ASTM D6774-02(2010)

(Test Method)Standard Test Method for Crimp and Shrinkage Properties for Textured Yarns Using a Dynamic Textured Yarn Tester (Withdrawn 2019)

Standard Test Method for Crimp and Shrinkage Properties for Textured Yarns Using a Dynamic Textured Yarn Tester (Withdrawn 2019)

SIGNIFICANCE AND USE

Test Method D6774, for determining maximum total contraction, crimp, and residual fiber shrinkage in textured filament yarns is suitable for acceptance testing of commercial shipments.

If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use the samples for such a comparative tests that are as homogeneous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing and randomly assigned in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

The properties and their variability as measured by this method relate to bulk appearance, stretch and recovery of fabrics and dyeability of yarns.

For some yarns, elapsed time between processing and testing has a marked effect on the results, of this test, especially during the first 72 h. The effect is caused by stress decay which is known to be minimal beyond the seventh day and after which time the yarn remains relatively stable. Therefore, specimens should only be compared if tested after the same elapsed time. Samples can be tested at-line, thus having little to no elapsed time between processing and testing.

SCOPE

1.1 This test method covers the determination of crimp contraction, residual fiber shrinkage and their variability of all types of filament yarns (partially oriented yarn (POY), fully oriented yarn (FOY), flat yarns, textured and bulked continuous filament (BCF) carpet yarns) using an automated tester.

Note 1—For another method of testing crimp in textured yarns, refer to Test Method D4031.

1.1.1 This method may also be used for non-textured yarns.

1.2 This test method is limited to crimped, multi-filament yarns ranging from 22.0 to 890 dtex (15 to 800 denier) and for BCF yarns from 890 to 4200 dtex (800 to 3800 denier).

1.3 The values stated in either SI or US customary units are to be regarded separately as standard. Within the text, the U.S. customary units are in parentheses. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6774 − 02 (Reapproved 2010)

Standard Test Method for

Crimp and Shrinkage Properties for Textured Yarns Using a

1

Dynamic Textured Yarn Tester

This standard is issued under the fixed designation D6774; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 For definitions of textile terms in this test method, refer

1.1 This test method covers the determination of crimp

to Terminology D4849. For other textile terms used in this test

contraction, residual fiber shrinkage and their variability of all

method, refer to Terminology D123.

types of filament yarns (partially oriented yarn (POY), fully

oriented yarn (FOY), flat yarns, textured and bulked continu-

4. Summary of Test Method

ous filament (BCF) carpet yarns) using an automated tester.

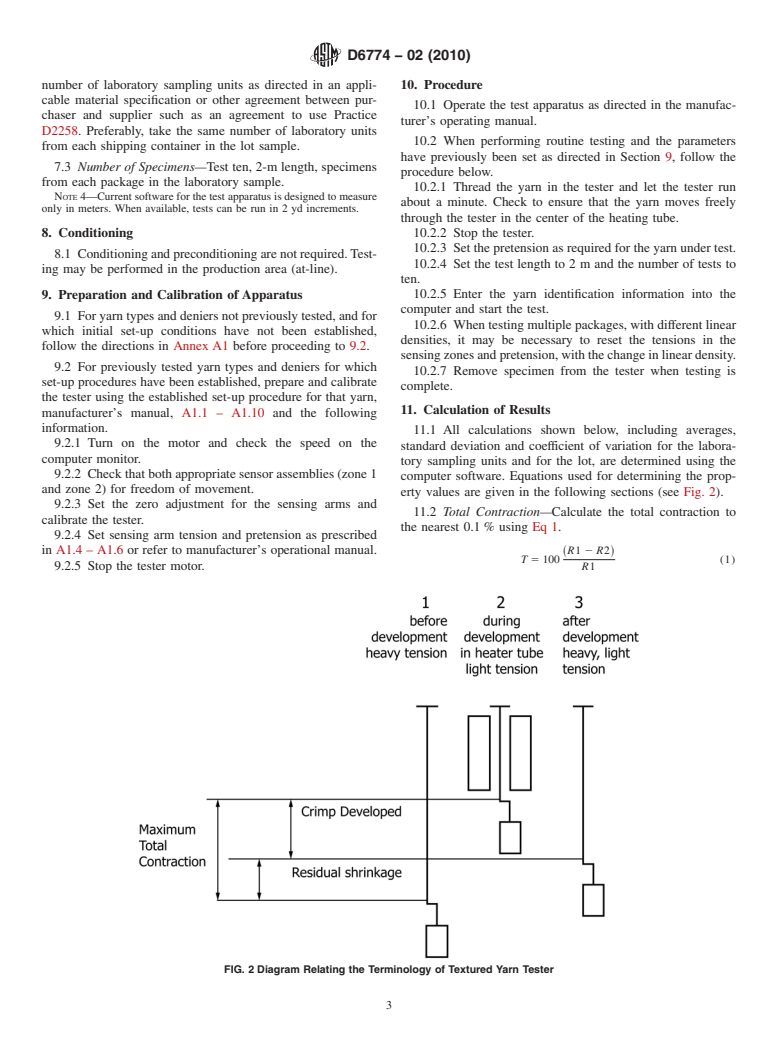

4.1 The specimen passes through a pretension device to

NOTE1—Foranothermethodoftestingcrimpintexturedyarns,referto

remove crimp. The specimen then passes, at a constant speed,

Test Method D4031.

around an input roller, to a calibrated sensor which maintains a

1.1.1 This method may also be used for non-textured yarns.

specific tension.

1.2 This test method is limited to crimped, multi-filament

4.1.1 Subsequently, the specimen passes through a heating

yarns ranging from 22.0 to 890 dtex (15 to 800 denier) and for element, at a low tension, where the specimen shrinks and

BCF yarns from 890 to 4200 dtex (800 to 3800 denier).

again is crimped.

4.1.2 The crimped specimen then goes to an intermediate

1.3 The values stated in either SI or US customary units are

roll, at a low tension.

to be regarded separately as standard. Within the text, the U.S.

4.1.3 The specimen then travels to a second sensor, which

customary units are in parentheses. The values stated in each

maintains a tension equal to the pretension applied, to remove

system are not exact equivalents; therefore, each system shall

developed crimp.

be used independently of the other. Combining values from the

two systems may result in nonconformance with the method.

4.2 Residual fiber shrinkage, crimp developed, and maxi-

mum total contraction are calculated by the computer software

1.4 This standard does not purport to address all of the

using speeds of the input, intermediate and output rolls.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5.1 Test Method D6774, for determining maximum total

contraction, crimp, and residual fiber shrinkage in textured

2. Referenced Documents

filament yarns is suitable for acceptance testing of commercial

2 shipments.

2.1 ASTM Standards:

5.1.1 If there are differences of practical significance be-

D123 Terminology Relating to Textiles

tween reported test results for two laboratories (or more),

D2258 Practice for Sampling Yarn for Testing

comparative tests should be performed to determine if there is

D4031 Test Method for Bulk Properties of Textured Yarns

a statistical bias between them, using competent statistical

D4849 Terminology Related to Yarns and Fibers

assistance. As a minimum, use the samples for such a com-

parative tests that are as homogeneous as possible, drawn from

thesamelotofmaterialasthesamplesthatresultedindisparate

1

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

results during initial testing and randomly assigned in equal

and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers.

numbers to each laboratory. The test results from the labora-

Current edition approved June 1, 2010. Published September 2010. Originally

tories involved should be compared using a statistical test for

approved in 2002. Last previous edition approved in 2002 as D6774-02. DOI:

10.1520/D6774-02R10.

unpaired data, a probability level chosen prior to the testing

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

series. If a bias is found, either its cause must be found and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

corrected, or future test results for that material must be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. adjusted in consideration of the known bias.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6774 − 02 (2010)

5.2 The properties and their variability as measured by th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.