ASTM B429/B429M-06

(Specification)Standard Specification for Aluminum-Alloy Extruded Structural Pipe and Tube

Standard Specification for Aluminum-Alloy Extruded Structural Pipe and Tube

ABSTRACT

This specification covers UNS A96061 or A96063 aluminum alloy extruded pipes and tubes intended for use in structural applications. The structural pipes and tubes that may be produced through a bridge/porthole type die or other approved methods are not for use in fluid-carrying applications involving pressure. Both alloys may be extrusion press solution heat treated to produce the specified tempers. Each pipe or tube should be supplied with plain square-cut ends and mill finished unless otherwise specified. Samples for chemical analysis should be taken from the materials by drilling, sawing, turning, or clipping and subjected to suitable chemical or spectrochemical methods of analysis.

SCOPE

empers shown in , and in those standard sizes shown in , as well as in other nonstandard sizes as agreed upon between the purchaser and supplier. Such pipe and tube is intended for use in structural applications such as highway and bridge rails, chain-link fence posts, handrails, sign structures, awning supports, lighting brackets, etc. Structural pipe and tube is not intended for fluid-carrying applications involving pressure.Note 1

For drawn seamless tube used in pressure applications see Specifications B 210 and B 210M, for seamless pipe and seamless extruded tube used in pressure applications see Specifications B 241/B 241M, and for drawn tube and pipe for general purpose applications see Specification B 483/B 483M.

1.2 Alloy and temper designations are in accordance with ANSI H35.1. The equivalent Unified Numbering System alloy designations are those of preceded by A9, for example, A96061 for alloy 6061 in accordance with Practice E 527.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see .

1.4 UnitsThe values stated in either inch-pound units or SI units are to be regarded separately as standard. SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the specification.

1.4.1 While this standard is a combined SI and inch-pound standard, standard pipe sizes are not applicable to SI units, therefore non-rationalized SI units (soft conversions) are shown for reader convenience. Rationalized [hard converted] SI units are shown in brackets while non-rationalized (soft converted) SI units are shown in parentheses.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B429/B429M – 06

Standard Specification for

1

Aluminum-Alloy Extruded Structural Pipe and Tube

This standard is issued under the fixed designation B429/B429M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This specification covers aluminum-alloy pipe and ex-

bility of regulatory limitations prior to use.

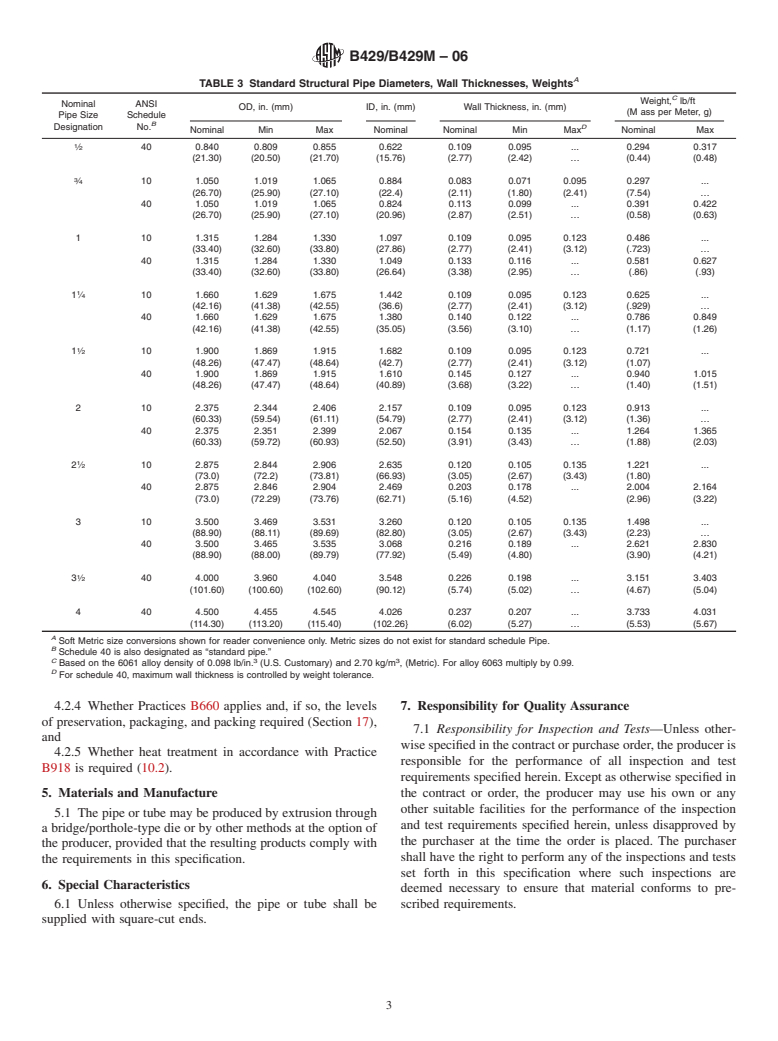

truded tube in those selected alloys shown in Table 1 and

tempers shown inTable 2, and in those standard sizes shown in

2. Referenced Documents

Tables 3 and 4, as well as in other nonstandard sizes as agreed

2.1 The following documents of the date of issue in effect

uponbetweenthepurchaserandsupplier.Suchpipeandtubeis

on date of material procurement form a part of this specifica-

intended for use in structural applications such as highway and

tion to the extent referenced herein:

bridge rails, chain-link fence posts, handrails, sign structures,

2

2.2 ASTM Standards:

awning supports, lighting brackets, etc. Structural pipe and

B210 Specification for Aluminum and Aluminum-Alloy

tube is not intended for fluid-carrying applications involving

Drawn Seamless Tubes

pressure.

B210M Specification for Aluminum and Aluminum-Alloy

NOTE 1—For drawn seamless tube used in pressure applications see

Drawn Seamless Tubes (Metric)

Specifications B210 and B210M, for seamless pipe and seamless extruded

B241/B241M Specification for Aluminum and Aluminum-

tube used in pressure applications see Specifications B241/B241M, and

Alloy Seamless Pipe and Seamless Extruded Tube

for drawn tube and pipe for general purpose applications see Specification

B483/B483M Specification for Aluminum and Aluminum-

B483/B483M.

Alloy Drawn Tube and Pipe for General PurposeApplica-

1.2 Alloy and temper designations are in accordance with

tions

ANSI H35.1. The equivalent Unified Numbering System alloy

B557 Test Methods for Tension Testing Wrought and Cast

designations are those ofTable 1 preceded byA9, for example,

Aluminum- and Magnesium-Alloy Products

A96061 for alloy 6061 in accordance with Practice E527.

B557M TestMethodsforTensionTestingWroughtandCast

1.3 For acceptance criteria for inclusion of new aluminum

Aluminum- and Magnesium-Alloy Products (Metric)

and aluminum alloys in this specification, see Annex A2.

B660 Practices for Packaging/Packing of Aluminum and

1.4 Units—The values stated in either inch-pound units or

Magnesium Products

SI units are to be regarded separately as standard. SI units are

B666/B666M Practice for Identification Marking ofAlumi-

showninbrackets.Thevaluesstatedineachsystemmaynotbe

num and Magnesium Products

exact equivalents; therefore each system shall be used inde-

B807/B807M Practice for Extrusion Press Solution Heat

pendentlyoftheother.Combiningvaluesfromthetwosystems

Treatment for Aluminum Alloys

may result in non-conformance with the specification.

B881 TerminologyRelatingtoAluminum-andMagnesium-

1.4.1 While this standard is a combined SI and inch-pound

Alloy Products

standard, standard pipe sizes are not applicable to SI units,

B918 Practice for Heat Treatment of Wrought Aluminum

therefore non-rationalized SI units (soft conversions) are

Alloys

shown for reader convenience. Rationalized [hard converted]

E29 Practice for Using Significant Digits in Test Data to

SI units are shown in brackets while non-rationalized (soft

Determine Conformance with Specifications

converted) SI units are shown in parentheses.

E34 Test Methods for ChemicalAnalysis ofAluminum and

1.5 This standard does not purport to address all of the

Aluminum-Base Alloys

safety concerns, if any, associated with its use. It is the

E55 Practice for Sampling Wrought Nonferrous Metals and

Alloys for Determination of Chemical Composition

1

This specification is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

2

Aluminum Alloy Wrought Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 15, 2006. Published March 2006. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1965. Last previous edition approved in 2002 as B429 – 02. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0429_B0429M-06. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.