ASTM E1962-04

(Test Method)Standard Test Method for Ultrasonic Surface Examinations Using Electromagnetic Acoustic Transducer (EMAT) Techniques

Standard Test Method for Ultrasonic Surface Examinations Using Electromagnetic Acoustic Transducer (EMAT) Techniques

SIGNIFICANCE AND USE

EMAT techniques show benefits and advantages over conventional piezoelectric ultrasonic techniques in special applications where flexibility in the type of wave mode generation is desired. EMATs are highly efficient in the generation of surface waves.

Since EMATs are highly efficient in the generation of surface waves, and since acoustic techniques utilizing surface waves are proven effective for detecting surface and near-surface discontinuities, they should be considered for any applications where conventional penetrant testing and magnetic particle NDT techniques are effective but undesirable.

Since EMAT techniques are non-contacting, they should be considered for ultrasonic examinations where applications involve automation, high-speed inspections, moving objects, applications in remote or hazardous locations, applications to objects at elevated temperatures, or objects with rough surfaces.

The purpose of this test method is to promote the EMAT technique of the ultrasonic method as a viable alternative to conventional PT and MPT methods for detecting the presence of surface and near-surface material discontinuities.

The use of EMATs and the selection of appropriate operating parameters presuppose a knowledge of the geometry of the component; the probable location, size, orientation, and reflectivity of the expected flaws; the allowable range of EMAT lift-off; and the laws of physics governing the propagation of ultrasonic waves. This procedure pertains to a specific EMAT surface inspection application.

SCOPE

1.1 This test method covers guidelines for utilizing EMAT techniques for detecting material discontinuities that are primarily open to the surface (for example, cracks, seams, laps, cold shuts, laminations, through leaks, lack of fusion). This technique can be sensitive to flaws and discontinuities that are not surface-breaking, provided their proximity to the surface is less than or equal to the Rayleigh wave length.

1.2 This test method covers procedures for the non-contact coupling of surface waves into a material via electromagnetic fields.

1.3 The procedures of this test method are applicable to any material in which acoustic waves can be introduced electromagnetically. This includes any material that is either electrically conductive or ferromagnetic, or both.

1.4 This test method is intended to provide examination capabilities for in-process, final, and maintenance applications.

1.5 This test method does not provide standards for the evaluation of derived indications. Interpretation, classification, and ultimate evaluation of indications, albeit necessary, are beyond the scope of this document. Separate specifications or agreement will be necessary to define the type, size, location, and direction of indications considered acceptable or non-acceptable.

1.6 The values stated in inch-pound units are to be regarded as the standards. The SI units given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1962 – 04

Standard Test Method for

Ultrasonic Surface Examinations Using Electromagnetic

1

Acoustic Transducer (EMAT) Techniques

This standard is issued under the fixed designation E 1962; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method covers guidelines for utilizing EMAT 2.1 ASTM Standards:

techniques for detecting material discontinuities that are pri- E 543 Practice for Agencies Performing Nondestructive

marily open to the surface (for example, cracks, seams, laps, Testing

cold shuts, laminations, through leaks, lack of fusion). This E 587 Practice for Ultrasonic Angle-Beam Examination by

technique can also be sensitive to flaws and discontinuities that the Contact Method

are not surface-breaking, provided their proximity to the E 1316 Terminology for Nondestructive Examinations

surface is less than or equal to the Rayleigh wave length. E 1774 Guide to Electromagnetic Acoustic Transducers

1.2 This test method covers procedures for the non-contact (EMATs)

coupling of surface waves into a material via electromagnetic E 1816 PracticeforUltrasonicExaminationsUsingElectro-

fields. magnetic Acoustic Transducer (EMAT) Techniques

1.3 The procedures of this test method are applicable to any 2.2 ANSI/ASNT Standards:

material in which acoustic waves can be introduced electro- Recommended Practice SNT-TC-1A Personnel Qualifica-

3

magnetically. This includes any material that is either electri- tion and Certification in Nondestructive Testing

cally conductive or ferromagnetic, or both. ANSI/ASNT CP-189 Standard for Qualification and Certi-

3

1.4 This test method is intended to provide examination fication of Nondestructive Testing Personnel

capabilities for in-process, final, and maintenance applications. 2.3 Military Standard:

1.5 This test method does not provide standards for the MIL-STD-410 Nondestructive Testing Personnel Qualifica-

4

evaluation of derived indications. Interpretation, classification, tion and Certification

and ultimate evaluation of indications, albeit necessary, are

3. Terminology

beyondthescopeofthistestmethod.Separatespecificationsor

3.1 Definitions:

agreement will be necessary to define the type, size, location,

and direction of indications considered acceptable or non- 3.1.1 Additional related terminology is defined inTerminol-

ogy E 1316.

acceptable.

1.6 The values stated in inch-pound units are to be regarded 3.2 Definitions of Terms Specific to This Standard:

3.2.1 electromagnetic acoustic transducer (EMAT)—an

as the standards. The SI units given in parentheses are for

information only. electromagnetic device for converting electrical energy into

acoustical energy in the presence of a magnetic field.

1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.2.2 Lorentz forces—applied to electric currents when

placed in a magnetic field. Lorentz forces are perpendicular to

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- both the direction of the magnetic field and the current

direction. Lorentz forces are the forces responsible behind the

bility of regulatory limitations prior to use.

principle of electric motors.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This test method is under the jurisdiction of ASTM Committee E07 on the ASTM website.

3

Nondestructive Testing and is the direct responsibility of Subcommittee E07.06 on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Ultrasonic Method. 4th Floor, New York, NY 10036.

4

Current edition approved May 1, 2004. Published May 2004. Originally AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

approved in 1998. Last previous edition approved in 1998 as E 1962 - 98. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1962–04

3.2.3 magnetostrictive forces—forcesarisingfrommagnetic

domain wall movements within a magnetic material during

magnetization.

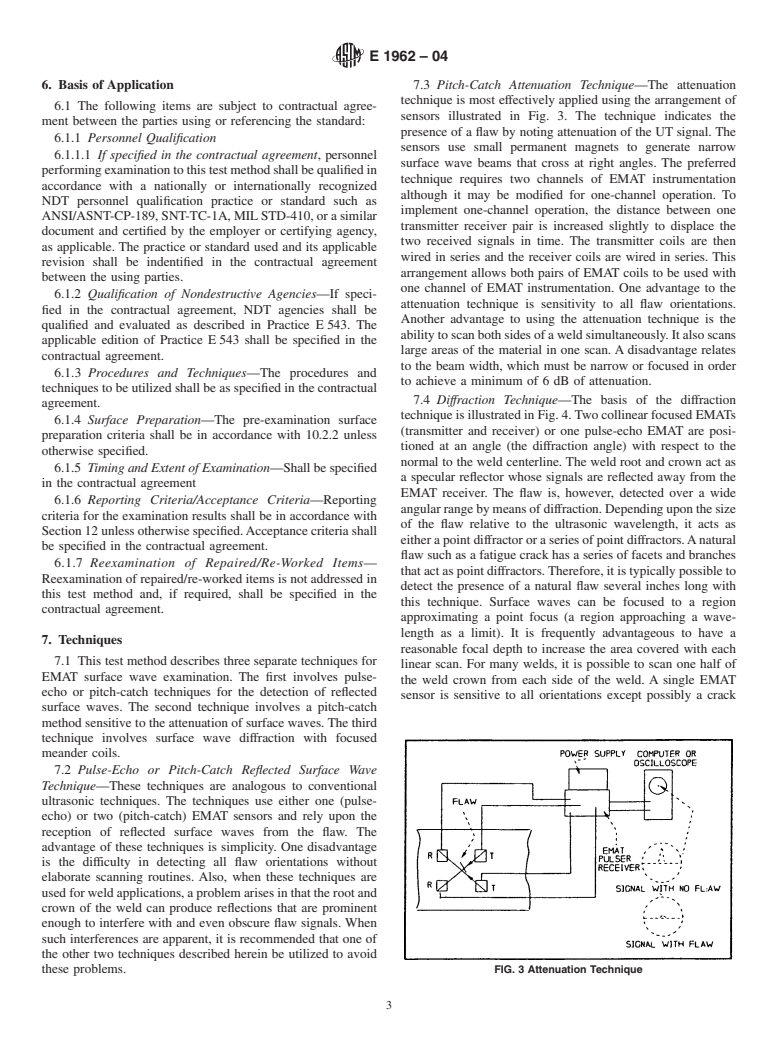

3.2.4 meander coil—an EMAT coil consisting of periodic,

winding, non-intersecting, and usually evenly-spaced conduc-

FIG. 2 Typical EMAT Meander Coil for Generation of Surface

tors.

Waves

4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.