ASTM F1233-98(2004)

(Test Method)Standard Test Method for Security Glazing Materials And Systems

Standard Test Method for Security Glazing Materials And Systems

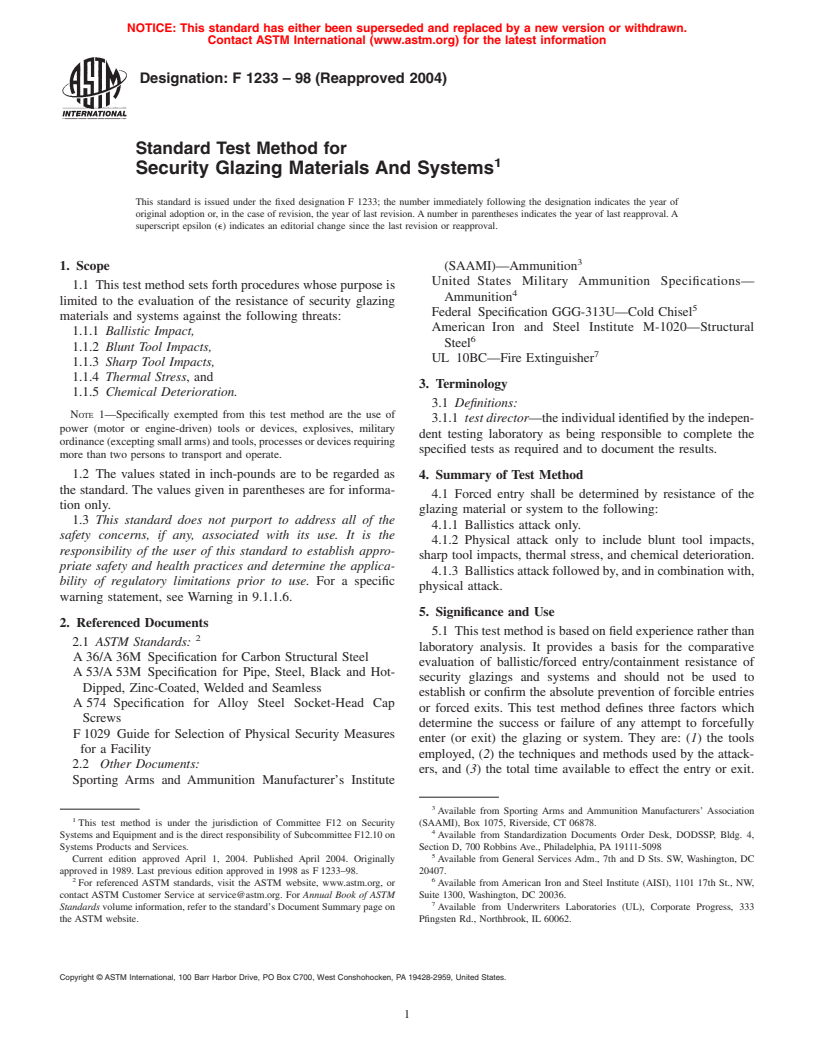

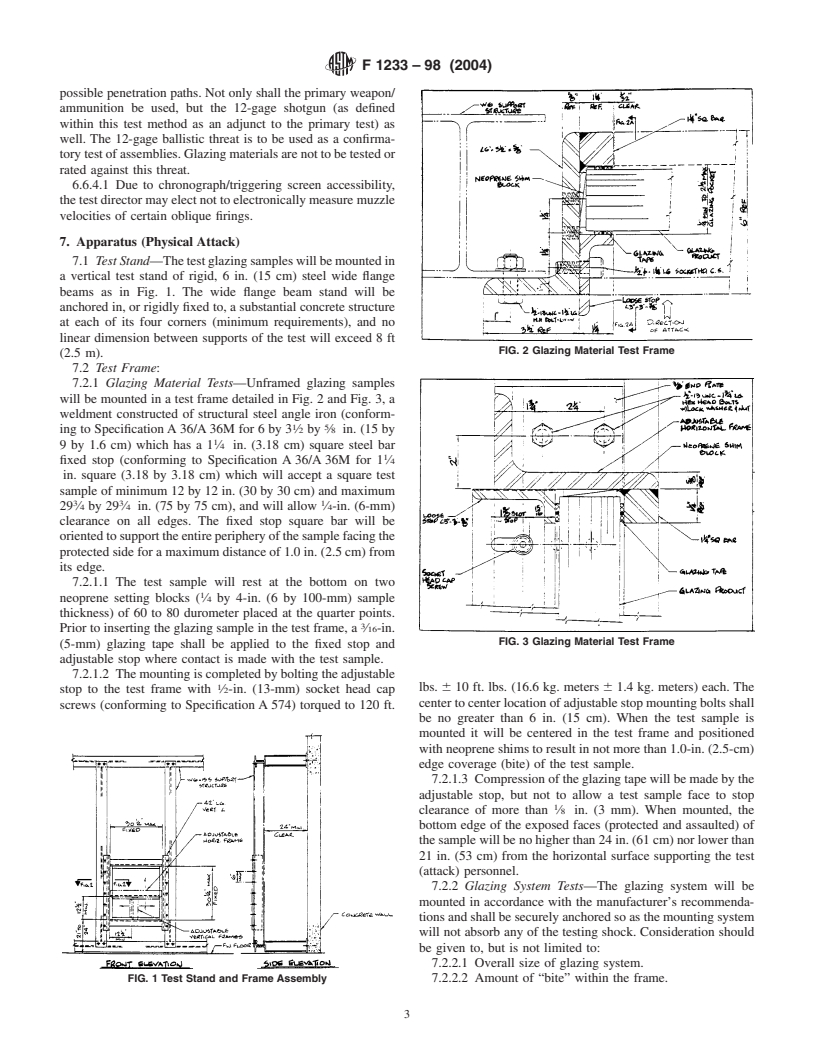

SIGNIFICANCE AND USE

This test method is based on field experience rather than laboratory analysis. It provides a basis for the comparative evaluation of ballistic/forced entry/containment resistance of security glazings and systems and should not be used to establish or confirm the absolute prevention of forcible entries or forced exits. This test method defines three factors which determine the success or failure of any attempt to forcefully enter (or exit) the glazing or system. They are: (1) the tools employed, (2) the techniques and methods used by the attackers, and (3) the total time available to effect the entry or exit. This test method defines two of the three factors (tools and techniques) and allows the third (duration) to vary in order to establish levels of forced entry or exit resistance.

SCOPE

1.1 This test method sets forth procedures whose purpose is limited to the evaluation of the resistance of security glazing materials and systems against the following threats:

1.1.1 Ballistic Impact,

1.1.2 Blunt Tool Impacts,

1.1.3 Sharp Tool Impacts,

1.1.4 Thermal Stress and

1.1.5 Chemical Deterioration.

Note 1—Specifically exempted from this test method are the use of power (motor or engine-driven) tools or devices, explosives, military ordinance (excepting small arms) and tools, processes or devices requiring more than two persons to transport and operate.

1.2 The values stated in inch-pounds are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific warning statement, see Warning in 9.1.1.6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F 1233–98(Reapproved 2004)

Standard Test Method for

1

Security Glazing Materials And Systems

This standard is issued under the fixed designation F 1233; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

3

1. Scope (SAAMI)—Ammunition

United States Military Ammunition Specifications—

1.1 This test method sets forth procedures whose purpose is

4

Ammunition

limited to the evaluation of the resistance of security glazing

5

Federal Specification GGG-313U—Cold Chisel

materials and systems against the following threats:

American Iron and Steel Institute M-1020—Structural

1.1.1 Ballistic Impact,

6

Steel

1.1.2 Blunt Tool Impacts,

7

UL 10BC—Fire Extinguisher

1.1.3 Sharp Tool Impacts,

1.1.4 Thermal Stress, and

3. Terminology

1.1.5 Chemical Deterioration.

3.1 Definitions:

NOTE 1—Specifically exempted from this test method are the use of

3.1.1 test director—theindividualidentifiedbytheindepen-

power (motor or engine-driven) tools or devices, explosives, military

dent testing laboratory as being responsible to complete the

ordinance(exceptingsmallarms)andtools,processesordevicesrequiring

specified tests as required and to document the results.

more than two persons to transport and operate.

1.2 The values stated in inch-pounds are to be regarded as

4. Summary of Test Method

the standard. The values given in parentheses are for informa-

4.1 Forced entry shall be determined by resistance of the

tion only.

glazing material or system to the following:

1.3 This standard does not purport to address all of the

4.1.1 Ballistics attack only.

safety concerns, if any, associated with its use. It is the

4.1.2 Physical attack only to include blunt tool impacts,

responsibility of the user of this standard to establish appro-

sharp tool impacts, thermal stress, and chemical deterioration.

priate safety and health practices and determine the applica-

4.1.3 Ballisticsattackfollowedby,andincombinationwith,

bility of regulatory limitations prior to use. For a specific

physical attack.

warning statement, see Warning in 9.1.1.6.

5. Significance and Use

2. Referenced Documents

5.1 Thistestmethodisbasedonfieldexperienceratherthan

2

2.1 ASTM Standards:

laboratory analysis. It provides a basis for the comparative

A36/A36M Specification for Carbon Structural Steel

evaluation of ballistic/forced entry/containment resistance of

A53/A53M Specification for Pipe, Steel, Black and Hot-

security glazings and systems and should not be used to

Dipped, Zinc-Coated, Welded and Seamless

establish or confirm the absolute prevention of forcible entries

A 574 Specification for Alloy Steel Socket-Head Cap

or forced exits. This test method defines three factors which

Screws

determine the success or failure of any attempt to forcefully

F1029 Guide for Selection of Physical Security Measures

enter (or exit) the glazing or system. They are: (1) the tools

for a Facility

employed, (2) the techniques and methods used by the attack-

2.2 Other Documents:

ers, and (3) the total time available to effect the entry or exit.

Sporting Arms and Ammunition Manufacturer’s Institute

3

Available from Sporting Arms and Ammunition Manufacturers’ Association

1

This test method is under the jurisdiction of Committee F12 on Security (SAAMI), Box 1075, Riverside, CT 06878.

4

Systems and Equipment and is the direct responsibility of Subcommittee F12.10 on Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Systems Products and Services. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098

5

Current edition approved April 1, 2004. Published April 2004. Originally Available from General Services Adm., 7th and D Sts. SW, Washington, DC

approved in 1989. Last previous edition approved in 1998 as F1233–98. 20407.

2 6

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Iron and Steel Institute (AISI), 1101 17th St., NW,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Suite 1300, Washington, DC 20036.

7

Standards volume information, refer to the standard’s Document Summary page on Available from Underwriters Laboratories (UL), Corporate Progress, 333

the ASTM website. Pfingsten Rd., Northbrook, IL 60062.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1233–98 (2004)

This test method defines two of the three factors (tools and 6.3.1 Aluminumfoil,kitchenfoil,orequivalent,0.00094in.

techniques) and allows the third (duration) to vary in order to (.024 mm) 610% thick. Alloy may be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.