ASTM B827-97

(Practice)Standard Practice for Conducting Mixed Flowing Gas (MFG) Environmental Tests

Standard Practice for Conducting Mixed Flowing Gas (MFG) Environmental Tests

SCOPE

1.1 This practice provides procedures for conducting environmental tests involving exposures to controlled quantities of corrosive gas mixtures.

1.2 This practice provides for the required equipment and methods for gas, temperature, and humidity control which enable tests to be conducted in a reproducible manner. Reproducibility is measured through the use of control coupons whose corrosion films are evaluated by mass gain, coulometry, or by various electron and X-ray beam analysis techniques. Reproducibility can also be measured by in-situ corrosion rate monitors using electrical resistance or mass/ frequency change methods.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See 5.1.2.4.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 827 – 97

Standard Practice for

Conducting Mixed Flowing Gas (MFG) Environmental Tests

This standard is issued under the fixed designation B 827; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1193 Specification for Reagent Water

D 1607 Test Method for Nitrogen Dioxide Content of the

1.1 This practice provides procedures for conducting envi-

Atmosphere (Griess-Saltzman Reaction)

ronmental tests involving exposures to controlled quantities of

D 2912 Test Method for Oxidant Content of the Atmo-

corrosive gas mixtures.

sphere (Neutral KI)

1.2 This practice provides for the required equipment and

D 2914 Test Methods for Sulfur Dioxide Content of the

methods for gas, temperature, and humidity control which

Atmosphere (West-Gaeke Method)

enable tests to be conducted in a reproducible manner. Repro-

D 3449 Test Method for Sulfur Dioxide in Workplace At-

ducibility is measured through the use of control coupons

mospheres (Barium Perchlorate Method)

whose corrosion films are evaluated by mass gain, coulometry,

D 3464 Test Method for Average Velocity in a Duct Using a

or by various electron and X-ray beam analysis techniques.

Thermal Anemometer

Reproducibility can also be measured by in situ corrosion rate

D 3609 Practice for Calibration Techniques Using Perme-

monitors using electrical resistance or mass/frequency change

ation Tubes

methods.

D 3824 Test Methods for Continuous Measurement of Ox-

1.3 The values stated in SI units are to be regarded as the

ides of Nitrogen in the Ambient or Workplace Atmosphere

standard.

by the Chemiluminescent Method

1.4 This standard does not purport to address all of the

D 4230 Test Method of Measuring Humidity With Cooled-

safety concerns, if any, associated with its use. It is the

Surface Condensation (Dew-Point) Hygrometer

responsibility of the user of this standard to establish appro-

E 902 Practice for Checking the Operating Characteristics

priate safety and health practices and determine the applica-

of X-Ray Photoelectron Spectrometers

bility of regulatory limitations prior to use. See 5.1.2.4.

G 91 Practice for Monitoring Atmospheric SO Using Sul-

2. Referenced Documents

fation Plate Technique

2.1 ASTM Standards:

3. Terminology

B 542 Terminology Relating to Electrical Contacts and

3.1 Definitions relating to electrical contacts are in accor-

Their Use

dance with Terminology B 542.

B 765 Guide for Selection of Porosity Tests for Electrode-

posits and Related Metallic Coatings

4. Significance and Use

B 808 Test Method for Monitoring of Atmospheric Corro-

2 4.1 Mixed flowing gas (MFG) tests are used to simulate or

sion Chambers by Quartz Crystal Microbalances

amplify exposure to environmental conditions which electrical

B 810 Test Method for Calibration of Atmospheric Corro-

contacts or connectors can be expected to experience in various

sion Test Chambers by Change in Mass of Copper Cou-

2 application environments (1, 2).

pons

4.2 Test samples which have been exposed to MFG tests

B 825 Test Method for Coulometric Reduction of Surface

2 have ranged from bare metal surfaces, to electrical connectors,

Films on Metallic Test Samples

and to complete assemblies.

B 826 Test Method for Monitoring Atmospheric Corrosion

2 4.3 The specific test conditions are usually chosen so as to

Tests by Electrical Resistance Probes

B 845 Guide for Mixed Flowing Gas (MFG) Tests for

Electrical Contacts

Annual Book of ASTM Standards, Vol 11.01.

1 5

This practice is under the jurisdiction of ASTM Committee B-2 on Nonferrous Annual Book of ASTM Standards, Vol 11.03.

Metals and Alloys and is the direct responsibility of Subcommittee B02.11 on Discontinued; see 1991 Book of ASTM Standards, Vol 11.03.

Electrical Contact Test Methods. Discontinued; see 1990 Annual Book of ASTM Standards, Vol 11.03.

Current edition approved Dec. 10, 1997. Published September 1998. Originally Annual Book of ASTM Standards, Vol 03.06.

published as B827-92. Last previous edition B827-92. Annual Book of ASTM Standards, Vol 03.02.

2 10

Annual Book of ASTM Standards, Vol 03.04. The boldface numbers in parentheses refer to the list of references at the end

Annual Book of ASTM Standards, Vol 02.05. of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 827

simulate, in the test laboratory, the effects of certain represen- 5.1.1.3 The chamber shall have provision for maintaining

tative field environments or environmental severity levels on uniformity of the average gas flow velocity within 620%ofa

standard metallic surfaces, such as copper and silver coupons specified value or of the chamber average when the chamber is

or porous gold platings (1, 2). empty. For chambers with a dimension of more than 0.5 m,

4.4 Because MFG tests are simulations, both the test con- measurement points shall be in accordance with Test Method

ditions and the degradation reactions (chemical reaction rate, B 810. For chambers with all dimensions of less than 0.5 m, a

composition of reaction products, etc.) may not always re- minimum of five points shall be measured at locations in the

semble those found in the service environment of the product plane of sample exposure (perpendicular to the expected flow

being tested in the MFG test. A guide to the selection of direction) that are equidistant from each other and the walls of

simulation conditions suitable for a variety of environments is the chamber. After all five or more data values are recorded, all

found in Guide B 845. measurements shall be repeated a second time. After the two

4.5 The MFG exposures are generally used in conjunction sets of measurements are recorded, a third complete set shall be

with procedures which evaluate contact or connector electrical recorded. The arithmetic average of the 15 or more measure-

performance such as measurement of electrical contact resis- ments shall be the chamber average. See 7.5 and 7.6.8. If a hot

tance before and after MFG exposure. wire anemometer is used for gas velocity measurements, it

4.6 The MFG tests are useful for connector systems whose shall be made in accordance with Test Method D 3464, with

contact surfaces are plated or clad with gold or other precious the exception that sample sites shall be in accordance with Test

metal finishes. For such surfaces, enviromentally produced Method B 810.

failures are often due to high resistance or intermittences 5.1.1.4 A sample access port is desirable. This should be

caused by the formation of insulating contamination in the designed such that control coupons can be removed or replaced

contact region. This contamination, in the form of films and without interrupting the flow of gases. Corrosion test chamber

hard particles, is generally the result of pore corrosion and corrosion rates have been shown to be a function of the

corrosion product migration or tarnish creepage from pores in presence or absence of light (3, 4). Provision for controlling the

the precious metal coating and from unplated base metal test illumination level in accordance with a test specification

boundaries, if present. shall be made.

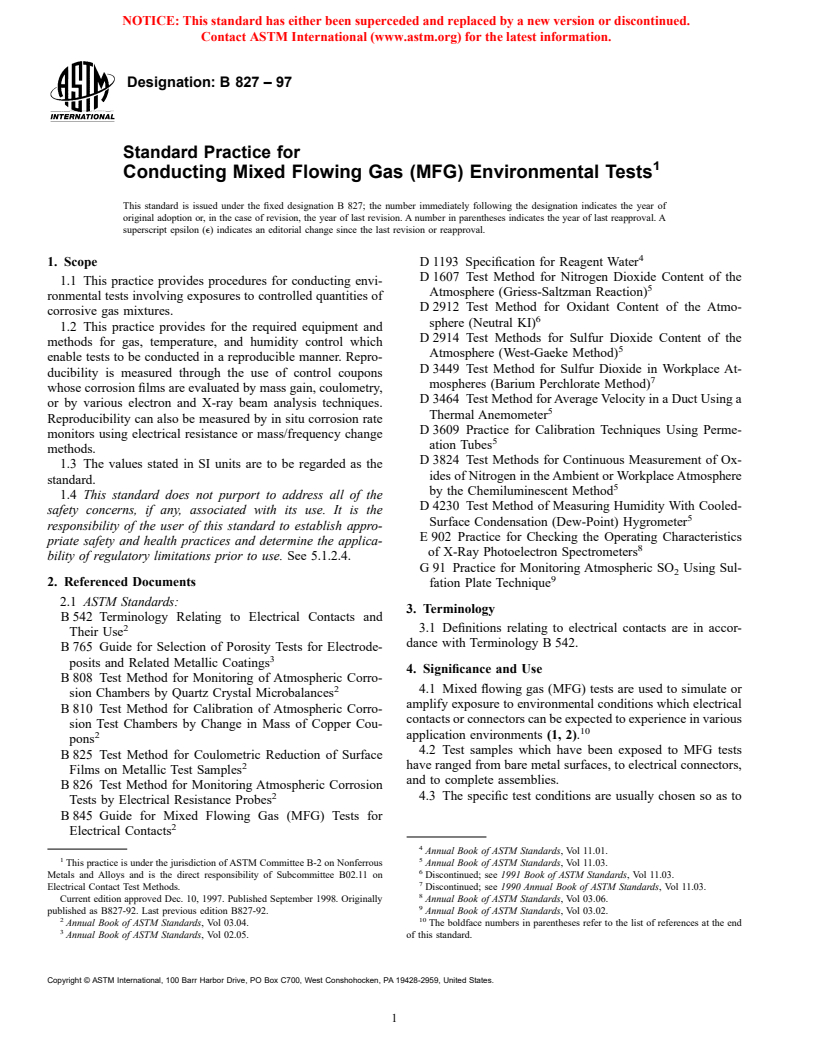

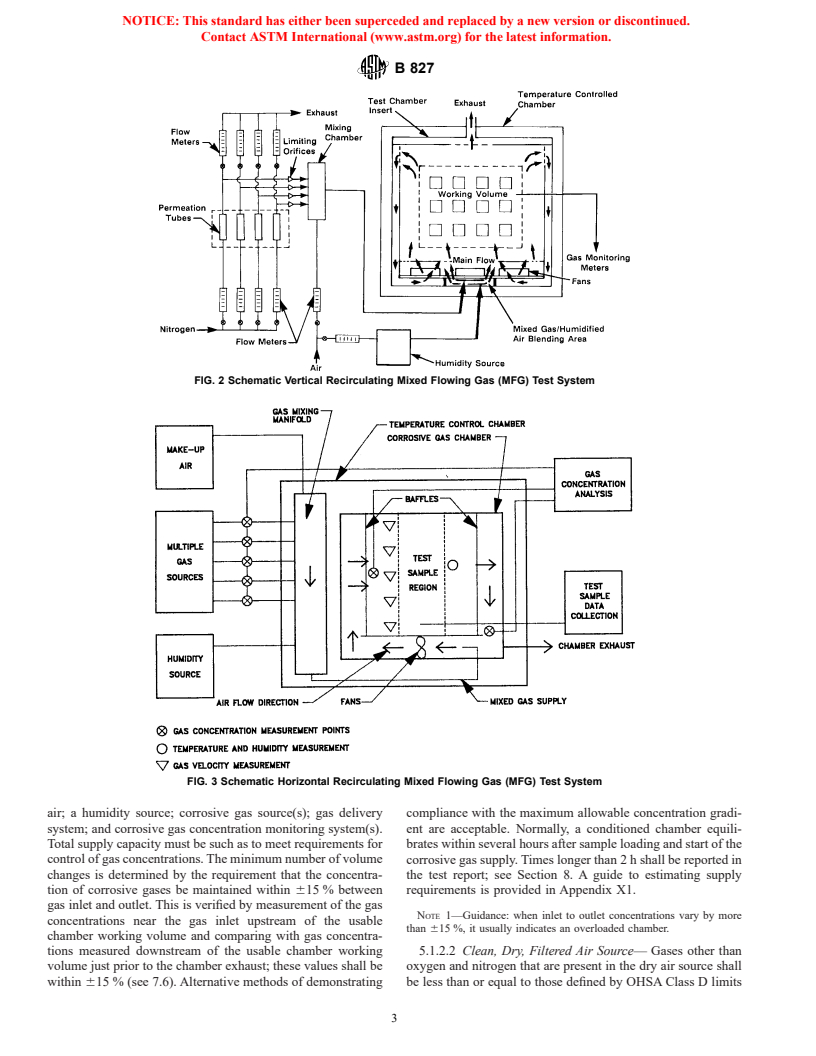

4.7 The MFG exposures can be used to evaluate novel 5.1.1.5 Examples of test chamber systems are diagrammed

electrical contact metallization for susceptibility to degradation in Figs. 1-3. They are not to be considered exclusive examples.

due to environmental exposure to the test corrosive gases. 5.1.2 Gas Supply System:

4.8 The MFG exposures can be used to evaluate the 5.1.2.1 Description and Requirements—The gas supply sys-

shielding capability of connector housings which may act as a tem consists of five main parts: a source of clean, dry, filtered

barrier to the ingress of corrosive gases.

4.9 The MFG exposures can be used to evaluate the

susceptibility of other connector materials such as plastic

housings to degradation from the test corrosive gases.

4.10 The MFG tests are not normally used as porosity tests.

For a guide to porosity testing, see Guide B 765.

4.11 The MFG tests are generally not applicable where the

failure mechanism is other than pollutant gas corrosion such as

in tin-coated separable contacts.

5. Apparatus

5.1 Apparatus required to conduct MFG tests are divided

into four major categories, corrosion test chamber, gas supply

system, chamber monitoring system, and chamber operating

system.

5.1.1 Corrosion Test Chamber:

5.1.1.1 The chamber shall consist of an enclosure made of

nonreactive, low-absorbing, nonmetallic materials contained

within a cabinet or oven capable of maintaining the tempera-

ture to a maximum tolerance of6 1°C with a preferred

tolerance held to 60.5°C within the usable chamber working

space accordance with 7.3, with a means to introduce and

exhaust gases from the chamber.

5.1.1.2 The chamber isolates the reactive gases from the

external environment. Chamber materials that are not low-

absorbing can affect test conditions by absorbing or emitting

reactive gases, leading to control and reproducibility problems.

The chamber construction shall be such that the leak rate is less

FIG. 1 Schematic Flow-Through Mixed Flowing Gas (MFG) Test

than 3 % of the volume exchange rate. System

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 827

FIG. 2 Schematic Vertical Recirculating Mixed Flowing Gas (MFG) Test System

FIG. 3 Schematic Horizontal Recirculating Mixed Flowing Gas (MFG) Test System

air; a humidity source; corrosive gas source(s); gas delivery compliance with the maximum allowable concentration gradi-

system; and corrosive gas concentration monitoring system(s). ent are acceptable. Normally, a conditioned chamber equili-

Total supply capacity must be such as to meet requirements for brates within several hours after sample loading and start of the

control of gas concentrations. The minimum number of volume corrosive gas supply. Times longer than 2 h shall be reported in

changes is determined by the requirement that the concentra-

the test report; see Section 8. A guide to estimating supply

tion of corrosive gases be maintained within 615 % between requirements is provided in Appendix X1.

gas inlet and outlet. This is verified by measurement of the gas

NOTE 1—Guidance: when inlet to outlet concentrations vary by more

concentrations near the gas inlet upstream of the usable

than 615 %, it usually indicates an overloaded chamber.

chamber working volume and comparing with gas concentra-

tions measured downstream of the usable chamber working 5.1.2.2 Clean, Dry, Filtered Air Source— Gases other than

volume just prior to the chamber exhaust; these values shall be oxygen and nitrogen that are present in the dry air source shall

within 615 % (see 7.6). Alternative methods of demonstrating be less than or equal to those defined by OHSA Class D limits

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 827

with the following additional constraint. Gases other than chambers to ensure the absence of uncalibrated gas streams.

nitrogen, oxygen, carbon dioxide, noble gases, methane, ni- 5.1.2.6 Corrosive Gas Concentration Monitoring System—

trous oxide, and hydrogen shall be less than 0.005 (ppm) by Standard measurement systems for very low level gas concen-

volume total and shall be High Efficiency Particulate Arrestants trations are listed in Table 1, which provides for gases in

(HEPA) filtered. common use in present mixed flowing gas systems, for testing

5.1.2.3 Humidity Source—The humidity source shall use electrical contact performance.

distilled or deionized water, Specification D 1193, Type 1 or (1) Each instrument must be characterized for interference

better, and shall introduce no extraneous material. The humid- with the gases specified, both individually and mixed.

ity source shall be maintained equivalent to Specification (2) Depending on the exact equipment set used, it may not

D 1193 Type II or better, with the exception that electrical be possible to accurately measure the concentration of some

resistivity shall be maintained equivalent to Specification gases, such as chlorine, in combination with any of the other

D 1193 Type IV. The time averaged value of humidity shall be gases.

within 61 % relative humidity of the specified value with (3) The analytic instruments shall be maintained and

absolute variations no greater than 63 % relative humidity calibrated electronically in accordance with the manufacturers’

from the specified value. recommendations. Standard gas sources shall also be calibrated

5.1.2.4 Corrosive Gas Sources—Corrosive (test) gases, in accordance with the manufacturers’ specifications, or in

such as nitrogen dioxide, hydrogen sulfide, chlorine, sulfur accordance with Practice D 3609. Gas concentration analyzers

dioxide, etc. shall be of chemically pure grade or better. Such shall be calibrated to standard gas sources in accordance with

gases are frequently supplied in a carrier gas such as nitrogen the manufacturers’ recommendations. They shall be calibrated

which shall be of Pre-Purified grade or better. before and after each test and whenever the indicated concen-

tration changes exceed the allowed variation in the test

NOTE 2—Caution: This practice involves the use of hazardous mate-

specification.

rials, procedures, and equipment. The gas concentrations in the test

(4) Control of the temperature and humidity within the test

chamber may be within permissible exposure limits (PEL). However,

concentrations in the compressed gas cylinders or permeation devices are chamber itself is part of the chamber monitoring system which

often above the PEL, and may exceed the immediately dangerous to life

is described in 5.1.3

and health level (IDHL). This practice does not address safety issues

NOTE 3—If the chlorine monitor is not being used during the test, it

associated with MFG testing.

need not be calibrated during the test.

5.1.2.5 Gas Delivery System—The gas delivery system is

5.1.3 Chamber Monitoring System—Chamber monitoring

comprised of three

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.