ASTM D7715-11

(Specification)Standard Specification for Fully-Formulated Glycerin Base Engine Coolant for Heavy-Duty Engines

Standard Specification for Fully-Formulated Glycerin Base Engine Coolant for Heavy-Duty Engines

SCOPE

1.1 This specification covers the requirements for fully-formulated glycerin base coolants for cooling systems of heavy-duty engines. When concentrates are used at 40 to 60 % glycerin concentration by volume in water of suitable quality (see Appendix X1), or when prediluted glycerin base engine coolants (50 volume % min) are used without further dilution, they will function effectively during both winter and summer to provide protection against corrosion, cavitation, freezing, and boiling.

1.2 This specification is intended to cover the requirements for engine coolants prepared from virgin glycerin.

Note 1—This specification is based on the knowledge of the performance of engine coolants prepared from new or virgin ingredients that comply with Specification D7640.

1.3 The coolants governed by this specification are categorized as follows: Coolant Type Description V-FF Glycerin base concentrate VI-FF Glycerin predilute (50 vol %)

1.4 Coolant concentrates meeting this specification do not require addition of supplemental coolant additive (SCA) until the first maintenance interval when a maintenance dose of SCA is required to continue protection in certain heavy duty engine cooling systems, particularly those of the wet cylinder liner-in-block design. The SCA additions are defined by and are the primary responsibility of the engine manufacturer or vehicle manufacturer. If they provide no instructions, follow the SCA supplier's instructions.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7715 – 11

Standard Specification for

Fully-Formulated Glycerin Base Engine Coolant for Heavy-

Duty Engines

This standard is issued under the fixed designation D7715; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers the requirements for fully-

formulated glycerin base coolants for cooling systems of D1126 Test Method for Hardness in Water

heavy-duty engines. When concentrates are used at 40 to 60 % D1293 Test Methods for pH of Water

glycerin concentration by volume in water of suitable quality D3306 Specification for Glycol Base Engine Coolant for

(see Appendix X1), or when prediluted glycerin base engine Automobile and Light-Duty Service

coolants (50 volume % min) are used without further dilution, D3321 Test Method for Use of the Refractometer for Field

theywillfunctioneffectivelyduringbothwinterandsummerto Test Determination of the Freezing Point of Aqueous

provide protection against corrosion, cavitation, freezing, and Engine Coolants

boiling. D4327 Test Method forAnions in Water by Suppressed Ion

1.2 This specification is intended to cover the requirements Chromatography

for engine coolants prepared from virgin glycerin. D4725 Terminology for Engine Coolants

D5828 Test Method for Compatibility of Supplemental

NOTE 1—This specification is based on the knowledge of the perfor-

Coolant Additives (SCAs) and Engine Coolant Concen-

mance of engine coolants prepared from new or virgin ingredients that

trates

comply with Specification D7640.

D6130 Test Method for Determination of Silicon and Other

1.3 The coolants governed by this specification are catego-

Elements in Engine Coolant by Inductively Coupled

rized as follows:

Plasma-Atomic Emission Spectroscopy

Coolant Type Description

D7583 Test Method for John Deere Coolant Cavitation Test

V-FF Glycerin base concentrate

D7640 Specification for Engine Coolant Grade Glycerin

VI-FF Glycerin predilute (50 vol %)

E29 Practice for Using Significant Digits in Test Data to

1.4 Coolant concentrates meeting this specification do not

Determine Conformance with Specifications

require addition of supplemental coolant additive (SCA) until

2.2 Other Standards:

thefirstmaintenanceintervalwhenamaintenancedoseofSCA

Federal Method 2540B Total Dissolved Solids Dried at 103

is required to continue protection in certain heavy duty engine

- 105°C

cooling systems, particularly those of the wet cylinder liner-

in-block design. The SCAadditions are defined by and are the

3. Terminology

primary responsibility of the engine manufacturer or vehicle

3.1 Definitions:

manufacturer. If they provide no instructions, follow the SCA

3.1.1 supplemental coolant additive (SCA), n—additive

supplier’s instructions.

used in conventionally inhibited heavy duty engine coolants

1.5 The values stated in SI units are to be regarded as

required to maintain protection against general corrosion,

standard. The values given in parentheses are for information

cylinder liner pitting, and scaling in heavy duty engines.

only.

3.1.2 glycerin base engine coolant , n—engine coolant in

1.6 This standard does not purport to address all of the

which the freeze point depressant is 1,2,3 propane triol, with

safety concerns, if any, associated with its use. It is the

inhibitors to minimize foaming and corrosion.

responsibility of the user of this standard to establish appro-

3.1.3 For other definitions and terms used in this specifica-

priate safety and health practices and determine the applica-

tion, refer to Terminology D4725.

bility of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ThisspecificationisunderthejurisdictionofASTMCommitteeD15onEngine contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Coolants and Related Fluids and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

D15.93 on Research and Long Range Planning. the ASTM website.

Current edition approved Nov. 1, 2011. Published December 2011. DOI: Standard Method for the Examination of Water and Wastewater, American

10.1520/D7715-11. Public Health Association, et al, 1015 15th Street, N.W. Washington, DC 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7715 – 11

4. General Requirements liquid cooled exhaust manifold. Test methods for cavitation

corrosion and hot surface scaling are under development by

4.1 Concentrated and prediluted coolants shall meet all of

ASTM Committee D15. Until these procedures are approved,

the physical, chemical and performance requirements of Speci-

the mandatory requirements of Annex A1 shall apply.

fication D7640, Tables 1, 2, and 3.

5.2 Lack of compatibility between the coolant and SCA

4.2 The coolant concentrate mixed with water or the predi-

product’s chemistry may cause the solute to precipitate out of

luted coolant, when maintained with maintenance doses of

solution, with potential adverse effects in the vehicle or engine

SCAin accordance with the engine manufacturer’s recommen-

cooling system. A test procedure for compatibility (Test

dations,andthoseontheproductlabel,shallbesuitableforuse

Method D5828) has been developed and approved. The com-

in a properly maintained cooling system in normal service for

patibility of SCA and coolant concentrate solutions meeting

a minimum of two years (see Appendix X1).

this specification shall be determined using (Test Method

D5828) and the results reported.

5. Additional Requirements

5.3 Both the concentrated and prediluted coolants shall

5.1 The coolant concentrate or prediluted coolant addition-

contain less than 50 µg/g sulfate ion.

ally shall provide protection in operating engines against

6. Keywords

cavitation corrosion (also termed liner pitting) and against

scaling of internal engine hot surfaces. Hot surfaces typically 6.1 cavitation; fully-formulated heavy-duty engine coolant;

arewithintheenginehead,headspacer,uppercylinderliner,or glycerin; supplemental coolant additive maintenance dose

ANNEX

(Mandatory Information)

A1. REQUIREMENTS FOR FULLY FORMULATED HEAVY DUTY ENGINE COOLANT

A1.1 Laboratory data or in-service experience demonstrat- A1.1.2 Coolants that have completed Test Method D7583

ing a positive influence on reducing cavitation corrosion in an with a maximum pit count of 200 are regarded as passing the

operating engine is required (see Table A1.1). requirements of Annex A1.

A1.1.3 Several chemical compositions have been tested

A1.1.1 In-service qualification tests may consist of single-

extensively by producers and users and satisfactorily minimize

or multiple-cylinder engine tests.At the option of the engine or

cylinder liner cavitation in actual test engines. Coolants meet-

vehicle manufacturer, such testing may be conducted in “loose

ing either of the following compositions are regarded as

engines”orinenginesfullyintegratedintoanapplication,such

passing the requirements of Annex A1:

as a vehicle, a power boat, or a stationary power source. One

–

A1.1.3.1 A minimum concentration of nitrite (as NO )of

such test has been developed.

1200 µg/g (ppm) in the 50 volume % predilute coolant, or

A1.1.3.2 A minimum combined concentration of nitrite (as

– –2

NO ) plus molybdate (as MoO in the 50 volume %

2 4

predilute coolant of 780 µg/g (ppm). At least 300 µg/g (ppm)

“A Comparison of Engine Coolant in an Accelerated Heavy-Duty Engine

– –2

Cavitation Test,” SAE Technical Paper 960883, SAE International, 400 Common- each of NO and MoO must be present.

2 4

wealth Drive, Warrendale, PA 15096–0001.

TABLE A1.1 Cavitation Protection Options Meeting the Requirements of Annex A1

Utilize One of Predilute or Acceptance

the Following Concentrate Criteria

In-service test Per agreement Agreement between engine manufacturer and coolant supplier for

test criteria

Laboratory test (Test Method D7583) Per tested formulation 200 pit count measured per Test Method D7583 , max

–

Chemical composition nitrite formulation Predilute Nnitrite (as NO ) of 1200 µg/g (ppm), min

–

Nitrite formulation Concentrate Nitrite (as NO )of

2400 µg/g (ppm) , min

–

Combined nitrite and molybdate formulation Predilute Combined concentration of nitrite (as NO ) plus molybdate as

–2

(MoO ) of 780 µg/g (ppm), min (at least 300 µg/g (ppm) each of

– –2

NO and MoO must be present)

2 4

–

Combined nitrite and molybdate formulation Concentrate Combined concentration of nitrite (as NO ) plus molybdate (as

–2

MoO ) of 1560 µg/g (ppm), min (at least 600 µg/g (ppm) each of

– –2

NO and MoO must be present)

2 4

D7715 – 11

A1.1.3.3 The above concentrations are doubled for coolant types) minimize the deposition of calcium and magnesium

concentrates. compounds on heat rejecting surfaces. No specific chemical

requirements for hot surface scaling and deposits resistance

A1.2 Both concentrated and prediluted coolants under this have been established at this time. A test procedure is under

specification shall contain additives to minimize hot surface development by ASTM Committee D15 and will be incorpo-

scaling deposits. Certain additives (polyacrylate and other rated into the specification when approved.

APPENDIXES

(Nonmandatory Information)

X1. COOLANT MAINTENANCE FOR HEAVY DUTY ENGINES

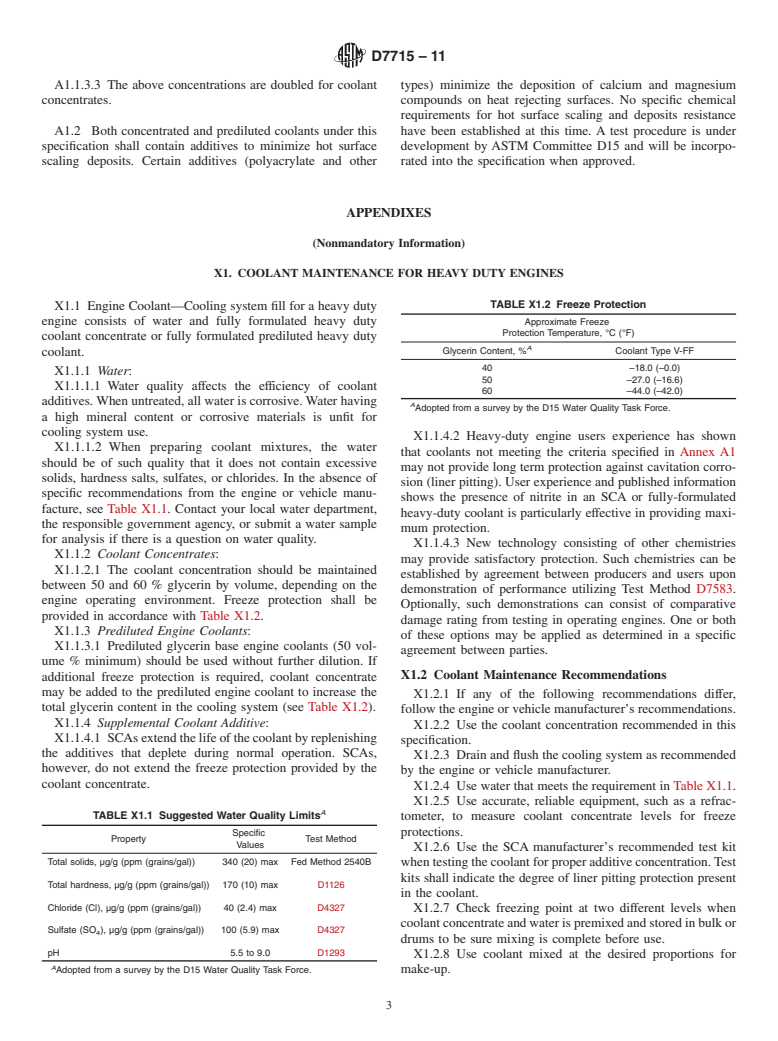

TABLE X1.2 Freeze Protection

X1.1 Engine Coolant—Cooling system fill for a heavy duty

engine consists of water and fully formulated heavy duty Approximate Freeze

Protection Temperature, °C (°F)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.