ASTM D7740-11(2016)

(Practice)Standard Practice for Optimization, Calibration, and Validation of Atomic Absorption Spectrometry for Metal Analysis of Petroleum Products and Lubricants

Standard Practice for Optimization, Calibration, and Validation of Atomic Absorption Spectrometry for Metal Analysis of Petroleum Products and Lubricants

SIGNIFICANCE AND USE

5.1 Accurate elemental analysis of petroleum products and lubricants is necessary for the determination of chemical properties, which are used to establish compliance with commercial and regulatory specifications.

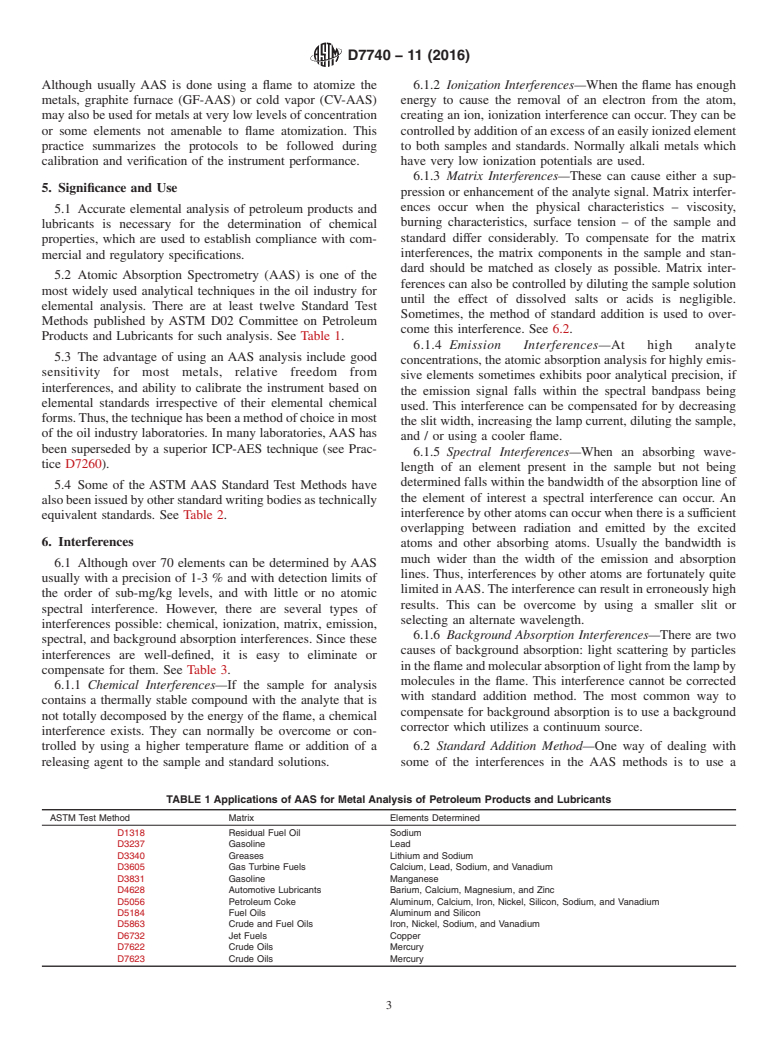

5.2 Atomic Absorption Spectrometry (AAS) is one of the most widely used analytical techniques in the oil industry for elemental analysis. There are at least twelve Standard Test Methods published by ASTM D02 Committee on Petroleum Products and Lubricants for such analysis. See Table 1.

5.3 The advantage of using an AAS analysis include good sensitivity for most metals, relative freedom from interferences, and ability to calibrate the instrument based on elemental standards irrespective of their elemental chemical forms. Thus, the technique has been a method of choice in most of the oil industry laboratories. In many laboratories, AAS has been superseded by a superior ICP-AES technique (see Practice D7260).

5.4 Some of the ASTM AAS Standard Test Methods have also been issued by other standard writing bodies as technically equivalent standards. See Table 2. (A) Excerpted from ASTM MNL44, Guide to ASTM Test Methods for the Analysis of Petroleum Products and Lubricants, 2nd edition, Ed., Nadkarni, R. A. Kishore, ASTM International, West Conshohocken, PA, 2007.

SCOPE

1.1 This practice covers information on the calibration and operational guidance for elemental measurements using atomic absorption spectrometry (AAS).

1.1.1 AAS Related Standards—Test Methods D1318, D3237, D3340, D3605, D3831, D4628, D5056, D5184, D5863, D6732; Practices D7260 and D7455; and Test Methods D7622 and D7623.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7740 − 11 (Reapproved 2016)

Standard Practice for

Optimization, Calibration, and Validation of Atomic

Absorption Spectrometry for Metal Analysis of Petroleum

Products and Lubricants

This standard is issued under the fixed designation D7740; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

1.1 This practice covers information on the calibration and

D4177 Practice for Automatic Sampling of Petroleum and

operationalguidanceforelementalmeasurementsusingatomic

Petroleum Products

absorption spectrometry (AAS).

D4307 Practice for Preparation of Liquid Blends for Use as

1.1.1 AAS Related Standards—Test Methods D1318,

Analytical Standards

D3237, D3340, D3605, D3831, D4628, D5056, D5184,

D4628 Test Method for Analysis of Barium, Calcium,

D5863,D6732;PracticesD7260andD7455;andTestMethods

Magnesium, and Zinc in Unused Lubricating Oils by

D7622 and D7623.

Atomic Absorption Spectrometry

1.2 The values stated in SI units are to be regarded as

D5056 Test Method for Trace Metals in Petroleum Coke by

standard. No other units of measurement are included in this

Atomic Absorption

standard.

D5184 Test Methods for Determination of Aluminum and

1.3 This standard does not purport to address all of the

Silicon in Fuel Oils by Ashing, Fusion, Inductively

safety concerns, if any, associated with its use. It is the Coupled Plasma Atomic Emission Spectrometry, and

responsibility of the user of this standard to establish appro-

Atomic Absorption Spectrometry

priate safety and health practices and determine the applica- D5863 Test Methods for Determination of Nickel,

bility of regulatory limitations prior to use.

Vanadium, Iron, and Sodium in Crude Oils and Residual

Fuels by Flame Atomic Absorption Spectrometry

2. Referenced Documents

D6299 Practice for Applying Statistical Quality Assurance

and Control Charting Techniques to Evaluate Analytical

2.1 ASTM Standards:

Measurement System Performance

D1318 Test Method for Sodium in Residual Fuel Oil (Flame

D6732 Test Method for Determination of Copper in Jet

Photometric Method)

Fuels by Graphite Furnace Atomic Absorption Spectrom-

D3237 TestMethodforLeadinGasolinebyAtomicAbsorp-

etry

tion Spectroscopy

D6792 Practice for Quality System in Petroleum Products

D3340 Test Method for Lithium and Sodium in Lubricating

and Lubricants Testing Laboratories

Greases by Flame Photometer (Withdrawn 2013)

D7260 Practice for Optimization, Calibration, and Valida-

D3605 Test Method for Trace Metals in Gas Turbine Fuels

tion of Inductively Coupled Plasma-Atomic Emission

by Atomic Absorption and Flame Emission Spectroscopy

Spectrometry (ICP-AES) for ElementalAnalysis of Petro-

D3831 Test Method for Manganese in Gasoline By Atomic

leum Products and Lubricants

Absorption Spectroscopy

D7455 Practice for Sample Preparation of Petroleum and

Lubricant Products for Elemental Analysis

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

D7622 Test Method for Total Mercury in Crude Oil Using

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

Combustion and Direct Cold Vapor Atomic Absorption

mittee D02.03 on Elemental Analysis.

Method with Zeeman Background Correction

Current edition approved April 1, 2016. Published May 2016. Originally

approved in 2011. Last previous edition approved in 2011 as D7740 – 11. DOI: D7623 Test Method for Total Mercury in Crude Oil Using

10.1520/D7740-11R16.

Combustion-Gold Amalgamation and Cold Vapor Atomic

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Absorption Method

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

The last approved version of this historical standard is referenced on

www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7740 − 11 (2016)

3. Terminology 3.1.16 monochromator, n—device that isolates a single

atomic resonance line from the line spectrum emitted by the

3.1 Definitions:

hollow cathode lamp, excluding all other wavelengths.

3.1.1 absorbance, n—logarithmtothebase10oftheratioof

3.1.17 nebulizer, n—device that generates an aerosol by

the reciprocal of the transmittance.

flowing a liquid over a surface that contains an orifice from

3.1.2 atomic absorption spectrometry, n—analytical tech-

which gas flows at a high velocity.

nique for measuring metal content of solutions, based on a

3.1.18 NIST, n—National Institute of Standards and

combination of flame source, hollow cathode lamp,

Technology, Gaithersburg, MD. Formerly known as National

photomultiplier, and a readout device.

Bureau of Standards.

3.1.3 atomizer, n—usually a flame source used to decom-

3.1.19 precision, n—closeness of agreement between test

pose the chemical constituents in a solution to its elemental

results obtained under prescribed conditions.

components.

3.1.20 quality assurance, n—system of activities, the pur-

3.1.4 blank, n—solutionwhichissimilarincompositionand

pose of which is to provide to the producer and user of a

contentstothesamplesolutionbutdoesnotcontaintheanalyte

product, measurement, or service the assurance that it meets

being measured.

the defined standards of quality with a stated level of confi-

3.1.5 burner, n—flamedeviceusedtoatomizetheanalyteby dence.

burning in a high temperature flame mixed of a fuel and an

3.1.21 quality control, n—planned system of activities

oxidant.

whose purpose is to provide a level of quality that meets the

needs of users; also the uses of such a system.

3.1.6 calibration, n—process by which the relationship

between signal intensity and elemental concentration is deter-

3.1.22 quality control sample, n—for use in quality assur-

mined for a specific element analysis.

ance program to determine and monitor the precision and

stability of a measurement system; a stable and homogenous

3.1.7 calibration curve, n—plot of signal intensity versus

material having physical or chemical properties, or both,

elemental concentration using data obtained by making mea-

similar to those of typical samples tested by the analytical

surements with standards.

measurement system.

3.1.8 calibration standard, n—material with a certified

3.1.22.1 Discussion—This material should be properly

value for a relevant property, issued by or traceable to a

stored to ensure sample integrity, and is available in sufficient

national organization such as NIST, and whose properties are

quantity for repeated long term testing.

known with sufficient accuracy to permit its use to evaluate the

3.1.23 reference material, n—material with accepted refer-

same property of another sample.

ence value(s), accompanied by an uncertainty at a stated level

3.1.9 certified reference material, n—reference material one

of confidence for desired properties, which may be used for

or more of whose property values are certified by a technically

calibration or quality control purposes in the laboratory.

validprocedure,accompaniedbyatraceablecertificateorother

3.1.24 refractory elements, n—elements forming difficult-

documentation which is issued by a certifying body.

to-dissociate oxides during combustion.

3.1.10 check standard, n—material having an assigned

3.1.25 repeatability, n—difference between two test results,

(known) value (reference value) used to determine the accu-

obtained by the same operator with the same apparatus under

racy of the measurement system or instrument.

constant operating conditions on identical test material would,

3.1.10.1 Discussion—This practice is not used to calibrate

in the long term and correct operation of the test method,

the measurement instrument or system.

exceed the values given only in one case in twenty.

3.1.11 detection limit, n—concentration of an analyte that

3.1.26 reproducibility, n—difference between two single

resultsinasignalintensitythatissomemultiple(typicallytwo)

and independent results, obtained by different operators work-

times the standard deviation of the background intensity at the

ingindifferentlaboratoriesonidenticaltestmaterials,wouldin

measurement wavelength.

the long run, in the normal and correct operation of the test

method, exceed the values given only one case in twenty.

3.1.12 dilution factor, n—ratio of sample weight of the

aliquot taken to the final diluted volume of its solution. 3.1.27 spectrometer, n—instrument used to measure the

emission or absorption spectrum emitted by a species in the

3.1.12.1 Discussion—The dilution factor is used to multiply

vaporized sample.

the observed reading and obtain the actual concentration of the

analyte in the original sample.

3.1.28 spectrum, n—arrayofthecomponentsofanemission

or absorption arranged in the order of some varying character-

3.1.13 graphite furnace, n—electrothermal device for atom-

istics such as wavelength, mass, or energy.

izing the metal constituents.

3.1.29 standard reference material, n—trademark for refer-

3.1.14 hollow cathode lamp, n—device consisting of a

ence materials certified by NIST.

quartz envelope containing a cathode of the metal to be

determined and a suitable anode.

4. Summary of Practice

3.1.15 hydride generation, n—device to atomize some met- 4.1 An Atomic Absorption Spectrometer (AAS) is used to

als which form gaseous hydrides. determine the metal composition of various liquid matrices.

D7740 − 11 (2016)

Although usually AAS is done using a flame to atomize the 6.1.2 Ionization Interferences—When the flame has enough

metals, graphite furnace (GF-AAS) or cold vapor (CV-AAS) energy to cause the removal of an electron from the atom,

may also be used for metals at very low levels of concentration creating an ion, ionization interference can occur. They can be

or some elements not amenable to flame atomization. This controlledbyadditionofanexcessofaneasilyionizedelement

practice summarizes the protocols to be followed during to both samples and standards. Normally alkali metals which

calibration and verification of the instrument performance. have very low ionization potentials are used.

6.1.3 Matrix Interferences—These can cause either a sup-

5. Significance and Use

pression or enhancement of the analyte signal. Matrix interfer-

ences occur when the physical characteristics – viscosity,

5.1 Accurate elemental analysis of petroleum products and

burning characteristics, surface tension – of the sample and

lubricants is necessary for the determination of chemical

standard differ considerably. To compensate for the matrix

properties, which are used to establish compliance with com-

interferences, the matrix components in the sample and stan-

mercial and regulatory specifications.

dard should be matched as closely as possible. Matrix inter-

5.2 Atomic Absorption Spectrometry (AAS) is one of the

ferences can also be controlled by diluting the sample solution

most widely used analytical techniques in the oil industry for

until the effect of dissolved salts or acids is negligible.

elemental analysis. There are at least twelve Standard Test

Sometimes, the method of standard addition is used to over-

Methods published by ASTM D02 Committee on Petroleum

come this interference. See 6.2.

Products and Lubricants for such analysis. See Table 1.

6.1.4 Emission Interferences—At high analyte

5.3 The advantage of using an AAS analysis include good

concentrations, the atomic absorption analysis for highly emis-

sensitivity for most metals, relative freedom from

sive elements sometimes exhibits poor analytical precision, if

interferences, and ability to calibrate the instrument based on

the emission signal falls within the spectral bandpass being

elemental standards irrespective of their elemental chemical

used. This interference can be compensated for by decreasing

forms.Thus,thetechniquehasbeenamethodofchoiceinmost

the slit width, increasing the lamp current, diluting the sample,

of the oil industry laboratories. In many laboratories,AAS has

and / or using a cooler flame.

been superseded by a superior ICP-AES technique (see Prac-

6.1.5 Spectral Interferences—When an absorbing wave-

tice D7260).

length of an element present in the sample but not being

determined falls within the bandwidth of the absorption line of

5.4 Some of the ASTM AAS Standard Test Methods have

the element of interest a spectral interference can occur. An

alsobeenissuedbyotherstandardwritingbodiesastechnically

interference by other atoms can occur when there is a sufficient

equivalent standards. See Table 2.

overlapping between radiation and emitted by the excited

6. Interferences

atoms and other absorbing atoms. Usually the bandwidth is

much wider than the width of the emission and absorption

6.1 Although over 70 elements can be determined by AAS

lines. Thus, interferences by other atoms are fortunately quite

usually with a precision of 1-3 % and with detection limits of

limited inAAS.The interference can result in erroneously high

the order of sub-mg/kg levels, and with little or no atomic

results. This can be overcome by using a smaller slit or

spectral interference. However, there are several types of

selecting an alternate wavelength.

interferences possible: chemical, ionization, matrix, emission,

6.1.6 Background Absorption Interferences—There are two

spectral, and background absorption interferences. Since these

causes of background absorption: light scattering by particles

interferences are well-defined, it is easy to eliminate or

intheflameandmolecularabsorptionoflightfromthelampby

compensate for them. See Table 3.

molecules in the flame. This interference cannot be corrected

6.1.1 Chemical Interferences—If the sample for analysis

with standard addition method. The most common way to

contains a thermally stable compound with the analyte that is

compensate for background absorption is to use a background

not totally decomposed by the energy of the flame, a chemical

corrector which utilizes a continuum source.

interference exists. They can normally be overcome or con-

trolled by using a higher temperature flame or addition of a 6.2 Standard Addition Method—One way of dealing with

releasing agent to the sample and standard solutions. some of the interferences in the AAS methods is to use a

TABLE 1 Applications of AAS for Metal Analysis of Petroleum Products and Lubricants

ASTM Test Method Matrix Elements Determined

D1318 Residual Fuel Oil Sodium

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7740 − 11 D7740 − 11 (Reapproved 2016)

Standard Practice for

Optimization, Calibration, and Validation of Atomic

Absorption Spectrometry for Metal Analysis of Petroleum

Products and Lubricants

This standard is issued under the fixed designation D7740; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers information on the calibration and operational guidance for elemental measurements using atomic

absorption spectrometry (AAS).

1.1.1 AAS Related Standards—Test Methods D1318, D3237, D3340, D3605, D3831, D4628, D5056, D5184, D5863, D6732;

Practices D7260 and D7455; and Test Methods D7622 and D7623.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D1318 Test Method for Sodium in Residual Fuel Oil (Flame Photometric Method)

D3237 Test Method for Lead in Gasoline by Atomic Absorption Spectroscopy

D3340 Test Method for Lithium and Sodium in Lubricating Greases by Flame Photometer (Withdrawn 2013)

D3605 Test Method for Trace Metals in Gas Turbine Fuels by Atomic Absorption and Flame Emission Spectroscopy

D3831 Test Method for Manganese in Gasoline By Atomic Absorption Spectroscopy

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D4307 Practice for Preparation of Liquid Blends for Use as Analytical Standards

D4628 Test Method for Analysis of Barium, Calcium, Magnesium, and Zinc in Unused Lubricating Oils by Atomic Absorption

Spectrometry

D5056 Test Method for Trace Metals in Petroleum Coke by Atomic Absorption

D5184 Test Methods for Determination of Aluminum and Silicon in Fuel Oils by Ashing, Fusion, Inductively Coupled Plasma

Atomic Emission Spectrometry, and Atomic Absorption Spectrometry

D5863 Test Methods for Determination of Nickel, Vanadium, Iron, and Sodium in Crude Oils and Residual Fuels by Flame

Atomic Absorption Spectrometry

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D6732 Test Method for Determination of Copper in Jet Fuels by Graphite Furnace Atomic Absorption Spectrometry

D6792 Practice for Quality System in Petroleum Products and Lubricants Testing Laboratories

D7260 Practice for Optimization, Calibration, and Validation of Inductively Coupled Plasma-Atomic Emission Spectrometry

(ICP-AES) for Elemental Analysis of Petroleum Products and Lubricants

D7455 Practice for Sample Preparation of Petroleum and Lubricant Products for Elemental Analysis

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

Current edition approved July 1, 2011April 1, 2016. Published August 2011May 2016. Originally approved in 2011. Last previous edition approved in 2011 as D7740 – 11.

DOI: 10.1520/D7740–11.10.1520/D7740-11R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7740 − 11 (2016)

D7622 Test Method for Total Mercury in Crude Oil Using Combustion and Direct Cold Vapor Atomic Absorption Method with

Zeeman Background Correction

D7623 Test Method for Total Mercury in Crude Oil Using Combustion-Gold Amalgamation and Cold Vapor Atomic Absorption

Method

D7740 − 11 (2016)

3. Terminology

3.1 Definitions:

3.1.1 absorbance, n—logarithm to the base 10 of the ratio of the reciprocal of the transmittance.

3.1.2 atomic absorption spectrometry, n—analytical technique for measuring metal content of solutions, based on a combination

of flame source, hollow cathode lamp, photomultiplier, and a readout device.

3.1.3 atomizer, n—usually a flame source used to decompose the chemical constituents in a solution to its elemental

components.

3.1.4 blank, n—solution which is similar in composition and contents to the sample solution but does not contain the analyte

being measured.

3.1.5 burner, n—flame device used to atomize the analyte by burning in a high temperature flame mixed of a fuel and an oxidant.

3.1.6 calibration, n—process by which the relationship between signal intensity and elemental concentration is determined for

a specific element analysis.

3.1.7 calibration curve, n—plot of signal intensity versus elemental concentration using data obtained by making measurements

with standards.

3.1.8 calibration standard, n—material with a certified value for a relevant property, issued by or traceable to a national

organization such as NIST, and whose properties are known with sufficient accuracy to permit its use to evaluate the same property

of another sample.

3.1.9 certified reference material, n—reference material one or more of whose property values are certified by a technically valid

procedure, accompanied by a traceable certificate or other documentation which is issued by a certifying body.

3.1.10 check standard, n—material having an assigned (known) value (reference value) used to determine the accuracy of the

measurement system or instrument.

3.1.10.1 Discussion—

This practice is not used to calibrate the measurement instrument or system.

3.1.11 detection limit, n—concentration of an analyte that results in a signal intensity that is some multiple (typically two) times

the standard deviation of the background intensity at the measurement wavelength.

3.1.12 dilution factor, n—ratio of sample weight of the aliquot taken to the final diluted volume of its solution.

3.1.12.1 Discussion—

The dilution factor is used to multiply the observed reading and obtain the actual concentration of the analyte in the original

sample.

3.1.13 graphite furnace, n—electrothermal device for atomizing the metal constituents.

3.1.14 hollow cathode lamp, n—device consisting of a quartz envelope containing a cathode of the metal to be determined and

a suitable anode.

3.1.15 hydride generation, n—device to atomize some metals which form gaseous hydrides.

3.1.16 monochromator, n—device that isolates a single atomic resonance line from the line spectrum emitted by the hollow

cathode lamp, excluding all other wavelengths.

3.1.17 nebulizer, n—device that generates an aerosol by flowing a liquid over a surface that contains an orifice from which gas

flows at a high velocity.

3.1.18 NIST, n—National Institute of Standards and Technology, Gaithersburg, MD. Formerly known as National Bureau of

Standards.

3.1.19 precision, n—closeness of agreement between test results obtained under prescribed conditions.

3.1.20 quality assurance, n—system of activities, the purpose of which is to provide to the producer and user of a product,

measurement, or service the assurance that it meets the defined standards of quality with a stated level of confidence.

3.1.21 quality control, n—planned system of activities whose purpose is to provide a level of quality that meets the needs of

users; also the uses of such a system.

3.1.22 quality control sample, n—for use in quality assurance program to determine and monitor the precision and stability of

a measurement system; a stable and homogenous material having physical or chemical properties, or both, similar to those of

typical samples tested by the analytical measurement system.

D7740 − 11 (2016)

3.1.22.1 Discussion—

This material should be properly stored to ensure sample integrity, and is available in sufficient quantity for repeated long term

testing.

3.1.23 reference material, n—material with accepted reference value(s), accompanied by an uncertainty at a stated level of

confidence for desired properties, which may be used for calibration or quality control purposes in the laboratory.

3.1.24 refractory elements, n—elements forming difficult-to-dissociate oxides during combustion.

3.1.25 repeatability, n—difference between two test results, obtained by the same operator with the same apparatus under

constant operating conditions on identical test material would, in the long term and correct operation of the test method, exceed

the values given only in one case in twenty.

3.1.26 reproducibility, n—difference between two single and independent results, obtained by different operators working in

different laboratories on identical test materials, would in the long run, in the normal and correct operation of the test method,

exceed the values given only one case in twenty.

3.1.27 spectrometer, n—instrument used to measure the emission or absorption spectrum emitted by a species in the vaporized

sample.

3.1.28 spectrum, n—array of the components of an emission or absorption arranged in the order of some varying characteristics

such as wavelength, mass, or energy.

3.1.29 standard reference material, n—trademark for reference materials certified by NIST.

4. Summary of Practice

4.1 An Atomic Absorption Spectrometer (AAS) is used to determine the metal composition of various liquid matrices. Although

usually AAS is done using a flame to atomize the metals, graphite furnace (GF-AAS) or cold vapor (CV-AAS) may also be used

for metals at very low levels of concentration or some elements not amenable to flame atomization. This practice summarizes the

protocols to be followed during calibration and verification of the instrument performance.

5. Significance and Use

5.1 Accurate elemental analysis of petroleum products and lubricants is necessary for the determination of chemical properties,

which are used to establish compliance with commercial and regulatory specifications.

5.2 Atomic Absorption Spectrometry (AAS) is one of the most widely used analytical techniques in the oil industry for

elemental analysis. There are at least twelve Standard Test Methods published by ASTM D02 Committee on Petroleum Products

and Lubricants for such analysis. See Table 1.

5.3 The advantage of using an AAS analysis include good sensitivity for most metals, relative freedom from interferences, and

ability to calibrate the instrument based on elemental standards irrespective of their elemental chemical forms. Thus, the technique

has been a method of choice in most of the oil industry laboratories. In many laboratories, AAS has been superseded by a superior

ICP-AES technique (see Practice D7260).

5.4 Some of the ASTM AAS Standard Test Methods have also been issued by other standard writing bodies as technically

equivalent standards. See Table 2.

6. Interferences

6.1 Although over 70 elements can be determined by AAS usually with a precision of 1-3 % and with detection limits of the

order of sub-mg/kg levels, and with little or no atomic spectral interference. However, there are several types of interferences

TABLE 1 Applications of AAS for Metal Analysis of Petroleum Products and Lubricants

ASTM Test Method Matrix Elements Determined

D1318 Residual Fuel Oil Sodium

D3237 Gasoline Lead

D3340 Greases Lithium and Sodium

D3605 Gas Turbine Fuels Calcium, Lead, Sodium, and Vanadium

D3831 Gasoline Manganese

D4628 Automotive Lubricants Barium, Calcium, Magnesium, and Zinc

D5056 Petroleum Coke Aluminum, Calcium, Iron, Nickel, Silicon, Sodium, and Vanadium

D5184 Fuel Oils Aluminum and Silicon

D5863 Crude and Fuel Oils Iron, Nickel, Sodium, and Vanadium

D6732 Jet Fuels Copper

D7622 Crude Oils Mercury

D7623 Crude Oils Mercury

D7740 − 11 (2016)

A

TABLE 2 Equivalent AAS Test Methods

Analysis ASTM Standard EI Standard ISO Standard DIN Standard

Lead in Gasoline D3237 IP 428 8691

Analysis of Gas Turbine Fuels D3605 IP 413 51-790T3

Additive Elements in Lube Oils D4628 IP 308 51-391T1

Al and Si in Fuel Oils D5184 IP 377 10478 51-416

A

Excerpted from ASTM MNL44, Guide to ASTM Test Methods for the Analysis of Petroleum Products and Lubricants, 2nd edition, Ed., Nadkarni, R. A. Kishore, ASTM

International, West Conshohocken, PA, 2007.

possible: chemical, ionization, matrix, emission, spectral, and background absorption interferences. Since these interferences are

well-defined, it is easy to eliminate or compensate for them. See Table 3.

6.1.1 Chemical Interferences—If the sample for analysis contains a thermally stable compound with the analyte that is not

totally decomposed by the energy of the flame, a chemical interference exists. They can normally be overcome or controlled by

using a higher temperature flame or addition of a releasing agent to the sample and standard solutions.

6.1.2 Ionization Interferences—When the flame has enough energy to cause the removal of an electron from the atom, creating

an ion, ionization interference can occur. They can be controlled by addition of an excess of an easily ionized element to both

samples and standards. Normally alkali metals which have very low ionization potentials are used.

6.1.3 Matrix Interferences—These can cause either a suppression or enhancement of the analyte signal. Matrix interferences

occur when the physical characteristics – viscosity, burning characteristics, surface tension – of the sample and standard differ

considerably. To compensate for the matrix interferences, the matrix components in the sample and standard should be matched

as closely as possible. Matrix interferences can also be controlled by diluting the sample solution until the effect of dissolved salts

or acids is negligible. Sometimes, the method of standard addition is used to overcome this interference. See 6.2.

6.1.4 Emission Interferences—At high analyte concentrations, the atomic absorptio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.