ASTM C1541-02

(Specification)Standard Specification for Shielded Transition Couplings Using Flexible Poly Vinyl Chloride (PVC) Gaskets to Connect Dissimilar DWV Pipe and Fittings

Standard Specification for Shielded Transition Couplings Using Flexible Poly Vinyl Chloride (PVC) Gaskets to Connect Dissimilar DWV Pipe and Fittings

SCOPE

1.1 This specification covers the performance of shielded transition couplings using flexible PVC gaskets to join dissimilar DWV pipe and fittings above and below ground up to and including 10-in. pipe and fittings.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parenthesis are for information only.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards of any other organization.

1.4 The following precaution pertains only to the test method portion, Sections of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1541 – 02

Standard Specification for

Shielded Transition Couplings Using Flexible Poly Vinyl

Chloride (PVC) Gaskets to Connect Dissimilar DWV Pipe

and Fittings

This standard is issued under the fixed designation C 1541; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

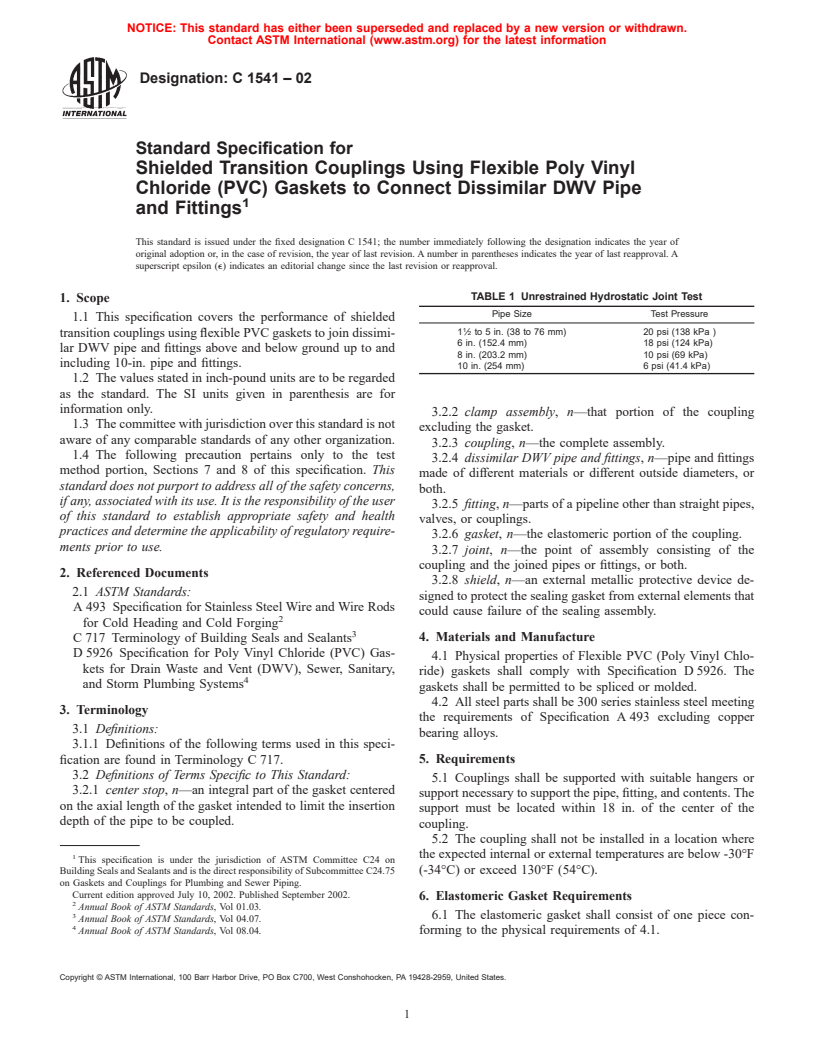

TABLE 1 Unrestrained Hydrostatic Joint Test

1. Scope

Pipe Size Test Pressure

1.1 This specification covers the performance of shielded

1 ⁄2 to 5 in. (38 to 76 mm) 20 psi (138 kPa )

transition couplings using flexible PVC gaskets to join dissimi-

6 in. (152.4 mm) 18 psi (124 kPa)

lar DWV pipe and fittings above and below ground up to and

8 in. (203.2 mm) 10 psi (69 kPa)

including 10-in. pipe and fittings.

10 in. (254 mm) 6 psi (41.4 kPa)

1.2 The values stated in inch-pound units are to be regarded

as the standard. The SI units given in parenthesis are for

information only.

3.2.2 clamp assembly, n—that portion of the coupling

1.3 The committee with jurisdiction over this standard is not

excluding the gasket.

aware of any comparable standards of any other organization.

3.2.3 coupling, n—the complete assembly.

1.4 The following precaution pertains only to the test

3.2.4 dissimilar DWV pipe and fittings, n—pipe and fittings

method portion, Sections 7 and 8 of this specification. This

made of different materials or different outside diameters, or

standard does not purport to address all of the safety concerns,

both.

if any, associated with its use. It is the responsibility of the user

3.2.5 fitting, n—parts of a pipeline other than straight pipes,

of this standard to establish appropriate safety and health

valves, or couplings.

practices and determine the applicability of regulatory require-

3.2.6 gasket, n—the elastomeric portion of the coupling.

ments prior to use.

3.2.7 joint, n—the point of assembly consisting of the

coupling and the joined pipes or fittings, or both.

2. Referenced Documents

3.2.8 shield, n—an external metallic protective device de-

2.1 ASTM Standards:

signed to protect the sealing gasket from external elements that

A 493 Specification for Stainless Steel Wire and Wire Rods

could cause failure of the sealing assembly.

for Cold Heading and Cold Forging

4. Materials and Manufacture

C 717 Terminology of Building Seals and Sealants

D 5926 Specification for Poly Vinyl Chloride (PVC) Gas-

4.1 Physical properties of Flexible PVC (Poly Vinyl Chlo-

kets for Drain Waste and Vent (DWV), Sewer, Sanitary,

ride) gaskets shall comply with Specification D 5926. The

and Storm Plumbing Systems

gaskets shall be permitted to be spliced or molded.

4.2 All steel parts shall be 300 series stainless steel meeting

3. Terminology

the requirements of Specification A 493 excluding copper

3.1 Definitions:

bearing alloys.

3.1.1 Definitions of the following terms used in this speci-

5. Requirements

fication are found in Terminology C 717.

3.2 Definitions of Terms Specific to This Standard:

5.1 Couplings shall be supported with suitable hangers or

3.2.1 center stop, n—an integral part of the gasket centered

support necessary to support the pipe, fitting, and contents. The

on the axial length of the gasket intended to limit the insertion

support must be located within 18 in. of the center of the

depth of the pipe to be coupled.

coupling.

5.2 The coupling shall not be installed in a location where

1 the expected internal or external temperatures are below -30°F

This specification is under the jurisdiction of ASTM Committee C24 on

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.75 (-34°C) or exceed 130°F (54°C).

on Gaskets and Couplings for Plumbing and Sewer Piping.

Current edition approved July 10, 2002. Published September 2002.

6. Elastomeric Gasket Requirements

Annual Book of ASTM Standards, Vol 01.03.

6.1 The elastomeric gasket shall consist of one piece con-

Annual Book of ASTM Standards, Vol 04.07.

Annual Book of ASTM Standards, Vol 08.04. forming to the physical requirements of 4.1.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1541–02

FIG. 1 Deflection Test

6.2 The elastomeric gasket shall have an inside center 8.2 Deflection Test—Each coupling tested shall be mounted

stop-ring spaced an equal distance from the ends to serve as a between two pieces of pipe as provided in 8.1. The out bound

stop between the pipe/fitting ends. The center stop ring shall ends of the pipe shall be closed with test plugs. The assembly

not create an enlargement chamber or recess with a ledge, shall be filled with water, all air expelled, and hydrostatically

shoulder or reduction of pipe area or offer an obstruction to pressurized to 4.3 psi (29.6 kPa) for the duration of the test.

flow. A gasket without an inside center stop shall be permitted One pipe shall be rigidly supported and while the assembly is

in tubular transition applications, where telescoping of pipe is under pressure, the opposite end of the other pipe shall be

necessary. raised ⁄2 in. (12.7 mm) per linear foot of pipe. The pressure

6.3 The elastomeric gasket shall be free from imperfections shall be maintained for 15 min and leakage shall not be

and porosity that affects its use and serviceability.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.