ASTM D5713-05

(Test Method)Standard Test Method for Analysis of High Purity Benzene for Cyclohexane Feedstock by Capillary Gas Chromatography

Standard Test Method for Analysis of High Purity Benzene for Cyclohexane Feedstock by Capillary Gas Chromatography

SIGNIFICANCE AND USE

This test method is designed to obtain benzene purity on the basis of impurities normally present in benzene and may be used for final product inspections and process control.

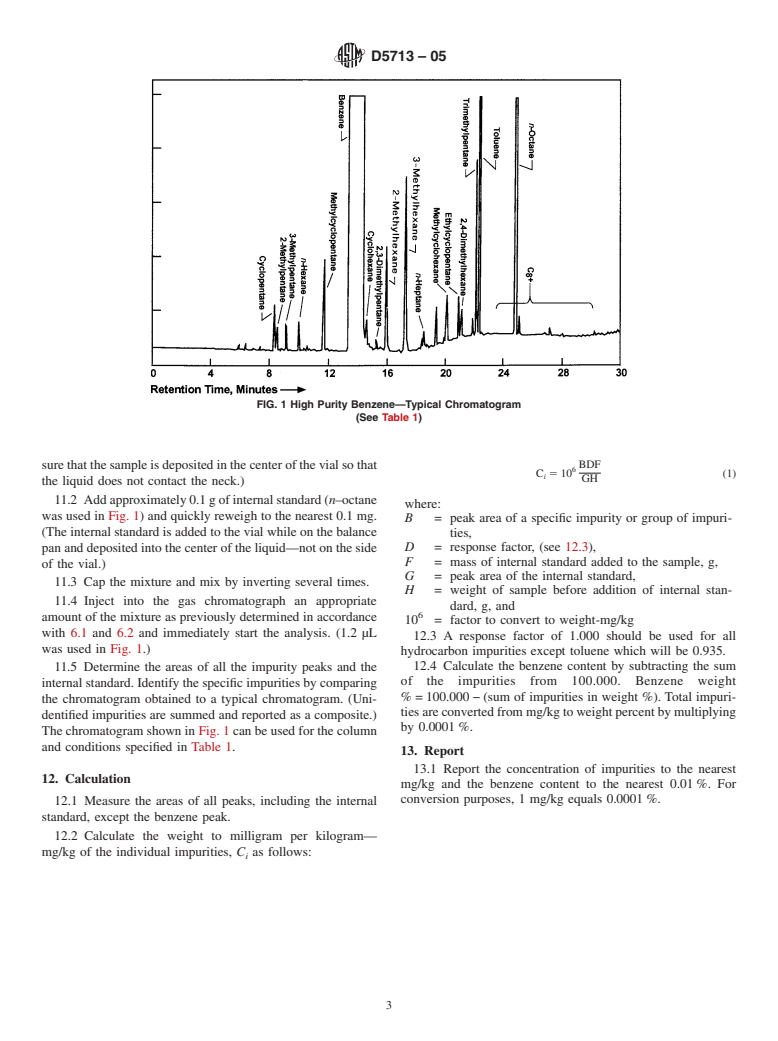

This test method will detect the following impurities: toluene, methylcyclopentane, n-hexane, 2-methylhexane, cyclohexane, cyclopentane, 2-methylpentane, 2,3-dimethylpentane, 3-methylhexane, n-heptane, methylcyclohexane, ethylcyclopentane, 2,4-dimethylhexane, trimethylpentane, and others where specific impurity standards are available. Absolute purity cannot be accurately determined if unknown impurities are present.

SCOPE

1.1 This test method covers the determination of specific impurities in, and the purity of benzene for cyclohexane feedstock by gas chromatography.

1.2 This test method has been found applicable to benzene in the range from 99 to 100 % purity and to impurities at concentrations of 2 to 10 000 mg/kg.

1.3 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded off in accordance with the rounding-off method of Practice E 29.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see 7.1 and Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D5713–05

Standard Test Method for

Analysis of High Purity Benzene for Cyclohexane Feedstock

1

by Capillary Gas Chromatography

This standard is issued under the fixed designation D5713; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E355 Practice for Gas Chromatography Terms and Rela-

tionships

1.1 This test method covers the determination of specific

E1510 Practice for Installing Fused Silica Open Tubular

impurities in, and the purity of benzene for cyclohexane

Capillary Columns in Gas Chromatographs

feedstock by gas chromatography.

2.2 Other Document:

1.2 This test method has been found applicable to benzene

OSHA Regulations 29 CFR paragraphs 1910.1000 and

in the range from 99 to 100% purity and to impurities at

3

1910.1200

concentrations of 2 to 10000 mg/kg.

1.3 In determining the conformance of the test results using

3. Terminology

this method to applicable specifications, results shall be

3.1 Definitions:

rounded off in accordance with the rounding-off method of

3.1.1 For definition of terms used in this test method see

Practice E29.

Terminology D4790.

1.4 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

4. Summary of Test Method

standard.

4.1 Inthistestmethod,thechromatogrampeakareaforeach

1.5 This standard does not purport to address all of the

impurity is compared to the peak area of the internal standard

safety concerns, if any, associated with its use. It is the

(n-octane or other suitable known) added to the sample. From

responsibility of the user of this standard to establish appro-

the response factor of toluene relative to that of the internal

priate safety and health practices and determine the applica-

standard, and using a response factor of 1.00 for nonaromatic

bility of regulatory limitations prior to use. For a specific

impurities and the amount of internal standard added, the

hazard statement, see 7.1 and Section 8.

concentrations of the impurities are calculated. The benzene

content is obtained by subtracting the total amount of all

2. Referenced Documents

2 impurities from 100.00.

2.1 ASTM Standards:

D3437 Practice for Sampling and Handling Liquid Cyclic

5. Significance and Use

Products

5.1 Thistestmethodisdesignedtoobtainbenzenepurityon

D4790 TerminologyofAromaticHydrocarbonsandRelated

thebasisofimpuritiesnormallypresentinbenzeneandmaybe

Chemicals

used for final product inspections and process control.

D6809 Guide for Quality Control and Quality Assurance

5.2 This test method will detect the following impurities:

Procedures for Aromatic Hydrocarbons and Related Ma-

toluene, methylcyclopentane, n-hexane, 2-methylhexane, cy-

terials

clohexane, cyclopentane, 2-methylpentane, 2,3-

E29 Practice for Using Significant Digits in Test Data to

dimethylpentane,3-methylhexane, n-heptane,methylcyclohex-

Determine Conformance with Specifications

ane, ethylcyclopentane, 2,4-dimethylhexane, trimethylpentane,

E260 Practice for Packed Column Gas Chromatography

and others where specific impurity standards are available.

Absolute purity cannot be accurately determined if unknown

1

This test method is under the jurisdiction of ASTM Committee D16 on

impurities are present.

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

Subcommittee D16.01 on Benzene, Toluene, Xylenes, Cyclohexane and Their

6. Apparatus

Derivatives.

6.1 Gas Chromatograph—Anygaschromatographhavinga

Current edition approved July 1, 2005. Published August 2005. Originally

approved in 1995. Last previous edition approved in 2000 as D5713–00. DOI:

temperatureprogrammableoven,flameionizationdetectorand

10.1520/D5713-05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5713–05

TABLE 2 Intermediate Precision and Reproducibility

a splitter injector suitable for use with a fused silica capillary

column may be used, provided the system has sufficient Average

Intermediate

Component Concentration ppm Reproducibility

sensitivitythatwillgiveaminimumpe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.