ASTM F14-80(2010)

(Practice)Standard Practice for Making and Testing Reference Glass-Metal Bead-Seal

Standard Practice for Making and Testing Reference Glass-Metal Bead-Seal

SIGNIFICANCE AND USE

The term reference as employed in this practice implies that both the glass and the metal of the reference glass-metal seal will be a standard reference material such as those supplied for other physical tests by the National Institute of Standards and Technology, or a secondary reference material whose sealing characteristics have been determined by seals to a standard reference material (see NIST Special Publication 260). Until standard reference materials for seals are established by the NIST, secondary reference materials may be agreed upon between producer and user.

SCOPE

1.1 This practice covers procedures for preparing and testing reference glass-to-metal bead-seals for determining the magnitude of thermal expansion (or contraction) mismatch between the glass and metal. Tests are in accordance with method F218 (2).

1.2 This practice applies to all glass-metal combinations, established or experimental, particularly those intended for electronic components.

1.3 The practical limit of the test in devising mismatch is approximately 300 ppm, above which the glass is likely to fracture.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F14 − 80(Reapproved 2010)

Standard Practice for

Making and Testing Reference Glass-Metal Bead-Seal

This standard is issued under the fixed designation F14; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Practice

1.1 This practice covers procedures for preparing and test- 3.1 Seals of a standard configuration are prepared from a

ing reference glass-to-metal bead-seals for determining the representative sample of each metal and glass to be tested.

magnitude of thermal expansion (or contraction) mismatch Each material is prepared by an approved method and sized as

between the glass and metal. Tests are in accordance with specified. The seal is formed, annealed, and measured for

method F218 (2). optical retardation from which the axial stress and expansion

mismatch are calculated. At least two specimens are required

1.2 This practice applies to all glass-metal combinations,

from which average values are obtained.

established or experimental, particularly those intended for

electronic components.

4. Significance and Use

1.3 The practical limit of the test in devising mismatch is

4.1 The term reference as employed in this practice implies

approximately 300 ppm, above which the glass is likely to

that both the glass and the metal of the reference glass-metal

fracture.

seal will be a standard reference material such as those

1.4 This standard does not purport to address all of the

supplied for other physical tests by the National Institute of

safety concerns, if any, associated with its use. It is the

Standards and Technology, or a secondary reference material

responsibility of the user of this standard to establish appro-

whose sealing characteristics have been determined by seals to

priate safety and health practices and determine the applica-

a standard reference material (see NIST Special Publication

bility of regulatory limitations prior to use. 4

260). Until standard reference materials for seals are estab-

lished by the NIST, secondary reference materials may be

2. Referenced Documents

agreed upon between producer and user.

2.1 ASTM Standards:

F15 Specification for Iron-Nickel-Cobalt Sealing Alloy

5. Apparatus

F30 Specification for Iron-Nickel Sealing Alloys

5.1 Polarimeter, as specified in Method F218 for measuring

F31 Specification for Nickel-Chromium-Iron SealingAlloys

optical retardation and analyzing stress in glass.

F79 Specification for Type 101 Sealing Glass

F105 Specification for Type 58 Borosilicate Sealing Glass

5.2 Heat-Treating and Oxidizing Furnaces, with suitable

F218 Test Method for Measuring Optical Retardation and

controls and with provisions for appropriate atmospheres

Analyzing Stress in Glass

(Annex A1) for preconditioning metal, if required.

F256 Specification for Chromium-Iron Sealing Alloys with

5.3 Glassworking Lamp or Sealing Furnace, radiant tube,

18 or 28 Percent Chromium

muffle, or r-f induction with suitable controls and provision for

F257 Specification for Twenty-eight Percent (28 %)

use with inert atmosphere.

Chromium-Iron Alloy for Sealing to Glass (Withdrawn

5.4 Annealing Furnace, with capability of controlled cool-

1973)

ing.

1 5.5 Ultrasonic Cleaner, optional.

This practice is under the jurisdiction of ASTM Committee C14 on Glass and

Glass Products and is the direct responsibility of Subcommittee C14.04 on Physical

5.6 Micrometer Caliper, with index permitting direct read-

and Mechanical Properties.

ing of 0.02 cm.

Current edition approved April 1, 2010. Published May 2010. Originally

approved in 1961. Last previous edition approved in 2005 as F14 – 80 (2005). DOI:

10.1520/F0014-80R10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from National Institute of Standards and Technology (NIST), 100

Standards volume information, refer to the standard’s Document Summary page on Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov. C14

the ASTM website. Gulati, S. T., and Hagy, H. E., “Expansion Measurement Using Short

The last approved version of this historical standard is referenced on CylindricalSeal:TheoryandMeasurement,”ThermalExpansion6,editedbyIanD.

www.astm.org. Peggs, Plenum, New York, N. Y., 1978, pp. 113–130.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F14 − 80 (2010)

6. Materials 9.1.1 Placethesealinanindex-matchingliquidandposition

its axis in a direction 45° from the direction of vibration of the

6.1 Metal—Representative rod stock with out-of-round not

polarizer and analyzer, so that the line of sight is at the

exceeding 1 % shall be selected, preferably with a diameter in

midpoint of the glass bead.

the range 0.5 to 4 mm. Smaller diameters result in a loss of

sensitivity and larger diameters tend to be cumbersome and 9.1.2 Determine the retardation along the light path through

impractical. Surfaces shall be relatively free of scratches, the glass in terms of degrees of rotation of the analyzer. Rotate

machine marks, pits, or inclusions that would induce localized

in a direction that causes the black fringe seen within the glass

stresses. Length requirements are discussed in 6.2.

to move toward the glass-metal interface. Stop rotation of the

analyzer when the center of the black fringe is coincident with

6.2 Glass—Representative glass tubing of suitable optical

the glass-metal interface. This condition is termed the point of

transmission with an inside diameter 0.15 to 0.25 mm larger

extinction.

than the metal rod diameter.The outside diameter of the tubing

shall preferably be such that it produces a glass-to-metal

NOTE 1—Sealing combinations may exist in which the thermal expan-

diameterratiobetween1.5and2.Thelengthofthetubingshall

sion coefficients of glass and metal at room temperature may differ

exceed four times the finished glass diameter.The length of the

significantly. In these cases it may be important to record the temperature

metal rod must exceed the length of the tubing. Surface

oftherefractionliquid(ortheseal)atthetimetheretardationismeasured.

contaminants shall be removed to reduce the risk of making

9.1.3 Repeat the above for a total of four measurements per

bubbly seals. An ultrasonic water mark is recommended.

seal equally spaced around the interface. Calculate average

7. Seal-Making Procedure

rotation, A.

9.1.4 Recordtheopticalretardationsindegrees,theindexof

7.1 The seal may be made either by flame-working tech-

niques or by heating the tubing-rod assembly in a furnace. In refraction of the liquid, a

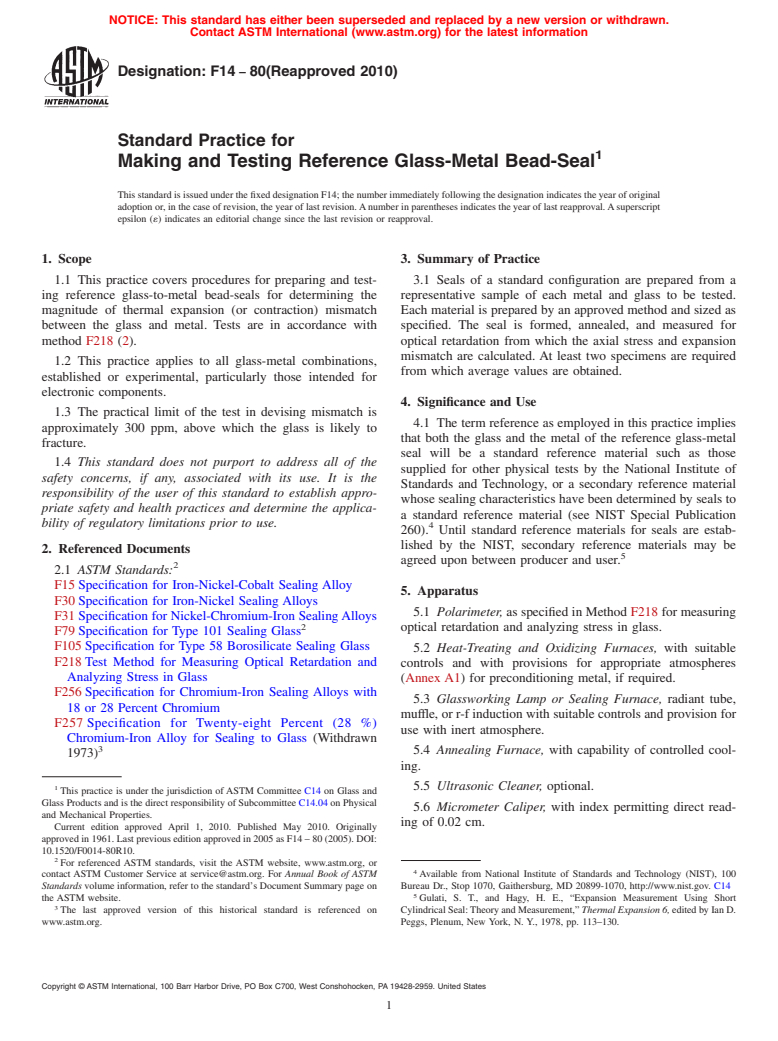

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.