ASTM A1022/A1022M-14a

(Specification)Standard Specification for Deformed and Plain Stainless Steel Wire and Welded Wire for Concrete Reinforcement

Standard Specification for Deformed and Plain Stainless Steel Wire and Welded Wire for Concrete Reinforcement

ABSTRACT

This specification covers stainless steel wire and welded wire reinforcements from hot-rolled stainless steel rod to be used as concrete reinforcement with corrosion resistant and magnetic permeability properties. The material shall be cold-worked, drawn or rolled, and plain or deformed. Materials shall adhere to deformation requirements. Tensile, yield, and weld shear strengths shall be measured. Bend tests shall also be performed. Dimensional requirements and permissible variations in width, length, weight, density, cross-sectional area, diameter, and average spacings of wires are specified. Guidelines for sampling, inspection, rejection, retest, certification, and packaging are given.

SCOPE

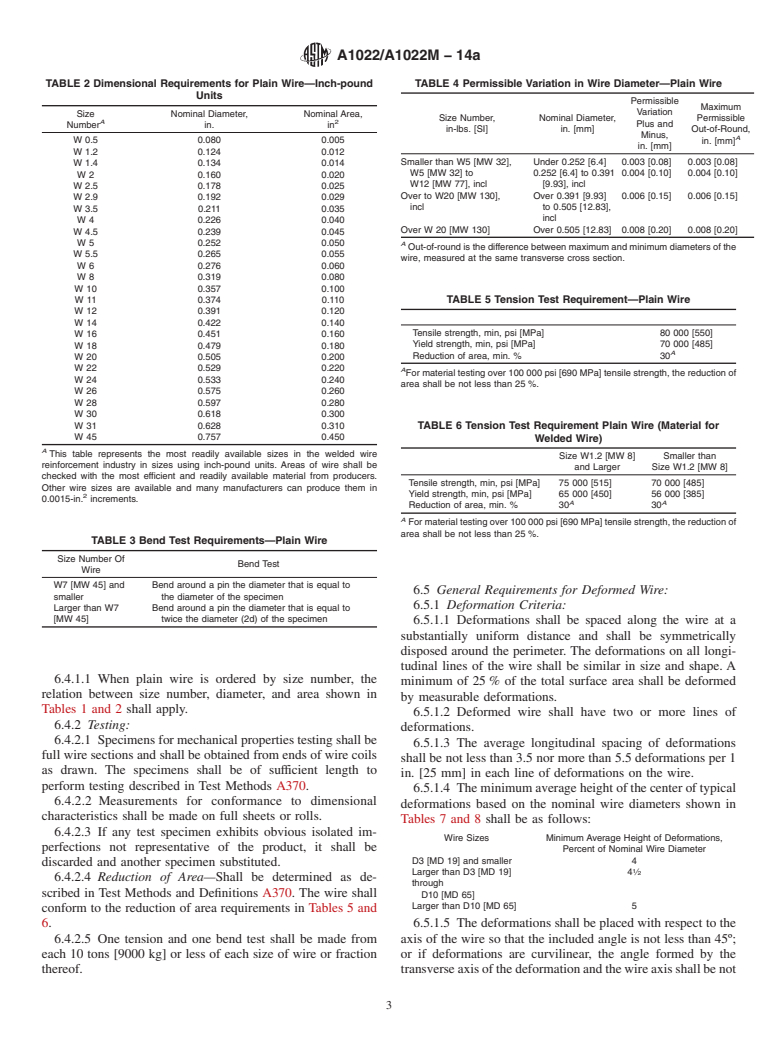

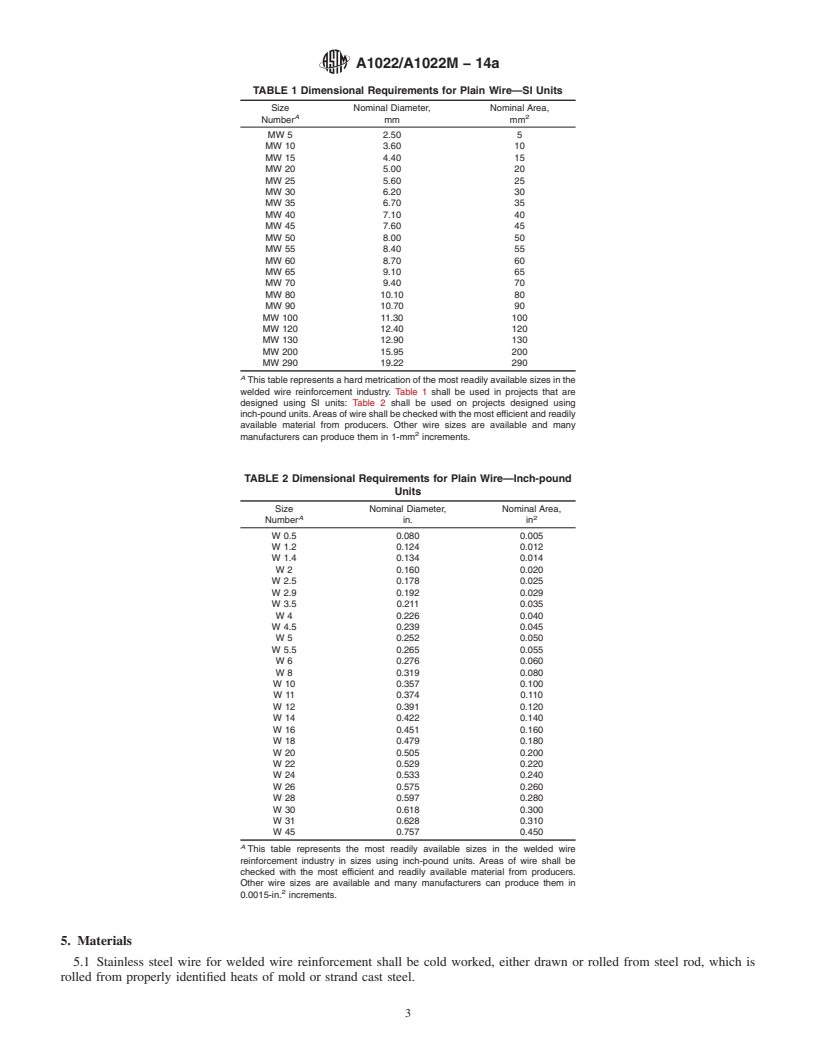

1.1 This specification covers stainless steel wire and welded wire reinforcement produced from hot-rolled stainless steel rod. The stainless steel wire is cold-worked, drawn or rolled, plain (non-deformed) or deformed or a combination of deformed and plain. It is used as concrete reinforcement for applications requiring resistance to corrosion or controlled magnetic permeability, or both. Common wire sizes and dimensions are found in this specification. Actual wire sizes are not restricted to those shown in the tables.

1.2 Supplement S1 describes high strength wire, which shall be furnished when specifically ordered. It shall be permissible to furnish high strength wire in place of regular wire if mutually agreed to by the purchaser and supplier.

1.2.1 A supplementary requirement (S2) of an optional nature is provided. It shall apply only when specified by the purchaser. In order to obtain a corrosion tested or controlled magnetic permeability product, steel conforming to Supplementary Requirement S2 should be ordered.

1.3 The chemical composition of the steel (stainless grade) shall be selected for suitability to the application involved by agreement between the manufacturer and the purchaser. Use Specification A276 for chemical requirements. The UNS designations are to be included with the type number and noted in brackets, that is, austenitic stainless steels as Type 304 [S30400], 304L [S30403], 316 [S31600], 316L [S31603], 316N [S31651], 316LN [S31653] and duplex stainless steels, Types 2205 [S32205] and 329 [S32900].

Note 1: Only austenitic and duplex stainless steels are usually recommended for use as reinforcement in concrete because of their high corrosion resistance. Austenitic stainless steels have good general corrosion resistance, strength characteristics which can be improved by cold working, good toughness and ductility properties at low temperatures, and low magnetic permeability. Duplex stainless steels have generally a corrosion resistance greater than that of most austenitic steels and are magnetic. Other stainless steels with different chemical compositions than the series and types mentioned above, may be used for less restrictive applications.

1.4 Wire for welded wire reinforcement is generally manufactured at 75 ksi [520 MPa] yield strength level. Other strength levels shall be by agreement between the purchaser and manufacturer.

Note 2: The term used to refer to yield strength levels are the same as those in ASTM Standards for welded wire reinforcement.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A1022/A1022M −14a

StandardSpecification for

Deformed and Plain Stainless Steel Wire and Welded Wire

1

for Concrete Reinforcement

This standard is issued under the fixed designation A1022/A1022M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

the series and types mentioned above, may be used for less restrictive

1. Scope*

applications.

1.1 Thisspecificationcoversstainlesssteelwireandwelded

1.4 Wire for welded wire reinforcement is generally manu-

wire reinforcement produced from hot-rolled stainless steel

factured at 75 ksi [520 MPa] yield strength level. Other

rod. The stainless steel wire is cold-worked, drawn or rolled,

strength levels shall be by agreement between the purchaser

plain (non-deformed) or deformed or a combination of de-

and manufacturer.

formed and plain. It is used as concrete reinforcement for

applications requiring resistance to corrosion or controlled

NOTE 2—The term used to refer to yield strength levels are the same as

those in ASTM Standards for welded wire reinforcement.

magnetic permeability, or both. Common wire sizes and

dimensionsarefoundinthisspecification.Actualwiresizesare

1.5 The values stated in either inch-pound units or SI units

not restricted to those shown in the tables.

are to be regarded separately as standard. Within the text, the

SI units are shown in brackets. The values stated in each

1.2 SupplementS1describeshighstrengthwire,whichshall

system may not be exact equivalents; therefore, each system

be furnished when specifically ordered. It shall be permissible

shall be used independently of the other. Combining values

to furnish high strength wire in place of regular wire if

from the two systems may result in non-conformance with the

mutually agreed to by the purchaser and supplier.

standard.

1.2.1 A supplementary requirement (S2) of an optional

nature is provided. It shall apply only when specified by the

2. Referenced Documents

purchaser. In order to obtain a corrosion tested or controlled

2

2.1 ASTM Standards:

magnetic permeability product, steel conforming to Supple-

A276Specification for Stainless Steel Bars and Shapes

mentary Requirement S2 should be ordered.

A342/A342MTest Methods for Permeability of Weakly

1.3 The chemical composition of the steel (stainless grade)

Magnetic Materials

shall be selected for suitability to the application involved by

A370Test Methods and Definitions for Mechanical Testing

agreement between the manufacturer and the purchaser. Use

of Steel Products

Specification A276 for chemical requirements. The UNS

A700Guide for Packaging, Marking, and Loading Methods

designationsaretobeincludedwiththetypenumberandnoted

for Steel Products for Shipment

in brackets, that is, austenitic stainless steels as Type 304

E83Practice for Verification and Classification of Exten-

[S30400], 304L [S30403], 316 [S31600], 316L [S31603],

someter Systems

316N [S31651], 316LN [S31653] and duplex stainless steels,

3

2.2 Military Standards:

Types 2205 [S32205] and 329 [S32900].

MIL-STD-129Marking for Shipment and Storage

3

NOTE 1—Only austenitic and duplex stainless steels are usually 2.3 Federal Standard:

recommended for use as reinforcement in concrete because of their high

Fed.Std.No.123Marking for Shipments (Civil Agencies)

corrosion resistance. Austenitic stainless steels have good general corro- 4

2.4 ACI Standard:

sion resistance, strength characteristics which can be improved by cold

ACI318Building Code Requirements for Structural Con-

working,goodtoughnessandductilitypropertiesatlowtemperatures,and

crete

low magnetic permeability. Duplex stainless steels have generally a

corrosion resistance greater than that of most austenitic steels and are

magnetic.Otherstainlesssteelswithdifferentchemicalcompositionsthan

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel, the ASTM website.

3

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

A01.05 on Steel Reinforcement. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

Current edition approved Oct. 1, 2014. Published October 2014. Originally www.dodssp.daps.mil.

4

approved in 2001. Last previous edition approved in 2014 as A1022/A1022M – 14. Available fromAmerican Concrete Institute (ACI), P.O. Box 9094, Farmington

DOI: 10.1520/A1022_A1022

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A1022/A1022M − 14 A1022/A1022M − 14a

Standard Specification for

Deformed and Plain Stainless Steel Wire and Welded Wire

1

for Concrete Reinforcement

This standard is issued under the fixed designation A1022/A1022M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers stainless steel wire and welded wire reinforcement produced from hot-rolled stainless steel rod.

The stainless steel wire is cold-worked, drawn or rolled, plain (non-deformed) or deformed or a combination of deformed and

plain. It is used as concrete reinforcement for applications requiring resistance to corrosion or controlled magnetic permeability,

or both. Common wire sizes and dimensions are found in this specification. Actual wire sizes are not restricted to those shown in

the tables.

1.2 Supplement S1 describes high strength wire, which shall be furnished when specifically ordered. It shall be permissible to

furnish high strength wire in place of regular wire if mutually agreed to by the purchaser and supplier.

1.2.1 A supplementary requirement (S2) of an optional nature is provided. It shall apply only when specified by the purchaser.

In order to obtain a corrosion tested or controlled magnetic permeability product, steel conforming to Supplementary Requirement

S2 should be ordered.

1.3 The chemical composition of the steel (stainless grade) shall be selected for suitability to the application involved by

agreement between the manufacturer and the purchaser. Use Specification A276 for chemical requirements. The UNS designations

are to be included with the type number and noted in brackets, that is, austenitic stainless steels as Type 304 [S30400], 304L

[S30403], 316 [S31600], 316L [S31603], 316N [S31651], 316LN [S31653] and duplex stainless steels, Types 2205 [S32205] and

329 [S32900].

NOTE 1—Only austenitic and duplex stainless steels are usually recommended for use as reinforcement in concrete because of their high corrosion

resistance. Austenitic stainless steels have good general corrosion resistance, strength characteristics which can be improved by cold working, good

toughness and ductility properties at low temperatures, and low magnetic permeability. Duplex stainless steels have generally a corrosion resistance

greater than that of most austenitic steels and are magnetic. Other stainless steels with different chemical compositions than the series and types mentioned

above, may be used for less restrictive applications.

1.4 Wire for welded wire reinforcement is generally manufactured at 75 ksi [520 MPa] yield strength level. Other strength levels

shall be by agreement between the purchaser and manufacturer.

NOTE 2—The term used to refer to yield strength levels are the same as those in ASTM Standards for welded wire reinforcement.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units

are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A276 Specification for Stainless Steel Bars and Shapes

A342/A342M Test Methods for Permeability of Weakly Magnetic Materials

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

3

A700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Shipment (Withdrawn 2014)

E83 Practice for Verification and Classification of Extensometer Systems

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.05

on Steel Reinforcement.

Current edition approved June 1, 2014Oct. 1, 2014. Published June 2014October 2014. Originally approved in 2001. Last previous edition approved in 20132014 as

A1022/A1022M – 13.14. DOI: 10.1520/A1022_A1022M-14.10.1520/A1022_A1022M-14A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.