ASTM E1962-98

(Test Method)Standard Test Method for Ultrasonic Surface Examinations Using Electromagnetic Acoustic Transducer (EMAT) Techniques

Standard Test Method for Ultrasonic Surface Examinations Using Electromagnetic Acoustic Transducer (EMAT) Techniques

SCOPE

1.1 This test method covers guidelines for utilizing EMAT techniques for detecting material discontinuities that are primarily open to the surface (for example, cracks, seams, laps, cold shuts, laminations, through leaks, lack of fusion). This technique can be sensitive to flaws and discontinuities that are not surface-breaking, provided their proximity to the surface is less than or equal to the Rayleigh wave length.

1.2 This test method covers procedures for the non-contact coupling of surface waves into a material via electromagnetic fields.

1.3 The procedures of this test method are applicable to any material in which acoustic waves can be introduced electromagnetically. This includes any material that is either electrically conductive or ferromagnetic, or both.

1.4 This test method is intended to provide examination capabilities for in-process, final, and maintenance applications.

1.5 This test method does not provide standards for the evaluation of derived indications. Interpretation, classification, and ultimate evaluation of indications, albeit necessary, are beyond the scope of this document. Separate specifications or agreement will be necessary to define the type, size, location, and direction of indications considered acceptable or non-acceptable.

1.6 The values stated in inch-pound units are to be regarded as the standards. The SI units given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1962 – 98

Standard Test Method for

Ultrasonic Surface Examinations Using Electromagnetic

Acoustic Transducer (EMAT) Techniques

This standard is issued under the fixed designation E 1962; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 587 Practice for Ultrasonic Angle-Beam Examination by

the Contact Method

1.1 This test method covers guidelines for utilizing EMAT

E 1316 Terminology for Nondestructive Examinations

techniques for detecting material discontinuities that are pri-

E 1774 Guide to Electromagnetic Acoustic Transducers

marily open to the surface (for example, cracks, seams, laps,

(EMATs)

cold shuts, laminations, through leaks, lack of fusion). This

E 1816 Practice for Ultrasonic Examinations Using Electro-

technique can also be sensitive to flaws and discontinuities that

magnetic Acoustic Transducer (EMAT) Techniques

are not surface-breaking, provided their proximity to the

2.2 ANSI/ASNT Standards:

surface is less than or equal to the Rayleigh wave length.

Recommended Practice SNT-TC-1A Personnel Qualifica-

1.2 This test method covers procedures for the non-contact

tion and Certification in Nondestructive Testing

coupling of surface waves into a material via electromagnetic

ANSI/ASNT CP-189 Standard for Qualification and Certi-

fields.

fication of Nondestructive Testing Personnel

1.3 The procedures of this test method are applicable to any

2.3 Military Standard:

material in which acoustic waves can be introduced electro-

MIL-STD-410 Nondestructive Testing Personnel Qualifica-

magnetically. This includes any material that is either electri-

tion and Certification

cally conductive or ferromagnetic, or both.

1.4 This test method is intended to provide examination

3. Terminology

capabilities for in-process, final, and maintenance applications.

3.1 Definitions:

1.5 This test method does not provide standards for the

3.1.1 Additional related terminology is defined in Terminol-

evaluation of derived indications. Interpretation, classification,

ogy E 1316.

and ultimate evaluation of indications, albeit necessary, are

3.2 Definitions of Terms Specific to This Standard:

beyond the scope of this document. Separate specifications or

3.2.1 electromagnetic acoustic transducer (EMAT)—an

agreement will be necessary to define the type, size, location,

electromagnetic device for converting electrical energy into

and direction of indications considered acceptable or non-

acoustical energy in the presence of a magnetic field.

acceptable.

3.2.2 Lorentz forces—applied to electric currents when

1.6 The values stated in inch-pound units are to be regarded

placed in a magnetic field. Lorentz forces are perpendicular to

as the standards. The SI units given in parentheses are for

both the direction of the magnetic field and the current

information only.

direction. Lorentz forces are the forces responsible behind the

1.7 This standard does not purport to address all of the

principle of electric motors.

safety concerns, if any, associated with its use. It is the

3.2.3 magnetostrictive forces—forces arising from magnetic

responsibility of the user of this standard to establish appro-

domain wall movements within a magnetic material during

priate safety and health practices and determine the applica-

magnetization.

bility of regulatory limitations prior to use.

3.2.4 meander coil—an EMAT coil consisting of periodic,

2. Referenced Documents winding, non-intersecting, and usually evenly-spaced conduc-

tors.

2.1 ASTM Standards:

Annual Book of ASTM Standards, Vol 03.03.

1 3

This test method is under the jurisdiction of ASTM Committee E-7 on Available from American National Standards Institute, 11 W. 42nd St. 13th

Nondestructive Testing and is the direct responsibility of Subcommittee E07.06 on Floor, New York, NY 10036.

Ultrasonic Method. Available from the Superintendent of Documents, U.S. Government Printing

Current edition approved July 10, 1998. Published December 1998. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1962

4. Summary of Test Method

4.1 The techniques outlined in this test method address the

electromagnetic generation of Rayleigh acoustic wave modes

for sensitivity to surface or near-surface flaws or discontinui-

ties. Flaws are detected by reflection or attenuation of acoustic

FIG. 2 Typical EMAT Meander Coil for Generation of Surface

waves from interactions at discontinuity interfaces. Waves

4.2 Fig. 1 shows one typical EMAT setup for the generation

5. Significance and Use

of Rayleigh waves. An external magnetic induction Bo parallel

to the surface is applicable on ferromagnetic material. The

5.1 EMAT techniques show benefits and advantages over

magnetic field may be generated by a permanent magnet, a conventional piezoelectric ultrasonic techniques in special

pulsed magnet, or a DC electromagnet. A meander RF coil is applications where flexibility in the type of wave mode

generation is desired. EMATs are highly efficient in the

oriented in the plane of and near the surface of the object to be

generation of surface waves.

tested. The magnetic field lines are tangential to the coil and

5.2 Since EMATs are highly efficient in the generation of

perpendicular to the conductor. The coil is excited by an RF

surface waves, and since acoustic techniques utilizing surface

toneburst pulse produced by a specialized EMAT pulser. A

waves are proven effective for detecting surface and near-

surface current is induced in the test sample by transformer

surface discontinuities, they should be considered for any

action. The surface current interacts with the external magnetic

applications where conventional penetrant testing and mag-

field by means of the Lorentz force. This disturbance is

netic particle NDT techniques are effective but undesirable.

transferred to the lattice of the solid and is thus the ultrasonic

5.3 Since EMAT techniques are non-contacting, they should

source responsible for producing the surface acoustic waves.

be considered for ultrasonic examinations where applications

As shown in Fig. 1, an ordinary meander coil produces

involve automation, high-speed inspections, moving objects,

bidirectional waves. In practice, specially designed meander

applications in remote or hazardous locations, applications to

coils can be designed to produce unidirectional waves.

objects at elevated temperatures, or objects with rough sur-

4.3 Fig. 2 illustrates a typical meander coil for generation of

faces.

surface waves. The following relationship must be valid for

5.4 The purpose of this test method is to promote the EMAT

Rayleigh wave generation with a meander coil:

technique of the ultrasonic method as a viable alternative to

V 5 2Df (1) conventional PT and MPT methods for detecting the presence

R

of surface and near-surface material discontinuities.

where:

5.5 The use of EMATs and the selection of appropriate

V 5 Rayleigh wave velocity,

R

operating parameters presuppose a knowledge of the geometry

D 5 separation of adjacent conductors, and

of the component; the probable location, size, orientation, and

f 5 frequency.

reflectivity of the expected flaws; the allowable range of EMAT

4.4 Surface flaws or discontinuities lead to reflection or

lift-off; and the laws of physics governing the propagation of

attenuation of the surface waves. Either pulse-echo or pitch-

ultrasonic waves. This procedure pertains to a specific EMAT

catch modes can be used. Upon approaching the receiver

surface inspection application.

EMAT, the reflected or attenuated ultrasonic waves produce

6. Basis of Application

oscillations within the conductor in the presence of the

magnetic field and thus induce a voltage in the receiver coil 6.1 Personnel Qualification—NDT Personnel should be

(similar to an electric generator) allowing detection. qualified in accordance with a nationally recognized NDT

FIG. 1 Typical EMAT Configuration for Rayleigh Wave Generation

E 1962

personnel qualification practice or standard such as ANSI/

ASNT-CP-189, SNT-TC-1A, MIL STD-410, or a similar docu-

ment. The practice or standard used and its applicable revision

shall be specified in the contractual agreement between the

using parties.

6.2 Procedures and Techniques—The procedures and tech-

niques to be utilized shall be as described in this document

unless otherwise specified. Specific techniques may be speci-

fied in the contractual agreement.

6.3 Reporting Criteria/Acceptance Criteria—Reporting cri-

teria for the examination results shall be in accordance with

Section 12 unless otherwise specified. Acceptance criteria shall

be specified in the contractual agreement.

6.4 Reexamination of Repaired/Re-Worked Items—

Reexamination of repaired/re-worked items is not addressed in

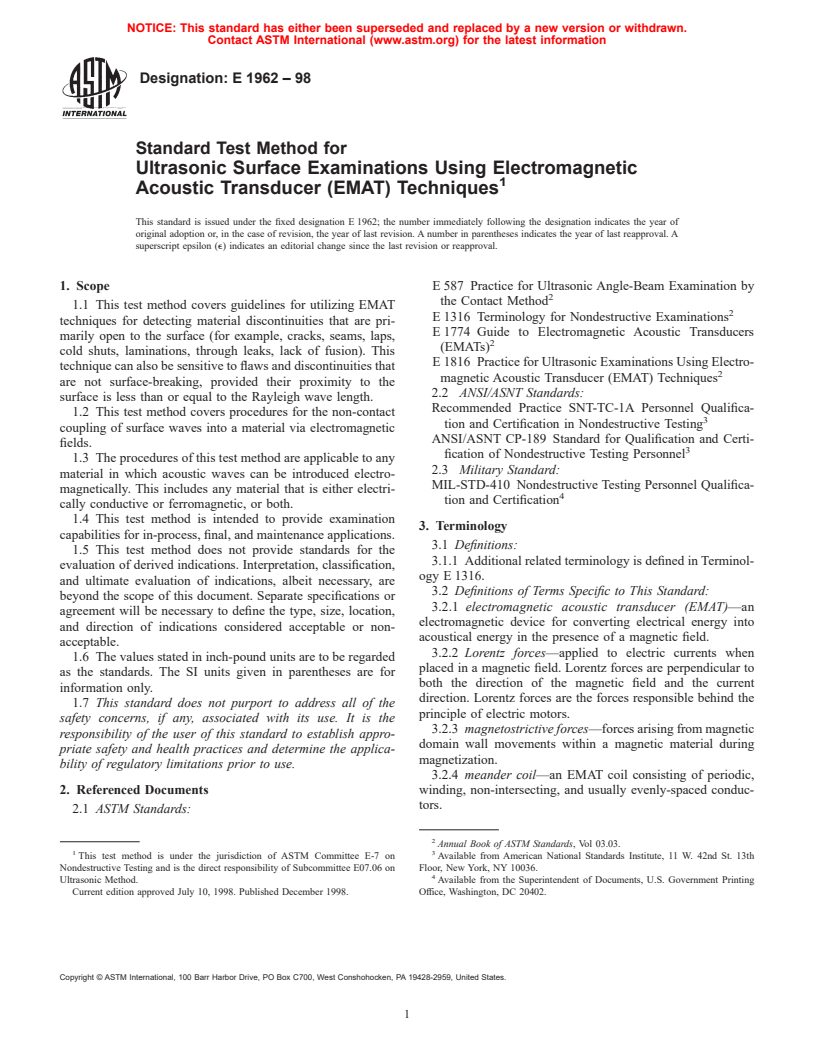

FIG. 3 Attenuation Technique

this test method and, if required, shall be specified in the

contractual agreement.

to the beam width, which must be narrow or focused in order

to achieve a minimum of 6 dB of attenuation.

7. Techniques

7.4 Diffraction Technique—The basis of the diffraction

7.1 This test method describes three separate techniques for

technique is illustrated in Fig. 4. Two collinear focused EMATs

EMAT surface wave examination. The first involves pulse-

(transmitter and receiver) or one pulse-echo EMAT are posi-

echo or pitch-catch techniques for the detection of reflected

tioned at an angle (the diffraction angle) with respect to the

surface waves. The second technique involves a pitch-catch

normal to the weld centerline. The weld root and crown act as

method sensitive to the attenuation of surface waves. The third

a specular reflector whose signals are reflected away from the

technique involves surface wave diffraction with focused

EMAT receiver. The flaw is, however, detected over a wide

meander coils.

angular range by means of diffraction. Depending upon the size

7.2 Pulse-Echo or Pitch-Catch Reflected Surface Wave

of the flaw relative to the ultrasonic wavelength, it acts as

Technique—These techniques are analogous to conventional

either a point diffractor or a series of point diffractors. A natural

ultrasonic techniques. The techniques use either one (pulse-

flaw such as a fatigue crack has a series of facets and branches

echo) or two (pitch-catch)EMAT sensors and rely upon the

that act as point diffractors. Therefore, it is typically possible to

reception of reflected surface waves from the flaw. The

detect the presence of a natural flaw several inches long with

advantage of these techniques is simplicity. One disadvantage

this technique. Surface waves can be focused to a region

is the difficulty in detecting all flaw orientations without

approximating a point focus (a region approaching a wave-

elaborate scanning routines. Also, when these techniques are

length as a limit). It is frequently advantageous to have a

used for weld applications, a problem arises in that the root and

reasonable focal depth to increase the area covered with each

crown of the weld can produce reflections that are prominent

linear scan. For many welds, it is possible to scan one half of

enough to interfere with and even obscure flaw signals. When

the weld crown from each side of the weld. A single EMAT

such interferences are apparent, it is recommended that one of

sensor is sensitive to all orientations except possibly a crack

the other two techniques described herein be utilized to avoid

parallel to the incident beam. Therefore, two sensors with

these problems.

positive and negative diffraction angles will be sensitive to all

7.3 Pitch-Catch Attenuation Technique—The attenuation flaw orientations.

technique is most effectively applied using the arrangement of

8. Apparatus

sensors illustrated in Fig. 3. The technique indicates the

presence of a flaw by noting attenuation of the UT signal. The 8.1 The apparatus may be considered to consist of the

sensors use small permanent magnets to generate narrow EMAT sensor and the EMAT instrumentation. The sensor

surface wave beams that cross at right angles. The preferred consists of an RF coil and a source of magnetic field. The

technique requires two channels of EMAT instrumentation instrumentation consists of a tone burst pulser/receiver, a data

although it may be modified for one-channel operation. To acquisition system or display device such as an oscilloscope,

implement one-channel operation, the distance between one an impedance matching network, a preamplifier (preferred),

transmitter receiver pair is increased slightly to displace the and a well shielded cable from the pulser/receiver to the sensor.

two received signals in time. The transmitter coils are then 8.2 Coil Design:

wired in series and the receiver coils are wired in series. This 8.2.1 A meander coil is used to produce surface waves. Coil

arrangement allows both pairs of EMAT coils to be used with design and conductor spacing required to produce a given

one channel of EMAT instrumentation. One advantage to the frequency has been discussed in 4.3. The coil may be focused

attenuation technique is sensitivity to all flaw orientations. or nonfocused depending upon the technique being used and

Another advantage to using the attenuation technique is the the desired resolution and sensitivity. Fig. 5 gives an example

ability to scan both sides of a weld simultaneously. It also scans of typical design parameters for a focused coil, similar to that

large areas of the material in one scan. A disadvantage relates used for the diffraction technique. Many EMAT coils are

E 1962

FIG. 4 The Diffraction Technique

FIG. 5 Design Parameters for Typical Focused EMAT Coil

flexible printed circuits produced by photoetching on a polya- The purpose of the wearplate is to maintain a constant liftoff

mide substrate. The surface of the coil can be backed with a for the EMAT coil. The wearplate should be pliable and

thin layer of foam and covered with a thin (0.001 to 0.005 in.) conform to irregular or curved surfaces. The polyamide sub-

wearplate of high molecular weight polyethylene or titanium. strate usually has a thickness of 0.001 or 0.002 in. For “as

E 1962

welded” crowns, the selected frequency for any of the tech- than those reference reflectors exemplifying the necessary

niques should be no greater than necessary in order to sensitivity. Flaw dimensions of length, depth, and width, must

minimize the respon

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.