ASTM F1976-13

(Test Method)Standard Test Method for Impact Attenuation of Athletic Shoe Cushioning Systems and Materials (Withdrawn 2022)

Standard Test Method for Impact Attenuation of Athletic Shoe Cushioning Systems and Materials (Withdrawn 2022)

SIGNIFICANCE AND USE

5.1 This test method is used by athletic footwear manufacturers and others, both as a tool for development of athletic shoe cushioning systems and as a test of the general cushioning characteristics of athletic footwear products, materials and components. Adherence to the requirements and recommendations of this test method will provide repeatable results that can be compared among laboratories.

5.2 Data obtained by these procedures are indicative of the impact attenuation of athletic shoe cushioning systems under the specific conditions employed.

5.3 This test method is designed to provide data on the force versus displacement response of athletic footwear cushioning systems under essentially uniaxial impact loads at rates that are similar to those of heel and forefoot impacts during different athletic activities.

5.4 The peak or maximum values of force, acceleration, displacement, and strain are dependent on the total impact energy applied to the specimen. These values are normalized to provide comparative results for a reference value of total energy input.

5.5 Impact attenuation outcomes are strongly dependent on initial conditions (impact mass, impact velocity, contact area, etc.) and on specimen size and the specimen’s prior history of compressive loading. Therefore results should be compared only for specimens of the same nominal size and prior conditioning.Note 1—Impact test outcomes have been found to correlate with in-vivo loads (peak ground reaction force, peak plantar pressure, lower extremity acceleration) experienced by runners. Relationships between test outcomes and subjective perceptions of cushioning have also been found. However, there is no direct evidence of a correlation between scores on this test method and the probability of injury among users of a particular athletic footwear product.

SCOPE

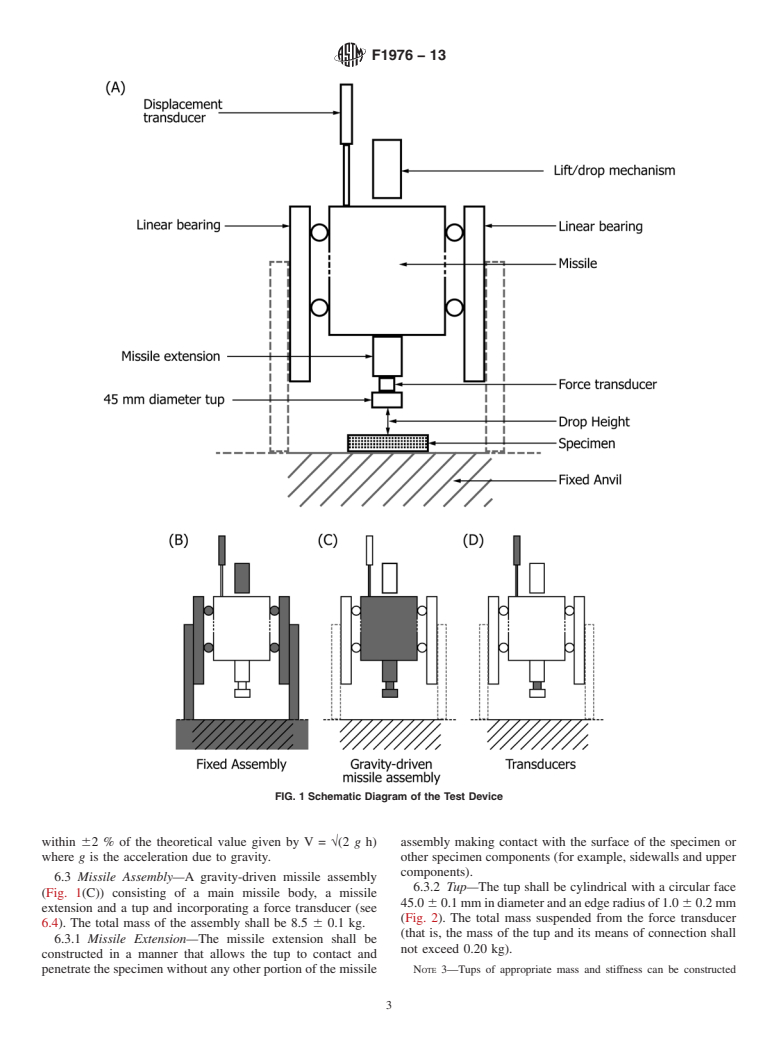

1.1 This test method describes the use of a gravity-driven impact test to measure certain impact attenuation characteristics of cushioning systems and cushioning materials employed in the soles of athletic shoes.

1.2 This test method uses an 8.5 kg mass dropped from a height of 30-70 mm to generate force-time profiles that are comparable to those observed during heel and forefoot impacts during walking, running and jump landings.

1.3 This test method is intended for use on the heel and or forefoot regions of whole, intact athletic shoe cushioning systems. An athletic shoe cushioning system is defined as all of the layers of material between the wearer's foot and the ground surface that are normally considered a part of the shoe. This may include any of the following components: outsole or other abrasion resistant outer layer, a midsole of compliant cushioning materials or structures forming an intermediate layer, an insole, insole board, or other material layers overlying the midsole, parts of the upper and heel counter reinforcement which extend beneath the foot, and an insock, sockliner or other cushioning layers, either fixed or removable, inside the shoe.

1.4 This test method may also be employed in to measure the impact attenuation of cushioning system components and cushioning material specimens.

1.5 This test method is not intended for use as a test of shoes classified by the manufacturer as children's shoes.

1.6 The type, size or dimensions and thickness of the specimen, the total energy input and prior conditioning shall qualify test results obtained by this test method.

1.6.1 The range of tests results is limited by the calibrated range of the test device’s force transducer. Combinations of thin specimens, high specimen stiffness and high total energy input may produce forces that exceed the transducer’s capacity and are hence not measurable. In practice, the specified force transducer range (10 kN) accommodates more than 99 % of typical shoe soles and cushioning material specimens that are 7 mm or more in thickness at a total energy input...

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1976 − 13 An American National Standard

Standard Test Method for

Impact Attenuation of Athletic Shoe Cushioning Systems

1

and Materials

This standard is issued under the fixed designation F1976; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope and are hence not measurable. In practice, the specified force

transducer range (10 kN) accommodates more than 99 % of

1.1 This test method describes the use of a gravity-driven

typical shoe soles and cushioning material specimens that are

impact test to measure certain impact attenuation characteris-

7 mm or more in thickness at a total energy input of 5 Joules.

tics of cushioning systems and cushioning materials employed

1.6.2 The nominal value of the total energy input applied by

in the soles of athletic shoes.

this test method is 5 J for shoes, such as running shoes, which

1.2 This test method uses an 8.5 kg mass dropped from a

are subject to moderate impacts during normal use. Total

height of 30-70 mm to generate force-time profiles that are

energy inputs of 7.0 J and 3.0 J may be used for shoes (e.g

comparable to those observed during heel and forefoot impacts

basketball shoes) which are subject to higher impact loads

during walking, running and jump landings.

during normal use. Other values of total energy input may be

1.3 This test method is intended for use on the heel and or used, if they are stated in the report.

1.6.3 Results from tests performed with different total

forefoot regions of whole, intact athletic shoe cushioning

systems.An athletic shoe cushioning system is defined as all of energy inputs or with different masses are not directly compa-

rable.

the layers of material between the wearer’s foot and the ground

surface that are normally considered a part of the shoe. This 1.6.4 Specimen thickness has a significant effect on impact

attenuation outcomes. Consequently, results from tests of

may include any of the following components: outsole or other

abrasion resistant outer layer, a midsole of compliant cushion- material specimens of different thicknesses cannot be directly

compared.

ing materials or structures forming an intermediate layer, an

insole, insole board, or other material layers overlying the 1.6.5 The impact attenuation of cushioning materials may

change over time and with use (e.g. wear or durability testing)

midsole, parts of the upper and heel counter reinforcement

which extend beneath the foot, and an insock, sockliner or or prior conditioning (e.g. from previous tests). Consequently,

other cushioning layers, either fixed or removable, inside the test results obtained using this test method shall be qualified by

the age and prior conditioning of the samples.

shoe.

1.4 This test method may also be employed in to measure 1.7 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

the impact attenuation of cushioning system components and

cushioning material specimens. standard.

1.8 This standard does not purport to address all of the

1.5 Thistestmethodisnotintendedforuseasatestofshoes

safety concerns, if any, associated with its use. It is the

classified by the manufacturer as children’s shoes.

responsibility of the user of this standard to establish appro-

1.6 The type, size or dimensions and thickness of the

priate safety and health practices and determine the applica-

specimen, the total energy input and prior conditioning shall

bility of regulatory limitations prior to use.

qualify test results obtained by this test method.

1.6.1 The range of tests results is limited by the calibrated

2. Referenced Documents

range of the test device’s force transducer. Combinations of

2

2.1 ASTM Standards:

thin specimens, high specimen stiffness and high total energy

E691 Practice for Conducting an Interlaboratory Study to

input may produce forces that exceed the transducer’s capacity

Determine the Precision of a Test Method

F1614 Test Method for Shock Attenuating Properties of

1

This test method is under the jurisdiction of ASTM Committee F08 on Sports

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

2

Subcommittee F08.54 on Athletic Footwear. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2013. Published August 2013. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1999. Last previous edition approved in 2006 as F1976 – 06. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1976-13. the AST

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.