ASTM D6732-01

(Test Method)Standard Test Method for Determination of Copper in Jet Fuels by Graphite Furnace Atomic Absorption Spectrometry

Standard Test Method for Determination of Copper in Jet Fuels by Graphite Furnace Atomic Absorption Spectrometry

SCOPE

1.1 This test method covers the determination of copper in jet fuels in the range of 5 to 100 μg/kg using graphite furnace atomic absorption spectrometry.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 6732 – 01

Standard Test Method for

Determination of Copper in Jet Fuels by Graphite Furnace

Atomic Absorption Spectrometry

This standard is issued under the fixed designation D 6732; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers the determination of copper in 4.1 An aliquot (typically 10 μL) of the sample is pipetted

jet fuels in the range of 5 to 100 μg/kg using graphite furnace onto a platform in the graphite furnace. The furnace is aligned

atomic absorption spectrometry. in the light path of the atomic absorption spectrometer

1.2 The values stated in SI units are to be regarded as equipped with background correction. The furnace is heated to

standard. low temperature to dry the sample completely without spatter-

1.3 This standard does not purport to address all of the ing. The furnace is then heated to a moderate temperature to

safety concerns, if any, associated with its use. It is the eliminate excess sample matrix. The furnace is further heated

responsibility of the user of this standard to establish appro- very rapidly to a temperature high enough to volatilize the

priate safety and health practices and determine the applica- analyte of interest. It is during this step that the amount of light

bility of regulatory limitations prior to use. absorbed by the copper atoms is measured by the spectrometer.

4.2 The light absorbed is measured over a specified period.

2. Referenced Documents

The integrated absorbance A produced by the copper in the

i

2.1 ASTM Standards:

samples is compared to a calibration curve constructed from

D 4057 Practice for Manual Sampling of Petroleum and measured A values for organo-metallic standards.

i

Petroleum Products

5. Significance and Use

D 4306 Practice for Aviation Fuel Sample Containers for

Tests Affected by Trace Contamination 5.1 At high temperatures aviation turbine fuels can oxidize

D 6299 Practice for Applying Statistical Quality Assurance and produce insoluble deposits that are detrimental to aircraft

Techniques to Evaluate Analytical Measurement System propulsion systems. Very low copper concentrations (in excess

Performance of 50 μg/kg) can significantly accelerate this thermal instability

of aviation turbine fuel. Naval shipboard aviation fuel delivery

3. Terminology

systems contain copper-nickel piping, which can increase

3.1 Definitions: copper levels in the fuel. This test method may be used for

3.1.1 radiant power, P, n—the rate at which energy is

quality checks of copper levels in aviation fuel samples taken

transported in a beam of radiant energy.

on shipboard, in refineries, and at fuel storage depots.

3.1.2 transmittance, T, n—the ratio of the radiant power

6. Interferences

transmitted by a material to the radiant power incident upon it.

3.2 Definitions of Terms Specific to This Standard: 6.1 Interferences most commonly occur due to light that is

3.2.1 absorbance, A, n—the logarithm to the base 10 of the absorbed by species other than the atomic species of interest.

ratio of the reciprocal of the transmittance, T: Generally, this is due to undissociated molecular particles from

the sample matrix. The char step in the furnace program is used

A 5 log ~1/T! 5 –log T (1)

10 10

to eliminate as much of the matrix as possible before the

3.2.2 integrated absorbance, A , n—the integrated area

i

atomization step. Spectrometers are equipped with background

under the absorbance peak generated by the atomic absorption

correction capabilities to control further possibilities of erro-

spectrometer.

neous results due to molecular absorption.

1 7. Apparatus

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee

7.1 Atomic Absorption Spectrometer—An atomic absorp-

D02.03 on Elemental Analysis.

tion spectrometer with the capability of setting the wavelength

Current edition approved Nov. 10, 2001. Published January 2002.

at 324.8 nm, setting the slit width at typically 0.7 nm, and using

Annual Book of ASTM Standards, Vol 05.02.

Annual Book of ASTM Standards, Vol 05.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6732

peak area integration for the atomic and background readings Practice D 4306. Add enough odorless kerosene to bring the

shall be used. The spectrometer shall be equipped with the total mass to a nominal 50.00 g. Seal the container and mix

following: well. See 12.1.1 for calculation of actual concentration.

7.1.1 Copper Hollow Cathode Lamp—as the elemental light

10.1.2 Working Standards of Nominally 20, 40, 60, 80, and

source.

100 μg/kg—Accurately weigh a nominal (All masses are

7.1.2 Background Correction Capability—to cover the

measured to the nearest 0.0001 g.) 0.20, 0.40, 0.60, 0.80, and

324.8 nm wavelength range.

1.00 g of the nominal 1 mg/kg intermediate stock standard into

7.1.3 Graphite Furnace Accessory—which uses pyrolyti-

five suitable containers. Add enough odorless kerosene to each

cally coated graphite tubes with L’vov platforms.

container to bring the total mass to a nominal 10.00 g. Seal

7.2 Autosampler or Manual Pipettor—capable of reproduc-

containers and mix well. This produces working standards of

ibly delivering 10 μL aliquots of samples, standards, and blank

nominal 20, 40, 60, 80, and 100 μg/kg, respectively. See 12.1.2

to the graphite furnace.

for calculations of actual concentrations.

7.3 Analytical Balance—capable of weighing 100 g 6

10.2 Calibration:

0.0001 g.

10.2.1 Prepare a standard calibration curve by using the

odorless kerosene as a blank and each of the five working

8. Reagents and Materials

standards. The instrument measures the integrated absorbance

8.1 Purity of Reagents—Reagent grade chemicals shall be

A of 10 μL of each working standard and blank. The working

i

used in all tests. Unless otherwise indicated, it is intended that

standards shall be prepared daily.

all reagents conform to the specifications of the Committee on

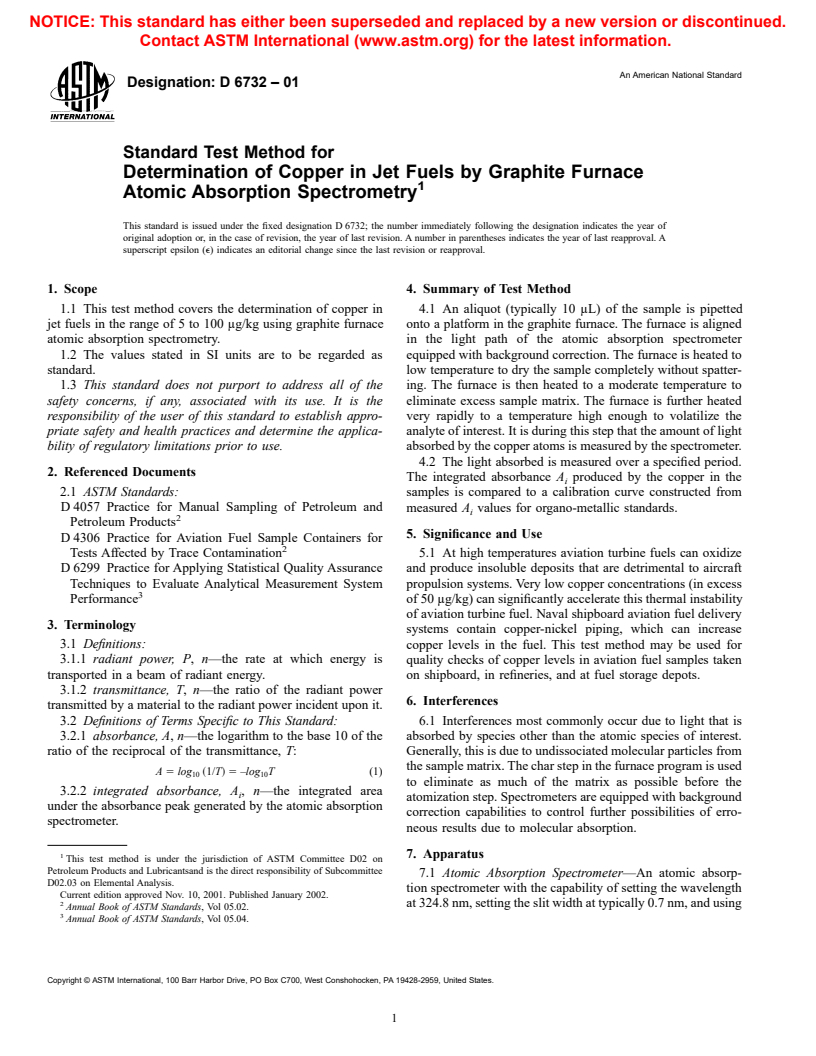

10.2.2 The calibration curve is constructed by plotting the

Analytical Reagents of the American Chemical Society where

corrected integrated absorbances (on y-axis) versus the con-

such specifications are available. Other grades may be used,

centrations of copper in the working standards in μg/kg (on

provided it is first ascertained that the reagent is of sufficiently

x-axis). See 12.2.1 for calculating corrected integrated absor-

high purity to permit its use without lessening the accuracy of

bance. Fig. 1 shows a typical calibration curve for atomic

the determination.

absorption spectroscopy. Many atomic absorption spectrom-

8.2 Odorless or Low Odor Kerosene, filtered through silica

eters have the capability of constructing the calibration curve

gel.

internally or by way of computer software. Construct the best

8.3 100 mg/kg Organo-metallic Standard for Copper,ora

possible fit of the data with available means.

multielement standard containing copper at 100 mg/kg.

8.4 Silica Gel, 100 to 200 mesh.

11. Procedure

8.5 Argon Gas, 99.999%,(Warning—Argon is a com-

11.1 Set the spectrometer at a wavelength of 324.8 nm and

pressed gas under high pressure) for graphite furnace gas flow

a slit width of typically 0.7 nm. Align the hollow cathode lamp

system.

and furnace assembly to obtain maximum transmittance.

8.6 Quality Control (QC) Samples, preferably are portions

11.2 Condition new (or reinstalled) graphite tube and L’vov

of one or more kerosene materials that are stable and repre-

platform with the temperature program provided by the spec-

sentative of the samples of interest. These QC samples can be

trometer manufacturer until the baseline shows no peaks.

used to check the validity of the testing process as described in

11.3 Calibrate the graphite furnace temperature controller at

Section 14. Use a stable QC concentrate, and dilute it on the

2300°C according to the spectrometer manufacturer’s instruc-

day of the QC check to the trace level required.

tions.

9. Sampling 11.4 When an autosampler is used with the graphite furnace,

use odorless kerosene as the rinse solution. Use only autosam-

9.1 Samples shall be taken in accordance with procedures

pler cups made of polyethylene, polypropylene, or TFE-

described in Practice D 4057.

fluorocarbon. Do not use polystyrene cups as these degrade and

9.2 Samples shall be thoroughly mixed in their containers

leak when used with organic solvents.

immediately prior to testing.

11.5 Calibrate the instrument by pipetting a 10 μL aliquot of

10. Calibration and Standardization

odorless kerosene as a blank and then 10 μL of each of the

standards onto the platform in the graphite tube. Then pipette

10.1 Preparation of Standards:

10 μL of each sample into the furnace and carry each through

10.1.1 Nominal 1 mg/kg Intermediate S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.