ASTM D3885-04

(Test Method)Standard Test Method for Abrasion Resistance of Textile Fabrics (Flexing and Abrasion Method)

Standard Test Method for Abrasion Resistance of Textile Fabrics (Flexing and Abrasion Method)

SCOPE

1.1 This test method covers the determination of the abrasion resistance of woven or nonwoven textile fabrics using the flexing and abrasion tester.

1.2 This test method applies to most woven and nonwoven fabrics providing they do not stretch excessively. It is not applicable to floor coverings.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. Within the text, the inch-pound units are shown in parentheses. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this test method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—For other test methods for abrasion resistance of textiles refer to Test Methods D 3884, D 3886, D 4157, D 4158, D 4966, and AATCC93.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3885–04

Standard Test Method for

Abrasion Resistance of Textile Fabrics (Flexing and

1

Abrasion Method)

This standard is issued under the fixed designation D 3885; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

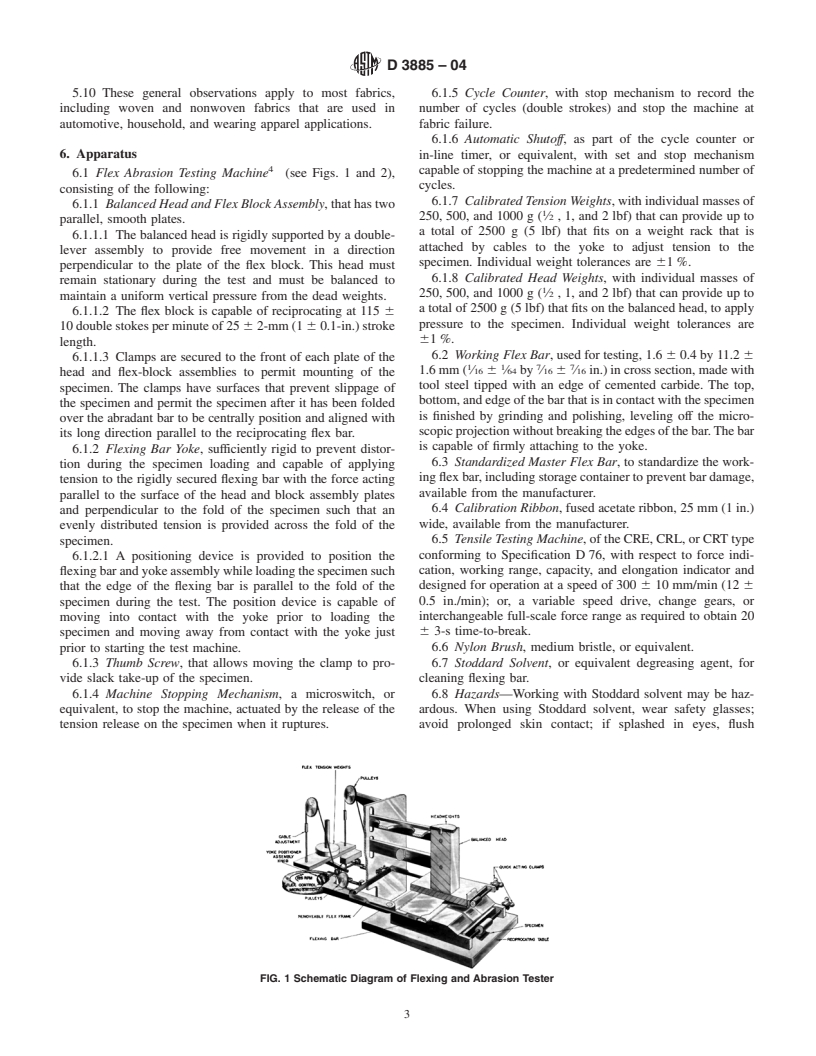

1. Scope D 3884 Test Method for Abrasion Resistance of Textile

2

Fabrics (Rotary Platform, Double-Head Method)

1.1 This test method covers the determination of the

D 3886 Test Method for Abrasion Resistance of Textile

abrasion resistance of woven or nonwoven textile fabrics using

Fabrics (Inflated Diaphragm Method)

the flexing and abrasion tester.

D 4157 Test Method for Abrasion Resistance of Textile

1.2 This test method applies to most woven and nonwoven

Fabrics (Oscillatory Cylinder Method)

fabrics providing they do not stretch excessively. It is not

D 4158 Test Method for Abrasion Resistance of Textile

applicable to floor coverings.

Fabrics (Uniform Abrasion Method)

1.3 The values stated in either SI units or inch-pound units

D 4966 Test Method for Abrasion Resistance of Textile

are to be regarded separately as the standard. Within the text,

Fabrics (Martindale Abrasion Tester Method)

the inch-pound units are shown in parentheses. The values

D 5035 Test Method for Breaking Strength and Elongation

stated in each system may not be exact equivalents; therefore,

of Textile Fabrics (Strip Method)

each system shall be used independently of the other. Combin-

2.2 AATCC Test Method:

ingvaluesfromthetwosystemsmayresultinnonconformance

AATCC 93 Abrasion Resistance of Fabrics: Accelerotor

with this test method.

4

Method

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions:

priate safety and health practices and determine the applica-

3.1.1 abrasion, n—the wearing away of any part of a

bility of regulatory limitations prior to use.

material by rubbing against another surface.

NOTE 1—For other test methods for abrasion resistance of textiles refer

3.1.2 abrasion cycle, n—onecompletemovementacrossthe

to Test Methods D 3884, D 3886, D 4157, D 4158, D 4966, and

surface of a textile.

AATCC93.

3.1.2.1 Discussion—The complete movement for an abra-

sion cycle is dependent on the action of the abrasion machine

2. Referenced Documents

and the test method used. It may consist of one back-and-forth

3

2.1 ASTM Standards:

unidirectional movement or one circular movement, or a

D 76 SpecificationforTensileTestingMachinesforTextiles

combination of both. For the flexing and abrasion method it is

D 123 Terminology Relating to Textiles

commonly called a double stroke as defined in 3.1.4.

D 1776 Practice for Conditioning Textiles for Testing

3.1.3 breaking force, n—the maximum force applied to a

D 2904 Practice for InterlaboratoryTesting of aTextileTest

material carried to rupture. (Compare breaking point, breaking

Method that Produces Normally Distributed Data

strength.)

D 2906 Practice for Statements on Precision and Bias for

3.1.4 double-stroke, n—in flexing and abrasion testing,an

Textiles

abrasion cycle that consists of one forward and one backward

motion.

3.1.5 flexibility, n—that property of a material by virtue of

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

which it may be flexed or bowed repeatedly without undergo-

and is the direct responsibility of Subcommittee D13.60 on Fabrics, Specific.

ing rupture.

Current edition approved Jan. 1, 2004. Published February 2004. Originally

3.1.6 standard atmosphere for preconditioning textiles,

approved in 1980. Last previous edition approved in 2002 as D 3885 – 02.

2

This test method is based upon the development described by Stoll, R.G.,“

n—asetofcontrolledconditionshavingatemperaturenotover

ImprovedMultipurposeAbrasionTesteranditsApplicationfortheEvaluationofthe

50°C (122°F), with respective tolerance of 61°C(2°F), and a

Wear Resistance of Textiles,” Textile Research Journal, July, 1949, p. 394.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standardsvolume information, refer to the standard’s Document Summary page on Available from the American Association of Textile Chemists and Colorists,

the ASTM website. P.O. Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3885–04

relative humidity of 5 to 25 6 2 % fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.