ASTM D820-93(2003)

(Test Method)Standard Test Methods for Chemical Analysis of Soaps Containing Synthetic Detergents

Standard Test Methods for Chemical Analysis of Soaps Containing Synthetic Detergents

ABSTRACT

These test methods detail the standard procedures for the chemical analysis of soaps containing synthetic detergents. The analytical procedures include the determination of the following chemical properties and substances: moisture and other matter volatile at a specified temperature; free alkali or free acid; anhydrous, salt-free soda soap; alcohol-soluble matter; matter insoluble in water; total alkalinity of matter insoluble in alcohol (alkaline salts); sodium silicate; phosphates; phosphates by colorimetric method using molybdenum blue); unsaponified and unsaponifiable matter; free fatty matter; chlorides in alcohol-soluble matter; rosin by McNicoll method; synthetic detergent by difference; and neutral inorganic salts.

SCOPE

1.1 These test methods cover procedures for the chemical analysis of soaps containing synthetic detergents.

1.2 The analytical procedures appear in the following order:

SectionsMoisture and Other Matter Volatile at 105°C (Oven Method)5 and 6Free Alkali or Free Acid7 and 8Anhydrous, Salt-Free, Soda Soap9-12Alcohol-Soluble Matter13 and 14Matter Insoluble in Water15Total Alkalinity of Matter Insoluble in Alcohol (Alkaline Salts)16 and 17Sodium Silicate18-20Phosphates21-28Phosphate (Colorimetric Method Using Molybdenum Blue)29-34Unsaponified and Unsaponifiable Matter35-39Free Fatty Matter40Chlorides in Alcohol-Soluble Matter41-43Rosin (McNicoll Method)44-47Synthetic Detergent (by Difference)48Neutral, Inorganic Salts49

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D820–93(Reapproved 2003)

Standard Test Methods for

Chemical Analysis of Soaps Containing Synthetic

Detergents

This standard is issued under the fixed designation D820; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1193 Specification for Reagent Water

D1768 Test Method for SodiumAlkylbenzene Sulfonate in

1.1 These test methods cover procedures for the chemical

Synthetic Detergents by Ultraviolet Absorption

analysis of soaps containing synthetic detergents.

D2357 for Qualitative Classification of Surfactants by In-

1.2 Theanalyticalproceduresappearinthefollowingorder:

frared Absorption

Sections

D2358 Test Method for Separation of Active Ingredient

Moisture and Other Matter Volatile at 105°C (Oven Method) 5 and 6

from Surfactant and Syndet Compositions

Free Alkali or Free Acid 7 and 8

D3049 Test Method for Synthetic Anionic Ingredient by

Anhydrous, Salt-Free, Soda Soap 9-12

Cationic Titration

Alcohol-Soluble Matter 13 and 14

Matter Insoluble in Water 15

Total Alkalinity of Matter Insoluble in Alcohol (Alkaline Salts) 16 and 17

3. Terminology

Sodium Silicate 18-20

3.1 Definitions:

Phosphates 21-28

Phosphate (Colorimetric Method Using Molybdenum Blue) 29-34

3.2 The term synthetic detergent in these test methods is

Unsaponified and Unsaponifiable Matter 35-39

defined in accordance with Terminology D459, as follows:

Free Fatty Matter 40

3.3 synthetic detergent—a detergent produced by chemical

Chlorides in Alcohol-Soluble Matter 41-43

Rosin (McNicoll Method) 44-47

synthesis and comprising an organic composition other than

Synthetic Detergent (by Difference) 48

soap.

Neutral, Inorganic Salts 49

3.4 Fordefinitionsofothertermsusedinthesetestmethods,

1.3 This standard does not purport to address all of the

refer to Terminology D459.

safety problems, if any, associated with its use. It is the

4. Purity of Reagents and Materials

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.1 Purity of Reagents—Reagent grade chemicals shall be

bility of regulatory limitations prior to use.

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit-

2. Referenced Documents

tee onAnalytical Reagents of theAmerican Chemical Society,

2.1 ASTM Standards: 6

where such specifications are available. Other grades may be

2 3

D216 Method for Distillation of Natural Gasoline

used, provided it is first ascertained that the reagent is of

D459 Terminology Relating to Soaps and Other Detergents

sufficiently high purity to permit its use without lessening the

D875 Method for Calculation of Olefins and Aromatics in

accuracy of the determination.

Petroleum Distillates from Bromine Number and Acid

4.2 Unless otherwise indicated, references to water shall be

4 5

Absorption

understood to mean reagent water conforming to Specification

D1193.

These test methods are under the jurisdiction of ASTM Committee D12 on

Soaps and Other Detergents and are the direct responsibility of Subcommittee

D12.12 on Analysis of Soaps and Synthetic Detergents.

Current edition approved May 17, 1993. Published July 1993. Originally

published as D820–45. Last previous edition D820–91. DOI: 10.1520/D0820- Reagent Chemicals, American Chemical Society Specifications, American

93R03. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Discontinued, see 1987 Annual Book of ASTM Standards, Vol 05.01. listed by the American Chemical Society, see Analar Standards for Laboratory

Annual Book of ASTM Standards, Vol 15.04. Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Discontinued, see 1984 Annual Book of ASTM Standards, Vol 05.01. and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

Annual Book of ASTM Standards, Vol 11.01. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D820–93 (2003)

MOISTURE AND OTHER MATTER VOLATILE AT

105°C (OVEN METHOD)

5. Apparatus

5.1 Dish—A porcelain or glass dish about 6 to 8 cm in

diameter and about 2 to 4 cm in depth will be required.

6. Procedure

6.1 Weigh 5 6 0.01 g of the sample in the dish, and dry to

constant weight in an air oven at a temperature of 105 6 2°C.

Constant weight is attained when heating for successive 1-h

periods shows a loss (or gain) of not more than 0.1%.

NOTE 1—Because of its established use in the trade, the term weight is

employed in these methods in place of the technically correct term mass.

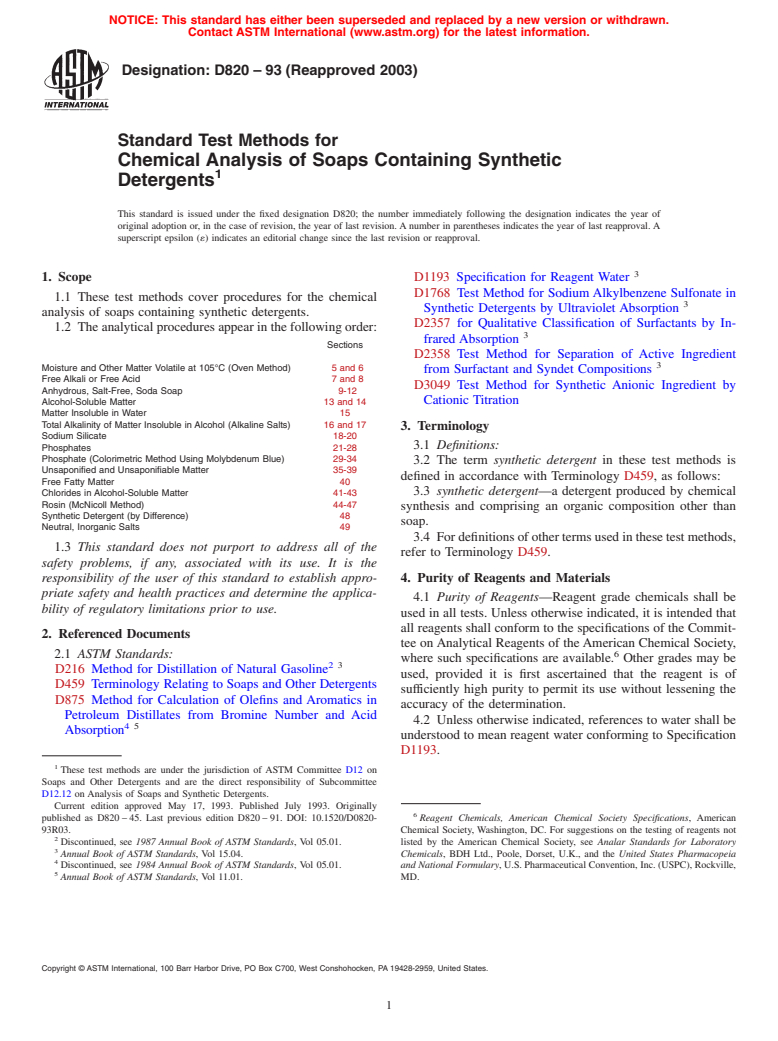

FIG. 1 Stokes Flask

FREE ALKALI OR FREE ACID

7. Reagents

7.1 Ethyl Alcohol, Neutral (95 %)—Freshly boiled, reagent

grade, ethyl alcohol, 95% or higher, neutral to phenolphtha-

lein, and containing only volatile denaturants, 95 mL, plus 5

mL of water.

7.2 Phenolphthalein Indicator Solution (10 g/litre)—

Dissolve1gof phenolphthalein in 50 mL of neutral ethyl

alcohol (95%) and mix with 50 mL of water (see 7.1).

8. Procedure

8.1 Weigh 5 to 10 6 0.01 g of the sample into a 300-mL

Erlenmeyer flask.Add 200 mLof neutral ethyl alcohol (95%).

Equip the flask with an air-cooled reflux condenser, and digest

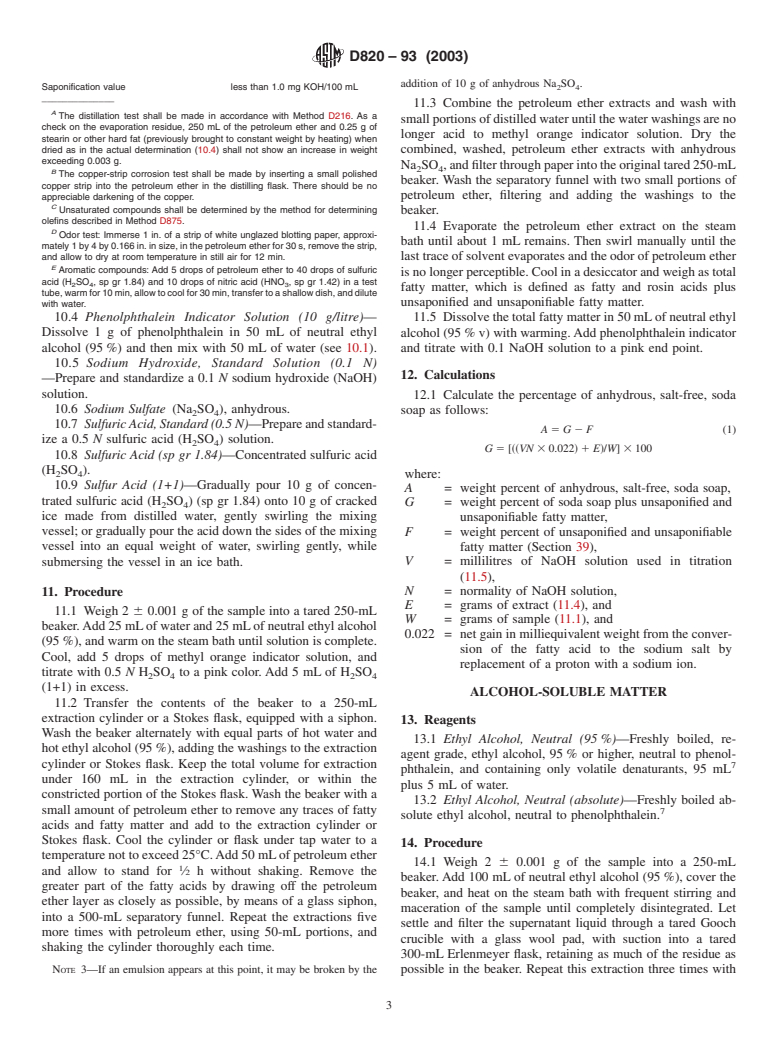

FIG. 2 Siphon

thesampleonasteambathuntilthesoapisdissolved(seeNote

2). Remove the condenser, add 0.5 mL of the phenolphthalein

10. Reagents

indicator solution, and titrate immediately with standard acid

10.1 Ethyl Alcohol, Neutral (95 %)—Freshly boiled, re-

or alkali. Calculate as NaOH, if alkaline, or as oleic acid, if

agent grade, ethyl alcohol, 95% or higher, neutral to phenol-

acid.

phthalein, and containing only volatile denaturants, 95 mL,

NOTE 2—In the analysis of soaps known to contain little or no alkaline

plus 5 mL of water.

salts, it is unnecessary to filter the hot alcoholic soap solution. However,

10.2 Methyl Orange Indicator Solution (1 g/litre)—

the filtration should be carried out in all cases where alkaline salts such as

Dissolve0.1gofmethylorangeinwateranddiluteto100mL.

silicates, phosphates, borates, and similar salts are present, since these are

10.3 Petroleum Ether—The solvent used shall be of the

knowntoaffectthefreealkalidetermination.Freealkalifiguresinsoapor

surfactant mixtures containing borax are unreliable, due to solubility of

pentane type, containing a minimum amount of isopentane,

borax in hot alcohol.

isohexane, and hexane, and boiling in the range 35 to 60°C.

ANHYDROUS, SALT-FREE, SODA SOAP

A

Distillation test:

Initial boiling point 35 to 38°C

Dry flask end point 52 to 60°C

9. Apparatus

Distilling under 54°C, min 95 %

9.1 Extraction Cylinder, 250-mL, graduated, glass-

Distilling under 40°C, max 60 %

Specific gravity at 15.5/15.5°C (60/60°F) 0.630 to 0.660

stoppered, about 39 mm (1 ⁄2 in.) in diameter and about 35.5

Color water-white

cm (14 in.) in length.

Doctor test sweet

9.2 Stokes Flask, 100-mL, round-bottom (with the bottom

Evaporation residue, 100 mL, max 0.0011 g

B

Copper-strip corrosion test noncorrosive

blownout),sealedontoa150-mLErlenmeyerflask.Adiagram

C

Unsaturated compounds trace only permitted

of the Stokes flask is shown in Fig. 1.

Residue in distilling flask neutral to methyl orange

D

9.3 Siphon, consisting of a two-hole rubber stopper fitted Blotter-strip odor test odorless within 12 min

E

Aromatic compounds no nitrobenzene odor

with small-diameter glass tubing as shown in Fig. 2.

J. T. Baker Analyzed Reagent 9268, or its equivalent, is suitable for this

Fischer Scientific A962, or its equivalent, is suitable for this purpose. purpose.

D820–93 (2003)

addition of 10 g of anhydrous Na SO .

Saponification value less than 1.0 mg KOH/100 mL 2 4

______________

11.3 Combine the petroleum ether extracts and wash with

A

The distillation test shall be made in accordance with Method D216.As a

smallportionsofdistilledwateruntilthewaterwashingsareno

check on the evaporation residue, 250 mL of the petroleum ether and 0.25 g of

longer acid to methyl orange indicator solution. Dry the

stearin or other hard fat (previously brought to constant weight by heating) when

dried as in the actual determination (10.4) shall not show an increase in weight

combined, washed, petroleum ether extracts with anhydrous

exceeding 0.003 g.

Na SO ,andfilterthroughpaperintotheoriginaltared250-mL

2 4

B

The copper-strip corrosion test shall be made by inserting a small polished

beaker. Wash the separatory funnel with two small portions of

copper strip into the petroleum ether in the distilling flask. There should be no

petroleum ether, filtering and adding the washings to the

appreciable darkening of the copper.

C

Unsaturated compounds shall be determined by the method for determining

beaker.

olefins described in Method D875.

11.4 Evaporate the petroleum ether extract on the steam

D

Odor test: Immerse 1 in. of a strip of white unglazed blotting paper, approxi-

bath until about 1 mL remains. Then swirl manually until the

mately 1 by 4 by 0.166 in. in size, in the petroleum ether for 30 s, remove the strip,

and allow to dry at room temperature in still air for 12 min. lasttraceofsolventevaporatesandtheodorofpetroleumether

E

Aromatic compounds: Add 5 drops of petroleum ether to 40 drops of sulfuric

isnolongerperceptible.Coolinadesiccatorandweighastotal

acid (H SO , sp gr 1.84) and 10 drops of nitric acid (HNO ,spgr1.42) inatest

2 4 3

fatty matter, which is defined as fatty and rosin acids plus

tube, warm for 10 min, allow to cool for 30 min, transfer to a shallow dish, and dilute

unsaponified and unsaponifiable fatty matter.

with water.

10.4 Phenolphthalein Indicator Solution (10 g/litre)— 11.5 Dissolvethetotalfattymatterin50mLofneutralethyl

Dissolve1gof phenolphthalein in 50 mL of neutral ethyl alcohol(95%v)withwarming.Addphenolphthaleinindicator

alcohol (95%) and then mix with 50 mL of water (see 10.1). and titrate with 0.1 NaOH solution to a pink end point.

10.5 Sodium Hydroxide, Standard Solution (0.1 N)

12. Calculations

—Prepare and standardize a 0.1 N sodium hydroxide (NaOH)

solution.

12.1 Calculate the percentage of anhydrous, salt-free, soda

10.6 Sodium Sulfate (Na SO ), anhydrous. soap as follows:

2 4

10.7 SulfuricAcid,Standard(0.5N)—Prepareandstandard-

A 5 G 2 F (1)

ize a 0.5 N sulfuric acid (H SO ) solution.

2 4

G 5[~~VN 30.022! 1 E!/W] 3100

10.8 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric acid

(H SO ).

2 4 where:

10.9 Sulfur Acid (1+1)—Gradually pour 10 g of concen-

A = weight percent of anhydrous, salt-free, soda soap,

trated sulfuric acid (H SO ) (sp gr 1.84) onto 10 g of cracked

G = weight percent of soda soap plus unsaponified and

2 4

ice made from distilled water, gently swirling the mixing

unsaponifiable fatty matter,

vessel; or gradually pour the acid down the sides of the mixing

F = weight percent of unsaponified and unsaponifiable

vessel into an equal weight of water, swirling gently, while fatty matter (Section 39),

submersing the vessel in an ice bath. V = millilitres of NaOH solution used in titration

(11.5),

N = normality of NaOH solution,

11. Procedure

E = grams of extract (11.4), and

11.1 Weigh 2 6 0.001 g of the sample into a tared 250-mL

W = grams of sample (11.1), and

beaker.Add25mLofwaterand25mLofneutralethylalcohol

0.022 = netgaininmilliequivalentweightfromtheconver-

(95%), and warm on the steam bath until solution is complete.

sion of the fatty acid to the sodium salt by

Cool, add 5 drops of methyl orange indicator solution, and

replacement of a proton with a sodium ion.

titrate with 0.5 N H SO to a pink color. Add 5 mL of H SO

2 4 2 4

(1+1) in excess.

ALCOHOL-SOLUBLE MATTER

11.2 Transfer the contents of the beaker to a 250-mL

extraction cylinder or a Stokes flask, equipped with a siphon.

13. Reagents

Wash the beaker alternately with equal parts of hot water and

13.1 Ethyl Alcohol, Neutral (95 %)—Freshly boiled, re-

hot ethyl alcohol (95%), adding the washings to the extraction

agent grade, ethyl alcohol, 95% or higher, neutral to phenol-

cylinder or Stokes flask. Keep the total volume for extraction 7

phthalein, and containing only volatile denaturants, 95 mL

under 160 mL in the extraction cylinder, or within the

plus 5 mL of water.

constricted portion of the Stokes flask. Wash the beaker with a

13.2 Ethyl Alcohol, Neutral (absolute)—Freshly boiled ab-

small amount of petroleum ether to remove any traces of fatty

solute ethyl alcohol, neutral to phenolphthalein.

acids and fatty matter and add to the extraction cylinder or

Stokes flask. Cool the cylinder or flask under tap water to a

14. Procedure

temperaturenottoexceed25°C.Add50mLofpetroleumether

14.1 Weigh 2 6 0.001 g of the sample into a 250-mL

and allow to stand for ⁄2 h without shaking. Remove the

beaker.Add 100 mLof neutral ethyl alcohol (95%), cover the

greater part of the fatty acids by drawing off the petroleum

beaker, and heat on the steam bath with frequent stirring and

ether layer as closely as possible, by means of a glass siphon,

maceration of the sample until completely disintegrated. Let

into a 500-mL separatory funnel. Repeat the extractions five

settle and filter the supernatant liquid through a tared Gooch

more times with petroleum ether, using 50-mL portions, and

crucible with a glass wool pad, with suction into a tared

shaking the cylinder thoroughly each time.

300-mL Erlenmeyer flask, retaining as much of the residue as

NOTE 3—If an emulsion appears at this point, it may be broken by the possible in the beaker. Repeat this extraction three times with

D820–93 (2003)

25-mL portions of hot neutral ethyl alcohol (95%), each time 18.2 Hydrofluoric Acid (sp gr 1.15)—Prepare a solution of

retaining as much of the residue as possible in the beaker. hydrofluoric acid (HF) having a specific gravity of 1.15.

Finally, evaporate any remaining alcohol and dissolve the 18.3 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric acid

residue in the smallest possible quantity of hot water (5 mL if (H SO ).

2 4

sufficient). Reprecipitate the alcohol-insoluble matter by

19. Procedure

slowlyadding,whilestirringvigorously,50mLofneutralethyl

alcohol (absolute). 19.1 When the material contains no mineral matter that is

insolubleinwater,igniteaportionofthesamplecontainingnot

NOTE 4—Solution and reprecipitation of alcohol-insoluble matter is

to exceed 0.2 g of silica (SiO ) in a platinum dish (Note 5)at

necessary for complete separation from alcohol-soluble matter.

alowtemperature.Whencharred,extractthesolublesaltswith

14.2 Heat the solution to boiling on the steam bath, filt

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.