ASTM F29-97(2022)

(Specification)Standard Specification for Dumet Wire for Glass-to-Metal Seal Applications

Standard Specification for Dumet Wire for Glass-to-Metal Seal Applications

ABSTRACT

This specification covers the properties and requirements for round, copper-coated 42 % nickel-iron wire, commonly known as dumet, intended primarily for sealing to soft glass. The wires shall conform to requirements stated for chemical composition, oxide coatings, dimension, internal and surface workmanship, and storage characteristics. Materials shall also undergo tests for thermal expansion, color of coating, diameter, reducible oxides, copper analysis, and metallography.

SCOPE

1.1 This specification covers round, copper-coated 42 % nickel-iron wire, commonly known as dumet, intended primarily for sealing to soft glass.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F29 −97 (Reapproved 2022)

Standard Specification for

Dumet Wire for Glass-to-Metal Seal Applications

ThisstandardisissuedunderthefixeddesignationF29;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E228Test Method for Linear Thermal Expansion of Solid

Materials With a Push-Rod Dilatometer

1.1 This specification covers round, copper-coated 42%

F14Practice for Making andTesting Reference Glass-Metal

nickel-ironwire,commonlyknownasdumet,intendedprimar-

Bead-Seal

ily for sealing to soft glass.

1.2 The values stated in inch-pound units are to be regarded

3. Ordering Information

as standard. The values given in parentheses are mathematical

3.1 The wire is usually supplied with a surface coating

conversions to SI units that are provided for information only

consisting of a mixture of copper oxides and fused sodium

and are not considered standard.

tetraborate (borax) which retards oxidation of the wire during

1.3 This standard does not purport to address all of the

sealing in glass and further aids wetting of the wire by the

safety concerns, if any, associated with its use. It is the

glass. The composite wire may also be purchased as bare wire

responsibility of the user of this standard to establish appro-

for specific applications.

priate safety, health, and environmental practices and deter-

3.2 Thesizeofthewire,ifapplicable,theboratecolorrange

mine the applicability of regulatory limitations prior to use.

designated as light, medium (regular), or dark, shall be

1.4 This international standard was developed in accor-

specified on each purchase order.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3.3 Package sizes shall be agreed upon between the pur-

Development of International Standards, Guides and Recom-

chaser and the seller.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4. Chemical Composition

4.1 The copper used in the manufacture of dumet shall be

2. Referenced Documents

99.90% minimum copper. Silver shall be included with the

2.1 ASTM Standards:

copper. The material shall be free of reducible oxides.

B170Specification for Oxygen-Free Electrolytic Copper—

4.2 The chemical composition of the nickel-iron core shall

Refinery Shapes

be as shown in Table 1.

D1535Practice for Specifying Color by the Munsell System

D1729Practice for Visual Appraisal of Colors and Color

5. Oxide Coating

Differences of Diffusely-Illuminated Opaque Materials

E3Guide for Preparation of Metallographic Specimens

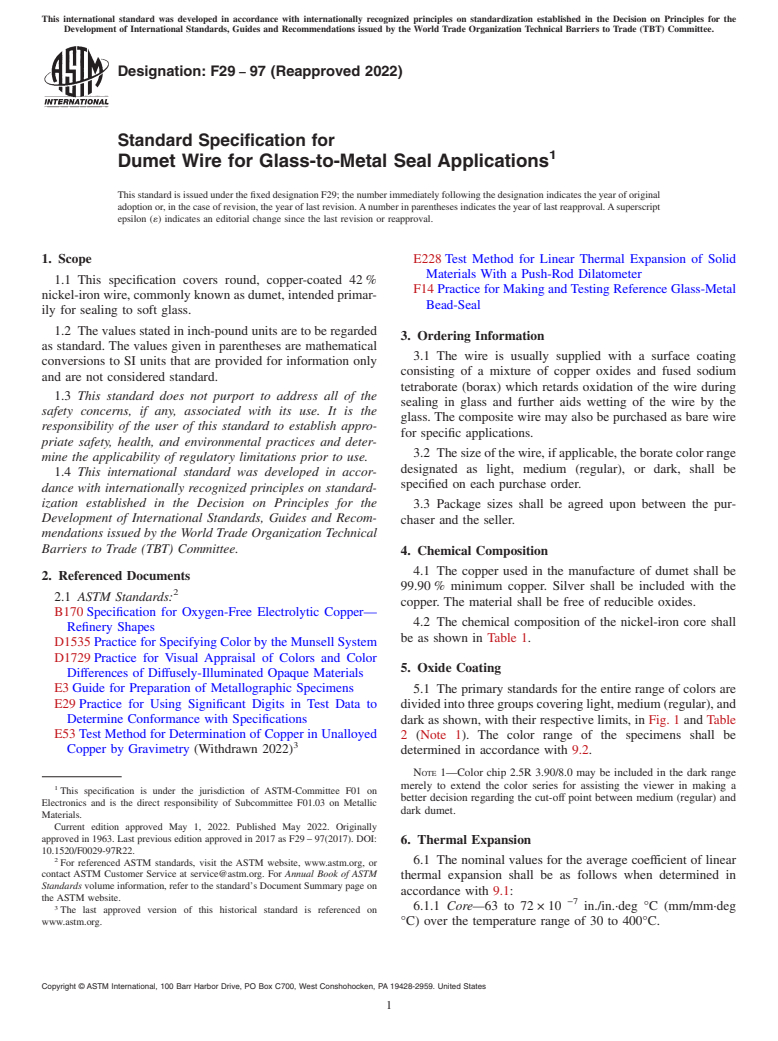

5.1 The primary standards for the entire range of colors are

E29Practice for Using Significant Digits in Test Data to dividedintothreegroupscoveringlight,medium(regular),and

Determine Conformance with Specifications

dark as shown, with their respective limits, in Fig. 1 and Table

E53Test Method for Determination of Copper in Unalloyed 2 (Note 1). The color range of the specimens shall be

Copper by Gravimetry (Withdrawn 2022)

determined in accordance with 9.2.

NOTE 1—Color chip 2.5R 3.90/8.0 may be included in the dark range

merely to extend the color series for assisting the viewer in making a

This specification is under the jurisdiction of ASTM-Committee F01 on

better decision regarding the cut-off point between medium (regular) and

Electronics and is the direct responsibility of Subcommittee F01.03 on Metallic

dark dumet.

Materials.

Current edition approved May 1, 2022. Published May 2022. Originally

approved in 1963. Last previous edition approved in 2017 as F29–97(2017). DOI:

6. Thermal Expansion

10.1520/F0029-97R22.

6.1 The nominal values for the average coefficient of linear

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

thermal expansion shall be as follows when determined in

Standards volume information, refer to the standard’s Document Summary page on

accordance with 9.1:

the ASTM website.

−7

6.1.1 Core—63 to 72×10 in./in.·deg °C (mm/mm·deg

The last approved version of this historical standard is referenced on

www.astm.org. °C) over the temperature range of 30 to 400°C.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F29−97 (2022)

TABLE 1 Chemical Requirements: Core Material

9.1.1 Heat the core rod specimen in a hydrogen atmosphere

Element Composition, % for1hat900°C; then cool it from 900 to 200 °C at a rate not

Nickel 41 to 43 exceeding 5°C/min.

Manganese 0.75 to 1.25

9.1.2 Determine the thermal expansion charateristics in

Silicon, max 0.30

accordance with Test Method E228.

Carbon, max 0.10

Sulfur, max 0.02

9.2 Color of Coating— Mount the color chips on a neutral

Phosphorus, max 0.02

Iron (by difference) remainder background (middle gray to white) as shown in Fig. 1. Wind

the specimen to be tested or compared on a flat surface similar

tothatshowninFig.1.Eachturnofthewireshouldlieparallel

TABLE 2 Color Ranges and Limits

and as close as possible to the preceding turn without overlap-

Medium (Regular)

ping. View the specimen in natural or artificial daylight in

Dark Range Light Range

Range

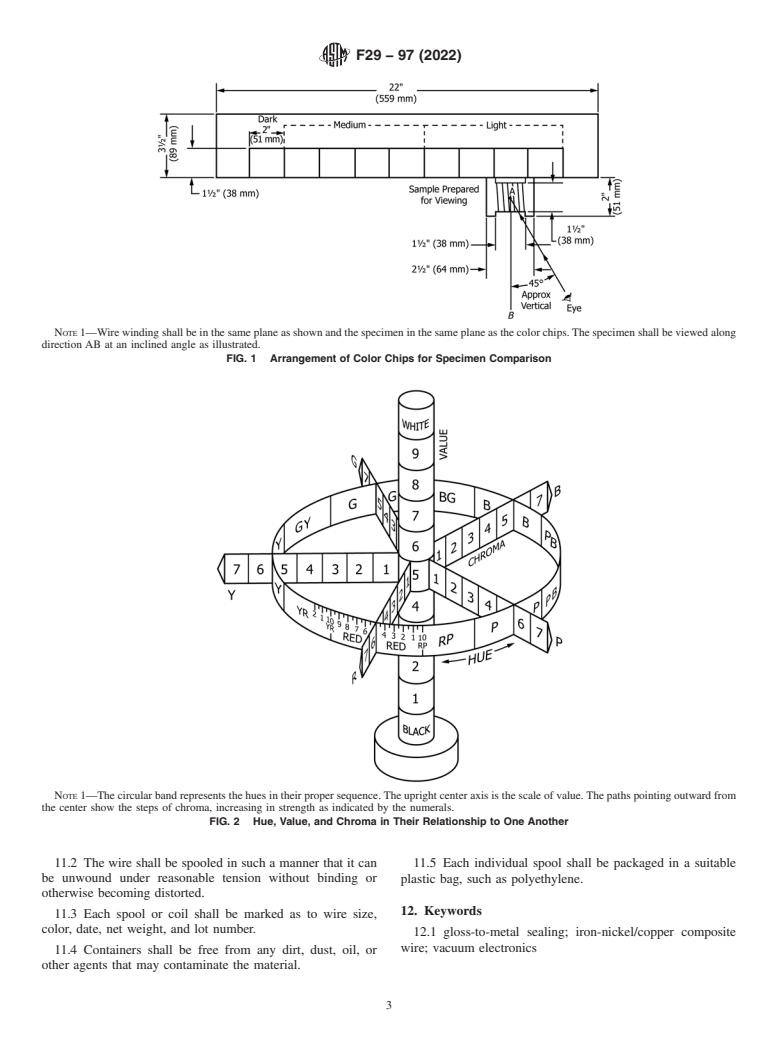

accordancewitheitherorbothMethodD1535,(Note3)orTest

Colors darker than chip 3.5R 3.5R 3.94/8.0 to 6.5R 7.5R 4.22/8.0 to 0.5YR

Method D1729, Fig. 2.

3.94/8.0 4.06/8.0, incl 4.56/8.0 incl

NOTE 3—Coated wire carries a mixture of copper oxides and fused

sodiumtetraborateonthesurfaceofthedumet,whichdissolves,whollyor

TABLE 3 Dimensional Tolerances in part, into the glass during the sealing operation. The sealing technique

is influenced by the amount of coating, and color has been established as

Diameter, in. (mm) Tolerance, in.

a means of estimating the thickness of this mixture.The color varies from

(mm)

a dark red-purple to a light yellow-red as the thickness decreases. The

0.007 to 0.013 (0.18 to 0.33) ±0.0003 (±0.008)

method,describedinTestMethodD1535,isbasedonthecolor-perception

Over 0.013 to 0.018 (0.33 to 0.46) ±0.0004 (±0.010)

attributes of hue, lightness, and saturation and is used as the means for

Over 0.018 (0.46) ±0.0005 (±0.013)

specifying color.This method employs the Munsell color-notation system

in which visual scales are assigned to each of the color-perception

attributes. In this system, the attributes are called hue, H, value, V, and

−7

6.1.2 Copper—177 6 3.5×10 in./in.·°C (mm/mm·deg

chroma,C,writt

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.