ASTM D7315-07

(Test Method)Standard Test Method for Determination of Turbidity Above 1 Turbidity Unit (TU) in Static Mode

Standard Test Method for Determination of Turbidity Above 1 Turbidity Unit (TU) in Static Mode

SCOPE

1.1 This test method covers the static determination of turbidity in water. Static refers to a sample that is removed from its source and tested in an isolated instrument. (See Section 4.)

1.2 This test method is applicable to the measurement of turbidities greater than 1.0 turbidity unit (TU). The upper end of the measurement range was left undefined because different technologies described in this test method can cover very different ranges. The round robin study covered the range of 0-4000 turbidity units because instrument verification in this range can typically be covered by standards that can be consistently reproduced.

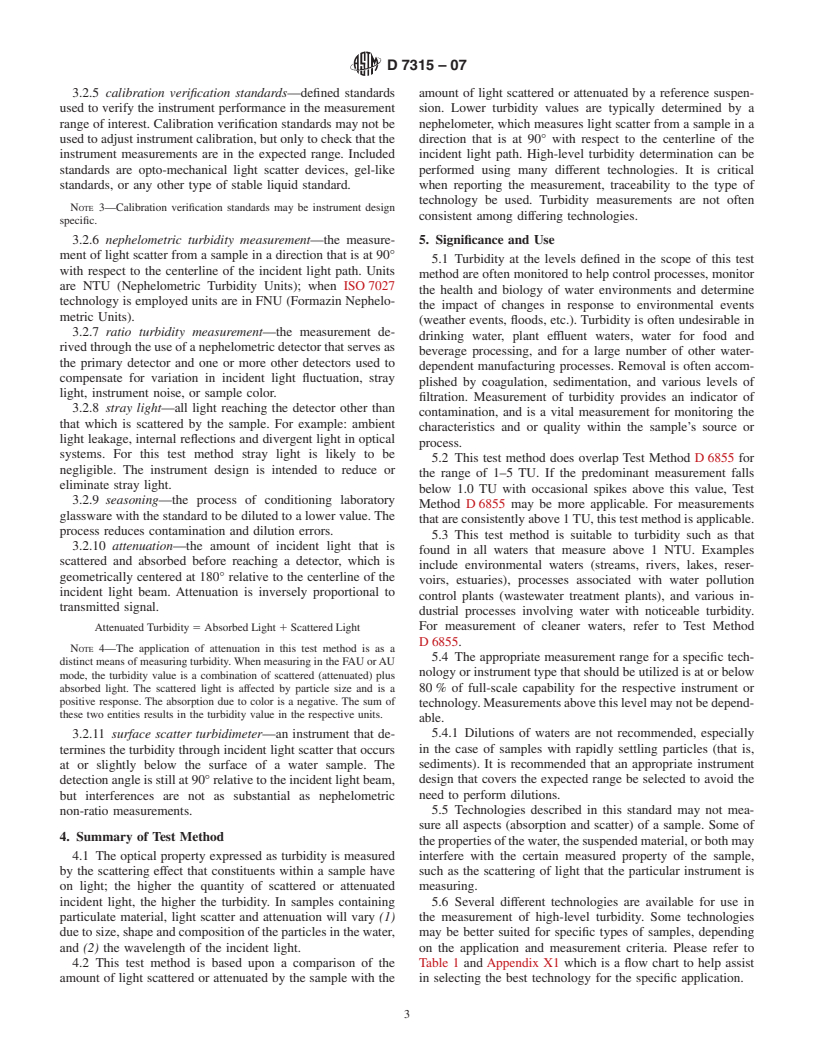

1.3 Many of the turbidity units and instrument designs covered in this test method are numerically equivalent in calibration when a common calibration standard is applied across those designs listed in Table 1. Measurement of a common calibration standard of a defined value will also produce equivalent results across these technologies.

1.3.1 In this test method calibration standards are often defined in NTU values, but the other assigned turbidity units, such as those in Table 1 are equivalent. For example, a 1 NTU formazin standard is also a 1 FNU, a 1 FAU, a 1 BU, and so forth.

1.4 This test method does not purport to cover all available technologies for high-level turbidity measurement.

1.5 This test method was tested on different natural waters and wastewater, and with standards that will serve as surrogates to samples. It is the user's responsibility to ensure the validity of this test method for waters of untested matrices.

1.6 Depending on the constituents within a high-level sample, the proposed sample preparation and measurement methods may or may not be applicable. Those samples with the highest particle densities typically prove to be the most difficult to measure. In these cases, and alternative measurement method such as the process monitoring method can be considered.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Refer to the MSDSs for all chemicals used in this procedure.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 7315 – 07

Standard Test Method for

Determination of Turbidity Above 1 Turbidity Unit (TU) in

Static Mode

This standard is issued under the fixed designation D 7315; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the static determination of

responsibility of the user of this standard to establish appro-

turbidity in water. Static refers to a sample that is removed

priate safety and health practices and determine the applica-

from its source and tested in an isolated instrument. (See

bility of regulatory limitations prior to use. Refer to the MSDSs

Section 4.)

for all chemicals used in this procedure.

1.2 This test method is applicable to the measurement of

turbidities greater than 1.0 turbidity unit (TU). The upper end

2. Referenced Documents

of the measurement range was left undefined because different

2.1 ASTM Standards:

technologies described in this test method can cover very

D 1129 Terminology Relating to Water

different ranges. The round robin study covered the range of

D 1193 Specification for Reagent Water

0–4000 turbidity units because instrument verification in this

D 1889 Test Method for Turbidity of Water

range can typically be covered by standards that can be

D 2777 Practice for Determination of Precision and Bias of

consistently reproduced.

Applicable Test Methods of Committee D19 on Water

1.3 Many of the turbidity units and instrument designs

D 4411 Guide for Sampling Fluvial Sediment in Motion

covered in this test method are numerically equivalent in

D 5847 Practice for Writing Quality Control Specifications

calibration when a common calibration standard is applied

for Standard Test Methods for Water Analysis

across those designs listed in Table 1. Measurement of a

D 6855 Test Method for Determination of Turbidity Below

common calibration standard of a defined value will also

5 NTU in Static Mode

produce equivalent results across these technologies.

E 691 Practice for Conducting an Interlaboratory Study to

1.3.1 In this test method calibration standards are often

Determine the Precision of a Test Method

defined in NTU values, but the other assigned turbidity units,

2.2 Other Referenced Standards:

such as those in Table 1 are equivalent. For example,a1NTU

USEPA Method 180.1 Methods for Chemical Analysis of

formazin standard is alsoa1FNU,a1FAU,a1BU,andso

Water and Wastes, Turbidity

forth.

ISO 7027 Water Quality—Determination of Turbidity

1.4 This test method does not purport to cover all available

United States Geological Survey (USGS) National Field

technologies for high-level turbidity measurement.

Manual for the Collection of Water Quality Data

1.5 This test method was tested on different natural waters

and wastewater, and with standards that will serve as surro-

3. Terminology

gates to samples. It is the user’s responsibility to ensure the

3.1 Definitions—For definitions of terms used in this test

validity of this test method for waters of untested matrices.

method refer to Terminology D 1129.

1.6 Depending on the constituents within a high-level

sample, the proposed sample preparation and measurement

methodsmayormaynotbeapplicable.Thosesampleswiththe

highestparticledensitiestypicallyprovetobethemostdifficult

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

to measure. In these cases, and alternative measurement contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

method such as the process monitoring method can be consid-

the ASTM website.

ered.

Available from United States Environmental Protection Association (EPA),

Ariel Rios Bldg., 1200 Pennsylvania Ave., NW, Washington, DC 20460, http://

www.epa.gov.

1 4

This test method is under the jurisdiction of ASTM Committee D19 on Water Available from International Organization for Standardization (ISO), 1 rue de

and is the direct responsibility of Subcommittee D19.07 on Sediments, Geomor- Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

phology, and Open-Channel Flow. AvailablefromUnitedStatedGeologicalSurvey(USGS),12201SunriseValley

Current edition approved April 15, 2007. Published May 2007. Drive, Reston, VA 20192, http://www.usgs.gov.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

D7315–07

TABLE 1 Summary of Known Instrument Designs, Applications, Ranges, and Reporting Units

Design and Typical Suggested

ProminentApplication Key Design Features

Reporting Unit Instrument Range Application Ranges

Nephelometric non-ratio White light turbidimeters. Comply Detector centered at 90° relative 0.0–40 0.0–40 Regulatory

(NTU) with USEPAMethod 180.1 for low to the incident light beam. Uses a

level turbidity monitoring. white light spectral source.

Ratio White Light Complies with ISWTR regulations Used a white light spectral 0–10000 0–40 Regulatory

turbidimeters (NTRU) and Standard Method 2130B. Can source. Primary detector centered 0–10000 other

be used for both low and high at 90°. Other detectors located at

level measurement. other angles.An instrument

algorithm uses a combination of

detector readings to generate the

turbidity reading.

Nephelometric, near-IR Complies with ISO7027. The Detector centered at 90° relative 0–1000 0–40 Regulatory (non-

turbidimeters, non-ratiometric wavelength is less susceptible to to the incident light beam. Uses a US)

(FNU) color interferences.Applicable for near-IR (780–900 nm) 0–1000 other

samples with color and good for monochromatic light source.

low level monitoring.

Nephelometric near-IR Complies with ISO7027. Uses a near-IR monochromatic 0–10000 0–40 Regulatory

turbidimeters, ratio metric Applicable for samples with high light source (780–900 nm). 0–10000 other

(FNRU) levels of color and for monitoring Primary detector centered at 90°.

to high turbidity levels. Other detectors located at other

angles.An instrument algorithm

uses a combination of detector

readings to generate the turbidity

reading.

Surface Scatter Turbidimeters Turbidity is determined through Detector centered at 90° relative 10–10000 10–10000

(NTU) light scatter from or near the to the incident light beam. Uses a

surface of a sample. white light spectral source.

Formazin Back Scatter (FBU) Not applicable for regulatory Uses a near-IR monochromatic 100–10000+ 100–10000

purposes. Best applied to high light source in the 780–900 nm

turbidity samples. Backscatter is range. Detector geometry is 30 6

common with but not all only 15° relative to the incident light

probe technology and is best beam.

applied in higher turbidity

samples.

Backscatter Unit (BU) Not applicable for regulatory Uses a white light spectral source 10–10000+ 100–10000+

purposes. Best applied for (400–680 nm range). Detector

samples with high level turbidity. geometry is 30 6 15° relative to

the incident light beam.

Formazin attenuation unit May be applicable for some Detector is geometrically centered 20–1000 20–1000 Regulatory

(FAU) regulatory purposes. This is at 180° relative to incident beam

commonly applied with (attenuation). Wavelength is

spectrophotometers. Best applied 780–900 nm.

for samples with high level

turbidity.

Light attenuation unit (AU) Not applicable for some regulatory Detector is geometrically centered 20–1000 20–1000

purposes. This is commonly at 180° relative to incident beam

applied with spectrophotometers. (attenuation). Wavelength is

400–680 nm.

Nephelometric Turbidity Is applicable to EPAregulatory Detectors are geometrically 0.02–4000 0–40 Regulatory

Multibeam Unit (NTMU) method GLI Method 2.Applicable centered at 90° and 180°.An 0–4000 other

to drinking water and wastewater instrument algorithm uses a

monitoring applications. combination of detector readings,

which may differ for turbidities

varying magnitude.

3.2 Definitions of Terms Specific to This Standard: 3.2.3 reference turbidity standard—a standard that is syn-

3.2.1 turbidity—an expression of the optical properties of a

thesized reproducibly from traceable raw materials by a skilled

sample that causes light rays to be scattered and absorbed analyst. All other standards are traced back to this standard.

rather than transmitted in straight lines through the sample.

The reference standard for turbidity is formazin (see 9.2.2).

Turbidity of water is caused by the presence of suspended and

3.2.4 calibration turbidity standard—a turbidity standard

dissolved matter such as clay, silt, finely divided organic

that is traceable and equivalent to the reference turbidity

matter, plankton, other microscopic organisms, organic acids,

standard to within defined accuracy, including commercially

and dyes.

prepared 4000 NTU Formazin, stabilized formazin (see 9.2.3),

3.2.2 turbidimeter—an instrument that measures light scat-

and styrenedivinylbenzene (SDVB) (see 9.2.4). These stan-

ter, attenuation, or both in a sample and quantitatively converts

dards may be used to calibrate the instrument.

the light scatter, the attenuation, or both to a displayed value.

Thelocationandtypeandnumberofdetectorsusedwilldictate

NOTE 1—Calibration standards may be instrument design specific.

the relative sensitivity for a typical technology. See Table 1 for

NOTE 2—Calibration standards that exceed 10 000 turbidity units are

examples of designs. commercially available.

D7315–07

3.2.5 calibration verification standards—defined standards amount of light scattered or attenuated by a reference suspen-

used to verify the instrument performance in the measurement sion. Lower turbidity values are typically determined by a

range of interest. Calibration verification standards may not be nephelometer, which measures light scatter from a sample in a

used to adjust instrument calibration, but only to check that the direction that is at 90° with respect to the centerline of the

instrument measurements are in the expected range. Included incident light path. High-level turbidity determination can be

standards are opto-mechanical light scatter devices, gel-like performed using many different technologies. It is critical

standards, or any other type of stable liquid standard. when reporting the measurement, traceability to the type of

technology be used. Turbidity measurements are not often

NOTE 3—Calibration verification standards may be instrument design

consistent among differing technologies.

specific.

5. Significance and Use

3.2.6 nephelometric turbidity measurement—the measure-

ment of light scatter from a sample in a direction that is at 90°

5.1 Turbidity at the levels defined in the scope of this test

with respect to the centerline of the incident light path. Units

method are often monitored to help control processes, monitor

are NTU (Nephelometric Turbidity Units); when ISO 7027

the health and biology of water environments and determine

technology is employed units are in FNU (Formazin Nephelo-

the impact of changes in response to environmental events

metric Units).

(weather events, floods, etc.). Turbidity is often undesirable in

3.2.7 ratio turbidity measurement—the measurement de-

drinking water, plant effluent waters, water for food and

rived through the use of a nephelometric detector that serves as

beverage processing, and for a large number of other water-

the primary detector and one or more other detectors used to

dependent manufacturing processes. Removal is often accom-

compensate for variation in incident light fluctuation, stray

plished by coagulation, sedimentation, and various levels of

light, instrument noise, or sample color.

filtration. Measurement of turbidity provides an indicator of

3.2.8 stray light—all light reaching the detector other than

contamination, and is a vital measurement for monitoring the

that which is scattered by the sample. For example: ambient

characteristics and or quality within the sample’s source or

light leakage, internal reflections and divergent light in optical

process.

systems. For this test method stray light is likely to be

5.2 This test method does overlap Test Method D 6855 for

negligible. The instrument design is intended to reduce or

the range of 1–5 TU. If the predominant measurement falls

eliminate stray light.

below 1.0 TU with occasional spikes above this value, Test

3.2.9 seasoning—the process of conditioning laboratory

Method D 6855 may be more applicable. For measurements

glassware with the standard to be diluted to a lower value. The

thatareconsistentlyabove1TU,thistestmethodisapplicable.

process reduces contamination and dilution errors.

5.3 This test method is suitable to turbidity such as that

3.2.10 attenuation—the amount of incident light that is

found in all waters that measure above 1 NTU. Examples

scattered and absorbed before reaching a detector, which is

include environmental waters (streams, rivers, lakes, reser-

geometrically centered at 180° relative to the centerline of the

voirs, estuaries), processes associated with water pollution

incident light beam. Attenuation is inversely proportional to

control plants (wastewater treatment plants), and various in-

transmitted signal.

dustrial processes involving water with noticeable turbidity.

Attenuated Turbidity 5 Absorbed Light 1 Scattered Light For measurement of cleaner waters, refer to Test Method

D 6855.

NOTE 4—The application of attenuation in this test method is as a

5.4 The appropriate measurement range for a specific tech-

distinct means of measuring turbidity.When measuring in the FAU orAU

nology or instrument type that should be utilized is at or below

mode, the turbidity value is a combination of scattered (attenuated) plus

absorbed light. The scattered light is affected by particle size and is a 80 % of full-scale capability for the respective instrument or

positive response. The absorption due to color is a negative. The sum of

technology.Measurementsabovethislevelmaynotbedepend-

these two entities results in the turbidity value in the respective units.

able.

3.2.11 surface scatter turbidimeter—an instrument that de- 5.4.1 Dilutions of waters are not recommended, especially

in the case of samples with rapidly settling particles (that is,

termines the turbidity through incident light scatter that occurs

at or slightly below the surface of a water sample. The sediments). It is recommended that an appropriate in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.