ASTM F2333-04(2011)

(Test Method)Standard Test Method for Traction Characteristics of the Athletic Shoe–Sports Surface Interface

Standard Test Method for Traction Characteristics of the Athletic Shoe–Sports Surface Interface

SIGNIFICANCE AND USE

This test method will be used by athletic footwear manufacturers to characterize the traction of the athletic shoe-sports surface interface, and as a tool for development of athletic shoe outsoles.

This test method will be used by researchers to determine the effect of sport surface conditions (for example, moisture, grass species, turf density, soil texture, soil composition, and so forth) on traction characteristics of the athletic shoe-sports surface interface.

This test method will be used by sports surface manufacturers to characterize the traction of the athletic shoe-sports surface interface, and as a tool for development of sports surfaces.

Careful adherence to the requirements and recommendations of this test method will provide results that compare with results from different laboratory sources.

The method will be used to research relationships between traction at athletic shoe-sports surface interfaces and athletic performance or injury. This research may lead to recommendations for appropriate levels of traction.

SCOPE

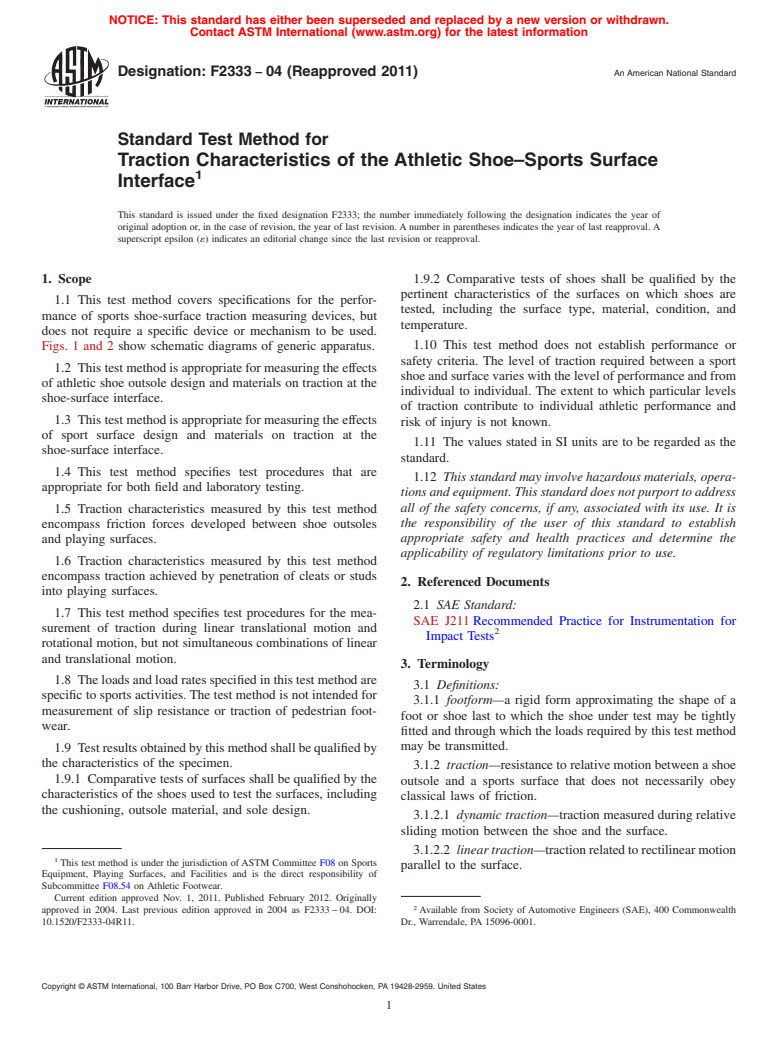

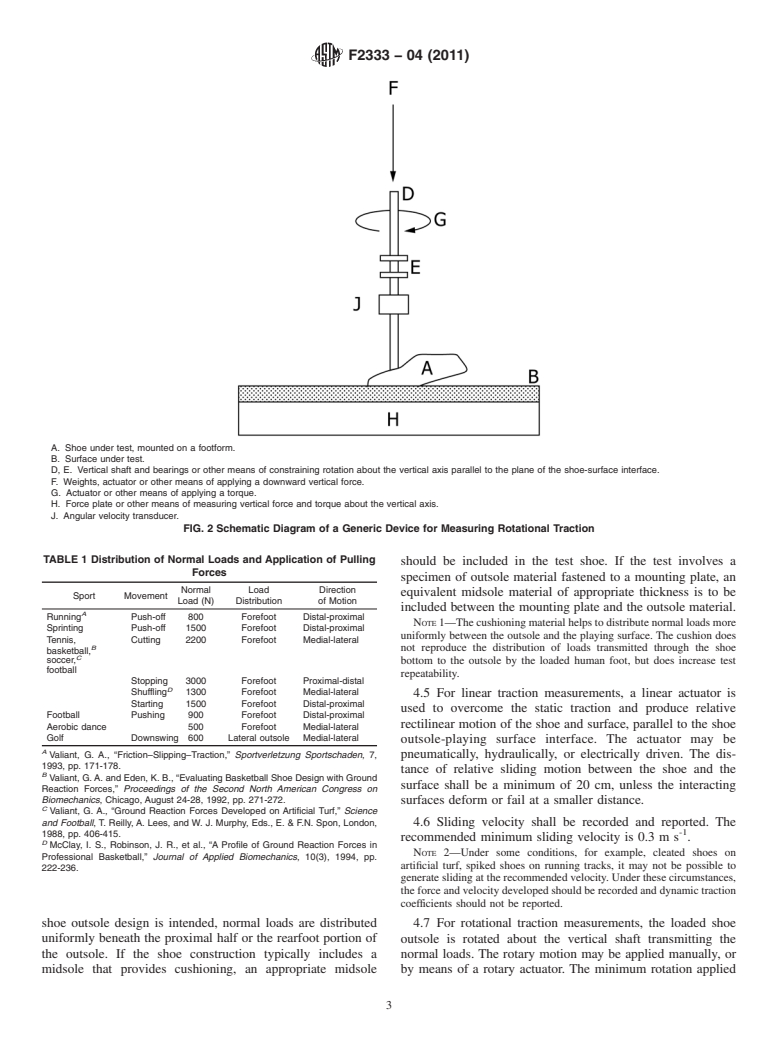

1.1 This test method covers specifications for the performance of sports shoe-surface traction measuring devices, but does not require a specific device or mechanism to be used. Figs. 1 and 2 show schematic diagrams of generic apparatus.

1.2 This test method is appropriate for measuring the effects of athletic shoe outsole design and materials on traction at the shoe-surface interface.

1.3 This test method is appropriate for measuring the effects of sport surface design and materials on traction at the shoe-surface interface.

1.4 This test method specifies test procedures that are appropriate for both field and laboratory testing.

1.5 Traction characteristics measured by this test method encompass friction forces developed between shoe outsoles and playing surfaces.

1.6 Traction characteristics measured by this test method encompass traction achieved by penetration of cleats or studs into playing surfaces.

1.7 This test method specifies test procedures for the measurement of traction during linear translational motion and rotational motion, but not simultaneous combinations of linear and translational motion.

1.8 The loads and load rates specified in this test method are specific to sports activities. The test method is not intended for measurement of slip resistance or traction of pedestrian footwear.

1.9 Test results obtained by this method shall be qualified by the characteristics of the specimen.

1.9.1 Comparative tests of surfaces shall be qualified by the characteristics of the shoes used to test the surfaces, including the cushioning, outsole material, and sole design.

1.9.2 Comparative tests of shoes shall be qualified by the pertinent characteristics of the surfaces on which shoes are tested, including the surface type, material, condition, and temperature.

1.10 This test method does not establish performance or safety criteria. The level of traction required between a sport shoe and surface varies with the level of performance and from individual to individual. The extent to which particular levels of traction contribute to individual athletic performance and risk of injury is not known.

1.11 The values stated in SI units are to be regarded as the standard.

1.12 This standard may involve hazardous materials, operations and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

A. Shoe under test, mounted on a footform.

B. Surface under test.

C. Guide rails with linear bearings or other means of maintaining rectilinear motion.

D, E. Vertical shaft and bearing mounted carriage or other means of maintaining motion parallel to the plane of the shoe-surface interface.

F. Weight...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2333 − 04 (Reapproved 2011) An American National Standard

Standard Test Method for

Traction Characteristics of the Athletic Shoe–Sports Surface

Interface

This standard is issued under the fixed designation F2333; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.9.2 Comparative tests of shoes shall be qualified by the

pertinent characteristics of the surfaces on which shoes are

1.1 This test method covers specifications for the perfor-

tested, including the surface type, material, condition, and

mance of sports shoe-surface traction measuring devices, but

temperature.

does not require a specific device or mechanism to be used.

1.10 This test method does not establish performance or

Figs. 1 and 2 show schematic diagrams of generic apparatus.

safety criteria. The level of traction required between a sport

1.2 This test method is appropriate for measuring the effects

shoe and surface varies with the level of performance and from

of athletic shoe outsole design and materials on traction at the

individual to individual. The extent to which particular levels

shoe-surface interface.

of traction contribute to individual athletic performance and

1.3 This test method is appropriate for measuring the effects

risk of injury is not known.

of sport surface design and materials on traction at the

1.11 The values stated in SI units are to be regarded as the

shoe-surface interface.

standard.

1.4 This test method specifies test procedures that are

1.12 This standard may involve hazardous materials, opera-

appropriate for both field and laboratory testing.

tions and equipment. This standard does not purport to address

1.5 Traction characteristics measured by this test method all of the safety concerns, if any, associated with its use. It is

the responsibility of the user of this standard to establish

encompass friction forces developed between shoe outsoles

and playing surfaces. appropriate safety and health practices and determine the

applicability of regulatory limitations prior to use.

1.6 Traction characteristics measured by this test method

encompass traction achieved by penetration of cleats or studs

2. Referenced Documents

into playing surfaces.

2.1 SAE Standard:

1.7 This test method specifies test procedures for the mea-

SAE J211 Recommended Practice for Instrumentation for

surement of traction during linear translational motion and

Impact Tests

rotational motion, but not simultaneous combinations of linear

and translational motion.

3. Terminology

1.8 Theloadsandloadratesspecifiedinthistestmethodare

3.1 Definitions:

specific to sports activities. The test method is not intended for

3.1.1 footform—a rigid form approximating the shape of a

measurement of slip resistance or traction of pedestrian foot-

foot or shoe last to which the shoe under test may be tightly

wear.

fitted and through which the loads required by this test method

may be transmitted.

1.9 Testresultsobtainedbythismethodshallbequalifiedby

the characteristics of the specimen.

3.1.2 traction—resistance to relative motion between a shoe

1.9.1 Comparative tests of surfaces shall be qualified by the

outsole and a sports surface that does not necessarily obey

characteristics of the shoes used to test the surfaces, including

classical laws of friction.

the cushioning, outsole material, and sole design.

3.1.2.1 dynamic traction—traction measured during relative

sliding motion between the shoe and the surface.

3.1.2.2 lineartraction—tractionrelatedtorectilinearmotion

This test method is under the jurisdiction of ASTM Committee F08 on Sports

parallel to the surface.

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

Subcommittee F08.54 on Athletic Footwear.

Current edition approved Nov. 1, 2011. Published February 2012. Originally

approved in 2004. Last previous edition approved in 2004 as F2333 – 04. DOI: Available from Society of Automotive Engineers (SAE), 400 Commonwealth

10.1520/F2333-04R11. Dr., Warrendale, PA 15096-0001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2333 − 04 (2011)

A. Shoe under test, mounted on a footform.

B. Surface under test.

C. Guide rails with linear bearings or other means of maintaining rectilinear motion.

D, E. Vertical shaft and bearing mounted carriage or other means of maintaining motion parallel to the plane of the shoe-surface interface.

F. Weights, actuator or other means of applying a downward vertical force.

G. Actuator or other means of applying a horizontal force.

H. Force plate or other means of measuring vertical and horizontal forces.

J. Velocity transducer.

FIG. 1 Schematic Diagram of a Generic Device for Measuring Linear Traction

3.1.2.3 rotational traction—traction related to rotational 4.2 Ashoe containing the outsole to be tested is pulled over

motion about an axis normal to the surface. a foot form, creating a tight fit capable of properly transmitting

forces through the shoe material to the outsole-playing surface

3.1.2.4 static traction—traction measured at the start of

interface. Alternatively, an outsole material specimen can be

relative sliding motion between the shoe and the surface.

fastened to a mounting plate and tested in the same manner as

3.1.3 traction ratio—ratio of the traction force or torque and

an outsole on an intact shoe.

the normal force acting at the shoe-surface interface.

4.3 The shoe on the footform is loaded against the test

3.1.3.1 dymamic traction ratio (T,R )—linear or rotational

k k

surface under a normal load specific to the sport category for

traction ratio measured during constant velocity relative mo-

which the shoe is intended. These normal loads, depending

tion between the shoes and the surface.

upon the sport, will typically be higher than an athlete’s body

3.1.3.2 linear traction ratio (T)—ratio of the force resisting

weight. Normal loads, and the shoe axes along which traction

relative rectilinear motion of the shoe parallel to the surface

needs are greatest, have been determined by research. Some of

and the normal force at the shoe-surface interface.

the loading conditions that have relevance for traction testing

3.1.3.3 rotational traction ratio (R)—ratio of the torque of outsoles designed for particular sports are itemized by sport

resisting relative rotational motion about an axis normal to the category in Table 1. Tests should be conducted at these normal

surface and the normal force acting at the shoe-surface loads or at a normal load of 1000 6 75 N unless otherwise

interface. specified. The normal loads can be applied by means of

weights or hydraulic cylinders, springs in compression or other

3.1.3.4 static traction ratio (T,R )—linear or rotational

s s

appropriate means and transmitted through a shaft to which the

traction ratio measured at the start of relative sliding motion

footform is securely attached.

between the shoe and the surface.

4.4 Thenormalloadisdistributedentirelybeneaththedistal

4. Summary of Test Method

half or the forefoot region of the outsole unless otherwise

4.1 A test shoe outsole or specimen is tested for traction specified. The proximal half or the rearfoot should not contact

characteristics on the type of playing surface for which the the playing surface except as noted in Table 1.Alternatively, if

shoe is intended. deemed appropriate for the sports movement for which the

F2333 − 04 (2011)

A. Shoe under test, mounted on a footform.

B. Surface under test.

D, E. Vertical shaft and bearings or other means of constraining rotation about the vertical axis parallel to the plane of the shoe-surface interface.

F. Weights, actuator or other means of applying a downward vertical force.

G. Actuator or other means of applying a torque.

H. Force plate or other means of measuring vertical force and torque about the vertical axis.

J. Angular velocity transducer.

FIG. 2 Schematic Diagram of a Generic Device for Measuring Rotational Traction

TABLE 1 Distribution of Normal Loads and Application of Pulling

should be included in the test shoe. If the test involves a

Forces

specimen of outsole material fastened to a mounting plate, an

Normal Load Direction

equivalent midsole material of appropriate thickness is to be

Sport Movement

Load (N) Distribution of Motion

included between the mounting plate and the outsole material.

A

Running Push-off 800 Forefoot Distal-proximal

NOTE1—Thecushioningmaterialhelpstodistributenormalloadsmore

Sprinting Push-off 1500 Forefoot Distal-proximal

uniformly between the outsole and the playing surface. The cushion does

Tennis, Cutting 2200 Forefoot Medial-lateral

B

not reproduce the distribution of loads transmitted through the shoe

basketball,

C

soccer, bottom to the outsole by the loaded human foot, but does increase test

football

repeatability.

Stopping 3000 Forefoot Proximal-distal

D

Shuffling 1300 Forefoot Medial-lateral

4.5 For linear traction measurements, a linear actuator is

Starting 1500 Forefoot Distal-proximal

used to overcome the static traction and produce relative

Football Pushing 900 Forefoot Distal-proximal

rectilinear motion of the shoe and surface, parallel to the shoe

Aerobic dance 500 Forefoot Medial-lateral

Golf Downswing 600 Lateral outsole Medial-lateral

outsole-playing surface interface. The actuator may be

A

Valiant, G. A., “Friction–Slipping–Traction,” Sportverletzung Sportschaden,7, pneumatically, hydraulically, or electrically driven. The dis-

1993, pp. 171-178.

tance of relative sliding motion between the shoe and the

B

Valiant, G. A. and Eden, K. B., “Evaluating Basketball Shoe Design with Ground

surface shall be a minimum of 20 cm, unless the interacting

Reaction Forces,” Proceedings of the Second North American Congress on

Biomechanics, Chicago, August 24-28, 1992, pp. 271-272. surfaces deform or fail at a smaller distance.

C

Valiant, G. A., “Ground Reaction Forces Developed on Artificial Turf,” Science

and Football, T. Reilly, A. Lees, and W. J. Murphy, Eds., E. & F.N. Spon, London, 4.6 Sliding velocity shall be recorded and reported. The

-1

1988, pp. 406-415.

recommended minimum sliding velocity is 0.3 m s .

D

McClay, I. S., Robinson, J. R., et al., “A Profile of Ground Reaction Forces in

NOTE 2—Under some conditions, for example, cleated shoes on

Professional Basketball,” Journal of Applied Biomechanics, 10(3), 1994, pp.

artificial turf, spiked shoes on running tracks, it may not be possible to

222-236.

generate sliding at the recommended velocity. Under these circumstances,

the force and velocity developed should be recorded and dynamic traction

coefficients should not be reported.

shoe outsole design is intended, normal loads are distributed 4.7 For rotational traction measurements, the loaded shoe

uniformly beneath the proximal half or the rearfoot portion of outsole is rotated about the vertical shaft transmitting the

the outsole. If the shoe construction typically includes a normal loads. The rotary motion may be applied manually, or

midsole that provides cushioning, an appropriate midsole by means of a rotary actuator. The minimum rotation applied

F2333 − 04 (2011)

motion manually (for example, by means of manually drawn cables).

shall be 90° unless the interacting surfaces deform or fail at a

Manual induction of motion is not recommended because it may be more

lesser rotation. The minimum rate of rotation shall be 45°/s.

variable than controlled mechanical actuators.

Angular velocity shall be recorded and reported.

6.5 Guides, or a means of maintaining rectilinear motion

4.8 For linear traction tests, the measured variables are

parallel to the shoe-playing surface interface, such as low

normal forces, horizontal or traction forces, and sliding veloc-

friction bearings, are required.

ity. For rotational traction tests, measured variables are normal

6.6 A means of maintaining the outsole or sample perpen-

forces, the moment (torque) resisting rotation about a vertical

dicular to the playing surface during rotation (for example, low

axis, and angular velocity during rotation. Traction ratios are

friction rotary bearings) is required for measurement of rota-

calculated from these measurements.

tional traction ratios.

4.9 All variables are recorded as functions of time, from

6.7 Transducers, signal conditioners and other instrumenta-

before the application of horizontal or rotational motion until

tion are required to measure normal force, horizontal force,

after the cessation of motion.

torque, velocity, and angular velocity. The performance of the

5. Significance and Use

measurement systems shall, as a minimum, conform to the

requirements of a CFC Class 100 Data Channel, as defined by

5.1 This test method will be used by athletic footwear

SAE J211. Anti-aliasing filters shall be used to filter data

manufacturers to characterize the traction of the athletic

channels at a -3dB cutoff frequency of 250 6 20 Hz before

shoe-sports surface interface, and as a tool for development of

they are digitized.

athletic shoe outsoles.

NOTE 4—For laboratory-based measurements, an appropriate means of

5.2 This test method will be used by researchers to deter-

measuring forces and torques is a multi-axis force plate to which the

mine the effect of sport surface conditions (for example,

surface being tested is securely attached (Figs. 1 and 2).

moisture, grass species, turf density, soil texture, soil

6.8 The apparatus should have the capability of differenti-

composition, and so forth) on traction characteristics of the

ating static traction forces from dynamic traction forces.

athletic shoe-sports surface interface.

Typically, the velocity or angular velocity measuring trans-

5.3 This test method will be used by sports surface manu-

ducer will be used for this purpose.

facturers to characterize the traction of the athletic shoe-sports

6.9 The data acquisition system should sample and store

surface interface, and as a tool for development of sports

force, torque, velocity, and angular velocity signals at a

surfaces.

minimum sampling rate of 500 samples/s.

5.4 Careful adherence to the requirements and recommen-

6.10 The complete apparatus used to make the traction

dations of this test method will provide results that compare

measurements shall be anchored or have a large enough inertia

with results from different laboratory sources.

to prevent it from being moved by the application of linear or

5.5 The method will be used to re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.