ASTM F1674-96

(Test Method)Standard Test Method for Joint Restraint Products for Use with PVC Pipe

Standard Test Method for Joint Restraint Products for Use with PVC Pipe

SCOPE

1.1 This test method describes a procedure for qualifying the performance of joint restraint products for use on PVC pressure pipe systems by evaluating the effect of the joint restraint product on the performance characteristics of PVC pipe during cyclic pressure tests and static pressure tests. The PVC pipe property values referenced in this test method are for Compounds 12454A and 12454B as described in Specification D1784. That includes, but is not limited to, pipe produced in accordance with the following standards:Specifications D1785 and D2241, AWWA C900, and AWWA C905.

1.2 This test method determines the short-term performance of a joint restraint product on PVC pipe, which involves the testing of restrained joint test sections to the minimum burst pressure requirements of the pipe to determine quick burst performance.

1.3 This test method determines the long-term effect of a joint restraint product on PVC pipe, which involves the testing of restrained joint test sections to the sustained pressure requirements of the pipe for a period of 1000 h.

1.4 This test method addresses restraint products that are rated at the full pressure capacity of the PVC pipe on which they are used. There are joint restraint devices available that are not rated at the full pressure capacity of the pipe. While those products have proven acceptable and useful in the marketplace, this test method does not apply to those products.

1.5 This test method determines the performance of a joint restraint product on PVC pipe subjected to cyclic pressure surges. The performance is compared to the baseline performance of pipe without joint restraint products established by Herbert W. Vinson.

1.6 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information purposes only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:F 1674–96

Standard Test Method for

Joint Restraint Products for Use with PVC Pipe

This standard is issued under the fixed designation F 1674; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This test method describes a procedure for qualifying

the performance of joint restraint products for use on PVC

2. Referenced Documents

pressure pipe systems by evaluating the effect of the joint

2.1 ASTM Standards:

restraint product on the performance characteristics of PVC

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

pipe during cyclic pressure tests and static pressure tests. The

Compounds and Chlorinated Poly(Vinyl Chloride)

PVC pipe property values referenced in this test method are for

(CPVC) Compounds

Compounds 12454Aand 12454B as described in Specification

D 1785 Specification for Poly(Vinyl Chloride) (PVC) Plas-

D 1784. That includes, but is not limited to, pipe produced in

tic Pipe, Schedules 40, 80, and 120

accordance with the following standards: Specifications

D 2241 Specification for Poly(Vinyl Chloride) (PVC)

D 1785 and D 2241, AWWA C 900, and AWWA C 905.

Pressure-Rated Pipe (SDR-Series)

1.2 This test method determines the short-term performance

F 412 Terminology Relating to Plastic Piping Systems

of a joint restraint product on PVC pipe, which involves the

2.2 AWWA Standards:

testing of restrained joint test sections to the minimum burst

AWWAC 900 Standard for Polyvinyl Chloride (PVC) Pres-

pressure requirements of the pipe to determine quick burst

sure Pipe, 4 in. Through 12 in., for Water Distribution

performance.

AWWA C 905 Standard for Polyvinyl Chloride (PVC) Wa-

1.3 This test method determines the long-term effect of a

ter Transmission Pipe, Nominal Diameters 14 in. Through

joint restraint product on PVC pipe, which involves the testing

36 in.

of restrained joint test sections to the sustained pressure

requirements of the pipe for a period of 1000 h.

3. Terminology

1.4 This test method addresses restraint products that are

3.1 Definitions—Definitions are in accordance with Termi-

rated at the full pressure capacity of the PVC pipe on which

nology F 412 unless otherwise specified.

theyareused.Therearejointrestraintdevicesavailablethatare

3.2 Descriptions of Terms Specific to This Standard: De-

not rated at the full pressure capacity of the pipe. While those

scriptions of Terms Specific to This Standard:

productshaveprovenacceptableandusefulinthemarketplace,

3.2.1 base hoop stress—the minimum hoop stress during

this test method does not apply to those products.

cyclic testing; the base hoop stress shall be one half the peak

1.5 This test method determines the performance of a joint

hoop stress.

restraint product on PVC pipe subjected to cyclic pressure

3.2.2 base pressure—the internal pressure required to

surges. The performance is compared to the baseline perfor-

achieve the base hoop stress in the pipe wall.

mance of pipe without joint restraint products established by

3.2.3 cycle—an increase in the internal pressure in a cyclic

Herbert W. Vinson.

pressure test specimen from the base pressure to the peak

1.6 The values stated in inch-pound units are to be regarded

pressure, followed by a decrease in the internal pressure to the

as the standard. The values in parentheses are for information

base pressure.

purposes only.

3.2.4 failure of the pipe—ballooning, bursting, cracking,

1.7 This standard does not purport to address all of the

splitting, or weeping (seepage of liquid) of the pipe during test.

safety concerns, if any, associated with its use. It is the

3.2.5 failure of the restraint product—structural failure of

responsibility of the user of this standard to establish appro-

the restraint product, leakage at the joint (where the restraint is

This test method is under the jurisdiction ofASTM Committee F-17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

Current edition approved April 10, 1996. Published June 1996. Annual Book of ASTM Standards, Vol 08.01.

2 4

Vinson, Herbert W., Response of PVC Pipe to Large, Repetitive Pressure Annual Book of ASTM Standards, Vol 08.04.

Surges, International Conference on Underground Plastic Pipe,American Society of Available from American Water Works Assn., 6666 W. Quincy Ave., Denver,

Civil Engineers, New York, NY, 1981, p. 491. CO 80235.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1674

TABLE 1 Minimum Burst Pressure Requirements for Some

also part of the sealing process, for example, a mechanical

Common Dimension Ratios, PVC Compounds 12454A or 12454B

joint), premature failure of the pipe that can be directly

attributed to the action of the restraint, or 0.25 in. (6.35 mm) of

A

Dimension Ratio (DR) Pressure, psi (kPa)

movement of the restraint mechanism on the pipe.

13.5 1000 (6895)

3.2.6 minimum burst pressure requirement—the minimum

14 985 (6791)

internal pressure that must be reached, within 60 to 70 s, in a

17 800 (5516)

18 755 (5205)

restrained joint test specimen without failure.

21 630 (4344)

3.2.7 movement of the restraint mechanism—slippage on

25 535 (3689)

the pipe of any part of the restraint mechanism which contacts

26 500 (3447)

32.5 400 (2758)

the pipe with the purpose of resisting thrust forces.

35 380 (2620)

3.2.8 peak hoop stress—the maximum hoop stress during

41 315 (2172)

cyclic testing.

51 260 (1793)

3.2.9 peak pressure—the internal pressure required to A

The pressures listed approximate a hoop stress of 6400 psi (44.13 MPa).

Some minor adjustments have been made to keep the test pressures uniform in

achieve the peak hoop stress in the pipe wall.

order to simplify testing.

3.2.10 restraint device for PVC pipe—a product which is

mechanically attached to or is an integral part of PVC pipe and

shown in Table 2. The minimum sustained pressure for other

isintendedtopreventseparationofajointinvolvingPVCpipe,

due to internal pressure or external force (that is, restraining of dimension ratios of pipe produced from PVC Compounds

12454A and 12454B (for example, pipe conforming to Speci-

a mechanical joint, PVC pipe or fitting bell, or flange adapter).

3.2.11 restrained joint test specimen—a test section that is fication D 1785) may be determined based on a hoop stress of

4200 psi (28.96 MPa).

assembled with the joint restraint product being tested. The

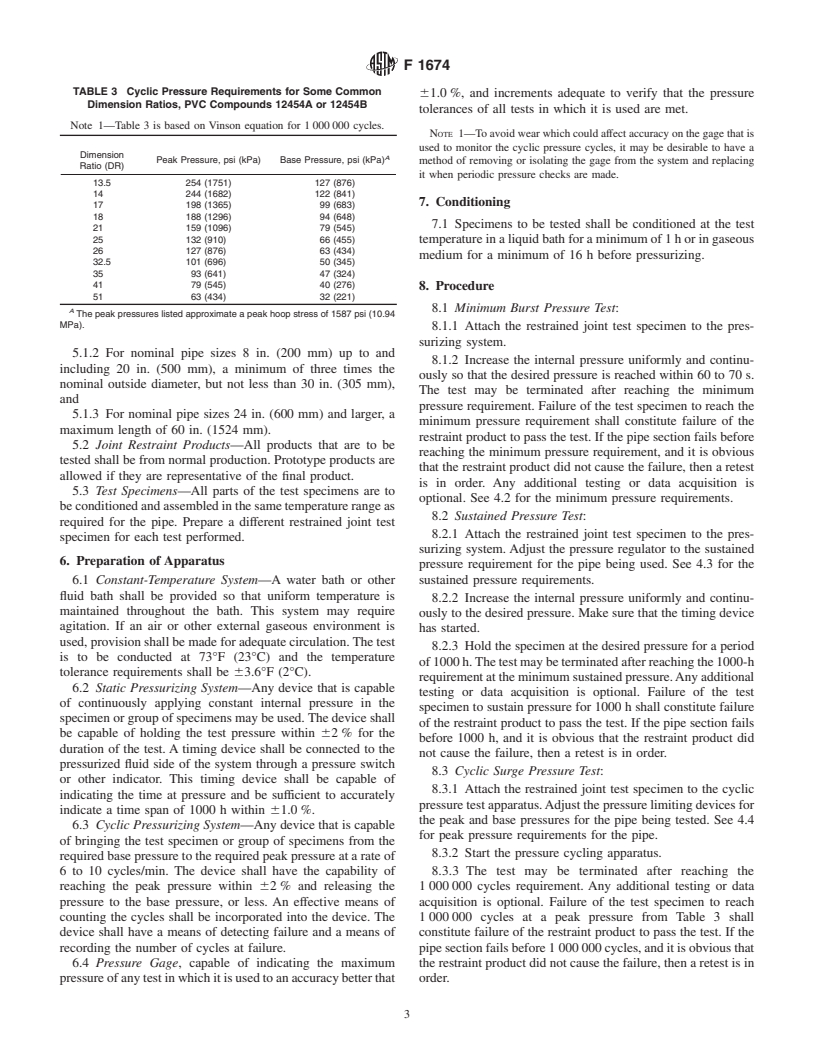

4.4 A cyclic surge pressure test of restrained joint test

ends of the pipe are capped and all of the load from the end

specimensdeterminestheeffectofthejointrestraintproducton

thrust is transferred to the pipe to induce longitudinal stress in

the cyclic fatigue life of PVC pipe. This test method provides

the pipe wall, in addition to hoop stress. The restraint device

a means for quickly identifying any reduction in performance

being tested should provide all resistance to joint separation.

that might result from the combination of the joint restraint

3.2.12 sustained pressure requirement—the internal pres-

product and the pipe.The peak hoop stress shall be determined

surethatmustbemaintainedfor1000hinarestrainedjointtest

for the pipe based on the Vinson equation for a period of

specimen for sustained pressure tests; it is dependent upon

1 000 000 cycles. The base pressure shall be one half of the

PVC compound and dimension ratio or pipe schedule.

peak pressure. The peak pressure requirements for some

3.2.13 Vinson Equation—An empirical equation developed

common dimension ratios are shown in Table 3. The peak

by H. W. Vinson for the conservative estimation of cyclic

pressure for other dimension ratios for pipe produced from

pressure surge limits in the design of typical PVC pipe and is

PVC Compounds 12454A and 12454B (for example, pipe

given by the following:

conforming to Specification D 1785) may be determined based

21 24.906

C 5 ~5.05 3 10 !S ~see Footnote 2!

on a hoop stress of 1587 psi (10.94 MPa).

where: 5. Sampling, Test Specimens, and Test Units

C = average number of cycles to failure and

5.1 Pipe Specimen Length—The specimen length shall be

S = peak hoop stress, psi, (MPa 3 145.04 = psi).

such that the distance between any combination of end closure

or restraint product is as follows:

4. Significance and Use

5.1.1 For nominal pipe sizes 6 in. (150 mm) or less, a

4.1 This test method is useful for establishing any effects

minimum of five times the nominal outside diameter, but not

that a joint restraint product has on the performance of PVC

less than 12 in. (305 mm),

pressure pipe. This test method is designed so that success in

all three parts of the test provides reasonable assurance that a

TABLE 2 Sustained Pressure Requirements for Some Common

joint restraint product may be used on PVC pipe at the full Dimension Ratios, PVC Compounds 12454A or 12454B

pressure rating and capacity of the pipe.

A

Dimension Ratio (DR) Pressure, psi (kPa)

4.2 Restrained joint test specimens shall be subjected to

internal pressures that are equal to the minimum burst pressure 13.5 670 (4619)

14 650 (4482)

requirements for the pipe alone. The minimum burst pressure

17 530 (3654)

requirements for some common dimension ratios are shown in

18 500 (3447)

21 420 (2896)

Table 1. The minimum burst pressures for other dimension

25 350 (2413)

ratios of pipe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.