ASTM A148/A148M-05

(Specification)Standard Specification for Steel Castings, High Strength, for Structural Purposes

Standard Specification for Steel Castings, High Strength, for Structural Purposes

SCOPE

1.1 This specification covers carbon steel, alloy steel, and martensitic stainless steel castings that are to be subjected to higher mechanical stresses than those covered in Specification A27/A27M.

1.2 Several grades of steel castings are covered, having the chemical composition and mechanical properties prescribed in Table 1 and Table 2.

1.3 The values stated in inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 148/A 148M – 05

Standard Specification for

1

Steel Castings, High Strength, for Structural Purposes

ThisstandardisissuedunderthefixeddesignationA148/A148M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

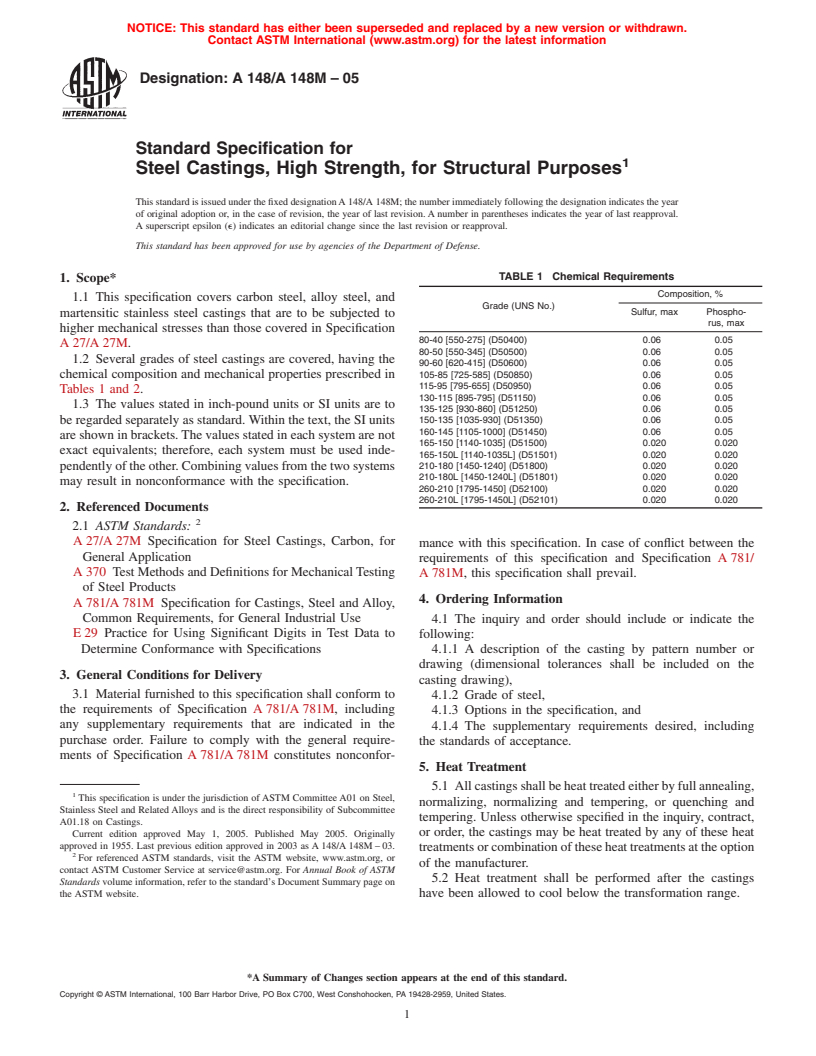

TABLE 1 Chemical Requirements

1. Scope*

Composition, %

1.1 This specification covers carbon steel, alloy steel, and

Grade (UNS No.)

Sulfur, max Phospho-

martensitic stainless steel castings that are to be subjected to

rus, max

higher mechanical stresses than those covered in Specification

80-40 [550-275] (D50400) 0.06 0.05

A27/A27M.

80-50 [550-345] (D50500) 0.06 0.05

1.2 Several grades of steel castings are covered, having the

90-60 [620-415] (D50600) 0.06 0.05

chemical composition and mechanical properties prescribed in 105-85 [725-585] (D50850) 0.06 0.05

115-95 [795-655] (D50950) 0.06 0.05

Tables 1 and 2.

130-115 [895-795] (D51150) 0.06 0.05

1.3 The values stated in inch-pound units or SI units are to

135-125 [930-860] (D51250) 0.06 0.05

beregardedseparatelyasstandard.Withinthetext,theSIunits 150-135 [1035-930] (D51350) 0.06 0.05

160-145 [1105-1000] (D51450) 0.06 0.05

areshowninbrackets.Thevaluesstatedineachsystemarenot

165-150 [1140-1035] (D51500) 0.020 0.020

exact equivalents; therefore, each system must be used inde-

165-150L [1140-1035L] (D51501) 0.020 0.020

210-180 [1450-1240] (D51800) 0.020 0.020

pendentlyoftheother.Combiningvaluesfromthetwosystems

210-180L [1450-1240L] (D51801) 0.020 0.020

may result in nonconformance with the specification.

260-210 [1795-1450] (D52100) 0.020 0.020

260-210L [1795-1450L] (D52101) 0.020 0.020

2. Referenced Documents

2

2.1 ASTM Standards:

A27/A27M Specification for Steel Castings, Carbon, for

mance with this specification. In case of conflict between the

General Application

requirements of this specification and Specification A781/

A370 TestMethodsandDefinitionsforMechanicalTesting

A781M, this specification shall prevail.

of Steel Products

4. Ordering Information

A781/A781M Specification for Castings, Steel and Alloy,

Common Requirements, for General Industrial Use 4.1 The inquiry and order should include or indicate the

E29 Practice for Using Significant Digits in Test Data to

following:

Determine Conformance with Specifications 4.1.1 A description of the casting by pattern number or

drawing (dimensional tolerances shall be included on the

3. General Conditions for Delivery

casting drawing),

3.1 Material furnished to this specification shall conform to

4.1.2 Grade of steel,

the requirements of Specification A781/A781M, including

4.1.3 Options in the specification, and

any supplementary requirements that are indicated in the

4.1.4 The supplementary requirements desired, including

purchase order. Failure to comply with the general require-

the standards of acceptance.

ments of Specification A781/A781M constitutes nonconfor-

5. Heat Treatment

5.1 Allcastingsshallbeheattreatedeitherbyfullannealing,

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

normalizing, normalizing and tempering, or quenching and

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

tempering. Unless otherwise specified in the inquiry, contract,

A01.18 on Castings.

Current edition approved May 1, 2005. Published May 2005. Originally or order, the castings may be heat treated by any of these heat

approved in 1955. Last previous edition approved in 2003 as A148/A148M–03.

treatmentsorcombinationoftheseheattreatmentsattheoption

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of the manufacturer.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 Heat treatment shall be performed after the castings

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. have been allowed to cool below the transformation range.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 148/A 148M – 05

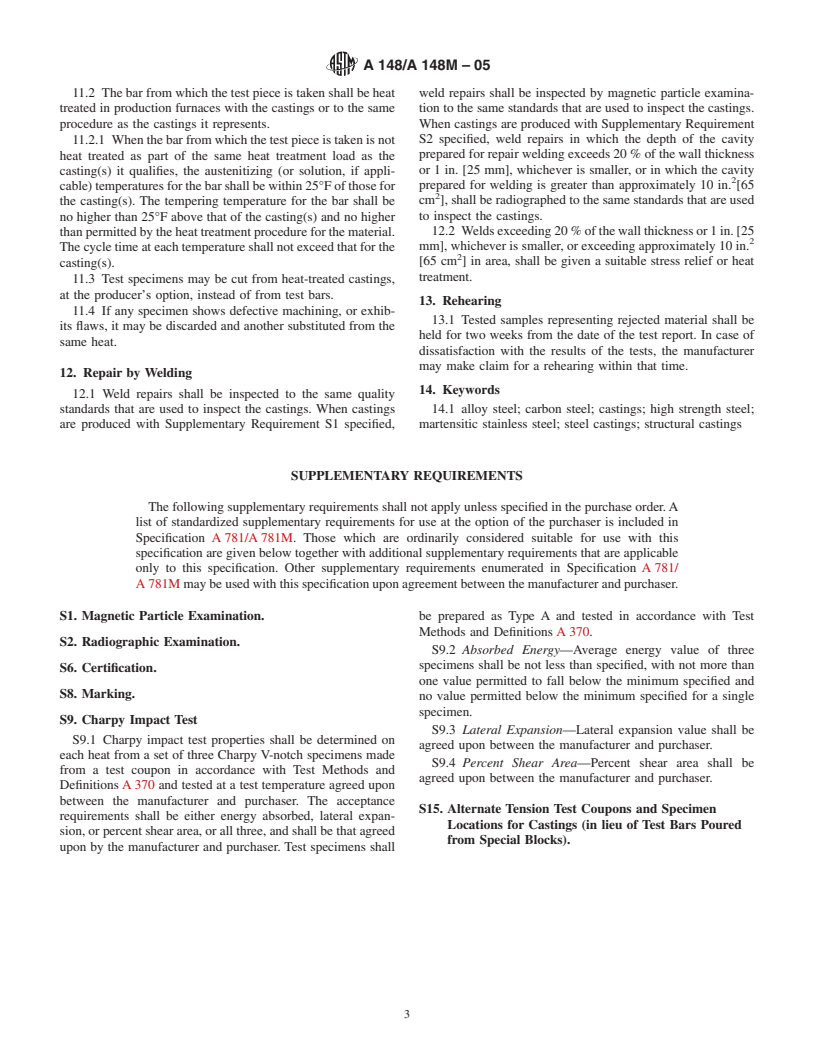

TABLE 2 Tensile Requirements

Tensile strength min, Yield point min, Elongation in 2

Grade ksi [MPa] ksi [MPa] in.or50mm, Reduction of Area, min, %

A

min, %

80-40 [550-275] 80 [550] 40 [275] 18 30

80-50 [550-345] 80 [550] 50 [345] 22 35

90-60 [620-415] 90 [620] 60 [415] 20 40

105-85 [725-585] 105 [725] 85 [585] 17 35

115-95 [795-655] 115 [795] 95 [655] 14 30

130-115 [895-795] 130 [895] 115 [795] 11 25

135-125 [930-860]

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.