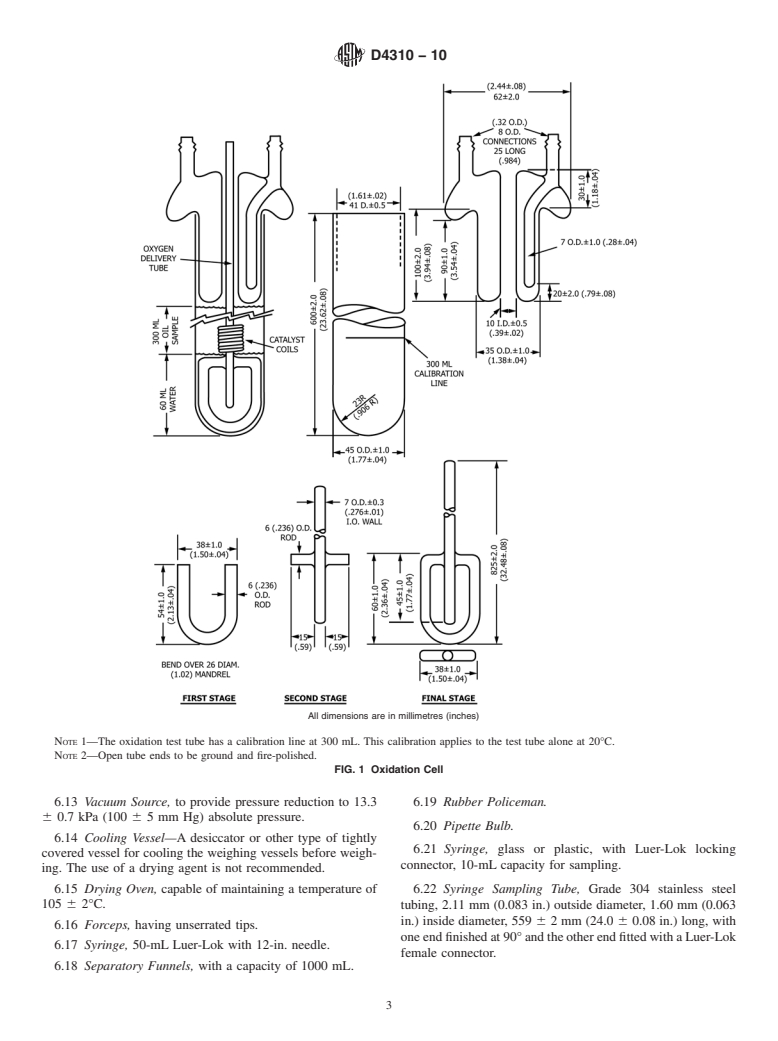

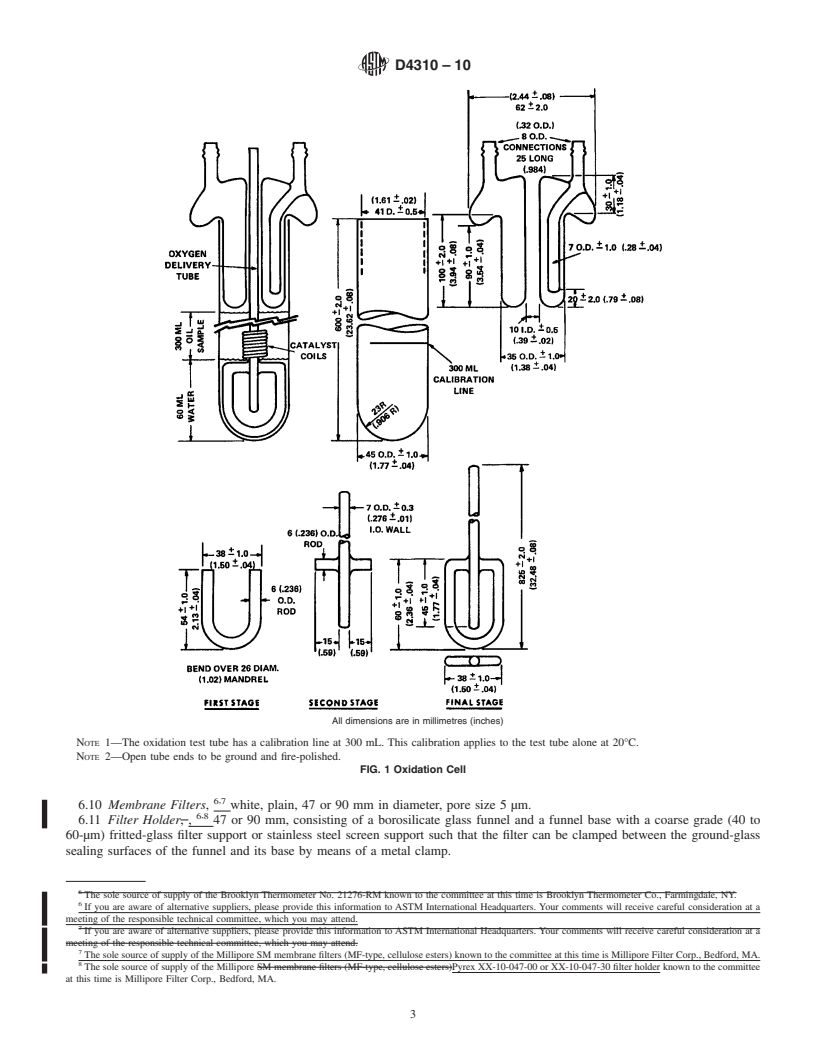

ASTM D4310-10

(Test Method)Standard Test Method for Determination of Sludging and Corrosion Tendencies of Inhibited Mineral Oils

Standard Test Method for Determination of Sludging and Corrosion Tendencies of Inhibited Mineral Oils

SIGNIFICANCE AND USE

Insoluble material may form in oils that are subjected to oxidizing conditions.

Significant formation of oil insolubles or metal corrosion products, or both, during this test may indicate that the oil will form insolubles or corrode metals, or both, during field service. However, no correlation with field service has been established.

SCOPE

1.1 This test method covers and is used to evaluate the tendency of inhibited mineral oil based steam turbine lubricants and mineral oil based anti-wear hydraulic oils to corrode copper catalyst metal and to form sludge during oxidation in the presence of oxygen, water, and copper and iron metals at an elevated temperature. The test method is also used for testing circulating oils having a specific gravity less than that of water and containing rust and oxidation inhibitors.

Note 1—During round robin testing copper and iron in the oil, water and sludge phases were measured. However, the values for the total iron were found to be so low (that is, below 0.8 mg), that statistical analysis was inappropriate. The results of the cooperative test program are available (see Section 17).

1.2 This test method is a modification of Test Method D943 where the oxidation stability of the same kinds of oils is determined by following the acid number of oil. The number of test hours required for the oil to reach an acid number of 2.0 mg KOH/g is the oxidation lifetime.

1.3 Procedure A of this test method requires the determination and report of the weight of the sludge and the total amount of copper in the oil, water, and sludge phases. Procedure B requires the sludge determination only. The acid number determination is optional for both procedures.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 WARNINGMercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s websitehttp://www.epa.gov/mercury/faq.htmfor additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Section 7 and X1.1.5.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4310 − 10

StandardTest Method for

Determination of Sludging and Corrosion Tendencies of

1

Inhibited Mineral Oils

This standard is issued under the fixed designation D4310; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* tional information. Users should be aware that selling mercury

and/or mercury containing products into your state or country

1.1 This test method covers and is used to evaluate the

may be prohibited by law.

tendency of inhibited mineral oil based steam turbine lubri-

1.6 This standard does not purport to address all of the

cants and mineral oil based anti-wear hydraulic oils to corrode

safety concerns, if any, associated with its use. It is the

copper catalyst metal and to form sludge during oxidation in

responsibility of the user of this standard to establish appro-

thepresenceofoxygen,water,andcopperandironmetalsatan

priate safety and health practices and determine the applica-

elevated temperature. The test method is also used for testing

bility of regulatory limitations prior to use. For specific

circulating oils having a specific gravity less than that of water

warning statements, see Section 7 and X1.1.5.

and containing rust and oxidation inhibitors.

NOTE 1—During round robin testing copper and iron in the oil, water

2. Referenced Documents

and sludge phases were measured. However, the values for the total iron

2

2.1 ASTM Standards:

were found to be so low (that is, below 0.8 mg), that statistical analysis

was inappropriate. The results of the cooperative test program are A510 Specification for General Requirements forWire Rods

available (see Section 16).

and Coarse Round Wire, Carbon Steel

B1 Specification for Hard-Drawn Copper Wire

1.2 This test method is a modification of Test Method D943

D664 Test Method for Acid Number of Petroleum Products

where the oxidation stability of the same kinds of oils is

by Potentiometric Titration

determinedbyfollowingtheacidnumberofoil.Thenumberof

D874 Test Method for Sulfated Ash from Lubricating Oils

test hours required for the oil to reach an acid number of 2.0

and Additives

mg KOH/g is the oxidation lifetime.

D943 Test Method for Oxidation Characteristics of Inhibited

1.3 Procedure A of this test method requires the determina-

Mineral Oils

tion and report of the weight of the sludge and the total amount

D1193 Specification for Reagent Water

of copper in the oil, water, and sludge phases. Procedure B

D3339 Test Method forAcid Number of Petroleum Products

requires the sludge determination only. The acid number

by Semi-Micro Color Indicator Titration

determination is optional for both procedures.

D4057 Practice for Manual Sampling of Petroleum and

1.4 The values stated in SI units are to be regarded as

Petroleum Products

standard. No other units of measurement are included in this

E1 Specification for ASTM Liquid-in-Glass Thermometers

3

standard.

2.2 Energy Institute Standard:

Specification for IP Standard Thermometers

1.5 WARNING—Mercury has been designated by many

4

2.3 British Standard:

regulatory agencies as a hazardous material that can cause

BS 1829 Reference Tables for Iron v. Constantan Thermo-

central nervous system, kidney and liver damage. Mercury, or

couples

its vapor, may be hazardous to health and corrosive to

materials.Cautionshouldbetakenwhenhandlingmercuryand

3. Terminology

mercury containing products. See the applicable product Ma-

3.1 Definitions:

terial Safety Data Sheet (MSDS) for details and EPA’s

website—http://www.epa.gov/mercury/faq.htm—for addi-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This test method is under the jurisdiction of ASTM Committee D02 on Standards volume information, refer to the standard’s Document Summary page on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of the ASTM website.

3

Subcommittee D02.09.0C on Oxidation of Turbine Oils. Available from Energy Institute, 61 New Cavendish St., London WIM, 8AR,

Current edition approved July 1, 2010. Published July 2010. Originally approved England.

4

in 1983. Last previous edition approved in 2009 as D4310–09. DOI: 10.1520/ Available from British Standards Institute (BSI), 389 Chiswick High Rd.,

D4310-10. London W4 4AL, U.K.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4310 − 10

3.1.1 sludge—a precipitate

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4310–09 Designation:D4310–10

Standard Test Method for

Determination of Sludging and Corrosion Tendencies of

1

Inhibited Mineral Oils

This standard is issued under the fixed designation D4310; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers and is used to evaluate the tendency of inhibited mineral oil based steam turbine lubricants and

mineral oil based anti-wear hydraulic oils to corrode copper catalyst metal and to form sludge during oxidation in the presence

of oxygen, water, and copper and iron metals at an elevated temperature. The test method is also used for testing circulating oils

having a specific gravity less than that of water and containing rust and oxidation inhibitors.

NOTE 1—During round robin testing copper and iron in the oil, water and sludge phases were measured. However, the values for the total iron were

foundtobesolow(thatis,below0.8mg),thatstatisticalanalysiswasinappropriate.Theresultsofthecooperativetestprogramareavailable(see Section

16).

1.2 ThistestmethodisamodificationofTestMethodD943wheretheoxidationstabilityofthesamekindsofoilsisdetermined

by following the acid number of oil. The number of test hours required for the oil to reach an acid number of 2.0 mg KOH/g is

the oxidation lifetime.

1.3 Procedure A of this test method requires the determination and report of the weight of the sludge and the total amount of

copper in the oil, water, and sludge phases. Procedure B requires the sludge determination only. The acid number determination

is optional for both procedures.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5

1.5 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central

nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware

that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific warning statements, see Section 7 and X1.1.5.

2. Referenced Documents

2

2.1 ASTM Standards:

A510 Specification for General Requirements for Wire Rods and Coarse Round Wire, Carbon Steel

B1 Specification for Hard-Drawn Copper Wire

D664 Test Method for Acid Number of Petroleum Products by Potentiometric Titration

D874 Test Method for Sulfated Ash from Lubricating Oils and Additives

D943 Test Method for Oxidation Characteristics of Inhibited Mineral Oils

D1193 Specification for Reagent Water

D3339 Test Method for Acid Number of Petroleum Products by Semi-Micro Color Indicator Titration

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

E1 Specification for ASTM Liquid-in-Glass Thermometers

3

2.2 Energy Institute Standard:

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.09.0C

on Oxidation of Turbine Oils.

Current edition approved Oct.July 1, 2009.2010. Published November 2009.July 2010. Originally approved in 1983. Last previous edition approved in 20062009 as

D4310–06b.D4310–09. DOI: 10.1520/D4310-109.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Energy Institute, 61 New Cavendish St., London WIM, 8AR, England.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.