ASTM D4846-96

(Test Method)Standard Test Method for Resistance to Unsnapping of Snap Fasteners

Standard Test Method for Resistance to Unsnapping of Snap Fasteners

SCOPE

1.1 This test method covers the determination of the force required to disengage snap fasteners by a pull perpendicular to and parallel with the plane of the snap fastener.

1.2 This test method requires attachment of snaps to specimens using specifications provided by the producers of the snaps.

1.3 This test method is used to establish correlation to wear conditions and for comparing different brands and types of snap fasteners.

1.4 The values stated in SI units are to be regarded as the standard. The values stated in the parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4846 – 96

Standard Test Method for

Resistance to Unsnapping of Snap Fasteners

This standard is issued under the fixed designation D 4846; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.4 For definitions of other textile terms used in this test

method, refer to Terminology D 123.

1.1 This test method covers the determination of the force

required to disengage snap fasteners by a pull perpendicular to

4. Summary of Test Method

and parallel with the plane of the snap fastener.

4.1 Snap fasteners mounted on strips of material near the

1.2 This test method requires attachment of snaps to speci-

end are tested on standard tensile testing machines equipped

mens using specifications provided by the producers of the

for testing the strength of textile fabrics and having sensitivity

snaps.

for accurate low force levels.

1.3 This test method is used to establish correlation to wear

4.2 Tests are made on snap fasteners before laundering with

conditions and for comparing different brands and types of

the option of testing again after a pre-determined number of

snap fasteners.

launderings or other types of refurbishing.

1.4 The values stated in SI units are to be regarded as the

standard. The values stated in the parentheses are for informa-

5. Significance and Use

tion only.

5.1 This test method may be used for acceptance testing of

1.5 This standard does not purport to address all of the

commercial shipments of snap fasteners, but caution is advised

safety concerns, if any, associated with its use. It is the

since information on between laboratory precision is incom-

responsibility of the user of this standard to establish appro-

plete. Comparative tests as directed in 5.1.1 are advisable.

priate safety and health practices and determine the applica-

5.1.1 In case of a dispute arising from differences in

bility of regulatory limitations prior to use.

reported test results when using Test Method D 4846 for

acceptance testing of commercial shipments, the purchaser and

2. Referenced Documents

seller should conduct comparative tests to determine if there is

2.1 ASTM Standards:

statistical bias between their laboratories. Competent statistical

D 76 Specification for Tensile Testing Machines for Tex-

2 assistance is recommended for the investigation of bias. As a

tiles

2 minimum, the two parties should take a group of test speci-

D 123 Terminology Relating to Textiles

2 mens that are as homogeneous as possible and that are from a

D 1776 Practice for Conditioning Textiles for Testing

lot of material of the type in question. The test specimens then

3. Definitions should be assigned randomly in equal numbers to each

laboratory for testing. The average results from the two

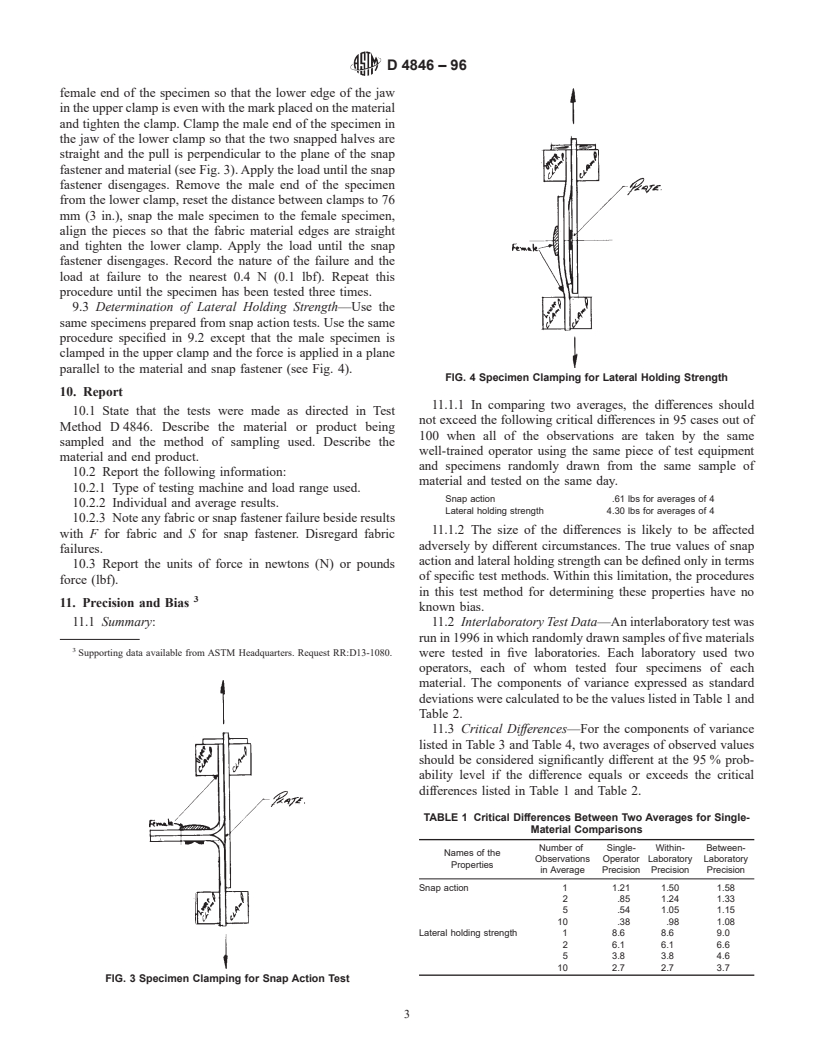

3.1 lateral holding strength, n—the force required to disen-

laboratories should be compared using Student’s t-test for

gage a snap fastener resulting from a pull in the plane parallel

unpaired data and an acceptable probability level chosen by the

to the material to which the snap fastener is attached.

two parties before testing is begun. If a bias is found, either its

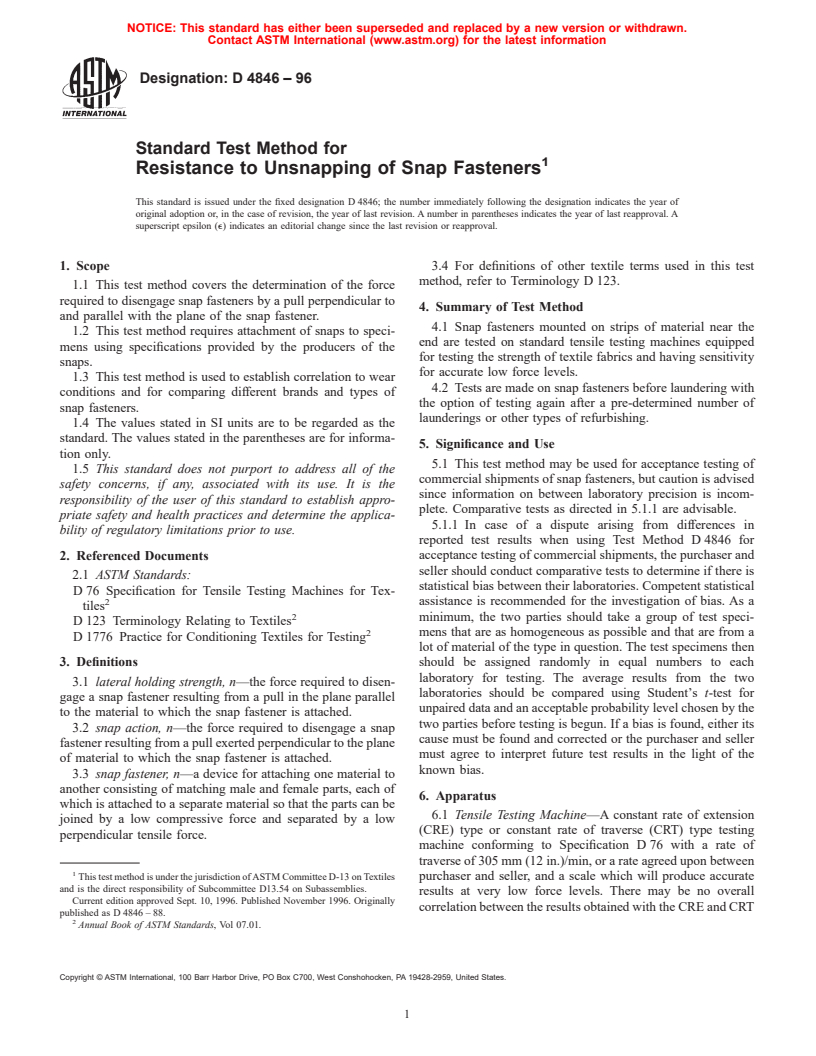

3.2 snap action, n—the force required to disengage a snap

cause must be found and corrected or the purchaser and seller

fastener resulting from a pull exerted perpendicular to the plane

must agree to interpret future test results in the light of the

of material to which the snap fastener is attached.

known bias.

3.3 snap fastener, n—a device for attaching one material to

another consisting of matching male and female parts, each of

6. Apparatus

which is attached to a separate material so that the parts can be

6.1 Tensile Testing Machine—A constant rate of extension

joined by a low compressive force and separated by a low

(CRE) type or constant rate of traverse (CRT) type testing

perpendicular tensile force.

machine conforming to Specification D 76 with a rate of

traverse of 305 mm (12 in.)/min, or a rate agreed upon between

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles purchaser and seller, and a scale which will produce accurate

and is the direct responsibility of Subcommittee D13.54 on Subassemblies.

results at very low force levels. There may be no overall

Current edition approved Sept. 10, 1996. Published November 1996. Originally

correlation between the results obtained with the CRE and CRT

published as D 4846 – 88.

Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4846–96

tensile testing machines. In the case of controversy, however, the male and female parts are packed separately, for each pair

the CRE method shall prevail. of boxes from a shipping carton in the lot sample, take five

6.2 Jaws—The back jaws of the clamps on the tensile male parts at random and match them with five female parts

testing machine should be at least the same width as the front taken at random.

jaws. The front jaws must be 25.4 mm (1 in.) wide. 7.3.2 Attached Snap Fasteners—From each garment in the

6.3 Aluminum Plate—A plate is required measuring 50 by laboratory sample, take five snap fasteners at random on

100 by4mm(2by4by ⁄8 in.) with dowel pins inserted (see garments with more than five. If less than five, take all snap

Fig. 1). fasteners from each garment.

6.4 Attaching Machine—A hand operated, foot operated, or

8. Conditioning

automatic machine for attaching snap fastener parts conform-

ing to specifications of seller.

8.1 Condition the specimens by bringing them from the dry

side to approximate moisture equilibrium for testing in the

7. Sampling

standard atmosphere for testing textiles as directed in Practice

7.1 Lot Sample—As a lot sample for acceptance testing,

D 1776.

take at random the number of shipping cartons of snap

9. Procedure

fasteners or shipping cartons of garments directed in an

applicable material specification or other agreement between

9.1 Preparing Specimens:

the purchaser and the seller. Consider shipping cartons of snap

9.1.1 Attaching Loose Snap Fasteners—When snap fasten-

fasteners or shipping cartons of garments to be the primary

ers are to be attached to a material typical to intended

sampling units.

production, the pinch setting and other conditions specified by

the seller must be used. Cut fabric specimens to dimensions of

NOTE 1—An adequate specification or other agreement between the

38 by 89 mm (1.5 by 3.5 in.) and attach male part to one fabric

purchaser and the seller requires taking into account the variability

between shipping cartons, units within a shipping carton, and between specimen and female part to the other fabric specimen, both

specimens from a unit within a shipping carton, to provide a sampling plan

approximately 19 mm ( ⁄4 in.) from the ends or edge of the

with a meaningful producer’s risk, consumer’s risk, acceptable quality

fabric specimens (see Fig. 2).

level, and limiting quality level.

9.1.2 Cutting Specimens From Garments—Cut specimen

7.2 Laboratory Sample—As a laboratory sample for accep-

from garments so that the snap fasteners are approximately 19

tance testing, proceed as follows:

mm ( ⁄4 in.) from

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.