ASTM E2223-12

(Practice)Standard Practice for Examination of Seamless, Gas-Filled, Steel Pressure Vessels Using Angle Beam Ultrasonics

Standard Practice for Examination of Seamless, Gas-Filled, Steel Pressure Vessels Using Angle Beam Ultrasonics

SIGNIFICANCE AND USE

5.1 The purpose of this practice is to provide a procedure for locating, detecting and estimating the relevance of longitudinally oriented crack-like discontinuities which have been previously indicated by AE examination.

5.2 This practice may be used for a pressure vessel that is situated in such a way as to limit access to the vessel's wall. Typical examples include tube trailers and gas tube railroad cars. Since the pressure vessels are stacked horizontally in a frame, with limited space between them, the circumferential location of a discontinuity may be a distance away from the search unit (several skip distances).

5.3 This practice has been shown to be effective for cylinders between 9 in. (229 mm) and 24 in. (610 mm) in diameter and wall thicknesses between 1/4 in. (6.4 mm) to 1 in. (26 mm) with discontinuities that are oriented longitudinally in pressure vessel sidewall.

5.4 To reliably detect discontinuities by the procedure in this practice, a significant part of the reflecting surface must be transverse to the beam direction.

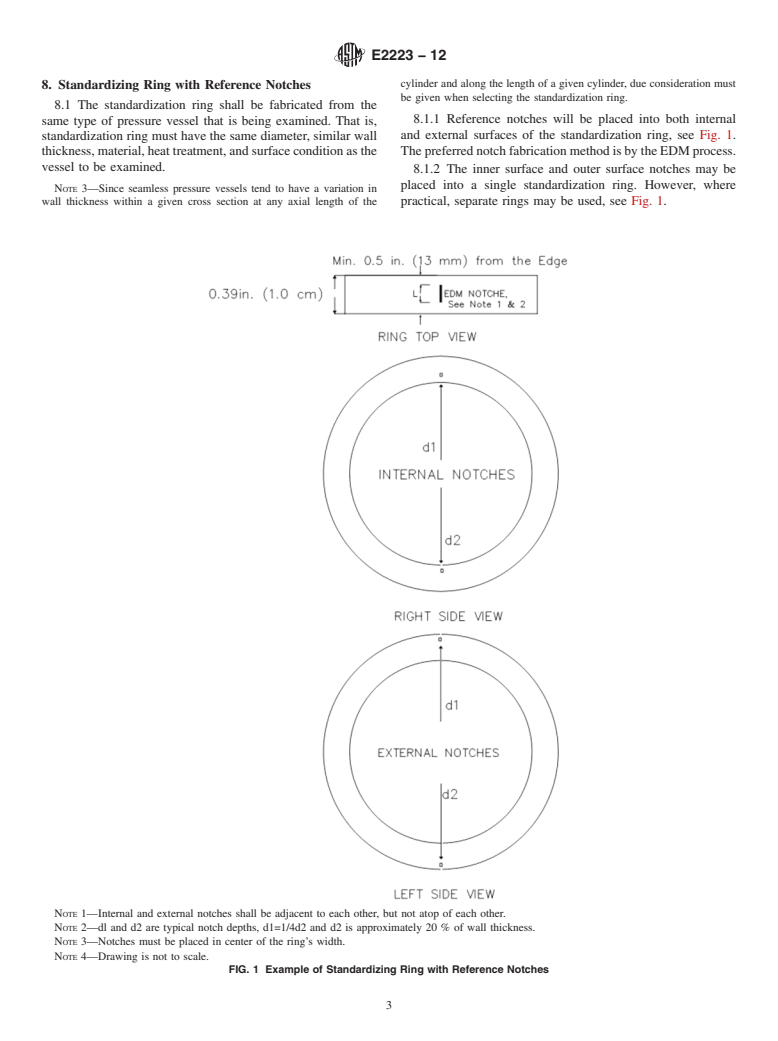

5.5 Evaluation of possible discontinuity in the end faces indicated by AE is not covered by this practice.

SCOPE

1.1 This practice describes a contact angle-beam shear wave ultrasonic technique to detect and locate the circumferential position of longitudinally oriented discontinuities and to compare the amplitude of the indication from such discontinuities to that of a specified reference notch. This practice does not address examination of the vessel ends. The basic principles of contact angle-beam examination can be found in Practice E587. Application to pipe and tubing, including the use of notches for standardization, is described in Practice E213.

1.2 This practice is appropriate for the ultrasonic examination of cylindrical sections of gas-filled, seamless, steel pressure vessels such as those used for the storage and transportation of pressurized gasses. It is applicable to both isolated vessels and those in assemblies.

1.3 The practice is intended to be used following an Acoustic Emission (AE) examination of stacked seamless gaseous pressure vessels (with limited surface scanning area) described in Test Method E1419.

1.4 This practice does not establish acceptance criteria. These are determined by the reference notch dimensions, which must be specified by the using parties.Note 1—Background information relating to the technical requirements of this practice can be found in the references sited in Test Method E1419, Appendix X1.

1.5 Dimensional values stated in in-pound units are regarded as standard; SI equivalents, in parentheses may be approximate.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2223 − 12

StandardPractice for

Examination of Seamless, Gas-Filled, Steel Pressure

1

Vessels Using Angle Beam Ultrasonics

This standard is issued under the fixed designation E2223; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 Thispracticedescribesacontactangle-beamshearwave

E213 Practice for Ultrasonic Testing of Metal Pipe and

ultrasonic technique to detect and locate the circumferential

Tubing

position of longitudinally oriented discontinuities and to com-

E543 Specification forAgencies Performing Nondestructive

pare the amplitude of the indication from such discontinuities

Testing

to that of a specified reference notch. This practice does not

E587 Practice for Ultrasonic Angle-Beam Contact Testing

address examination of the vessel ends. The basic principles of

E1316 Terminology for Nondestructive Examinations

contact angle-beam examination can be found in Practice

E1419 Practice for Examination of Seamless, Gas-Filled,

E587. Application to pipe and tubing, including the use of

Pressure Vessels Using Acoustic Emission

notches for standardization, is described in Practice E213.

E2192 Guide for Planar Flaw Height Sizing by Ultrasonics

1.2 This practice is appropriate for the ultrasonic examina- 3

2.2 ASNT Documents:

tion of cylindrical sections of gas-filled, seamless, steel pres-

Recommended Practice SNT-TC-1A for Personnel Qualifi-

sure vessels such as those used for the storage and transporta-

cation and Certification

tion of pressurized gasses. It is applicable to both isolated

ANSI/ASNT-CP-189 Standard for Qualification and Certifi-

vessels and those in assemblies.

cation of Nondestructive Testing Personnel

1.3 The practice is intended to be used following an 2.3 AIA Document:

Acoustic Emission (AE) examination of stacked seamless NAS-410 Nondestructive Testing Personnel Qualification

4

gaseous pressure vessels (with limited surface scanning area) and Certification

described in Test Method E1419.

3. Terminology

1.4 This practice does not establish acceptance criteria.

3.1 Terminology relating to this practice for angle-beam

These are determined by the reference notch dimensions,

shear wave ultrasonic examination is defined in Terminology

which must be specified by the using parties.

E1316.

NOTE 1—Background information relating to the technical require-

ments of this practice can be found in the references sited in Test Method

4. Summary of Methodology

E1419, Appendix X1.

4.1 An ultrasonic pulse-echo contact angle-beam, shear

1.5 Dimensional values stated in in-pound units are re-

wave technique with the beam directed circumferentially is

garded as standard; SI equivalents, in parentheses may be

used to locate surface breaking discontinuities in the cylindri-

approximate.

cal wall of a pressure vessel. The amplitude of the reflected

1.6 This standard does not purport to address all of the

signal from the discontinuity is compared to that of a known

safety concerns, if any, associated with its use. It is the

reference notch. Scanning is performed in both clockwise and

responsibility of the user of this standard to establish appro-

counter clockwise directions to detect and confirm the position

priate safety and health practices and determine the applica-

of the discontinuity identified in the AE examination report.

bility of regulatory limitations prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde- Standards volume information, refer to the standard’s Document Summary page on

structive Testing and are the direct responsibility of Subcommittee E07.06 on the ASTM website.

3

Ultrasonic Method. Available from the American Society for Nondestructive Testing, 1711 Arlin-

Current edition approved Nov. 1, 2012. Published November 2012. Originally gate Lane, P.O. Box 28518, Columbus, OH 43228-0518.

4

approved in 2002. Last previous edition approved in 2007 as E2223 - 07. DOI: Available from Aerospace Industries Association of America, Inc., 1250 Eye

10.1520/E2223-12. St., NW, Washington, DC 20005.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2223 − 12

5. Significance and Use 6.4.1 Reporting criteria for the examination results shall be

inaccordancewithSection 11unles

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2223 − 07 E2223 − 12

Standard Practice for

Examination of Seamless, Gas-Filled, Steel Pressure

1

Vessels Using Angle Beam Ultrasonics

This standard is issued under the fixed designation E2223; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice describes a contact angle-beam shear wave ultrasonic technique to detect and locate the circumferential

position of longitudinally oriented discontinuities and to compare the amplitude of the indication from such discontinuities to that

of a specified reference notch. This practice does not address examination of the vessel ends. The basic principles of contact

angle-beam examination can be found in Practice E587. Application to pipe and tubing, including the use of notches for

standardization, is described in Practice E213.

1.2 This practice is appropriate for the ultrasonic examination of cylindrical sections of gas-filled, seamless, steel pressure

vessels such as those used for the storage and transportation of pressurized gasses. It is applicable to both isolated vessels and those

in assemblies.

1.3 The practice is intended to be used following an Acoustic Emission (AE) examination of stacked seamless gaseous pressure

vessels (with limited surface scanning area) described in Test Method E1419.

1.4 This practice does not establish acceptance criteria. These are determined by the reference notch dimensions, which must

be specified by the using parties.

NOTE 1—Background information relating to the technical requirements of this practice can be found in the references sited in Test Method E1419,

Appendix X1.

1.5 Dimensional values stated in in-pound units are regarded as standard; SI equivalents, in parentheses may be approximate.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E213 Practice for Ultrasonic Testing of Metal Pipe and Tubing

E543 Specification for Agencies Performing Nondestructive Testing

E587 Practice for Ultrasonic Angle-Beam Contact Testing

E1316 Terminology for Nondestructive Examinations

E1419 Practice for Examination of Seamless, Gas-Filled, Pressure Vessels Using Acoustic Emission

E2192 Guide for Planar Flaw Height Sizing by Ultrasonics

3

2.2 ASNT Documents:

Recommended Practice SNT-TC-1A for Personnel Qualification and Certification

ANSI/ASNT-CP-189 Standard for Qualification and Certification of Nondestructive Testing Personnel

2.3 AIA Document:

4

NAS-410 Nondestructive Testing Personnel Qualification and Certification

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and are the direct responsibility of Subcommittee E07.06 on Ultrasonic

Method.

Current edition approved Dec. 1, 2007Nov. 1, 2012. Published January 2008November 2012. Originally approved in 2002 . 2002. Last previous edition approved in

20022007 as E2223 - 02.E2223 - 07. DOI: 10.1520/E2223-07.10.1520/E2223-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from the American Society for Nondestructive Testing, 1711 Arlingate Lane, P.O. Box 28518, Columbus, OH 43228-0518.

4

Available from Aerospace Industries Association of America, Inc., 1250 Eye St., NW, Washington, DC 20005.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2223 − 12

3. Terminology

3.1 Terminology relating to this practice for angle-beam shear wave ultrasonic examination is defined in Terminology E1316.

4. Summary of Methodology

4.1 An ultrasonic pulse-echo contact angle-beam, shear wave technique with the beam directed circumferentially is used to

locate surface breaking discontinuities in the cylindrical wall of a pressure vessel. The amplitude of the reflected signal from the

disc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.