ASTM D1155-03

(Test Method)Standard Test Method for Roundness of Glass Spheres

Standard Test Method for Roundness of Glass Spheres

SIGNIFICANCE AND USE

The roundness of glass spheres is one measureable aspect relating to their performance as a retroreflective media. The function of this test method is to measure the percent of true spheres as related to compliance with applicable specifications.

Note 1—This method has been used in other industrial areas outside the intended scope of this test method.

FIG. 1 Apparatus for Roundness Test of Glass Spheres

SCOPE

1.1 This test method covers the determination of the percent of true spheres in glass spheres used for retroreflective marking purposes and industrial uses.

1.2 This test method includes two procedures as follows:

1.2.1 Procedure A in which the selected specimen is split into two size ranges or groups prior to separation into true spheres and irregular particles, and

1.2.2 Procedure B in which the selected specimen is split into five size ranges or groups prior to separation.

1.2.3 In determining compliance with specification requirements, either Procedure A or Procedure B may be used. Where tests indicate failure to meet the specified percent of true spheres and irregular particles, the referee test shall be made in accordance with Procedure B.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1155–03

Standard Test Method for

1

Roundness of Glass Spheres

This standard is issued under the fixed designation D1155; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

2

1.1 This test method covers the determination of the 3.1 The glass particles are mechanically separated into true

percent of true spheres in glass spheres used for retroreflective spheres and irregular particles by controlled vibration on a

marking purposes and industrial uses. glass plate fixed at a predetermined slope.

1.2 This test method includes two procedures as follows:

4. Significance and Use

1.2.1 Procedure A, in which the selected specimen is split

4.1 The roundness of glass spheres is one measureable

into two size ranges or groups prior to separation into true

spheres and irregular particles, and aspect relating to their performance as a retroreflective media.

The function of this test method is to measure the percent of

1.2.2 Procedure B, in which the selected specimen is split

into five size ranges or groups prior to separation. true spheres as related to compliance with applicable specifi-

cations.

1.2.3 In determining compliance with specification require-

ments, either ProcedureAor Procedure B may be used. Where

NOTE 1—This method has been used in other industrial areas outside

tests indicate failure to meet the specified percent of true

the intended scope of this test method.

spheres and irregular particles, the referee test shall be made in

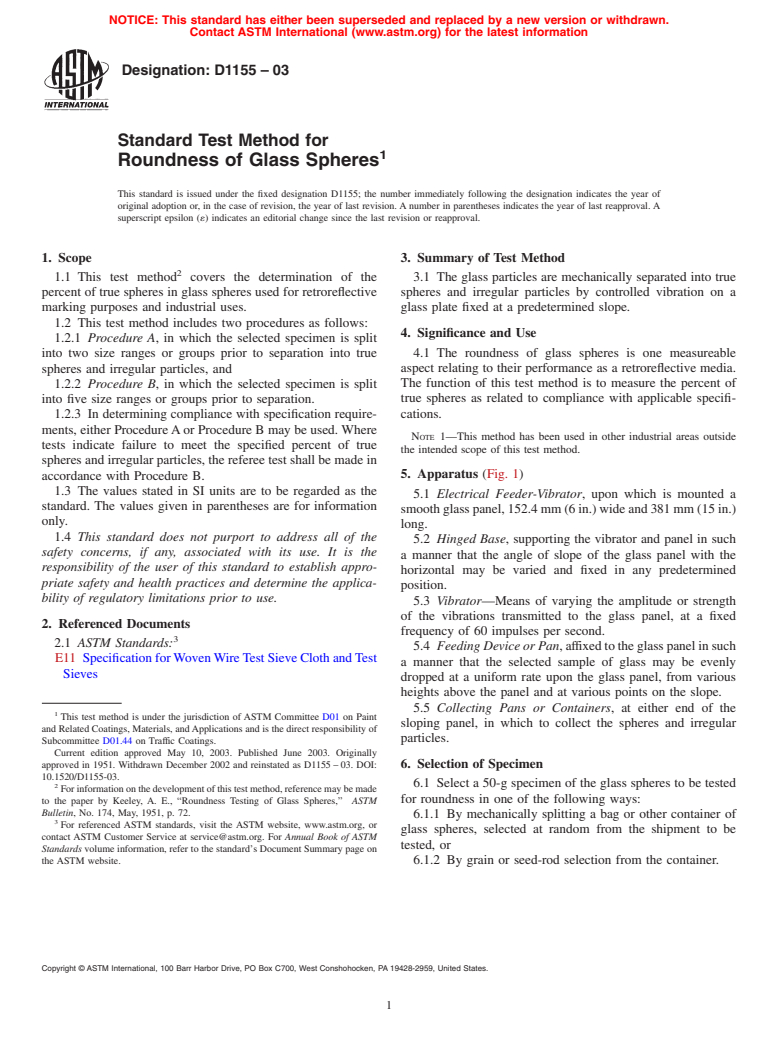

5. Apparatus (Fig. 1)

accordance with Procedure B.

1.3 The values stated in SI units are to be regarded as the

5.1 Electrical Feeder-Vibrator, upon which is mounted a

standard. The values given in parentheses are for information

smoothglasspanel,152.4mm(6in.)wideand381mm(15in.)

only.

long.

1.4 This standard does not purport to address all of the

5.2 Hinged Base, supporting the vibrator and panel in such

safety concerns, if any, associated with its use. It is the

a manner that the angle of slope of the glass panel with the

responsibility of the user of this standard to establish appro-

horizontal may be varied and fixed in any predetermined

priate safety and health practices and determine the applica-

position.

bility of regulatory limitations prior to use.

5.3 Vibrator—Means of varying the amplitude or strength

of the vibrations transmitted to the glass panel, at a fixed

2. Referenced Documents

frequency of 60 impulses per second.

3

2.1 ASTM Standards:

5.4 FeedingDeviceorPan,affixedtotheglasspanelinsuch

E11 SpecificationforWovenWireTestSieveClothandTest

a manner that the selected sample of glass may be evenly

Sieves

dropped at a uniform rate upon the glass panel, from various

heights above the panel and at various points on the slope.

5.5 Collecting Pans or Containers, at either end of the

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

sloping panel, in which to collect the spheres and irregular

and Related Coatings, Materials, andApplications and is the direct responsibility of

particles.

Subcommittee D01.44 on Traffic Coatings.

Current edition approved May 10, 2003. Published June 2003. Originally

approved in 1951. Withdrawn December 2002 and reinstated as D1155 – 03. DOI: 6. Selection of Specimen

10.1520/D1155-03.

2 6.1 Select a 50-g specimen of the glass spheres to be tested

Forinformationonthedevelopmentofthistestmethod,referencemaybemade

for roundness in one of the following ways:

to the paper by Keeley, A. E., “Roundness Testing of Glass Spheres,” ASTM

Bulletin, No. 174, May, 1951, p. 72.

6.1.1 By mechanically splitting a bag or other container of

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

glass spheres, selected at random from the shipment to be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tested, or

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 6.1.2 By grain or seed-rod selection from the container.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1155–03

FIG. 1 Apparatus for Roundness Test of Glass Spheres

7. Procedure A one-thirdpointoftheslope,sothatthespheresmaybedropped

in a uniform monolayer onto the glass panel from a height of

7.1 Sieve the selected specimen through a 300-µm (No. 50)

1

approximately 13 mm ( ⁄2 in.).

sieve (Note 2). Run the spheres retained on the sieve as one

group, and run the spheres passing the sieve as a second group. 7.3 Place the size

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.