ASTM F1069-87(2004)

(Specification)Standard Specification for Doors, Watertight, Gastight/Airtight and Weathertight, Individually Dogged, for Marine Use

Standard Specification for Doors, Watertight, Gastight/Airtight and Weathertight, Individually Dogged, for Marine Use

ABSTRACT

This specification covers the principal shapes and dimensions, and mechanical requirements for the manufacture of two types of individually dogged watertight, gastight/airtight, and weathertight doors of steel, aluminum, and glass-reinforced plastic construction. These doors, which shall be complete with frames, are built for access through bulkheads by marine personnel, and are intended to maintain the structural and tightness integrity of the bulkheads. The doors shall be classified into groups according to their area of application, as follow: Group A—watertight doors in the bridge front bulkhead and the unprotected bulkhead of deckhouses/superstructures, and deckhouses that enclose machinery openings; Group B—watertight doors in the deckhouse bulkheads partially protected or in the bulkhead of deckhouses/superstructures, and not around machinery openings, watertight and airtight doors below weather deck; Group C—airtight /gastight doors in the aft end bulkhead of the bridge, forecastle, and deckhouses at the weather deck level; and Group D—weathertight doors in the deckhouse above the weather deck level. All doors shall be certified for applicable tightness integrity prior to delivery.

SCOPE

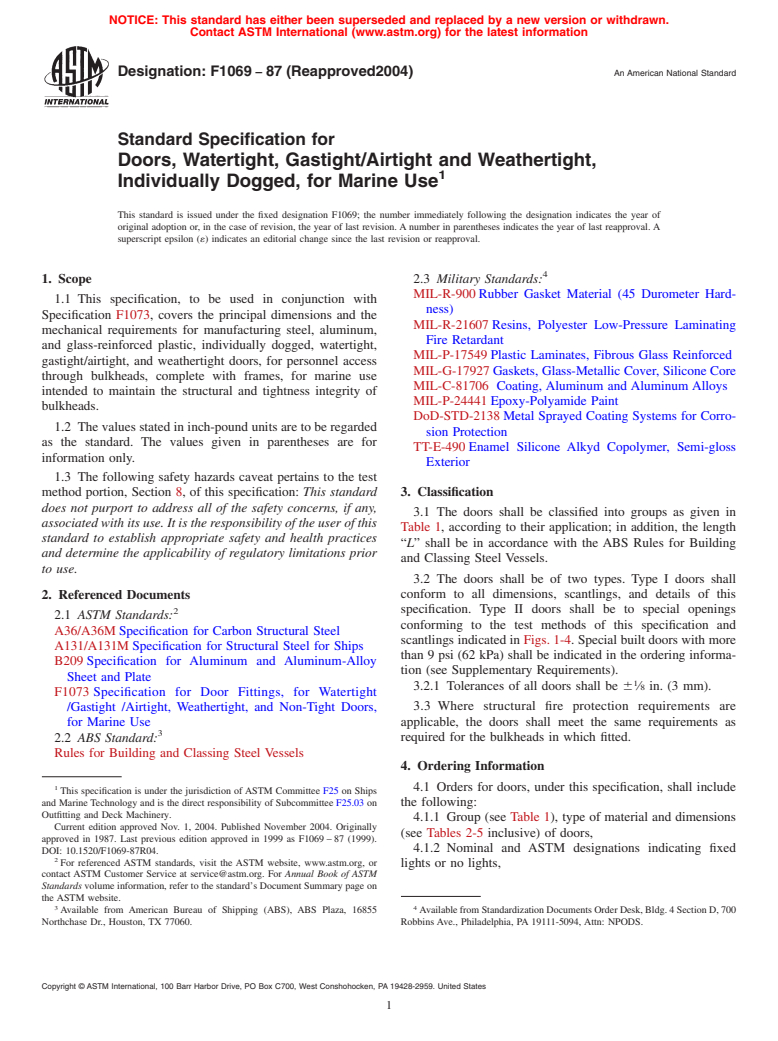

1.1 This specification, to be used in conjunction with Specification F1073, covers the principal dimensions and the mechanical requirements for manufacturing steel, aluminum, and glass-reinforced plastic, individually dogged, watertight, gastight/airtight and weathertight doors, for personnel access through bulkheads, complete with frames, for marine use intended to maintain the structural and tightness integrity of bulkheads.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1069 −87(Reapproved2004) An American National Standard

Standard Specification for

Doors, Watertight, Gastight/Airtight and Weathertight,

Individually Dogged, for Marine Use

This standard is issued under the fixed designation F1069; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 Military Standards:

MIL-R-900Rubber Gasket Material (45 Durometer Hard-

1.1 This specification, to be used in conjunction with

ness)

Specification F1073, covers the principal dimensions and the

MIL-R-21607Resins, Polyester Low-Pressure Laminating

mechanical requirements for manufacturing steel, aluminum,

Fire Retardant

and glass-reinforced plastic, individually dogged, watertight,

MIL-P-17549Plastic Laminates, Fibrous Glass Reinforced

gastight/airtight, and weathertight doors, for personnel access

MIL-G-17927Gaskets, Glass-Metallic Cover, Silicone Core

through bulkheads, complete with frames, for marine use

MIL-C-81706 Coating, Aluminum and Aluminum Alloys

intended to maintain the structural and tightness integrity of

MIL-P-24441Epoxy-Polyamide Paint

bulkheads.

DoD-STD-2138Metal Sprayed Coating Systems for Corro-

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

sion Protection

as the standard. The values given in parentheses are for

TT-E-490Enamel Silicone Alkyd Copolymer, Semi-gloss

information only.

Exterior

1.3 The following safety hazards caveat pertains to the test

method portion, Section 8, of this specification: This standard 3. Classification

does not purport to address all of the safety concerns, if any,

3.1 The doors shall be classified into groups as given in

associated with its use. It is the responsibility of the user of this

Table 1, according to their application; in addition, the length

standard to establish appropriate safety and health practices

“L” shall be in accordance with the ABS Rules for Building

and determine the applicability of regulatory limitations prior

and Classing Steel Vessels.

to use.

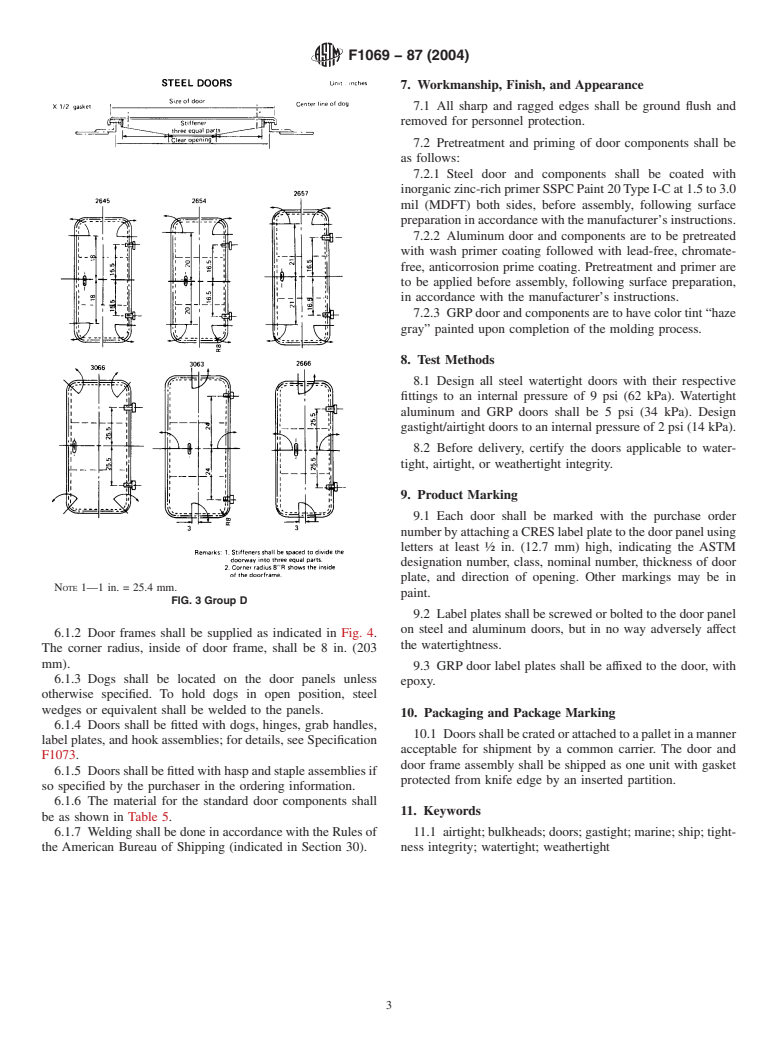

3.2 The doors shall be of two types. Type I doors shall

conform to all dimensions, scantlings, and details of this

2. Referenced Documents

2 specification. Type II doors shall be to special openings

2.1 ASTM Standards:

conforming to the test methods of this specification and

A36/A36MSpecification for Carbon Structural Steel

scantlings indicated in Figs. 1-4. Special built doors with more

A131/A131MSpecification for Structural Steel for Ships

than 9 psi (62 kPa) shall be indicated in the ordering informa-

B209Specification for Aluminum and Aluminum-Alloy

tion (see Supplementary Requirements).

Sheet and Plate

3.2.1 Tolerances of all doors shall be 6 ⁄8 in. (3 mm).

F1073 Specification for Door Fittings, for Watertight

/Gastight /Airtight, Weathertight, and Non-Tight Doors, 3.3 Where structural fire protection requirements are

applicable, the doors shall meet the same requirements as

for Marine Use

2.2 ABS Standard: required for the bulkheads in which fitted.

Rules for Building and Classing Steel Vessels

4. Ordering Information

1 4.1 Orders for doors, under this specification, shall include

This specification is under the jurisdiction ofASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.03 on

the following:

Outfitting and Deck Machinery.

4.1.1 Group (see Table 1), type of material and dimensions

Current edition approved Nov. 1, 2004. Published November 2004. Originally

(see Tables 2-5 inclusive) of doors,

approved in 1987. Last previous edition approved in 1999 as F1069–87 (1999).

4.1.2 Nominal and ASTM designations indicating fixed

DOI: 10.1520/F1069-87R04.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

lights or no lights,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available from American Bureau of Shipping (ABS), ABS Plaza, 16855 AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Northchase Dr., Houston, TX 77060. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1069−87(2004)

TABLE 1 Door Groups

Group Application

A

A (WT) Doors in the bridge front bulkhead and the unprotected bulkhead of

deckhouses/superstructures having the length of 0.4L or more

and deckhouses that enclose machinery openings.

A

B (WT) Doors in the deckhouse bulkheads partially protected or in the

bulkhead of deckhouses/superstructures having the length

below 0.4L and not around machinery openings, watertight and

airtight doors below weather deck.

B

C (AT/GT) Doors in the aft end bulkhead of the bridge, forecastle, and

deckhouses at the weather deck level.

C

D (WEAT) Doors in the deckhouse above the weather deck level.

A

WT—Indicates watertight.

B

AT/GT—Indicates airtight/gastight. (Airtight is Naval terminology and is iden-

tical to gastight doors in commercial vessels.)

C

WEAT—Indicates weathertight.

NOTE 1—1 in. = 25.4 mm.

FIG. 2Group C

4.2 Inspectionandacceptanceofdoorsshallbeagreedupon

between the purchaser and the supplier.

5. Materials and Manufacture

5.1 The materials and specifications shall be as shown in

Table 5.

5.2 Glass-reinforced plastic (GRP) material of doors and

frames shall meet the requirements of MIL-P-17549, Grade 1.

Inaddition,laminatemusthavetheflammabilitylimitsequalto

the requirements for Grade 2, Class A, of MIL-R-21607.

5.2.1 All GRP material that is drilled, cut, and sanded,

leavingthesurfaceexposed,shallbesealedwiththesameresin

as the exposed material.

NOTE 1—1 in. = 25.4 mm.

FIG. 1Group A and B

6. Construction, Shape, and Dimensions

6.1 The construction, shape, and clear opening dimensions

shall be as shown in Table 2, Table 3, Table 4, and Fig. 1, Fig.

4.1.3 Quantity of each hand of door (right hand/left hand), 2, and shall also conform to the following:

4.1.4 Test head to be indicated when Type II door is 6.1.1 A right-hand opening door shall be construed as one

required, and thatopenstowardyouwithhingeslocatedonrightsideofdoor.

4.1.5 Hasp and staple assemblies. A left-hand opening is similar but with hinges on the left.

F1069−87(2004)

7. Workmanship, Finish, and Appearance

7.1 All sharp and ragged edges shall be ground flus

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.