ASTM E133-92(2016)

(Specification)Standard Specification for Distillation Equipment

Standard Specification for Distillation Equipment

ABSTRACT

This specification covers distillation equipment. The equipment shall consist of the following: distillation flasks, condenser, cooling bath, metal shield or enclosure for flask (type 1 or type 2), heat source (gas burner or electric heater), flask support (type 1 or type 2), graduated cylinders, and thermometers.

SCOPE

1.1 This specification covers distillation equipment used in the following ASTM test methods: D86, D850, and (for approved alternative requirements only) Test Method D1078.

1.2 Some items of equipment included in this specification are common to all methods; other items are not. Therefore, those portions of this specification pertinent to the need must be selected.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E133 −92 (Reapproved 2016)

Standard Specification for

1

Distillation Equipment

This standard is issued under the fixed designation E133; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 4. Distillation Flasks

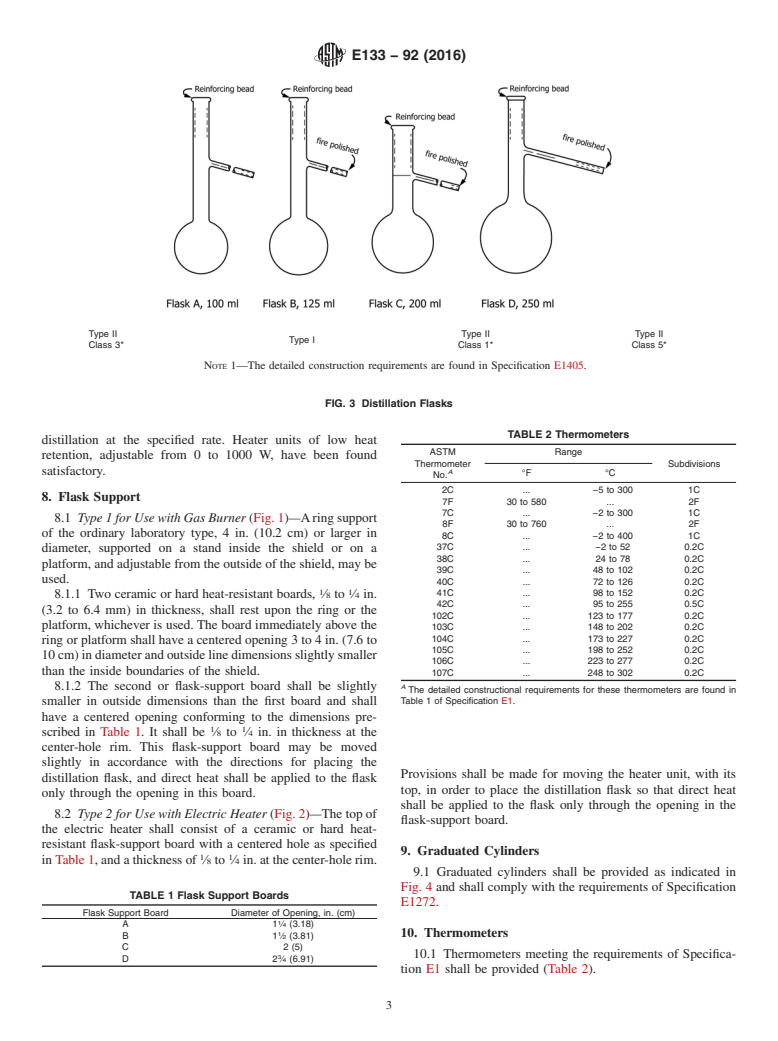

4.1 Flasks of heat-resistant glass shall be provided as

1.1 This specification covers distillation equipment used in

indicated in Fig. 3 and shall comply with the requirements of

the following ASTM test methods: D86, D850, and (for

Specification E1405.

approved alternative requirements only) Test Method D1078.

1.2 Some items of equipment included in this specification

5. Condenser and Cooling Bath

are common to all methods; other items are not. Therefore,

5.1 Typical approved types of condenser and cooling bath

those portions of this specification pertinent to the need must

are included in Fig. 1 and Fig. 2. These items are common to

be selected.

all methods covered by this specification.

1.3 The values stated in inch-pound units are to be regarded

5.2 The condenser shall be made of seamless brass tubing,

9

as standard. The values given in parentheses are mathematical

22 in. (55.88 cm) in length. It shall be ⁄16 in. (14.29 mm) in

conversions to SI units that are provided for information only outside diameter, and shall have a wall thickness of 0.031 to

and are not considered standard. 0.036 in. (0.08 to 0.09 cm).

5.3 Thecondensershallbesetsothatapproximately15.5in.

2. Referenced Documents

(39.4 cm) of the tube will be in contact with the cooling

2

medium, with about 2 in. (5 cm) outside the cooling bath at the

2.1 ASTM Standards:

1

upper end, and about 4 ⁄2 in. (11 cm) outside at the lower end.

D86 Test Method for Distillation of Petroleum Products and

The length of tube projecting at the upper end shall be straight

Liquid Fuels at Atmospheric Pressure

and shall be set at an angle of 75° with the vertical.The section

D850 Test Method for Distillation of Industrial Aromatic

of the tube inside the cooling bath may be either straight or

Hydrocarbons and Related Materials

bent in any suitable continuous, smooth curve. The average

D1078 Test Method for Distillation Range of Volatile Or-

gradient shall be 0.26 in. (0.66 cm)/linear in. (2.54 cm) of

ganic Liquids

condenser tube (sine of angle of 15°), and no section of the

E1 Specification for ASTM Liquid-in-Glass Thermometers

immersed portion of the condenser tube shall have a gradient

E1272 Specification for Laboratory Glass Graduated Cylin-

less than 0.24 in. (0.61 cm) nor more than 0.28 in. (0.71 cm-

ders

)⁄linear in. of tube. The projecting lower portion of the

E1405 Specification for Laboratory Glass Distillation Flasks

condenser tube shall be curved downward for a length of 3 in.

(7.62 cm) and slightly backward so as to ensure contact with

3. Apparatus Assembly

the wall of the receiving graduate at a point approximately 1 to

1

1 ⁄4 in. (2.54 to 3.18 cm) below the top of the graduate when it

3.1 Typical assemblies of the apparatus are shown in Fig. 1

is in position to receive the distillate. The lower end of the

and Fig. 2.

condenser tube shall be cut off at an acute angle so that the tip

may be brought into contact with the wall of the cylinder.

5.4 The capacity of the cooling bath shall be not less than

1

This specification is under the jurisdiction of ASTM Committee E41 on

3

340 in. (5.55 L) of cooling medium. The arrangement of the

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

Laboratory Ware and Supplies.

tube in the cooling bath shall be such that its center line shall

Current edition approved Sept. 1, 2016. Published September 2016. Originally

1

be not less than 1 ⁄4 in. (3.18 cm) below the plane of the top of

approved in 1958. Last previous edition approved in 2010 as E133 – 92 (2010).

3

the bath at its point of entrance and not less than ⁄4 in. (1.91

DOI: 10.1520/E0133-92R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or cm) above the floor of the bath at its exit.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.5 Clearances between the condenser tube and the walls of

Standards volume information, refer to the standard’s Document Summary page on

1

the ASTM website. the bath shall be at least ⁄2 in. (1.27 cm) except for the sections

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E133−92 (2016)

FIG. 1 Apparatus Assembly Using Ga

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E133 − 92 (Reapproved 2010) E133 − 92 (Reapproved 2016)

Standard Specification for

1

Distillation Equipment

This standard is issued under the fixed designation E133; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers distillation equipment used in the following ASTM test methods: D86, D850, and (for approved

alternative requirements only) Test Method D1078.

1.2 Some items of equipment included in this specification are common to all methods; other items are not. Therefore, those

portions of this specification pertinent to the need must be selected.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D86 Test Method for Distillation of Petroleum Products and Liquid Fuels at Atmospheric Pressure

D850 Test Method for Distillation of Industrial Aromatic Hydrocarbons and Related Materials

D1078 Test Method for Distillation Range of Volatile Organic Liquids

E1 Specification for ASTM Liquid-in-Glass Thermometers

E1272 Specification for Laboratory Glass Graduated Cylinders

E1405 Specification for Laboratory Glass Distillation Flasks

3. Apparatus Assembly

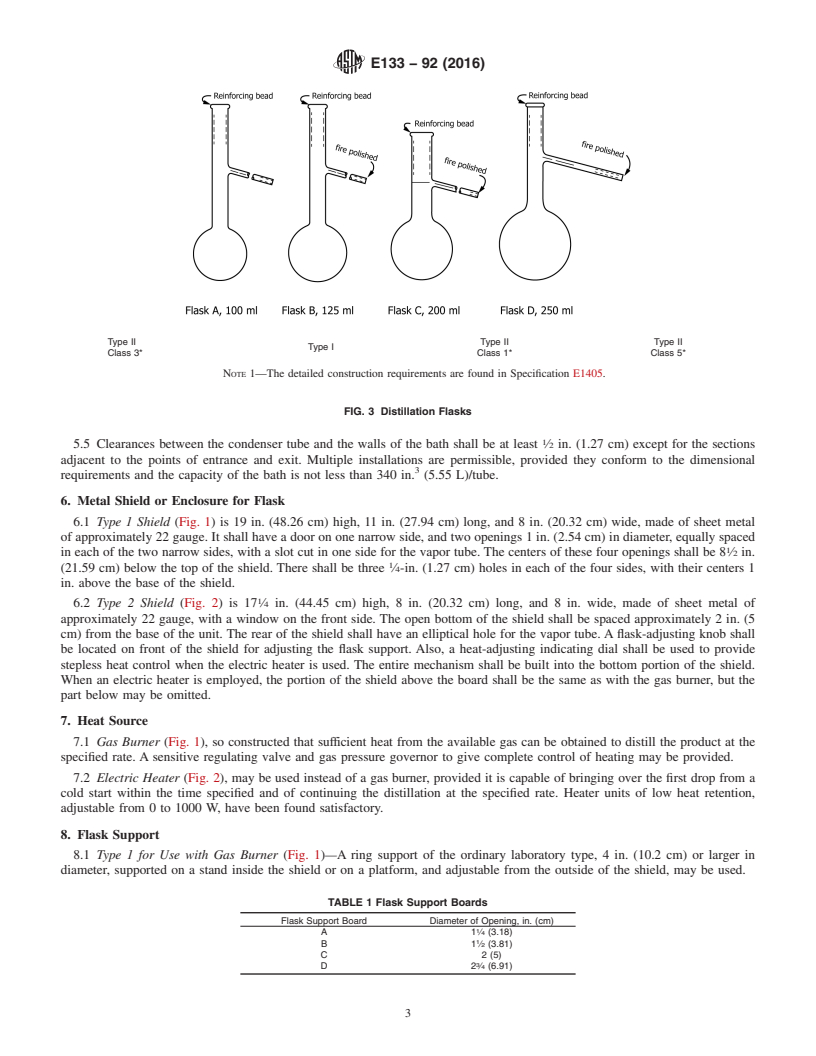

3.1 Typical assemblies of the apparatus are shown in Fig. 1 and Fig. 2.

4. Distillation Flasks

4.1 Flasks of heat-resistant glass shall be provided as indicated in Fig. 3 and shall comply with the requirements of Specification

E1405.

5. Condenser and Cooling Bath

5.1 Typical approved types of condenser and cooling bath are included in Fig. 1 and Fig. 2. These items are common to all

methods covered by this specification.

9

5.2 The condenser shall be made of seamless brass tubing, 22 in. (55.88 cm) in length. It shall be ⁄16 in. (14.29 mm) in outside

diameter, and shall have a wall thickness of 0.031 to 0.036 in. (0.08 to 0.09 cm).

5.3 The condenser shall be set so that approximately 15.5 in. (39.4 cm) of the tube will be in contact with the cooling medium,

1

with about 2 in. (5 cm) outside the cooling bath at the upper end, and about 4 ⁄2 in. (11 cm) outside at the lower end. The length

of tube projecting at the upper end shall be straight and shall be set at an angle of 75° with the vertical. The section of the tube

inside the cooling bath may be either straight or bent in any suitable continuous, smooth curve. The average gradient shall be 0.26

in. (0.66 cm)/linear in. (2.54 cm) of condenser tube (sine of angle of 15°), and no section of the immersed portion of the condenser

tube shall have a gradient less than 0.24 in. (0.61 cm) nor more than 0.28 in. (0.71 cm) ⁄linear in. of tube. The projecting lower

1

This specification is under the jurisdiction of ASTM Committee E41 on Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

ApparatusLaboratory Ware and Supplies.

Current edition approved July 1, 2010Sept. 1, 2016. Published July 2010September 2016. Originally approved in 1958. Last previous edition approved in 20052010 as

E133 – 92 (2005).(2010). DOI: 10.1520/E0133-92R10.10.1520/E0133-92R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E133 − 92 (2016)

FIG. 1 Apparatus Assembly Using Gas Burner

FIG. 2 Apparatus Assembly Using Electric Heater

portion of the condenser tube shall be curved downward for a length of 3 in. (7.62 cm) and slightly backward so as to ensure contact

1

with the wall of the receiving graduate at a point approximately 1 to 1 ⁄4 in. (2.54 to 3.18 cm) below the top of the graduate when

it is in position to receive the distillate. The lower end of the condenser tube shall be cut off at an acute angle so that the tip may

be brought into contact with the wall of the cylinder.

3

5.4 The capacity of the cooling bath shall be not less than

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.