ASTM A602-94(2004)

(Specification)Standard Specification for Automotive Malleable Iron Castings

Standard Specification for Automotive Malleable Iron Castings

ABSTRACT

This specification covers standards for castings of ferritic, pearlitic, tempered pearlitic, and tempered martensitic grades of malleable iron used in automotive products and industries. Castings shall be heat treated and shall be of Grades M3210, M4504, M5003, M5503, M7002, and M8501. Materials shall conform to the specified hardness range. Materials shall follow specified microstructure requirements based on distribution of temper-carbon nodules in the metal matrix. All grades shall have a minimum concentration of spheroidal primary carbides in the microstructure.

SCOPE

1.1 This specification covers castings of ferritic, pearlitic, tempered pearlitic, and tempered martensitic grades of malleable iron used in the products of the automotive and allied industries. Castings shall be heat treated to meet this specification.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 602 – 94 (Reapproved 2004)

Standard Specification for

Automotive Malleable Iron Castings

This standard is issued under the fixed designation A 602; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

TABLE 1 Grades of Malleable Iron

1. Scope

Casting Hardness

1.1 This specification covers castings of ferritic, pearlitic,

Grade Heat Treatment

Range

tempered pearlitic, and tempered martensitic grades of mal-

M3210 156 HB max annealed

leable iron used in the products of the automotive and allied

A

4.8 BID min

industries. Castings shall be heat treated to meet this specifi- M4504 163–217 HB air quenched and tempered

A

4.7–4.1 BID

cation.

M5003 187–241 HB air quenched and tempered

1.2 The values stated in inch-pound units are to be regarded A

4.4–3.9 BID

as the standard. The values given in parentheses are for

M5503 187–241 HB liquid quenched and tempered

A

4.4–3.9 BID

information only.

M7002 229–269 HB liquid quenched and tempered

A

4.0–3.7 BID

2. Referenced Documents

M8501 269–302 HB liquid quenched and tempered

A

3.7–3.5 BID

2.1 ASTM Standards:

A

Brinell impression diameter (BID) is the diameter in millimetres of the

E 10 Test Method for Brinell Hardness of Metallic Materi-

impression of a 10-mm ball at 3000-kg load.

als

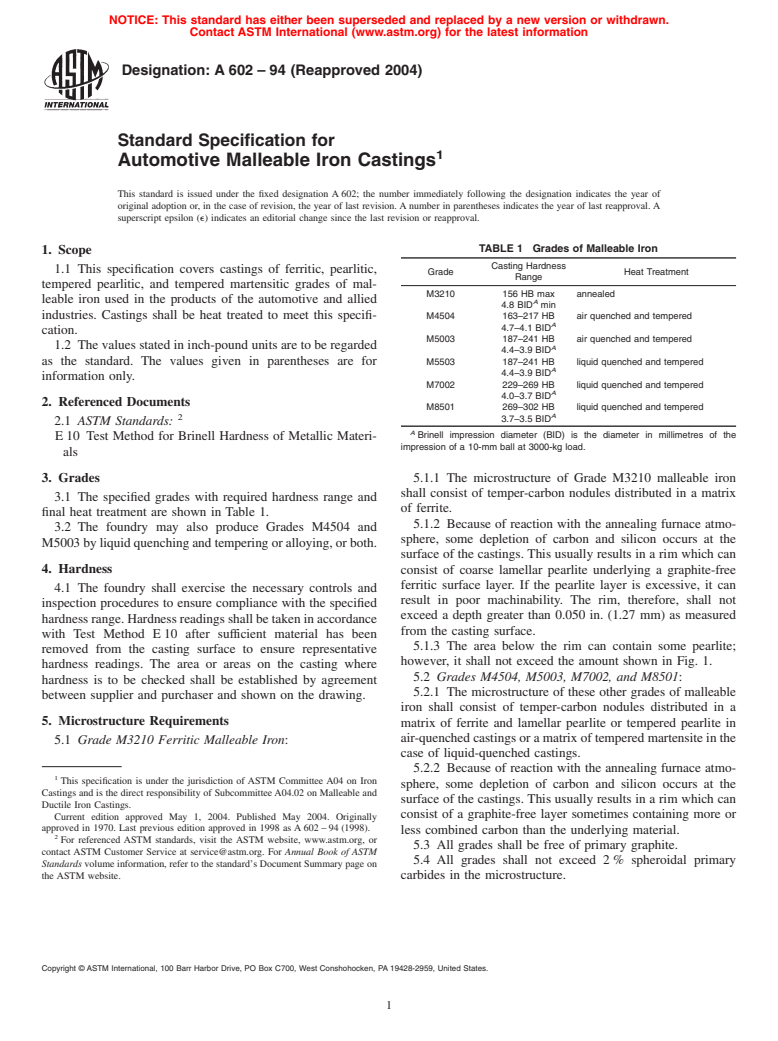

3. Grades 5.1.1 The microstructure of Grade M3210 malleable iron

shall consist of temper-carbon nodules distributed in a matrix

3.1 The specified grades with required hardness range and

of ferrite.

final heat treatment are shown in Table 1.

5.1.2 Because of reaction with the annealing furnace atmo-

3.2 The foundry may also produce Grades M4504 and

sphere, some depletion of carbon and silicon occurs at the

M5003byliquidquenchingandtemperingoralloying,orboth.

surface of the castings. This usually results in a rim which can

4. Hardness consist of coarse lamellar pearlite underlying a graphite-free

ferritic surface layer. If the pearlite layer is excessive, it can

4.1 The foundry shall exercise the necessary controls and

result in poor machinability. The rim, therefore, shall not

inspection procedures to ensure compliance with the specified

exceed a depth greater than 0.050 in. (1.27 mm) as measured

hardnessrange.Hardnessreadingsshallbetakeninaccordance

from the casting surface.

with Test Method E 10 after sufficient material has been

5.1.3 The area below the rim can contain some pearlite;

removed from the casting surface to ensure representative

however, it shall not exceed the amount shown in Fig. 1.

hardness readings. The area or areas on the casting where

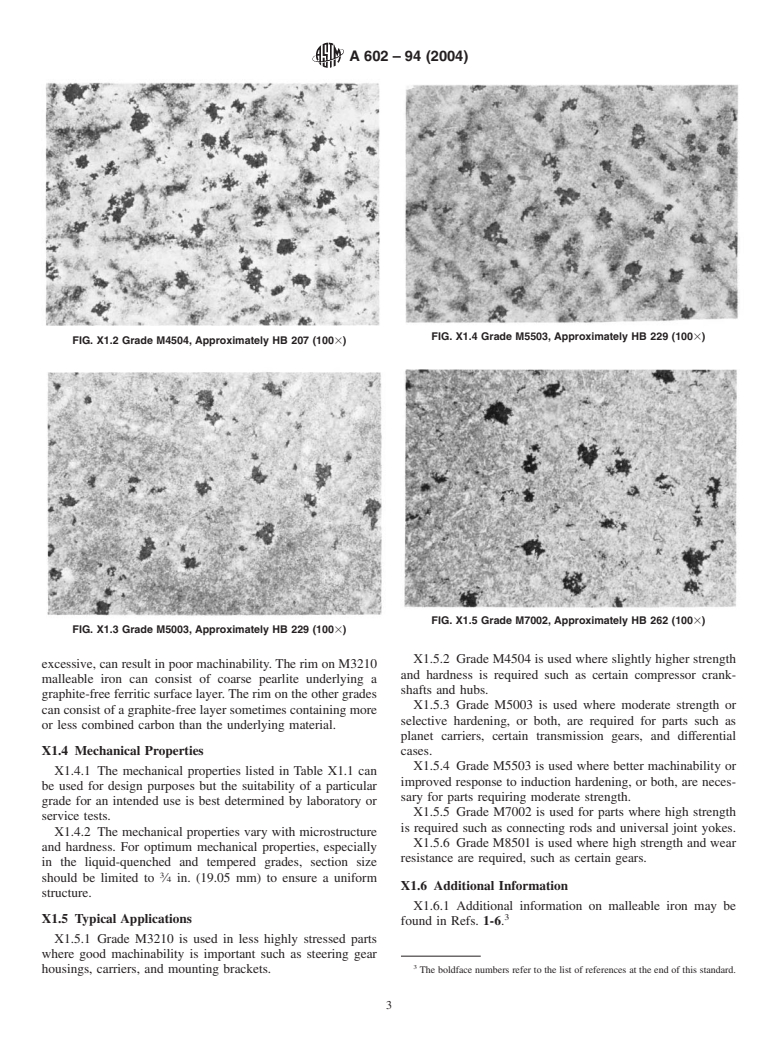

5.2 Grades M4504, M5003, M7002, and M8501:

hardness is to be checked shall be established by agreement

5.2.1 The microstructure of these other grades of malleable

between supplier and purchaser and shown on the drawing.

iron shall consist of temper-carbon nodules distributed in a

5. Microstructure Requirements

matrix of ferrite and lamellar pearlite or tempered pearlite in

air-quenched castings or a matrix of tempered martensite in the

5.1 Grade M3210 Ferritic Malleable Iron:

case of liquid-quenched castings.

5.2.2 Because of reaction with the annealing furnace atmo-

This specification is under the jurisdiction of ASTM Committee A04 on Iron

sphere, some depletion of carbon and silicon occurs at the

Castings and is the direct responsibility of SubcommitteeA04.02 on Malleable and

surface of the castings. This usually results in a rim which can

Ductile Iron Castings.

consist of a graphite-free layer sometimes containing more or

Current edition approved May 1, 2004. Published May 2004. Originally

approved in 1970. Last previous edition approved in 1998 as A 602 – 94 (1998).

less combined carbon than the underlying material.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.3 All grades shall be free of primary graphite.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.4 All grades shall not exceed 2 % spheroidal primary

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. carbides in the microstructure.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 602 – 94 (2004)

6. Quality Assurance

6.1 Sampling plans are a matter of agreement between

supplier and purchaser. The supplier shall employ adequate

equipment and controls to ensure that parts conform to the

agreed upon requirements.

7. General

7.1 Castings furnished to this specification shall be repre-

sentative of good foundry practice and shall conform to

dimensions and tolerances specified on the casting drawing.

7.2 Minor imperfections usually not associated with the

structural function may occur in castings. These imperfections

often are repairable; however, repairs shall be made only in

areas allowed by the purchaser and only by approved methods.

7.3 Additional casting requirements may be agreed upon

between the purchaser and supplier. These should appear as

FIG. 1 Reference Photomicrograph Showing Allowable Pearlite in

additional product requirements on the casting drawing.

Grade M3210 Iron (100 3;2%NitalEtch)

8. Keywords

5.5 The maximum surface ferrite layer and denodularized

zone shall be measured after polishing, etching in nital, and 8.1 casting; ferrite; malleable iron; mechanical properties;

viewing at 1003. pearlite; temper carbon nodules; tensile strength; yield strength

APPENDIX

(Nonmandatory Information)

X1. MATERIAL DESCRIPTION OF MALLEABLE IRON

X1.1 Definition and Classification

X1.1.1 malleable iron—a cast iron in which the graphite is

present as temper-carbon nodules instead of flakes, as in gray

iron, or small spherulites, as in ductile iron.

X1.1.2 The term malleable iron includes all grades of

malleable iron, including those with a ferritic, pearlitic, tem-

pered pearlite, or tempered martensite matrix.

X1.2 Chemical Composition

X1.2.1 The chemical composition of malleable iron gener-

ally conforms to the following range:

Element Composition, %

Total carb

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.