ASTM D1465-90(2000)

(Test Method)Standard Test Method for Blocking and Picking Points of Petroleum Wax

Standard Test Method for Blocking and Picking Points of Petroleum Wax

SCOPE

1.1 This test method covers the determination of the blocking point and picking point of petroleum wax.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D1465–90(Reapproved 2000) Technical Association of Pulp and Paper Industry

Suggested Method T 652

Standard Test Method for

Blocking and Picking Points of Petroleum Wax

This standard is issued under the fixed designation D1465; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This test method was prepared jointly by the Technical Association of the Pulp and Paper Industry and the American Society for Testing

and Materials.

1. Scope disruption (picking point) and where 50% of the specimen

width is disrupted (50% blocking point) are noted. The

1.1 This test method covers the determination of the block-

temperatures of corresponding points on the blocking plate are

ing point and picking point of petroleum wax.

reported as the picking point and blocking point or blocking

1.2 This standard does not purport to address all of the

range.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 Blocking of waxed paper, because of the relatively low

bility of regulatory limitations prior to use.

temperatures at which it may occur, can be a major problem to

2. Referenced Documents the paper-coating industry. For example, when the waxed

surfaces in a roll of waxed paper stick together, upon separa-

2.1 ASTM Standards:

tion the surface films are marred and the glossy finish is

D87 Test Method for Melting Point of Petroleum Wax

destroyed. The wax picking point and the wax blocking point

(Cooling Curve)

indicate an approximate temperature range at or above which

D2423 Test Method for Surface Wax on Waxed Paper or

waxed surfaces in contact with each other are likely to cause

Paperboard

surface film injury.

E1 Specification for ASTM Thermometers

6. Apparatus

3. Terminology

6.1 Wax Coating Device—Any manual- or machine-driven

3.1 Definitions:

waxer that gives uniform coatings of the desired weights to a

3.1.1 wax blocking point—the lowest temperature at which

strip of paper not less than 51 mm (2 in.) wide.

film disruption occurs across 50% of the waxed paper surface

6.2 Trimming Board,orotherdeviceforcuttingpaperstrips.

when the test strips are separated.

6.3 Paper Scales, sensitive to 0.002 g, or suitable balance

3.1.2 wax picking point—the temperature at which the first

for measuring basis weights of unwaxed and waxed paper.

film disruption occurs on the waxed paper when test strips are

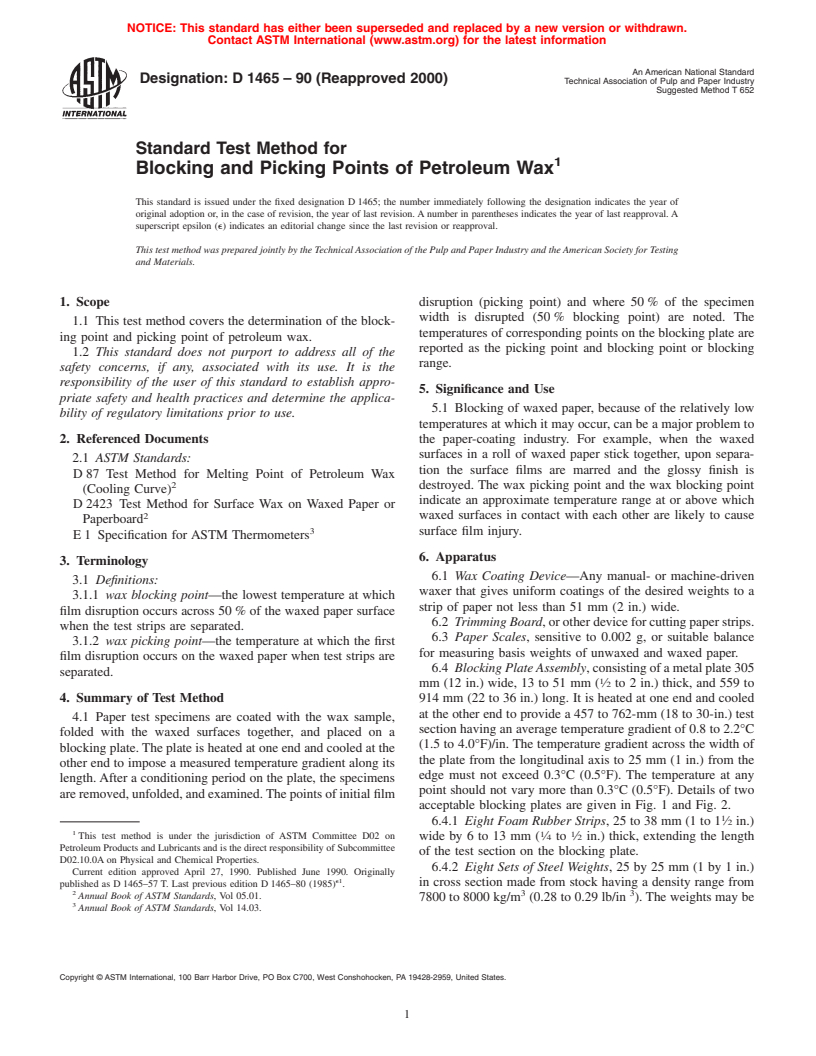

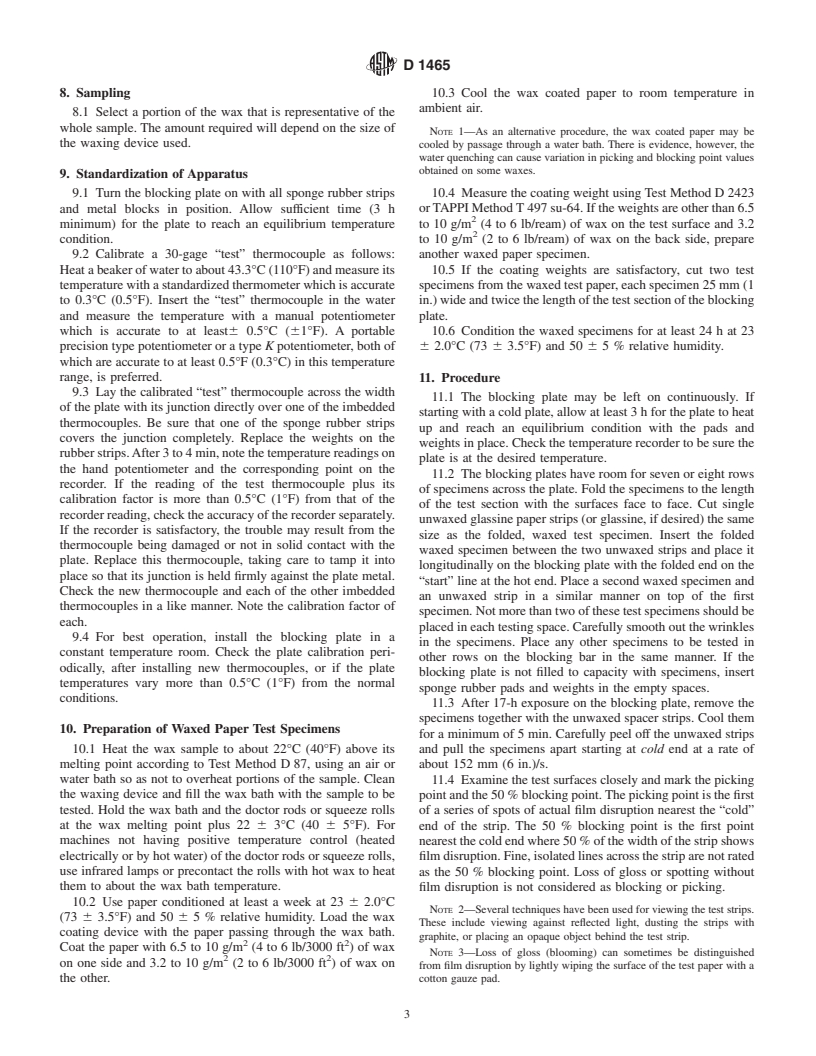

6.4 Blocking PlateAssembly,consistingofametalplate305

separated.

mm (12 in.) wide, 13 to 51 mm ( ⁄2 to 2 in.) thick, and 559 to

4. Summary of Test Method 914 mm (22 to 36 in.) long. It is heated at one end and cooled

at the other end to provide a 457 to 762-mm (18 to 30-in.) test

4.1 Paper test specimens are coated with the wax sample,

section having an average temperature gradient of 0.8 to 2.2°C

folded with the waxed surfaces together, and placed on a

(1.5 to 4.0°F)/in. The temperature gradient across the width of

blocking plate.The plate is heated at one end and cooled at the

the plate from the longitudinal axis to 25 mm (1 in.) from the

other end to impose a measured temperature gradient along its

edge must not exceed 0.3°C (0.5°F). The temperature at any

length.After a conditioning period on the plate, the specimens

point should not vary more than 0.3°C (0.5°F). Details of two

areremoved,unfolded,andexamined.Thepointsofinitialfilm

acceptable blocking plates are given in Fig. 1 and Fig. 2.

6.4.1 Eight Foam Rubber Strips,25to38mm(1to1 ⁄2 in.)

1 1

This test method is under the jurisdiction of ASTM Committee D02 on

wide by 6 to 13 mm ( ⁄4 to ⁄2 in.) thick, extending the length

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee

of the test section on the blocking plate.

D02.10.0Aon Physical and Chemical Properties.

6.4.2 Eight Sets of Steel Weights, 25 by 25 mm (1 by 1 in.)

Current edition approved April 27, 1990. Published June 1990. Originally

e1

in cross section made from stock having a density range from

published as D1465–57T. Last previous edition D1465–80 (1985) .

2 3 3

Annual Book of ASTM Standards, Vol 05.01.

7800 to 8000 kg/m (0.28 to 0.29 lb/in ). The weights may be

Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1465

FIG. 1 Type A Blocking Plate

FIG. 2 Type B Blocking Plate

in single lengths or in sections to give sets equaling the length in 1°F subdivisions, and conforming toThermometer 9C or 9F

of the test section of the blocking plate.

as prescribed in Specification E1.

6.5 Temperature Recorder, or indicator for measuring the

temperature gradient of the blocking plate.The instrument and

7. Test Paper

thermocouples when calibrated shall consistently be accurate

7.1 Paper—Cereal glassine of basis weight 46 to 51 g/m

to 6 0.3°C (0.5°F).

(28.5 to 31.5 lb/3000 ft ).

6.6 Thermometers—For water bath and wax bath on the

waxing device, use two ASTM Tag Closed Tester Thermom-

etershavingarangefrom−5to110°C(20to230°F),graduated

D1465

8. Sampling 10.3 Cool the wax coated paper to room temperature in

ambient air.

8.1 Select a portion of the wax that is representative of the

whole sample. The amount required will depend on the size of

NOTE 1—As an alternative procedure, the wax coated paper may be

the waxing device used. cooled by passage through a water bath. There is evidence, however, the

water quenching can cause variation in picking and blocking point values

obtained on some waxes.

9. Standardization of Apparatus

9.1 Turn the blocking plate on with all sponge rubber strips 10.4 Measure the coating weight usingTest Method D2423

and metal blocks in position. Allow sufficient time (3 h orTAPPIMethodT497su-64.Iftheweightsareotherthan6.5

minimum) for the plate to reach an equilibrium temperature to 10 g/m (4 to 6 lb/ream) of wax on the test surface and 3.2

condition. to 10 g/m (2 to 6 lb/ream) of wax on the back side, prepare

9.2 Calibrate a 30-gage “test” thermocouple as follows: another waxed paper specimen.

Heatabeakerofwatertoabout43.3°C(110°F)andmeasureits 10.5 If the coating weights are satisfactory, cut two test

temperaturewithastandardizedthermometerwhichisaccurate specimensfromthewaxedtestpaper,eachspecimen25mm(1

to 0.3°C (0.5°F). Insert the “test” thermocouple in the water in.)wideandtwicethelengthofthetestsectionoftheblocking

and measure the temperature with a manual potentiometer plate.

which is accurate to at least6 0.5°C (61°F). A portable 10.6 Condition the waxed specimens for at least 24 h at 23

precisiontypepotentiometeroratype Kpotentiometer,bothof 6 2.0°C (73 6 3.5°F) and 50 6 5 % relative humidity.

which are accurate to at least 0.5°F (0.3°C) in this temperature

range, is preferred.

11. Procedure

9.3 Lay the calibrated “test” thermocouple across th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.