ASTM F1070-87(1999)

(Specification)Standard Specification for Doors, Non-Tight, for Marine Use

Standard Specification for Doors, Non-Tight, for Marine Use

SCOPE

1.1 This specification to be used in conjunction with Specification F1073, covers the principal dimensions and the mechanical requirements for manufacturing steel, aluminum, and glass-reinforced plastic non-tight, personnel doors and dutch doors, with the exception of joiner, joiner dutch doors, and expanded metal doors, for marine use.

1.2 The doors will be used in non-tight bulkheads.

1.3 When fire protection requirements are applicable to the location of these doors, then the use of aluminum and glass-reinforced plastic doors shall be unacceptable.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1070 – 87 (Reapproved 1999)

Standard Specification for

Doors, Non-Tight, for Marine Use

This standard is issued under the fixed designation F 1070; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope MIL-C-81706 Coating, Aluminum and Aluminum Alloys

TT-E-490 Enamel, Silicone Alkyd Copolymer, Semi-gloss,

1.1 This specification to be used in conjunction with Speci-

Exterior

fication F 1073, covers the principal dimensions and the

DoD-STD-2138 Metal Sprayed Coating Systems for Corro-

mechanical requirements for manufacturing steel, aluminum,

sion Protection

and glass-reinforced plastic non-tight, personnel doors and

dutch doors, with the exception of joiner, joiner dutch doors,

3. Ordering Information

and expanded metal doors, for marine use.

3.1 Ordering for doors under this specification shall include

1.2 The doors will be used in non-tight bulkheads.

the following:

1.3 When fire protection requirements are applicable to the

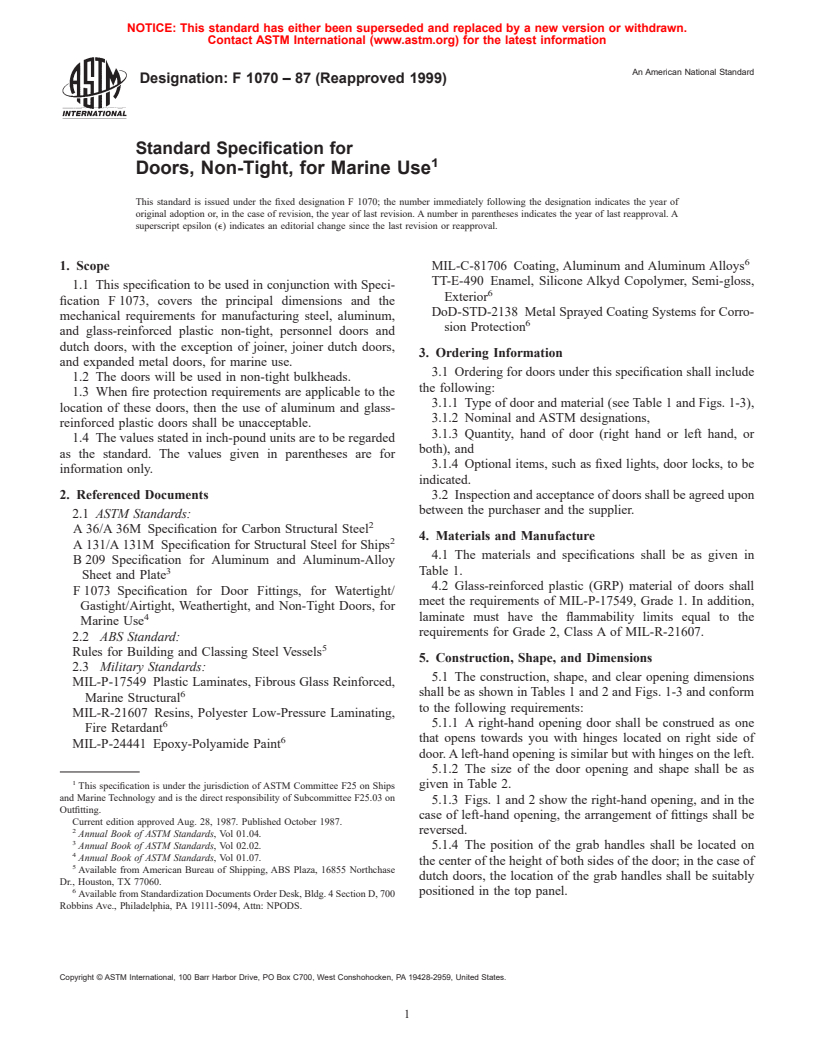

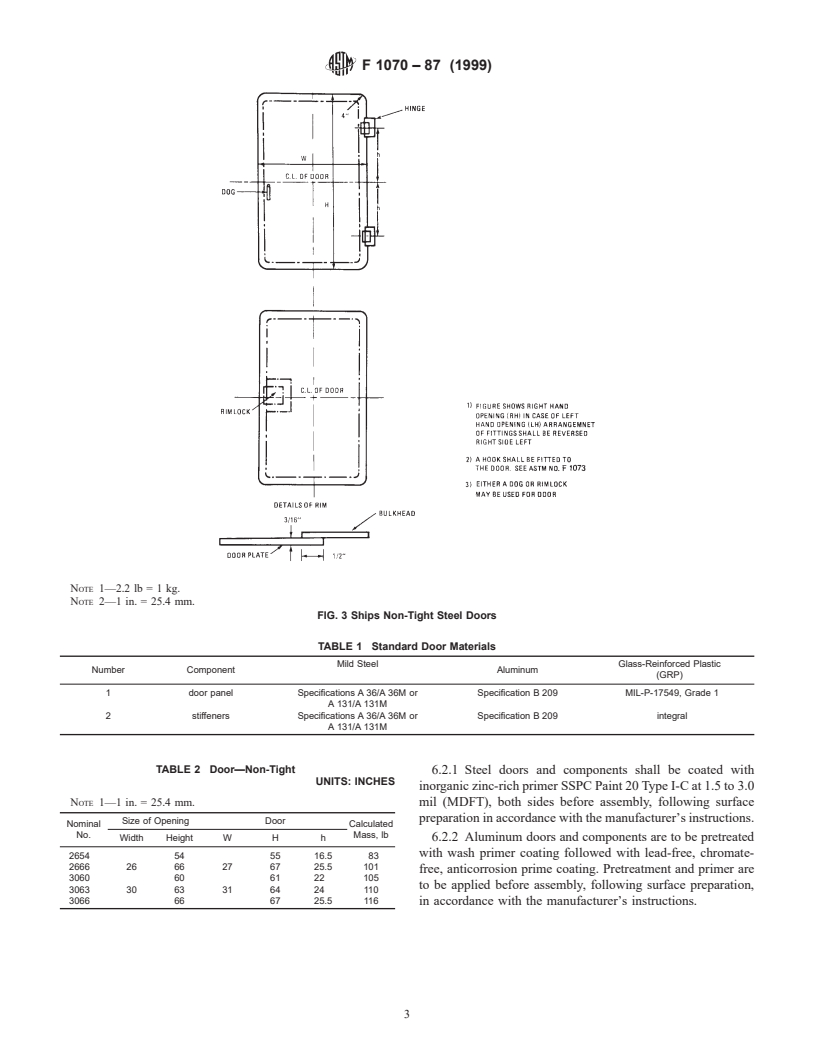

3.1.1 Type of door and material (see Table 1 and Figs. 1-3),

location of these doors, then the use of aluminum and glass-

3.1.2 Nominal and ASTM designations,

reinforced plastic doors shall be unacceptable.

3.1.3 Quantity, hand of door (right hand or left hand, or

1.4 The values stated in inch-pound units are to be regarded

both), and

as the standard. The values given in parentheses are for

3.1.4 Optional items, such as fixed lights, door locks, to be

information only.

indicated.

2. Referenced Documents 3.2 Inspection and acceptance of doors shall be agreed upon

between the purchaser and the supplier.

2.1 ASTM Standards:

A 36/A 36M Specification for Carbon Structural Steel

4. Materials and Manufacture

A 131/A 131M Specification for Structural Steel for Ships

4.1 The materials and specifications shall be as given in

B 209 Specification for Aluminum and Aluminum-Alloy

Table 1.

Sheet and Plate

4.2 Glass-reinforced plastic (GRP) material of doors shall

F 1073 Specification for Door Fittings, for Watertight/

meet the requirements of MIL-P-17549, Grade 1. In addition,

Gastight/Airtight, Weathertight, and Non-Tight Doors, for

4 laminate must have the flammability limits equal to the

Marine Use

requirements for Grade 2, Class A of MIL-R-21607.

2.2 ABS Standard:

Rules for Building and Classing Steel Vessels

5. Construction, Shape, and Dimensions

2.3 Military Standards:

5.1 The construction, shape, and clear opening dimensions

MIL-P-17549 Plastic Laminates, Fibrous Glass Reinforced,

6 shall be as shown in Tables 1 and 2 and Figs. 1-3 and conform

Marine Structural

to the following requirements:

MIL-R-21607 Resins, Polyester Low-Pressure Laminating,

6 5.1.1 A right-hand opening door shall be construed as one

Fire Retardant

that opens towards you with hinges located on right side of

MIL-P-24441 Epoxy-Polyamide Paint

door. A left-hand opening is similar but with hinges on the left.

5.1.2 The size of the door opening and shape shall be as

This specification is under the jurisdiction of ASTM Committee F25 on Ships given in Table 2.

and Marine Technology and is the direct responsibility of Subcommittee F25.03 on

5.1.3 Figs. 1 and 2 show the right-hand opening, and in the

Outfitting.

case of left-hand opening, the arrangement of fittings shall be

Current edition approved Aug. 28, 1987. Published October 1987.

reversed.

Annual Book of ASTM Standards, Vol 01.04.

Annual Book of ASTM Standards, Vol 02.02.

5.1.4 The position of the grab handles shall be located on

Annual Book of ASTM Standards, Vol 01.07.

the center of the height of both sides of the door; in the case of

Available from American Bureau of Shipping, ABS Plaza, 16855 Northchase

dutch doors, the location of the grab handles shall be suitably

Dr., Houston, TX 77060.

positioned in the top panel.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1070 – 87 (1999)

NOTE 1—1 in. = 25.4 mm.

FIG. 1 Non-Tight Doors (Square Corners)

FIG. 2 Non-Tight Doors (Radius Corners)

5.1.5 The material of the standard door components shall be 6. Workmanship, Finish, and Appearance

as shown

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.