ASTM F2853-10e1

(Test Method)Standard Test Method for Determination of Lead in Paint Layers and Similar Coatings or in Substrates and Homogenous Materials by Energy Dispersive X-Ray Fluorescence Spectrometry Using Multiple Monochromatic Excitation Beams

Standard Test Method for Determination of Lead in Paint Layers and Similar Coatings or in Substrates and Homogenous Materials by Energy Dispersive X-Ray Fluorescence Spectrometry Using Multiple Monochromatic Excitation Beams

SIGNIFICANCE AND USE

This test method may be used for quantitative determinations of Pb in painted and unpainted articles such as toys, children’s products, and other consumer products. Typical test time for quantification of Pb in homogenous samples is 1 to 3 min; and typical test time for quantification of Pb in paint is 4 to 8 min.

SCOPE

1.1 This test method uses energy dispersive X-ray fluorescence (EDXRF) spectrometry for detection and quantification of lead (Pb) in paint layers, similar coatings, or substrates and homogenous materials. The following material types were tested in the interlaboratory study for this standard test method: ABS plastic, polyethylene, polypropylene, PVC, glass, zinc alloy, wood, and fabric.

1.2 This technique may also be commonly referred to as High Definition X-ray Fluorescence (HDXRF) or Multiple Monochromatic Beam EDXRF (MMB-EDXRF).

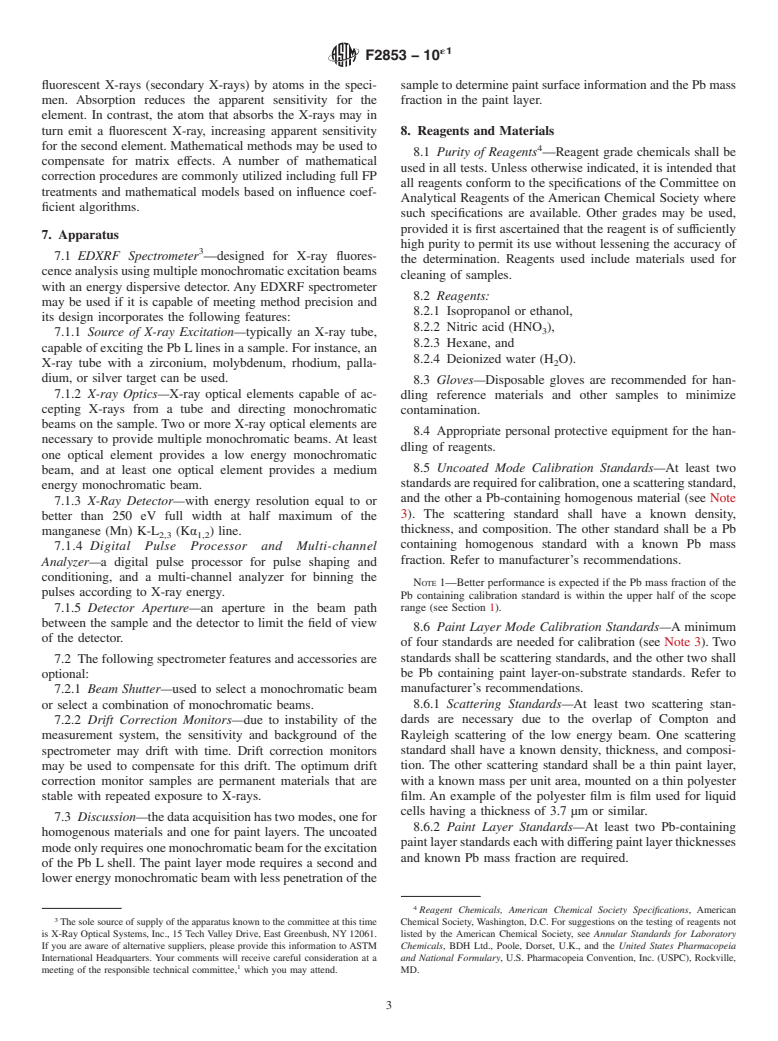

1.3 This test method is applicable for the products and materials described in 1.1 for a Pb mass fraction range of 14 to 1200 mg/kg for uncoated samples and 30 to 450 mg/kg for coated samples, as specified in Table 1 and determined by an interlaboratory study using representative samples

1.4 Ensure that the analysis area of the sample is visually uniform in appearance and at least as large as the X-ray excitation beam at the point of sample excitation.

1.5 For coating analysis, this test method is limited to paint and similar coatings. Metallic coatings are not covered by this test method.

1.6 X-ray Nomenclature—This standard names X-ray lines using the IUPAC convention with the Siegbahn convention in parentheses.

1.7 There are no known ISO equivalent methods to this standard.

1.8 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F2853 − 10

StandardTest Method for

Determination of Lead in Paint Layers and Similar Coatings

or in Substrates and Homogenous Materials by Energy

Dispersive X-Ray Fluorescence Spectrometry Using Multiple

1

Monochromatic Excitation Beams

This standard is issued under the fixed designation F2853; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Section 7.1.3 was changed editorially from “.≥ than 250 eV.” to correctly read “.equal to or better than 250

eV.” in July 2011.

1. Scope 1.9 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method uses energy dispersive X-ray fluores-

responsibility of the user of this standard to establish appro-

cence (EDXRF) spectrometry for detection and quantification

priate safety and health practices and determine the applica-

of lead (Pb) in paint layers, similar coatings, or substrates and

bility of regulatory limitations prior to use.

homogenous materials. The following material types were

testedintheinterlaboratorystudyforthisstandardtestmethod:

2. Referenced Documents

ABS plastic, polyethylene, polypropylene, PVC, glass, zinc

2

2.1 ASTM Standards:

alloy, wood, and fabric.

D883 Terminology Relating to Plastics

1.2 This technique may also be commonly referred to as

D6299 Practice for Applying Statistical Quality Assurance

High Definition X-ray Fluorescence (HDXRF) or Multiple

and Control Charting Techniques to Evaluate Analytical

Monochromatic Beam EDXRF (MMB-EDXRF).

Measurement System Performance

1.3 This test method is applicable for the products and

E135 Terminology Relating to Analytical Chemistry for

materials described in 1.1 for a Pb mass fraction range of 14 to

Metals, Ores, and Related Materials

1200 mg/kg for uncoated samples and 30 to 450 mg/kg for

E691 Practice for Conducting an Interlaboratory Study to

coated samples, as specified in Table 1 and determined by an

Determine the Precision of a Test Method

interlaboratory study using representative samples

F2576 Terminology Relating to Declarable Substances in

Materials

1.4 Ensure that the analysis area of the sample is visually

uniform in appearance and at least as large as the X-ray

3. Terminology

excitation beam at the point of sample excitation.

3.1 Definitions—DefinitionsoftermsapplyingtoXRF,plas-

1.5 For coating analysis, this test method is limited to paint

tics and declarable substances appear in Terminology D883,

and similar coatings. Metallic coatings are not covered by this

E135, and F2576.

test method.

3.2 Definitions of Terms Specific to This Standard:

1.6 X-ray Nomenclature—This standard names X-ray lines

3.2.1 Compton scattering—the inelastic scattering of an

using the IUPAC convention with the Siegbahn convention in

X-ray photon through its interaction with the bound electrons

parentheses.

of an atom. This process is also referred to as incoherent

1.7 There are no known ISO equivalent methods to this

scattering.

standard.

3.2.2 fundamental parameters (FP) model—a model for

1.8 The values stated in SI units are to be regarded as

calibration of X-ray fluorescence response, including the cor-

standard. No other units of measurement are included in this

rection of matrix effects, based on the theory describing the

standard.

physical processes of the interactions of X-rays with matter.

1

This test method is under the jurisdiction of ASTM Committee F40 on

2

Declarable Substances in Materials and is the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

F40.01 on Test Methods. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved July 1, 2010. Published July 2010. DOI:10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F2853–10´01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

F2853 − 10

TABLE 1 Mass Fraction Ranges for Various Sample Types

Sample Type Homogenous Material Lead (Pb) Mass

or Substrate Type Fraction

Range, mg/kg

Uncoated Non-PVC Plastic, 14–1200

Glass or Ceramic

Uncoated Metal 66–600

Uncoated PVC 376–1150

Paint Layer Plastic or Metal 30–450

Paint Layer Fabric 79–200

Paint Layer Wood 58

3.2.3 homogenous material—materials are considered ho- aperture.Dependingonthedataacquisitionmode(see13.1and

mogenous when the elemental composition as determined by 13.2),oneormoremonochromaticX-raybeamsarefocusedon

t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.