ASTM C426-15

(Test Method)Standard Test Method for Linear Drying Shrinkage of Concrete Masonry Units

Standard Test Method for Linear Drying Shrinkage of Concrete Masonry Units

SIGNIFICANCE AND USE

4.1 This test method is intended to evaluate the drying shrinkage characteristics of a given unit. The results of this laboratory method are considered in determining concrete masonry crack control provisions.

Note 1: The testing laboratory performing this test method should be evaluated in accordance with Practice C1093.

SCOPE

1.1 This test method covers a routine standardized procedure for determining the linear drying shrinkage of concrete masonry units or related concrete units under specified accelerated drying conditions.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C426 − 15

StandardTest Method for

1

Linear Drying Shrinkage of Concrete Masonry Units

This standard is issued under the fixed designation C426; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 3.2.1 linear drying shrinkage—in this test method, the

change in linear dimension of the test specimen due to drying

1.1 This test method covers a routine standardized proce-

from a saturated condition to an equilibrium weight and length

dure for determining the linear drying shrinkage of concrete

under specified accelerated drying conditions.

masonry units or related concrete units under specified accel-

erated drying conditions.

4. Significance and Use

1.2 The values stated in inch-pound units are to be regarded

4.1 This test method is intended to evaluate the drying

as standard. The values given in parentheses are mathematical

shrinkage characteristics of a given unit. The results of this

conversions to SI units that are provided for information only

laboratory method are considered in determining concrete

and are not considered standard.

masonry crack control provisions.

1.3 This standard does not purport to address all of the

NOTE 1—The testing laboratory performing this test method should be

safety concerns, if any, associated with its use. It is the

evaluated in accordance with Practice C1093.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use.

5.1 Strain Gauge—The instruments for measuring linear

drying shrinkage shall be so designed as to permit or provide

2. Referenced Documents

the conditions described in 5.1.1 through 5.1.5.

2

2.1 ASTM Standards:

NOTE 2—Strain gauges may be obtained with various gauge lengths.

C490PracticeforUseofApparatusfortheDeterminationof

The 10-in. (254-mm) gauge length is recommended for use with regular

Length Change of Hardened Cement Paste, Mortar, and

concrete masonry units, however, particular sizes of products may require

Concrete

other lengths. The length of the shrinkage specimen shall not be less than

C1093Practice for Accreditation of Testing Agencies for

required for a minimum gauge length (distance between gauge plugs) of

Masonry 6 in. (152.4 mm).

C1232Terminology of Masonry

5.1.1 A means of positive contact with the specimen that

2.2 ANSI Standard:

will ensure reproducible measurements of length.

3

B94.11M—1993 Twist Drills

5.1.2 Means for precise measurement, consisting of a dial

micrometer or other measuring device graduated to read in

3. Terminology

0.0001-in. (0.0025-mm) units, and accurate within 0.0001 in.

3.1 Terminology defined in Terminology C1232 shall apply (0.0025 mm) in any 0.0010-in. (0.025-mm) range, and within

for this test method. 0.0002 in. (0.0050-mm) in any 0.0100-in. (0.254-mm) range.

5.1.3 Sufficient range to allow for small variations in the

3.2 Definitions of Terms Specific to This Standard:

gauge lengths.

NOTE 3—If the shrinkage reference points are set carefully to position,

1

This test method is under the jurisdiction of ASTM Committee C15 on

a dial micrometer with a travel of 0.2 or 0.3 in. (5.1 or 7.6 mm) provides

Manufactured Masonry Units and is the direct responsibility of Subcommittee

ample range in the instrument.

C15.03 on Concrete Masonry Units and Related Units.

Current edition approved Dec. 1, 2015. Published January 2016. Originally 5.1.4 Means for checking the strain gauge at regular inter-

approved in 1958. Last previous edition approved in 2010 as C426–10. DOI:

vals against a standard reference bar. The standard reference

10.1520/C0426-15.

bar shall be protected from air currents by placing it inside a

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

wooden box which should be closed except when the strain

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

gauge is being checked against it.

the ASTM website.

3

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., NOTE 4—A standard reference bar shall be furnished by the manufac-

4th Floor, New York, NY 10036, http://www.ansi.org. turer of the instrument.Astandard bar of ordinary steel is satisfactory, but

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

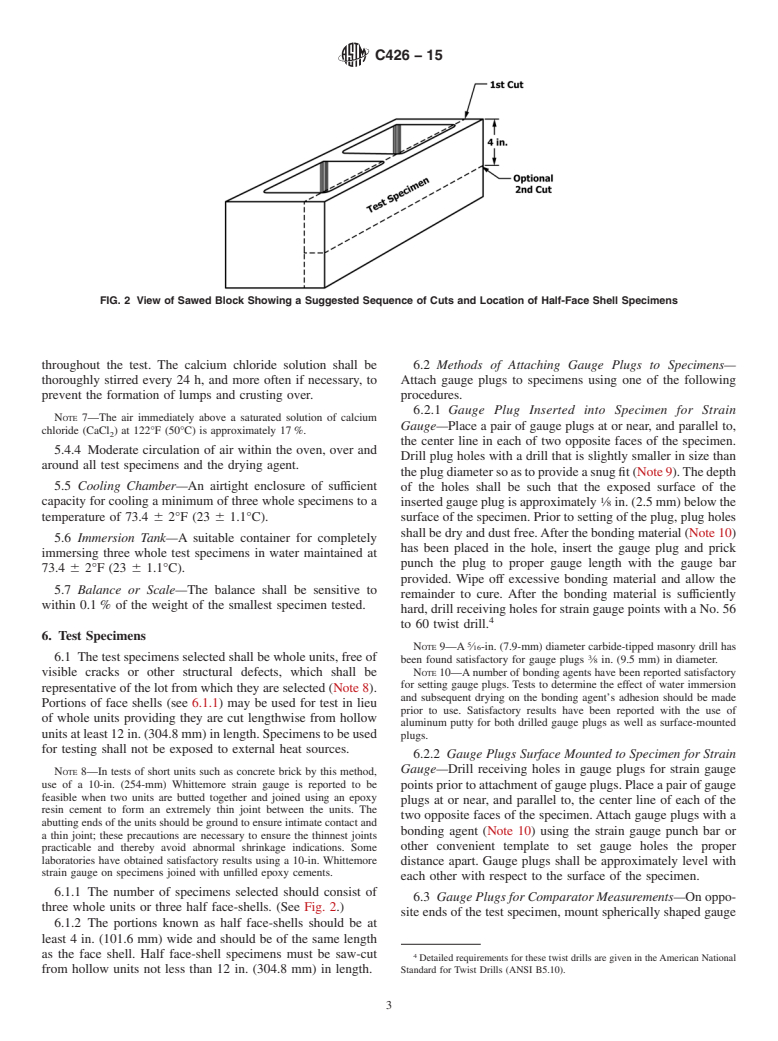

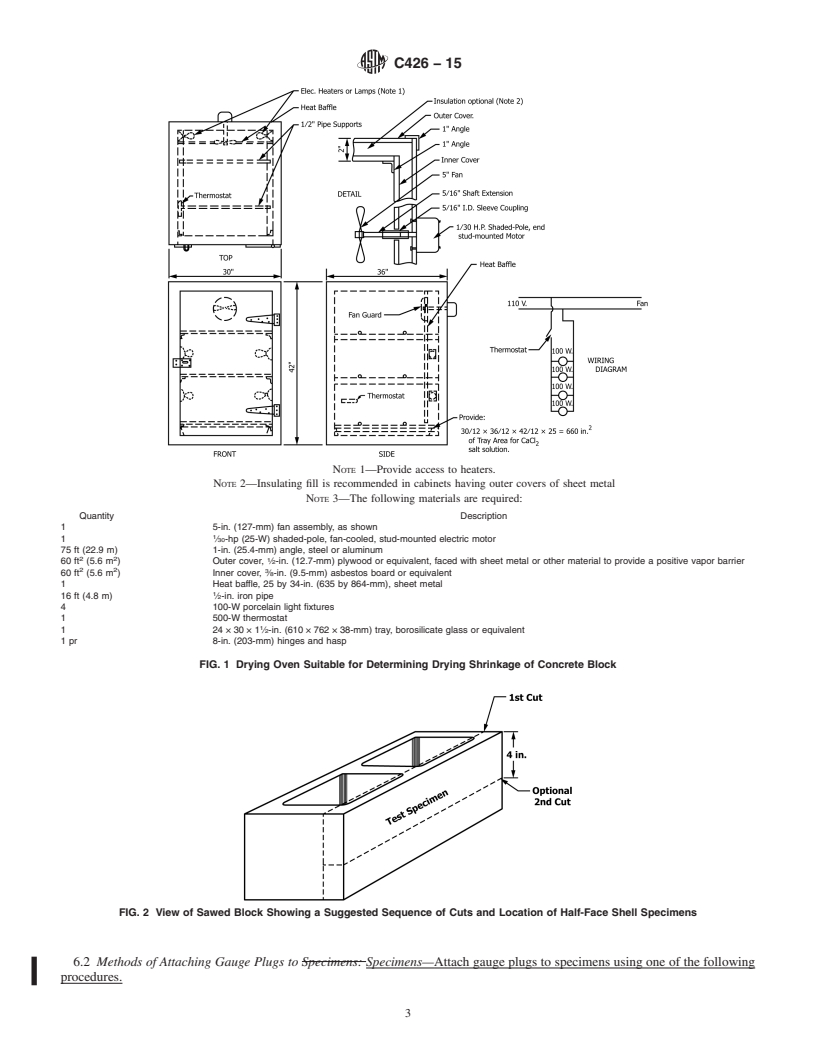

----

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C426 − 10 C426 − 15

Standard Test Method for

1

Linear Drying Shrinkage of Concrete Masonry Units

This standard is issued under the fixed designation C426; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This test method covers a routine standardized procedure for determining the linear drying shrinkage of concrete masonry

units or related concrete units under specified accelerated drying conditions.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C490 Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete

C1093 Practice for Accreditation of Testing Agencies for Masonry

C1232 Terminology of Masonry

2.2 ANSI Standard:

3

B94.11M—1993 Twist Drills

3. Terminology

3.1 Terminology defined in Terminology C1232 shall apply for this test method.

3.2 Definitions:Definitions of Terms Specific to This Standard:

3.2.1 linear drying shrinkage—in this test method, the change in linear dimension of the test specimen due to drying from a

saturated condition to an equilibrium weight and length under specified accelerated drying conditions.

4. Significance and Use

4.1 This test method is intended to evaluate the drying shrinkage characteristics of a given unit. The results of this laboratory

method are considered in determining concrete masonry crack control provisions.

NOTE 1—The testing laboratory performing this test method should be evaluated in accordance with Practice C1093.

5. Apparatus

5.1 Strain Gauge—The instruments for measuring linear drying shrinkage shall be so designed as to permit or provide the

conditions described in 5.1.1 through 5.1.5.

NOTE 2—Strain gauges may be obtained with various gauge lengths. The 10-in. (254-mm) gauge length is recommended for use with regular concrete

masonry units, however, particular sizes of products may require other lengths. The length of the shrinkage specimen shall not be less than required for

a minimum gauge length (distance between gauge plugs) of 6 in. (152.4 mm).

1

This test method is under the jurisdiction of ASTM Committee C15 on Manufactured Masonry Units and is the direct responsibility of Subcommittee C15.03 on Concrete

Masonry Units and Related Units.

Current edition approved Dec. 1, 2010Dec. 1, 2015. Published December 2010January 2016. Originally approved in 1958. Last previous edition approved in 20072010

as C426 – 07.C426 – 10. DOI: 10.1520/C0426-10.10.1520/C0426-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C426 − 15

5.1.1 A means of positive contact with the specimen that will ensure reproducible measurements of length.

5.1.2 Means for precise measurement, consisting of a dial micrometer or other measuring device graduated to read in 0.0001-in.

(0.0025-mm) units, and accurate within 0.0001 in. (0.0025 mm) in any 0.0010-in. (0.025-mm) range, and within 0.0002 in.

(0.0050-mm) in any 0.0100-in. (0.254-mm) range.

5.1.3 Sufficient range to allow for small variations in the gauge lengths.

NOTE 3—If the shrinkage reference points are set carefully to position, a dial micrometer with a travel of 0.2 or 0.3 in. (5.1 or 7.6 mm) provides ample

range in the instrum

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.