ASTM B75-02(2010)

(Specification)Standard Specification for Seamless Copper Tube

Standard Specification for Seamless Copper Tube

ABSTRACT

This specification establishes the requirements for seamless round, rectangular, and square copper tube suitable for general engineering applications. The tube shall be manufactured by such hot- and cold-working processes as to produce a homogeneous, uniform wrought structure in the finished product. It shall be cold drawn to the finished size and wall thickness. The requirements and size availability of tube in the tempers shall conform to the specified requirements. Tensile and yield strength test, Rockwell hardness test, expansion test, microscopical examination, hydrogen embrittlement, electromagnetic test, hydrostatic pressure test, pneumatic pressure test, electrical resistivity, and chemical composition shall be made to conform to specified requirements.

SCOPE

1.1 This specification establishes the requirements for seamless round, rectangular, and square copper tube suitable for general engineering applications.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B75 – 02 (Reapproved 2010)

Standard Specification for

1

Seamless Copper Tube

ThisstandardisissuedunderthefixeddesignationB75;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B153 Test Method for Expansion (Pin Test) of Copper and

2 Copper-Alloy Pipe and Tubing

1.1 This specification establishes the requirements for

B170 Specification for Oxygen-Free Electrolytic Copper—

seamless round, rectangular, and square copper tube suitable

Refinery Shapes

for general engineering applications.

B193 Test Method for Resistivity of Electrical Conductor

1.1.1 Tubes made from any of the following Copper UNS

Materials

No.designationsshallbesuppliedunlessotherwisespecifiedin

B251 Specification for General Requirements for Wrought

the contract or purchase order:

Seamless Copper and Copper-Alloy Tube

Copper UNS No. Type of Copper

B577 Test Methods for Detection of Cuprous Oxide (Hy-

C10100 Oxygen-free electronic

drogen Embrittlement Susceptibility) in Copper

C10200 Oxygen-free without residual deoxidants

B601 Classification for Temper Designations for Copper

C10300 Oxygen-free, extra low phosphorus

and Copper Alloys—Wrought and Cast

C10800 Oxygen-free, low phosphorus

C12000 Phosphorus deoxidized, low residual phosphorus

E3 Guide for Preparation of Metallographic Specimens

C12200 Phosphorus deoxidized, high residual phosphorus

E8 Test Methods for Tension Testing of Metallic Materials

1.2 The values stated in inch-pound units are the standard

E18 Test Methods for Rockwell Hardness of Metallic Ma-

except for grain size values which are given in SI units.

terials

1.3 This specification is the companion to SI Specification

E53 TestMethodforDeterminationofCopperinUnalloyed

B75M; therefore no SI equivalents are presented in this

Copper by Gravimetry

specification.

E62 Test Methods for Chemical Analysis of Copper and

4

1.4 The following hazard statement pertains only to the test

Copper Alloys (Photometric Methods)

method described in Sections 20.5.2.1, 21.2.9, and 21.2.10 of E112 Test Methods for Determining Average Grain Size

thisspecification: This standard does not purport to address all

E243 Practice for Electromagnetic (Eddy-Current) Exami-

of the safety concerns, if any, associated with its use. It is the nation of Copper and Copper-Alloy Tubes

responsibility of the user of this standard to establish appro-

E255 Practice for Sampling Copper and Copper Alloys for

priate safety and health practices and determine the applica- the Determination of Chemical Composition

bility of regulatory limitations prior to use.

E527 Practice for Numbering Metals and Alloys in the

Unified Numbering System (UNS)

2. Referenced Documents

3

3. Terminology, Specific

2.1 ASTM Standards:

B75M Specification for Seamless Copper Tube (Metric) 3.1 Definitions of Terms Specific to This Standard:

3.1.1 capable of—the test need not be performed by the

producerofthematerial.However,ifsubsequenttestingbythe

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

purchaser establishes that the material does not meet these

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube. requirements, the material shall be subject to rejection.

Current edition approved Oct. 1, 2010. Published December 2010. Originally

3.1.2 unaided eye, n—visual inspection without the use of

published as B75–28T. Last previous edition B75–02. DOI: 10.1520/B0075-

special equipment or enhancement excepting the use of cor-

02R10.

2

rective lenses.

For ASME Boiler and Pressure Vessel Code applications refer to related

Specification SB-75 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

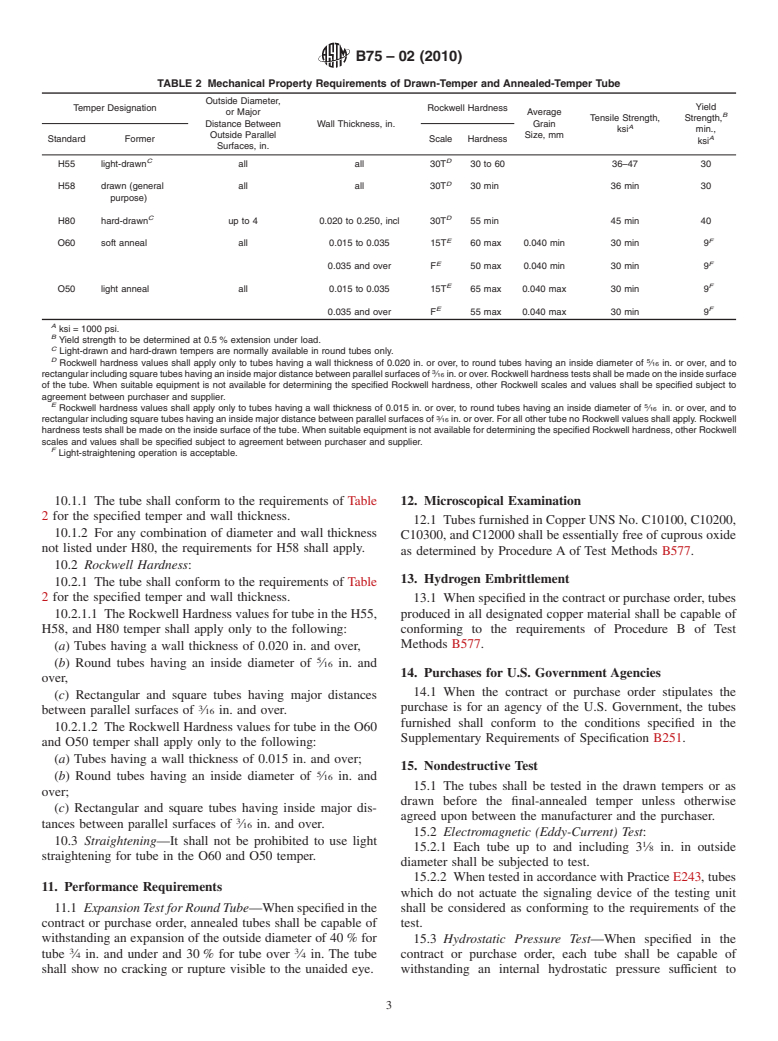

B75 – 02 (2010)

4. Ordering Information 6.1.1 Thesespecificationlimitsdonotprecludethepresence

of other elements. When included in the contract or purchase

4.1 Include the following information in orders for prod-

order,andagreeduponbythemanufacturerorsupplierandthe

ucts.

purchaser, limits shall be established and analysis required for

4.1.1 ASTM desig

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.