ASTM D6641/D6641M-01e1

(Test Method)Standard Test Method for Determining the Compressive Properties of Polymer Matrix Composite Laminates Using a Combined Loading Compression (CLC) Test Fixture

Standard Test Method for Determining the Compressive Properties of Polymer Matrix Composite Laminates Using a Combined Loading Compression (CLC) Test Fixture

SIGNIFICANCE AND USE

This test method is designed to produce compressive property data for material specifications, research and development, quality assurance, and structural design and analysis. When specific laminates are tested (primarily of the [90/0]ns family, although other laminates containing a maximum of 50 % 0° plies can be used), the data are frequently used to “back out” 0° ply strength, using laminate theory to calculate a 0° unidirectional lamina strength (1, 2). Factors that influence the compressive response include: type of material, methods of material preparation and lay-up, specimen stacking sequence, specimen preparation, specimen conditioning, environment of testing, speed of testing, time at temperature, void content, and volume percent reinforcement. Laminate properties, in the test direction, that may be obtained from this test method include:

5.1.1 Ultimate compressive strength,

5.1.2 Ultimate compressive strain,

5.1.3 Compressive (linear or chord) modulus of elasticity, and

5.1.4 Poisson’ratio in compression.

SCOPE

1.1 This test method establishes a procedure for determining the compressive strength and stiffness properties of polymer matrix composite materials using a combined loading compression (CLC) (1) or comparable test fixture. This test method is applicable to general flat laminates that are balanced and symmetric and contain at least one 0o ply. The standard specimen is untabbed, and, thus, for strength determination, the laminate is limited to a maximum of 50 % 0o plies, or equivalent (see 6.4).

1.2 The compressive force is introduced into the specimen by combined end- and shear-loading. In comparison, Test Method D3410/D3410M is a pure shear-loading compression test method and Test Method D695 is a pure end-loading test method.

1.3 Unidirectional (0o ply orientation) composites can be tested to determine unidirectional composite modulus and Poisson's ratio, but not compressive strength.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the test the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

Note 1--Additional procedures for determining the compressive properties of polymer matrix composites may be found in Test Methods D3410/D3410M, D5467, and D695.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 6641/D 6641M – 01

Standard Test Method for

Determining the Compressive Properties of Polymer Matrix

Composite Laminates Using a Combined Loading

Compression (CLC) Test Fixture

This standard is issued under the fixed designation D 6641/D 6641M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—The designation, D 6641/D 6641M, was editorially corrected to be a dual standard in December 2001.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 Thistestmethodestablishesaprocedurefordetermining

the compressive strength and stiffness properties of polymer

2. Referenced Documents

matrixcompositematerialsusingacombinedloadingcompres-

2 2.1 ASTM Standards:

sion (CLC) (1) or comparable test fixture. This test method is

D 695 Test Method for Compressive Properties of Rigid

applicable to general flat laminates that are balanced and

Plastics

symmetric and contain at least one 0° ply. The standard

D 883 Terminology Relating to Plastics

specimenisuntabbed,and,thus,forstrengthdetermination,the

D 3410/D 3410M Test Method for Compressive Properties

laminate is limited to a maximum of 50 % 0° plies, or

of Polymer Matrix Composite Materials with Unsupported

equivalent (see 6.4).

Gage Section by Shear Loading

1.2 The compressive force is introduced into the specimen

D 3878 Terminology for Composite Materials

by combined end- and shear-loading. In comparison, Test

D 5467 Test Method for Compressive Properties of Unidi-

Method D 3410/D 3410M is a pure shear-loading compression

rectional Polymer Matrix Composites Using a Sandwich

test method and Test Method D 695 is a pure end-loading test

Beam

method.

D 5687/D 5687M Guide for Preparation of Flat Composite

1.3 Unidirectional (0° ply orientation) composites can be

Panels with Processing Guidelines for Specimen Prepara-

tested to determine unidirectional composite modulus and

tion

Poisson’s ratio, but not compressive strength.

E4 Practices for Force Verification of Testing Machines

1.4 The values stated in either SI units or inch-pound units

E6 Terminology Relating to Methods of Mechanical Test-

are to be regarded separately as standard. Within the test the

ing

inch-pound units are shown in brackets. The values stated in

E 122 Practice for Calculating Sample Size to Estimate,

each system are not exact equivalents; therefore, each system

with a Specified Tolerable Error, the Average for a Char-

must be used independently of the other. Combining values

acteristic of a Lot or Process

from the two systems may result in nonconformance with the

E 132 Test Method for Poisson’s Ratio at Room Tempera-

standard.

ture

NOTE 1—Additional procedures for determining the compressive prop-

E 177 Practice for Use of the Terms Precision and Bias in

erties of polymer matrix composites may be found in Test Methods

ASTM Test Methods

D 3410/D 3410M, D 5467, and D 695.

E 456 Terminology Relating to Quality and Statistics

1.5 This standard does not purport to address all of the

E 1309 Guide for Identification of Fiber-Reinforced Poly-

safety concerns, if any, associated with its use. It is the

mer Matrix Composite Materials in Databases

responsibility of the user of this standard to establish appro-

E 1434 GuideforRecordingMechanicalTestDataofFiber-

Reinforced Composite Materials in Databases

This test method is under the jurisdiction of ASTM Committee D30 on

Composite Materials and is the direct responsibility of Subcommittee D30.04 on

Lamina and Laminate Test Methods. Annual Book of ASTM Standards, Vol 08.01.

Current edition approved March 10, 2001. Published May 2001. Annual Book of ASTM Standards, Vol 15.03.

2 5

Boldface numbers in parentheses refer to the list of references at the end of this Annual Book of ASTM Standards, Vol 03.01.

test method. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 6641/D 6641M – 01

FIG. 1 Photograph of a Typical Combined Loading Compression (CLC) Test Fixture

E 1471 Guide for Identification of Fibers, Fillers, and Core I—moment of inertia of specimen cross section

Materials in Computerized Material Property Databases l —specimen gage length

g

2.2 ASTM Adjunct: n—number of specimens

Combined Loading Compression (CLC) Test Fix- P—load carried by test specimen

f

ture, D 6641 P—load carried by test specimen at failure

2.3 Other Documents: s—as used in a lay-up code, denotes that the preceding ply

ANSI Y14.5-1999, “Dimensioning and Tolerancing— description for the laminate is repeated symmetrically about

Includes Inch and Metric” its midplane

ANSI B46.1-1995, “Surface Texture (Surface Roughness, s —sample standard deviation

n-1

Waviness and Lay)” V —volume fraction of 0° plies in laminate

V —volume fraction of 90° plies in laminate

3. Terminology

w—specimen gage width

–

3.1 Definitions—TerminologyD 3878definestermsrelating

x—sample mean (average)

to high-modulus fibers and their composites. Terminology

x—measured or derived property

i

D 883 defines terms relating to plastics. Terminology E6

e—indicated normal strain from strain transducer

defines terms relating to mechanical testing. Terminology

e —laminate axial strain

x

E 456 and Practice E 177 define terms relating to statistics. In

e —laminate in-plane transverse strain

y

the event of a conflict between terms, Terminology D 3878

e e —strain gage readings

1, 2

c

shall have precedence over the other Terminology standards.

v —compressive Poisson’s ratio

xy

3.2 Symbols:

A—cross-sectional area of specimen in gage section 4. Summary of Test Method

B —face-to-face percent bending in specimen

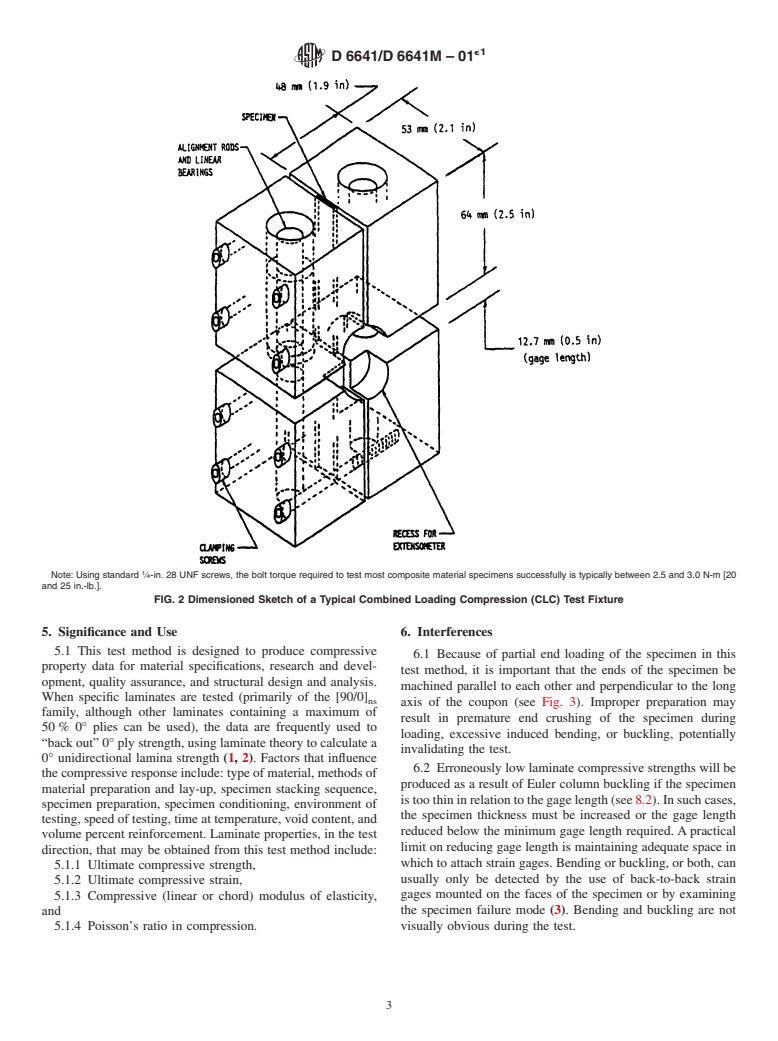

y 4.1 Atest fixture such as that shown in Figs. 1 and 2,orany

BF—back-out factor

comparable fixture, can be used to test the untabbed, straight-

CV—sample coefficient of variation, in percent

sided composite specimen of rectangular cross section shown

c

E —laminate compressive modulus

schematically in Fig. 3.Atypical specimen is 140 mm [5.5 in.]

cu

F —laminate ultimate compressive strength

long and 12 mm [0.5 in.] wide, having an unsupported (gage)

cu

F —compressive stress in 0° plies at laminate failure

0°plies length of 12 mm [0.5 in.] when installed in the fixture.Agage

cr

F —Euler buckling stress

length between 12 mm and 25 mm [1.0 in.] is acceptable,

G —through-thickness shear modulus of laminate

xz subject to specimen buckling considerations (see 8.2). This

G —in-plane shear modulus of the 0° plies

12 12-mm gage length provides sufficient space to install bonded

G ,G —through-thickness shear moduli of the 0° plies

13 23 strain gages when they are required. The fixture, which

h—specimen thickness

subjects the specimen to combined end- and shear-loading, is

itself loaded in compression between flat platens in a universal

testing machine. Load-strain data are collected until failure

A detailed drawing for the fabrication of the test fixture shown in Figs. 1 and

occurs (or until a specified strain level is achieved if only

2 is available from ASTM Headquarters. Order Adjunct No. ADJD6641.

compressive modulus or Poisson’s ratio, or both, is to be

Available from American National Standards Institute, 25 W. 43rd St., 4th

Floor, New York, NY 10036. determined,andnotthecompletestress-straincurvetofailure).

e1

D 6641/D 6641M – 01

Note: Using standard ⁄4-in. 28 UNF screws, the bolt torque required to test most composite material specimens successfully is typically between 2.5 and 3.0 N-m [20

and 25 in.-lb.].

FIG. 2 Dimensioned Sketch of a Typical Combined Loading Compression (CLC) Test Fixture

5. Significance and Use 6. Interferences

5.1 This test method is designed to produce compressive

6.1 Because of partial end loading of the specimen in this

property data for material specifications, research and devel-

test method, it is important that the ends of the specimen be

opment, quality assurance, and structural design and analysis.

machined parallel to each other and perpendicular to the long

When specific laminates are tested (primarily of the [90/0]

ns

axis of the coupon (see Fig. 3). Improper preparation may

family, although other laminates containing a maximum of

result in premature end crushing of the specimen during

50 % 0° plies can be used), the data are frequently used to

loading, excessive induced bending, or buckling, potentially

“back out” 0° ply strength, using laminate theory to calculate a

invalidating the test.

0° unidirectional lamina strength (1, 2). Factors that influence

6.2 Erroneously low laminate compressive strengths will be

the compressive response include: type of material, methods of

produced as a result of Euler column buckling if the specimen

material preparation and lay-up, specimen stacking sequence,

istoothininrelationtothegagelength(see8.2).Insuchcases,

specimen preparation, specimen conditioning, environment of

the specimen thickness must be increased or the gage length

testing, speed of testing, time at temperature, void content, and

reduced below the minimum gage length required. A practical

volume percent reinforcement. Laminate properties, in the test

limit on reducing gage length is maintaining adequate space in

direction, that may be obtained from this test method include:

which to attach strain gages. Bending or buckling, or both, can

5.1.1 Ultimate compressive strength,

usually only be detected by the use of back-to-back strain

5.1.2 Ultimate compressive strain,

gages mounted on the faces of the specimen or by examining

5.1.3 Compressive (linear or chord) modulus of elasticity,

and the specimen failure mode (3). Bending and buckling are not

5.1.4 Poisson’s ratio in compression. visually obvious during the test.

e1

D 6641/D 6641M – 01

Notes:

(1) The specimen ends must be parallel to each other within 0.03 mm [0.001 in.] and also perpendicular to the longitudinal axis of the specimen within 0.03 [0.001 in.].

(2) Nominal specimen thickness can be varied, but must be uniform. Thickness irregularities (for example, thickness taper or surface imperfections) shall not exceed

0.03 mm [0.001 in.] across the specimen width or 0.06 mm [0.002 in.] along the specimen length.

(3) The faces of the specimen may be lapped slightly to remove any local surface imperfections and irregularities, thus providing flatter surfaces for more uniform

gripping by the fixture.

FIG. 3 Typical Test Specimen Configuration

6.3 For a valid test, final failure of the specimen must occur fully fail the composite before specimen end crushing must not

within the gage section. Which failure modes are deemed induce significant stress concentrations at the ends of the gage

acceptable will be governed by the particular material, lami- section (4). Such stress concentrations will degrade the mea-

nate configuration, and application (see 10.1). sured compressive strength. For example, testing an untabbed

6.4 Continuous-fiber-reinforced laminates having more than high-strength unidirectional composite is likely to be unsuc-

50 % axially oriented (0°) plies may require higher than cessful because of the excessive clamping forces required to

acceptable fixture clamping forces to prevent end crushing. prevent specimen end crushing, whereas a lower strength

Therefore, such specimens are considered nonstandard. Exces- unidirectional composite may be successfully tested using

sive clamping forces induce at the ends of the gage section acceptable clamping forces. The use of a tabbed specimen to

local stress concentrations that may produce erroneously low increase the bearing area at the specimen ends is possible,

strength results (see 9.2.7). although nonstandard, and not desirable as tabs also induce

6.5 If the outermost plies of the laminate are oriented at 0°, stress concentrations at the ends of the gage section (1, 5).An

the local stress concentrations at the ends of the specimen gage untabbed thickness-tapered specimen, although nonstandard,

section may lead to premature failure of these primary load- has also been used to test successfully high-strength unidirec-

bearing plies, producing erroneously low laminate strength tional composites (5).

results. This is particularly true for specimens with low 6.7 In multidirectional laminates, edge effects can affect the

numbers of plies, since then the outer plies represent a measured strength and modulus of the laminate.

significant fraction of the total number of plies (1).

7. Apparatus and Supplies

6.6 The compressive strength and stiffness properties of

other laminate configurations may also be determined using 7.1 Micrometers and Calipers—A micrometer having a

this same untabbed specimen test method, subject to some suitable-size diameter ball-interface on irregular surfaces such

limitations (1). One limitation is that the fixture clamping as the bag-side of a laminate, and a flat anvil interface on

forces induced by the applied bolt torques required to success- machined edges or very smooth tooled surfaces, shall be used.

e1

D 6641/D 6641M – 01

A caliper of suitable size can also be used on machined edges statistically significant data, the procedures outlined in Practice

or very smooth tooled surfaces. The accuracy of these instru- E 122 should be consulted. The method of sampling shall be

ments shall be suitable for reading to within 1 % of the sample

reported.

length, width and thickness. For typical specimen geometries,

8.2 Geometry—The test specimen is an untabbed rectangu-

an instrument with an accuracy of 62.5 µm [60.0001 in.] is

larstripofthelaminatetobetested,asshowninFig.3.Aguide

desirable for thickness and width measurement, while an

to preparation of flat composite panels, with processing guide-

instrument with an accuracy of 625 µm [60.001 in.] is

lines for specimen preparation, is presented in Guide D 5687/

desirable for length measurements.

D 5687M. Specimen dimensions and tolerances must be in

7.2 Torque Wrench—Calibrated within the torque range

compliance with the requirements of Fig. 3. If axial strain is to

required.

be measured (for example, to monitor specimen bending, to

7.3 Testing Machine—Acalibrated testing machine shall be

determine the axial compressive modulus, or to obtain a

used which can be operated at constant crosshead speed over

stress-strain curve), two single-element axial strain gages or

the specified rang

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.