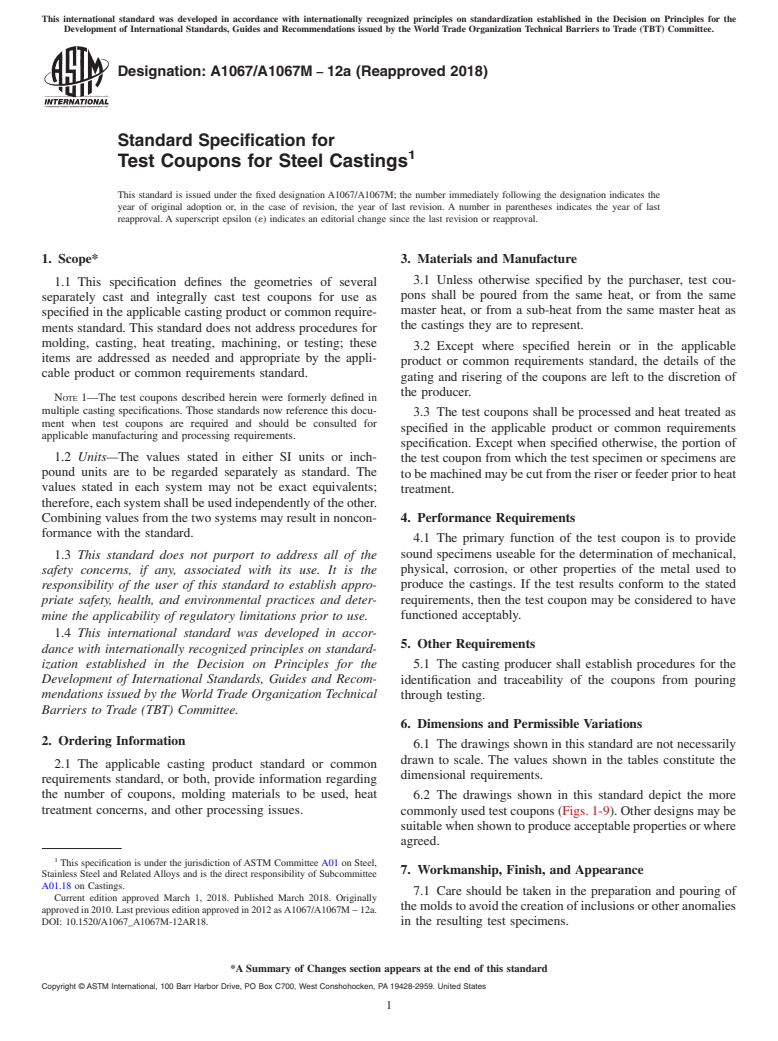

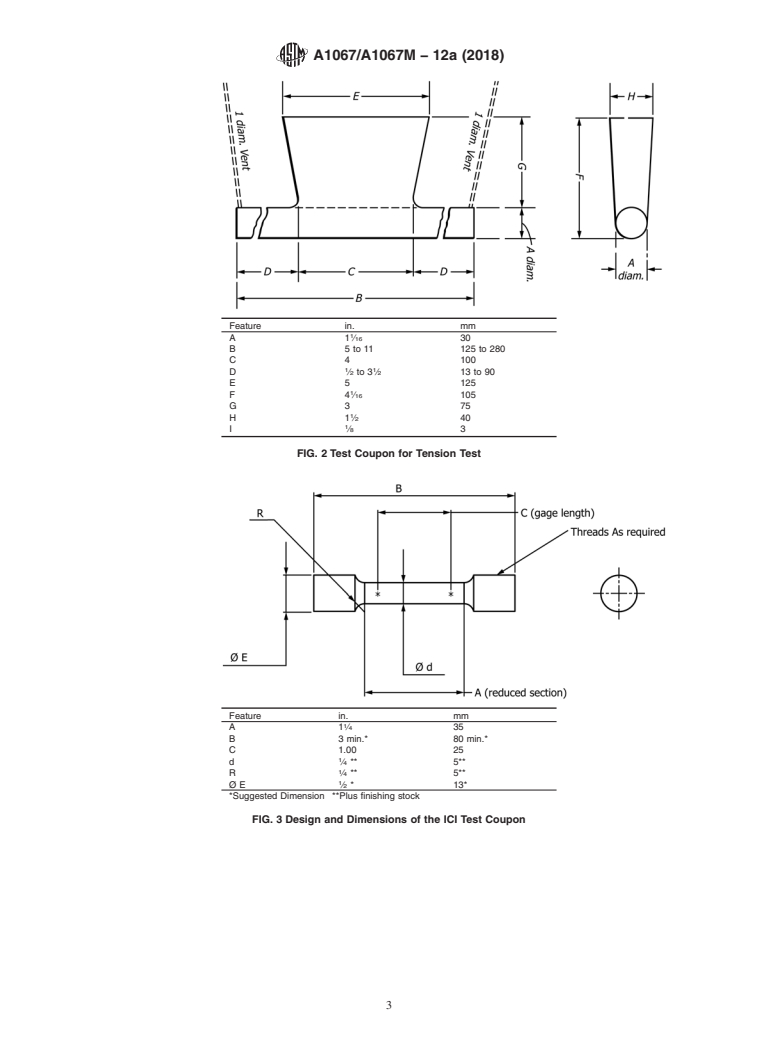

6. Dimensions and Permissible Variations

2. Ordering Information

6.1 The drawings shown in this standard are not necessarily

drawn to scale. The values shown in the tables constitute the

2.1 The applicable casting product standard or common

dimensional requirements.

requirements standard, or both, provide information regarding

the number of coupons, molding materials to be used, heat

6.2 The drawings shown in this standard depict the more

treatment concerns, and other processing issues.

commonly used test coupons (Figs. 1-9). Other designs may be

suitable when shown to produce acceptable properties or where

agreed.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

7. Workmanship, Finish, and Appearance

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.18 on Castings.

7.1 Care should be taken in the preparation and pouring of

Current edition approved March 1, 2018. Published March 2018. Originally

the molds to avoid the creation of inclusions or other anomalies

approved in 2010. Last previous edition approved in 2012 as A1067/A1067M – 12a.

DOI: 10.1520/A1067_A1067M-12AR18. in the resulting test specimens.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A1067/A1067M − 12a (2018)

Feature 4-leg design 2-leg design

in. mm in. mm

1 1

A2 ⁄4 60 2 ⁄4 60

1 1

B1 ⁄4 35 1 ⁄4 35

C2 50 2 50

1 1

D1 ⁄4 35 1 ⁄4 35

E Optional Optional Optional Optional

3 7

W8 ⁄8 215 3 ⁄8 100

T* * * *

L 5 min. 125 min. 5 min. 125 min.

1 1

R1 ⁄2 12.5 ⁄2 12.5

1 1

Rx 0 – ⁄16 0–2 0– ⁄16 0–2

*Use of and size of taper is at the discretion of the foundry.

FIG. 1 Test Coupons for Castings

8. Sampling 11. Product Marking

8.1 Care shall be taken in the production and processing of

11.1 Marking of test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.