ASTM A988/A988M-13

(Specification)Standard Specification for Hot Isostatically-Pressed Stainless Steel Flanges, Fittings, Valves, and Parts for High Temperature Service

Standard Specification for Hot Isostatically-Pressed Stainless Steel Flanges, Fittings, Valves, and Parts for High Temperature Service

ABSTRACT

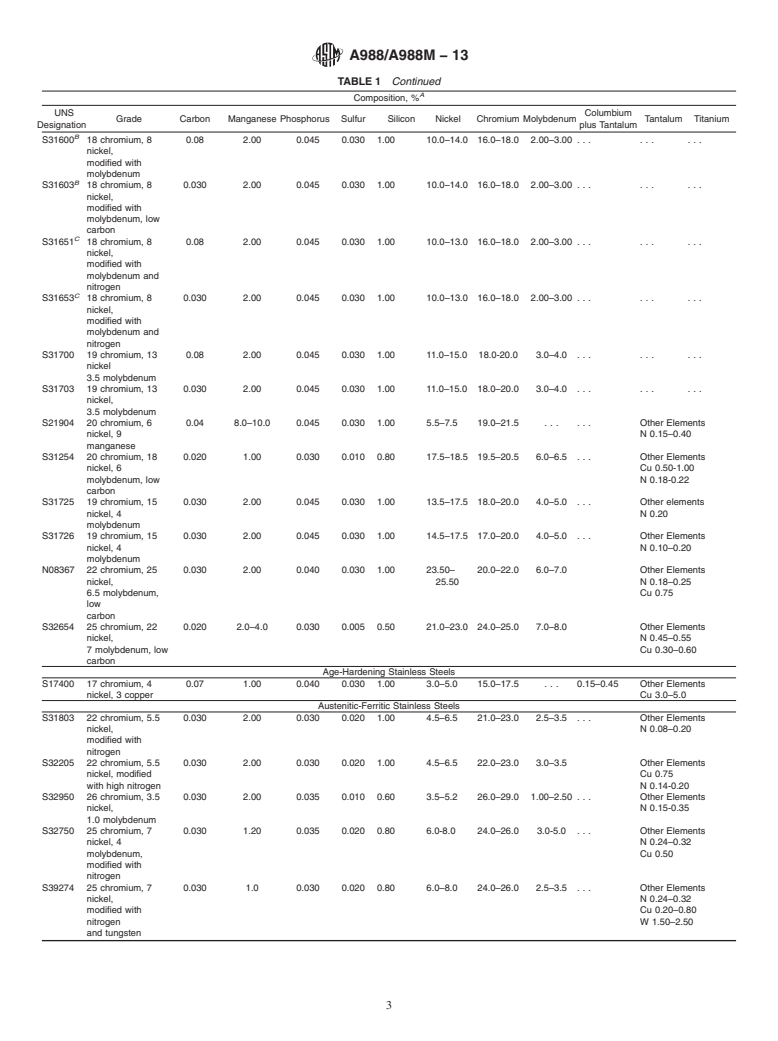

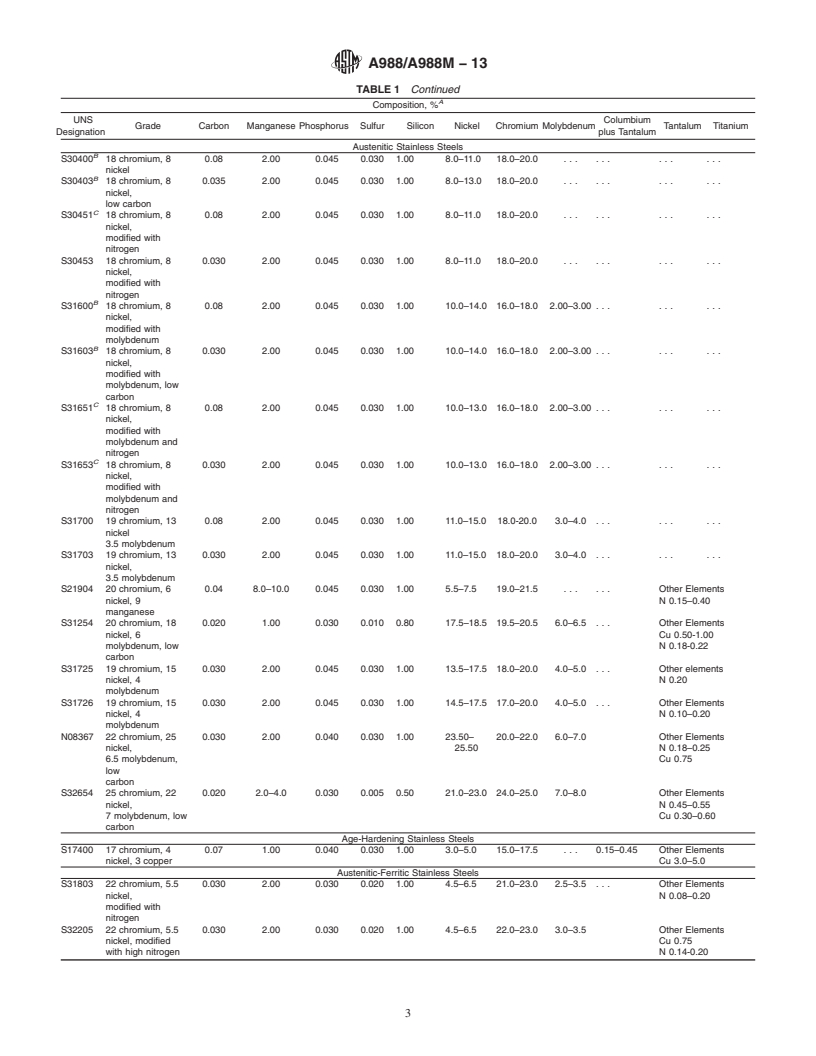

This specification covers hot isostatically-pressed, powder metallurgy, stainless steel piping components such as flanges, fittings, valves, and similar parts, for use in pressure systems and temperature service applications. The specification includes several grades of martensitic, austenitic, age hardening, and austenitic-ferritic stainless steels. Compacts shall be manufactured by placing a single powder blend into a can, evacuating the can, and sealing it. The powder shall be prealloyed and made by a melting method (such as but not limited to air or vacuum induction melting, followed by gas atomization) to produce the specified chemical composition for carbon, manganese, phosphorus, sulfur, nickel, chromium, molybdenum, columbium, tantalum, copper, tungsten, and nitrogen. Other manufacturing requirements including compact homogeneity, microstructure, and can material removal are given. Heat treatment requirements, such as austenitizing or solutioning, cooling, quenching, tempering, and ageing, and structural integrity requirements, such as density, hydrostatic tests, and ultrasonic tests are detailed as well. Mechanical properties include tensile strength, yield strength, elongation, and hardness. Product analysis shall conform to the chemical requirements.

SCOPE

1.1 This specification covers hot isostatically-pressed, powder metallurgy, stainless steel piping components for use in pressure systems. Included are flanges, fittings, valves, and similar parts made to specified dimensions or to dimensional standards, such as in ASME specification B16.5.

1.2 Several grades of martensitic, austenitic, age hardening, and austenitic-ferritic stainless steels are included in this specification.

1.3 Supplementary requirements are provided for use when additional testing or inspection is desired. These shall apply only when specified individually by the purchaser in the order.

1.4 This specification is expressed in both inch-pound units and in SI units. Unless the order specifies the applicable “M” specification designation (SI units), however, the material shall be furnished to inch-pound units.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as the standard. Within the text, the SI units are shown in parentheses. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.6 The following safety hazards caveat pertains only to test methods portions 8.1, 8.2, 9.5 – 9.7, and Section 10 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A988/A988M −13

StandardSpecification for

Hot Isostatically-Pressed Stainless Steel Flanges, Fittings,

1

Valves, and Parts for High Temperature Service

This standard is issued under the fixed designationA988/A988M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* the safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1.1 This specification covers hot isostatically-pressed, pow-

priate safety and health practices and determine the applica-

der metallurgy, stainless steel piping components for use in

bility of regulatory limitations prior to use.

pressure systems. Included are flanges, fittings, valves, and

similar parts made to specified dimensions or to dimensional

2. Referenced Documents

standards, such as in ASME specification B16.5.

2

2.1 ASTM Standards:

1.2 Several grades of martensitic, austenitic, age hardening,

A262Practices for Detecting Susceptibility to Intergranular

and austenitic-ferritic stainless steels are included in this

Attack in Austenitic Stainless Steels

specification.

A275/A275MPracticeforMagneticParticleExaminationof

1.3 Supplementary requirements are provided for use when

Steel Forgings

additional testing or inspection is desired. These shall apply

A745/A745MPractice for Ultrasonic Examination of Aus-

only when specified individually by the purchaser in the order.

tenitic Steel Forgings

A751Test Methods, Practices, and Terminology for Chemi-

1.4 This specification is expressed in both inch-pound units

cal Analysis of Steel Products

and in SI units. Unless the order specifies the applicable “M”

A923Test Methods for Detecting Detrimental Intermetallic

specificationdesignation(SIunits),however,thematerialshall

Phase in Duplex Austenitic/Ferritic Stainless Steels

be furnished to inch-pound units.

A961/A961MSpecification for Common Requirements for

1.5 The values stated in either inch-pound units or SI units

Steel Flanges, Forged Fittings, Valves, and Parts for

are to be regarded separately as the standard. Within the text,

Piping Applications

theSIunitsareshowninparentheses.Thevaluesstatedineach

B311Test Method for Density of Powder Metallurgy (PM)

system may not be exact equivalents; therefore, each system

Materials Containing Less Than Two Percent Porosity

shall be used independently of the other. Combining values

E112Test Methods for Determining Average Grain Size

from the two systems may result in non-conformance with the

E165Practice for Liquid Penetrant Examination for General

standard.

Industry

1.6 Thefollowingsafetyhazardscaveatpertainsonlytotest

E340Test Method for Macroetching Metals and Alloys

methods portions 8.1, 8.2, 9.5 – 9.7, and Section 10 of this

E606Practice for Strain-Controlled Fatigue Testing

specification: This standard does not purport to address all of

G48Test Methods for Pitting and Crevice Corrosion Resis-

tance of Stainless Steels and Related Alloys by Use of

1 Ferric Chloride Solution

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.22 onSteel Forgings and Wrought Fittings for PipingApplications and Bolting

2

Materials for Piping and Special Purpose Applications. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2013. Published October 2013. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1998. Last previous edition approved in 2011 as A988/A988M–11. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0988_A0988M-13. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A988/A988M−13

2.2 MSS Standard: 3.1.5 hot isostatic-pressing, n—aprocessforsimultaneously

SP 25 Standard Marking System for Valves, Fittings, heating and forming a compact in which the powder is

3

Flanges, and Unions contained in a sealed formable enclosure usually made from

2.3 ASME Specifications and Boiler and Pressure Vessel metal and the so-contained powder is subjected to equal

Codes: pressure from all directions at a temperature high enough to

B16.5Dimensional Standards for Steel Pipe Flanges and permit plastic deformation and consolidation of the powder

4

Flanged Fittings particles to take place.

2.4 ASME Specification IX Welding Qualifications:

3

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A988/A988M − 11 A988/A988M − 13

Standard Specification for

Hot Isostatically-Pressed Stainless Steel Flanges, Fittings,

1

Valves, and Parts for High Temperature Service

This standard is issued under the fixed designation A988/A988M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers hot isostatically-pressed, powder metallurgy, stainless steel piping components for use in pressure

systems. Included are flanges, fittings, valves, and similar parts made to specified dimensions or to dimensional standards, such

as in ASME specification B16.5.

1.2 Several grades of martensitic, austenitic, age hardening, and austenitic-ferritic stainless steels are included in this

specification.

1.3 Supplementary requirements are provided for use when additional testing or inspection is desired. These shall apply only

when specified individually by the purchaser in the order.

1.4 This specification is expressed in both inch-pound units and in SI units. Unless the order specifies the applicable “M”

specification designation (SI units), however, the material shall be furnished to inch-pound units.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as the standard. Within the text, the

SI units are shown in parentheses. The values stated in each system may not be exact equivalents; therefore, each system shall be

used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.6 The following safety hazards caveat pertains only to test methods portions 8.1, 8.2, 9.5 – 9.7, and Section 10 of this

specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of

regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A275/A275M Practice for Magnetic Particle Examination of Steel Forgings

A745/A745M Practice for Ultrasonic Examination of Austenitic Steel Forgings

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

A923 Test Methods for Detecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless Steels

A961/A961M Specification for Common Requirements for Steel Flanges, Forged Fittings, Valves, and Parts for Piping

Applications

B311 Test Method for Density of Powder Metallurgy (PM) Materials Containing Less Than Two Percent Porosity

E112 Test Methods for Determining Average Grain Size

E165 Practice for Liquid Penetrant Examination for General Industry

E340 Test Method for Macroetching Metals and Alloys

E606 Practice for Strain-Controlled Fatigue Testing

G48 Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys by Use of Ferric Chloride

Solution

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.22

onSteel Forgings and Wrought Fittings for Piping Applications and Bolting Materials for Piping and Special Purpose Applications.

Current edition approved May 1, 2011Oct. 1, 2013. Published June 2011October 2013. Originally approved in 1998. Last previous edition approved in 20072011 as

A988/A988M – 07.A988/A988M–11. DOI: 10.1520/A0988_A0988M-11.10.1520/A0988_A0988M-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A988/A988M − 13

2.2 MSS Standard:

3

SP 25 Standard Marking System for Valves, Fittings, Flanges, and Unions

2.3 ASME Specifications and Boiler and Pressure Vessel Codes:

4

B16.5 Dimensional Standards for Steel Pipe Flanges and Flanged Fittings

2.4 ASME Specificat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.