ASTM F2249-03

(Specification)Standard Specification for In-Service Test Methods for Temporary Grounding Jumper Assemblies Used on De-Energized Electric Power Lines and Equipment

Standard Specification for In-Service Test Methods for Temporary Grounding Jumper Assemblies Used on De-Energized Electric Power Lines and Equipment

ABSTRACT

This specification covers the in-service inspection and electrical testing of temporary protective grounding jumper assemblies used by electrical workers in the field on de-energized electric power lines, circuits, and equipment. These assemblies consist of flexible cables, ferrules, clamps, and connectors. The test procedures detailed here provide an objective means of determining if a grounding jumper assembly meets minimum electrical specifications. The application, care, use, and maintenance of this equipment are not addressed in this specification.

SCOPE

1.1 These specifications cover the in-service inspection and electrical testing of temporary protective grounding jumper assemblies which have been used by electrical workers in the field.

1.2 These specifications discuss methods for testing grounding jumper assemblies, which consist of the flexible cables, ferrules, clamps and connectors used in the temporary protective grounding of de-energized circuits.

1.3 Manufacturing specifications for these grounding jumper assemblies are in Specifications F 855.

1.4 The application, care, use, and maintenance of this equipment are beyond the scope of this specification.

1.5 Units of measurement used in this specification are in the Metric system (SI) with English units given in parentheses.

1.6 The following safety hazards caveat pertains only to the test portions of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 2249 – 03

Standard Specification for

In-Service Test Methods for Temporary Grounding Jumper

Assemblies Used on De-Energized Electric Power Lines and

Equipment

This standard is issued under the fixed designation F 2249; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope IEEE Standard 80–1986 IEEE Guide for Safety in AC

Substation Grounding

1.1 These specifications cover the in-service inspection and

IEEE Standard 1048–1990 IEEE Guide for the Protective

electrical testing of temporary protective grounding jumper

Grounding of Power Lines

assemblies which have been used by electrical workers in the

field.

3. Terminology

1.2 Thesespecificationsdiscussmethodsfortestingground-

3.1 Definitions of Terms Specific to This Standard:

ing jumper assemblies, which consist of the flexible cables,

3.1.1 grounding jumper assembly—grounding cable with

ferrules, clamps and connectors used in the temporary protec-

connectors and ground clamps attached, also called a ground-

tive grounding of de-energized circuits.

ing jumper or a protective ground assembly installed tempo-

1.3 Manufacturing specifications for these grounding

rarilyonde-energizedelectricpowercircuitsforthepurposeof

jumper assemblies are in Specifications F 855.

potential equalization and to conduct a short circuit current for

1.4 The application, care, use, and maintenance of this

a specified duration (time).

equipment are beyond the scope of this specification.

1.5 Units of measurement used in this specification are in

4. Significance and Use

the Metric system (SI) with English units given in parentheses.

4.1 Grounding jumper assemblies can be damaged by rough

1.6 The following safety hazards caveat pertains only to the

handling, long term usage, weathering, corrosion, or a combi-

test portions of this specification. This standard does not

nation thereof. This deterioration may be both physical and

purport to address all of the safety concerns, if any, associated

electrical.

with its use. It is the responsibility of the user of this standard

4.2 The test procedures in this specification provide an

to establish appropriate safety and health practices and

objective means of determining if a grounding jumper assem-

determine the applicability of regulatory requirements prior to

bly meets minimum electrical specifications. These methods

use.

permit testing of grounding jumper assemblies under con-

2. Referenced Documents trolled conditions.

4.3 Each responsible entity must determine the required

2.1 ASTM Standards:

safety margin for their workers during electrical fault condi-

B 193 Test Method for Resistivity of Electrical Conductor

2 tions. Guidelines for use in the determination of these condi-

Materials

tions are beyond the scope of this specification and can be

F 855 Specifications for Temporary Grounding Systems To

found in such standards as IEEE Standard 80–1986 and IEEE

Be Used on De-energized Electric Power Lines And

Standard 1048–1990.

Equipment

4 4.4 Mechanical damage, other than broken strands, may not

2.2 IEEE Standards:

significantly affect the cable resistance. Close manual and

visual inspection is required to detect some types of mechani-

cal damage.

This specification is under the jurisdiction of ASTM Committee F18 on

4.5 The test procedures in this specification should be

Electrical Protective Equipment for Workers and is the direct responsibility of

performed at a time interval established by the user to ensure

Subcommittee F18.45 on Mechanical Apparatus.

Current edition approved Feb. 10, 2003. Published April 2003.

that defective grounding jumper assemblies are detected and

Annual Book of ASTM Standards, Vol 02.03.

removed from service in a timely manner.

Annual Book of ASTM Standards, Vol 10.03.

4.6 Retest the grounding jumper assembly after performing

AvailablefromtheInstituteofElectricalandElectronicsEngineers,Inc.(IEEE)

1828 L St., NW, Suite 1202, Washington, CD 20036–5104. any maintenance, in order to ensure its integrity.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2249–03

5. Inspection of Grounding Jumper Assemblies of the cable ferrules and clamps. The allowable increase in

resistance is such as to permit the grounding jumper assembly

5.1 Visual inspection shall be made of all grounding jumper

to perform safely during electrical faults. The grounding

assemblies prior to testing.

jumper assembly, when subjected to its rated maximum fault

5.1.1 If the following defects are evident, the grounding

current and duration, must withstand the fault without its

jumpers may be rejected without electrical testing:

components separating, but some heat damage and discolora-

5.1.1.1 Cracked or broken ferrules and clamps,

tion is acceptable. The electrical resistance value for the

5.1.1.2 Exposed broken strands,

pass/fail criterion is made up of two parts (Fig. 1), the cable

5.1.1.3 Cut or badly mashed or flattened cable,

resistance and the resistance of the two ends containing short

5.1.1.4 Extensively damaged cable- covering material,

cable sections, ferrules and clamps. When the grounding

5.1.1.5 Swollen cable jacket or soft spots, indicating inter-

jumperassembliesaretestedwithadcsource,thedcresistance

nal corrosion, and

of the assembly is used for the pass or fail purposes. With an

5.1.1.6 Cable strands with a black deposit on them.

ac source, the impedance of the cable and the impedance of the

5.1.2 Grounding jumper assemblies which are visually de-

ends (ferrules and clamps) are used to determine if the

fective shall be removed from service and permanently

grounding jumper fails or passes the test.

marked, tagged or destroyed (if beyond repair) to prevent

re-use.

A

TABLE 1 Copper Cable Resistance, mV

5.1.3 Before the grounding jumper assembly can be placed

Grounding Resistance, mV/ft Resistance, mV/ft Resistance, mV/ft

back in service, it must pass the inspection requirements in

Cable Size at 5°C (41°F) at 20°C (68°F) at 35°C (95°F)

5.1.1, and the electrical requirements in Section 7.

#2 0.1471 0.1563 0.1655

5.1.4 All physical connections should be checked for tight-

1/0 0.0924 0.0983 0.1040

ness with specified torque values.

2/0 0.0733 0.0779 0.0825

4/0 0.0461 0.0490 0.0519

A

6. Cleaning and Measuring of Grounding Jumper

Values are calculated from data in Test Method B 193.

Assembly Prior to Electrical Testing

6.1 Identify the cable gage (AWG) and a make a precise 7.5.1 Cable Resistance—Table 1 provides resistance values

measurement of the cable length. See Fig. 1.

for various sizes of cables used in grounding jumper assem-

6.2 Thoroughly clean the jaws of the clamps with a stiff blies. The cable resistance can change with ambient tempera-

wire brush.

tures. A 69°F change in ambient temperatures will cause a

6.3 Attach the grounding jumper assembly clamps firmly to 62 % change in the measurement of resistance values. Table 1

the test set.

gives cable resistance values for a practical range of tempera-

tures (41, 68, and 95°F). Results from theASTM Round Robin

7. Electrical Requirements Tests have shown that an increase in cable resistance at a given

temperature due to aging effects should not exceed 5 %.

7.1 The user must select the test method with the desired

Therefore, the maximum acceptable resistance in cables used

precision and repeatability. The test instrument should be

in temporary protective grounding jumpers should be equal or

sufficiently accurate to detect at least a one foot or less change

less than 1.05 RL, when R = cable resistance from Table 1, and

in cable length to ensure that the cable meets requirements.

L = cable length in feet.

7.2 Each method must take into account a precise cable

7.5.2 Resistance and Impedance of Copper Grounding

resistance per foot and the length of the cable being tested.

Jumper Assemblies—See Table 1.

7.3 Electrical tests relative to this standard are:

7.3.1 DC resistance measurements,

7.3.2 AC impedance measurements, and

7.3.3 Temperature rise measurements (supplementary

method).

7.4 DC Resistance or AC Impedance Method—Equipment

required includes:

7.4.1 A minimum 10 A dc source controllable to 5 % of

output current, short circuit protected, or

FIG. 1 Resistance and Impedance of Copper Grounding Jumper

7.4.2 A minimum 10 A ac source controllable to 5 % of

Assemblies

output current, short circuit protected.

7.4.3 Measuring method for measurements of cable length

calibrated in inches or centimetres.

Y = resistance of clamps, ferrule and portions of the cable

7.5 In-Service Electrical Resistance Pass/Fail Criteria—

inside the ferrule, mV

Thepass/failcriterionofagroundingjumperassemblyisbased L = cable length expressed in feet (ferrule to ferrule mea-

on the resistance value of the assembly (cable, ferrules and

surement to the nearest inch, not including shrouded

clamps) which is higher than the established resistance value portion of some ferrules which cover the cable insula-

for new assemblies.This increase in resistance accounts for the

tion), and

R = cable resistance from Table 1, mV.

expected normal deterioration of the assembly due to aging,

contamination and corrosion, particularly in the contact areas

F2249–03

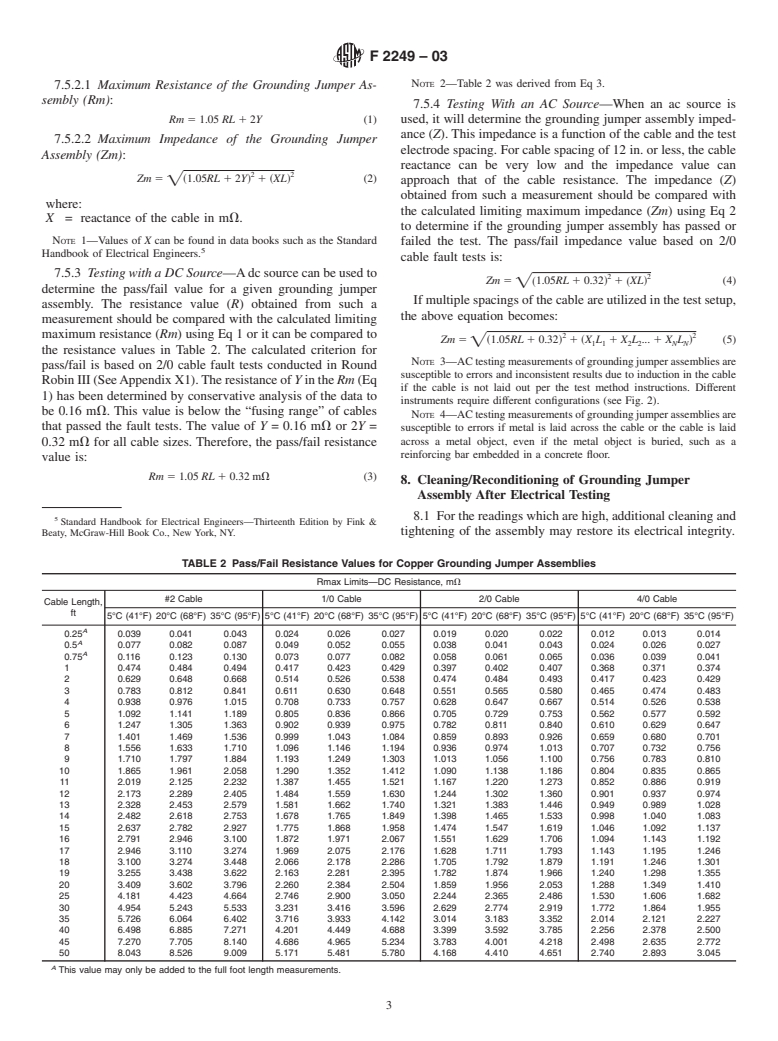

NOTE 2—Table 2 was derived from Eq 3.

7.5.2.1 Maximum Resistance of the Grounding Jumper As-

sembly (Rm):

7.5.4 Testing With an AC Source—When an ac source is

Rm 5 1.05 RL 1 2Y (1) used, it will determine the grounding jumper assembly imped-

ance (Z). This impedance is a function of the cable and the test

7.5.2.2 Maximum Impedance of the Grounding Jumper

electrode spacing. For cable spacing of 12 in. or less, the cable

Assembly (Zm):

reactance can be very low and the impedance value can

2 2

Zm 5 1.05RL 1 2Y 1 XL (2)

=~ ! ~ !

approach that of the cable resistance. The impedance (Z)

obtained from such a measurement should be compared with

where:

the calculated limiting maximum impedance (Zm) using Eq 2

X = reactance of the cable in mV.

to determine if the grounding jumper assembly has passed or

NOTE 1—Values of X can be found in data books such as the Standard

failed the test. The pass/fail impedance value based on 2/0

Handbook of Electrical Engineers.

cable fault tests is:

7.5.3 Testing with a DC Source—Adc source can be used to

2 2

Zm 5 ~1.05RL 1 0.32! 1 ~XL! (4)

=

determine the pass/fail value for a given grounding jumper

If multiple spacings of the cable are utilized in the test setup,

assembly. The resistance value (R) obtained from such a

the above equation becomes:

measurement should be compared with the calculated limiting

maximum resistance (Rm) using Eq 1 or it can be compared to 2 2

Zm 5 ~1.05RL 1 0.32! 1 ~X L 1 X L . 1 X L ! (5)

=

1 1 2 2 N N

the resistance values in Table 2. The calculated criterion for

NOTE 3—ACtestingmeasurementsofgroundingjumperassembliesare

pass/fail is based on 2/0 cable fault tests conducted in Round

susceptible to errors and inconsistent results due to induction in the cable

RobinIII(SeeAppendixX1).TheresistanceofYinthe Rm(Eq

if the cable is not laid out per the test method instructions. Different

1) has been determined by conservative analysis of the data to

instruments require different configurations (see Fig. 2).

be 0.16 mV. This value is below the “fusing range” of cables

NOTE 4—ACtestingmeasurementsofgroundingjumperassembliesare

that passed the fault tests. The value of Y = 0.16 mV or 2Y =

susceptible to errors if metal is laid across the cable or the cable is laid

0.32 mV for all cable sizes. Therefore, the pass/fail resistance across a metal object, even if the metal object is buried, such as a

reinforcing bar embedded in a concrete floor.

value is:

Rm 5 1.05 RL 1 0.32 mV (3)

8. Cleaning/Reconditioning of Grounding Jumper

Assembly After Electrical Testing

5 8.1 For the readings which are high, additional cleaning and

Standard Handbook for Electrical Engineers—Thirteenth Edition by Fink &

tightening of the assembly may restore its electrical integrity.

Beaty, McGraw-Hill Book Co., New York, NY.

TABLE 2 Pass/Fail Resistance Values for Copper Grounding Jumper Assemblies

Rmax Limits—DC Resistance, mV

#2 Cable 1/0 Cable 2/0 Cable 4/0 Cable

Cable Length,

ft

5°C (41°F) 20°C (68°F) 35°C (95°F) 5°C (41°F) 20°C (68°F) 35°C (95°F) 5°C (41°F) 20°C (68°F) 35°C (95°F) 5°C (41°F) 20°C (68°F) 35°C (95°F)

A

0.25 0.039 0.041 0.043 0.024 0.026 0.027 0.019 0.020 0.022 0.012 0.013 0.014

A

0.5 0.077 0.082 0.087 0.049 0.052 0.055 0.038 0.041 0.043 0.024 0.026 0.027

A

0.75 0.116 0.123 0.130 0.073 0.077 0.082 0.058 0.061 0.065 0.036 0.039 0.041

1 0.474 0.484 0.494 0.417 0.423 0.429 0.397 0.402 0.407 0.368 0.371 0.374

2 0.629 0.648 0.668 0.514 0.526 0.538 0.474 0.484 0.493 0.417 0.423 0.429

3 0.783 0.812 0.841 0.611 0.630 0.648 0.551 0.565 0.580 0.465 0.474 0.483

4 0.938 0.976 1.015 0.708 0.733 0.757 0.628 0.647 0.667 0.514 0.526 0.538

5 1.092 1.141 1.189 0.805 0.836 0.866 0.705 0.729 0.753 0.562 0.577 0.592

6 1.247 1.305 1.363 0.902 0.939 0.975 0.782 0.811 0.840 0.610 0.629 0.647

7 1.401 1.469 1.536 0.999 1.043 1.084 0.859 0.893 0.926 0.659 0.680 0.701

8 1.556 1.633 1.710 1.096 1.146 1.194 0.936 0.974 1.013 0.707 0.732 0.756

9 1.710 1.797 1.884 1.193 1.249 1.303 1.013 1.056 1.100 0.756 0.783 0.810

10 1.865 1.961 2.058 1.290 1.352 1.412 1.090 1.138 1.186 0.804 0.835 0.865

11 2.019 2.125 2.232 1.387 1.455 1.521 1.167 1.220 1.273 0.852 0.886 0.919

12 2.173 2.289 2.405 1.484 1.559 1.630 1.244 1.302 1.360 0.901 0.937 0.974

13 2.328 2.453 2.579 1.581 1.662 1.740 1.321 1.383 1.446 0.949 0.989 1.028

14 2.482 2.618 2.753 1.678 1.765 1.849 1.398 1.465 1.533 0.998 1.040 1.083

15 2.637 2.782 2.927 1.775 1.868 1.958 1.474 1.547 1.619 1.046 1.092 1.137

16 2.791 2.946 3.100 1.872 1.971 2.067 1.551 1.629 1.706 1.094 1.143 1.192

17 2.946 3.110 3.274 1.969 2.075 2.176 1.628 1.711 1.793 1.143 1.195 1.246

18 3.100 3.274 3.448 2.066 2.178 2.286 1.705 1.792 1.879 1.191 1.246 1.301

19 3.255 3.438 3.622 2.163 2.281 2.395 1.782 1.874 1.966 1.240 1.298 1.355

20 3.409 3.602 3.796 2.260 2.384 2.504 1.859 1.956 2.053 1.288 1.349 1.410

25 4.181 4.423 4.664 2.746 2.900 3.050 2.244 2.365 2.486 1.530 1.606 1.682

30 4.954 5.243 5.533 3.231 3.416 3.596 2.629 2.774 2.919 1.772 1.864 1.955

35 5.726 6.064 6.402 3.716 3.933 4.142 3.014 3.183 3.352 2.014 2.121 2.227

40 6.498 6.885 7.271 4.201 4.449 4.688 3.399 3.592 3.785 2.256 2.378 2.500

45 7.270 7.705 8.140 4.686 4.965 5.234 3.783 4.001 4.218 2.498 2.635 2.772

50 8.043 8.526 9.009 5.171 5.481 5.780 4.168 4.410 4.651 2.740 2.893 3.045

A

This value may o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.