ASTM F1959/F1959M-06ae1

(Test Method)Standard Test Method for Determining the Arc Rating of Materials for Clothing

Standard Test Method for Determining the Arc Rating of Materials for Clothing

SIGNIFICANCE AND USE

This test method is intended for the determination of the arc rating of a material, or a combination of materials.

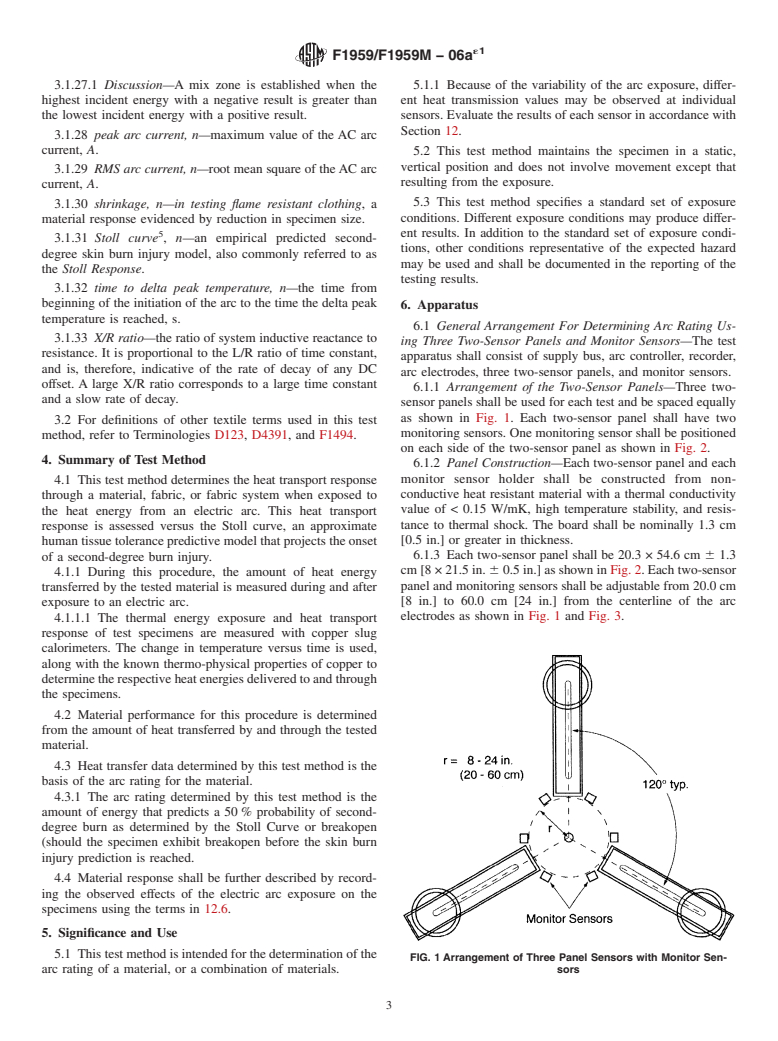

5.1.1 Because of the variability of the arc exposure, different heat transmission values may be observed at individual sensors. Evaluate the results of each sensor in accordance with Section 12.

This test method maintains the specimen in a static, vertical position and does not involve movement except that resulting from the exposure.

This test method specifies a standard set of exposure conditions. Different exposure conditions may produce different results. In addition to the standard set of exposure conditions, other conditions representative of the expected hazard may be used and shall be documented in the reporting of the testing results.

SCOPE

1.1 This test method is used to measure the arc rating of materials intended for use as flame resistant clothing for workers exposed to electric arcs that would generate heat flux rates from 84 to 25 120 kW/m 2 [2 to 600 cal/cm2s].

1.2 This test method will measure the arc rating of materials which meet the following requirements: less than 150 mm [6 in.] char length and less than 2 s after flame when tested in accordance with Test Method D 6413.

1.2.1 It is not the intent of this test method to evaluate non flame-resistant materials except where used as under layers in multiple-layer specimens.

1.3 The materials used in this test method are in the form of flat specimens.

1.4 This test method shall be used to measure and describe the properties of materials, products, or assemblies in response to convective and radiant energy generated by an electric arc under controlled laboratory conditions.

1.5 The values stated in SI units shall be regarded as standard except as noted. Within the text, alternate units are shown in brackets. The values stated in each system may not be exact equivalents therefore alternate systems must be used independently of the other. Combining values from the systems described in the text may result in nonconformance with the method.

1.6 This test method does not apply to electrical contact or electrical shock hazards.

1.7 This standard shall not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.1.8

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use. For specific precautions, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F1959/F1959M − 06a

StandardTest Method for

1

Determining the Arc Rating of Materials for Clothing

ThisstandardisissuedunderthefixeddesignationF1959/F1959M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Reference to a research report was added to 14.1 in April 2007.

1. Scope 1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method is used to measure the arc rating of

responsibility of the user of this standard to establish appro-

materials intended for use as flame resistant clothing for

priate safety and health practices and determine the applica-

workers exposed to electric arcs that would generate heat flux

2 2 bility of regulatory requirements prior to use. For specific

rates from 84 to 25 120 kW/m [2 to 600 cal/cm s].

precautions, see Section 7.

1.2 Thistestmethodwillmeasurethearcratingofmaterials

which meet the following requirements: less than 150 mm [6

2. Referenced Documents

in.] char length and less than 2 s afterflame when tested in

2

2.1 ASTM Standards:

accordance with Test Method D6413.

D123Terminology Relating to Textiles

1.2.1 It is not the intent of this test method to evaluate non

D1776Practice for Conditioning and Testing Textiles

flame-resistant materials except where used as under layers in

D4391Terminology Relating to The Burning Behavior of

multiple-layer specimens.

Textiles

1.3 Thematerialsusedinthistestmethodareintheformof

D6413Test Method for Flame Resistance of Textiles (Ver-

flat specimens.

tical Test)

E457Test Method for Measuring Heat-Transfer Rate Using

1.4 This test method shall be used to measure and describe

a Thermal Capacitance (Slug) Calorimeter

thepropertiesofmaterials,products,orassembliesinresponse

F1494Terminology Relating to Protective Clothing

to convective and radiant energy generated by an electric arc

3

2.2 ANSI/IEEE Standard:

under controlled laboratory conditions.

Standard Dictionary of Electrical and Electronics Terms

1.5 The values stated in SI units shall be regarded as

4

2.3 AATCC Standard:

standard except as noted. Within the text, alternate units are

AATCC Method 135-2001Dimensional Changes in Auto-

showninbrackets.Thevaluesstatedineachsystemmaynotbe

matic Home Laundering of Woven and Knit Fabrics

exact equivalents therefore alternate systems must be used

independentlyoftheother.Combiningvaluesfromthesystems

3. Terminology

described in the text may result in nonconformance with the

3.1 Definitions:

method.

3.1.1 ablation, n—in electrical arc testing, a physical re-

1.6 This test method does not apply to electrical contact or

sponseevidencedbysignificanterosionortheformationofone

electrical shock hazards.

or more large holes in a layer of a multilayer system.

1.7 This standard shall not be used to describe or appraise 3.1.1.1 Discussion—Anylayerinaspecimen(otherthanthe

the fire hazard or fire risk of materials, products, or assemblies

innermost layer) is considered to exhibit ablation when the

2 2

under actual fire conditions. However, results of this test may materialremovaloranyholeisatleast16cm [2.5in. ]inarea

be used as elements of a fire assessment which takes into

or at least 8 cm [3.1 in.] in length in any dimension. Single

account all of the factors which are pertinent to an assessment threadsacrosstheopeningorholedonotreducethesizeofthe

of the fire hazard of a particular end use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This test method is under the jurisdiction of ASTM Committee F18 on Standards volume information, refer to the standard’s Document Summary page on

Electrical Protective Equipment for Workers and is the direct responsibility of the ASTM website.

3

Subcommittee F18.65 on Wearing Apparel. Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

Current edition approved Nov. 15, 2006. Published January 2007. Originally 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331.

4

approved in 1997. Last previous edition approved in 2006 as F1959/F1959M–06. Technical Manual of the American Association of Textile Chemists and

DOI: 10.1520/F1959_F1959M-06AE01. Colorists.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

F1959/F1959M − 06a

hole for the purposes of this test method. Ablation in one or 3.1.12 breakopen threshold energy (E ),n—the incident

BT

more layers of material in a mulitlayer sy

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.