ASTM E82/E82M-14

(Test Method)Standard Test Method for Determining the Orientation of a Metal Crystal

Standard Test Method for Determining the Orientation of a Metal Crystal

SIGNIFICANCE AND USE

4.1 The physical properties of metals and other materials are often anisotropic (for example: Young's modulus will typically vary in different crystallographic directions). As such, it is often desirable or necessary to determine the orientation of a single crystal to ascertain the relation of any pertinent physical properties with respect to different directions in the material.

4.2 This test method can be used commercially as a quality control test in production situations in which a desired orientation, within prescribed limits, is required.

4.3 With the use of an adjustable, fixed holder that can later be mounted on a saw, lathe, or other machine, a single crystal material can be moved to a preferred orientation and subsequently sectioned, ground, or processed otherwise.

4.4 If the grains in a polycrystalline material are large enough, this test method can also be used to determine their orientations and differences in orientation can be documented or mapped or both.

SCOPE

1.1 This test method covers the back-reflection Laue procedure for determining the orientation of a metal crystal. The back-reflection Laue method for determining crystal orientation may be applied to macrograins and micrograins depending on the beam size within polycrystalline aggregates, as well as to single crystals of any size. This test method is described with reference to cubic crystals and other structures such as: hexagonal, tetragonal, or orthorhombic crystals.

1.2 Most natural crystals have well developed external faces, and the orientation of such crystals can usually be determined from inspection. The orientation of a crystal having poorly developed faces or no faces at all (for example, a metal crystal prepared in the laboratory) shall be determined by more elaborate methods. The most convenient and accurate of these involves the use of X-ray diffraction. The “orientation of a metal crystal” is known when the positions in space of the crystallographic axes of the unit cell have been located with reference to the surface geometry of the crystal specimen. This relation between unit cell position and surface geometry is most conveniently expressed by stereographic or gnomonic projection.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E82/E82M −14

Standard Test Method for

1

Determining the Orientation of a Metal Crystal

This standard is issued under the fixed designation E82/E82M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method covers the back-reflection Laue proce- 2.1 ASTM Standards:

dure for determining the orientation of a metal crystal. The E3 Guide for Preparation of Metallographic Specimens

back-reflection Laue method for determining crystal orienta-

3. Summary of Test Method

tion may be applied to macrograins and micrograins depending

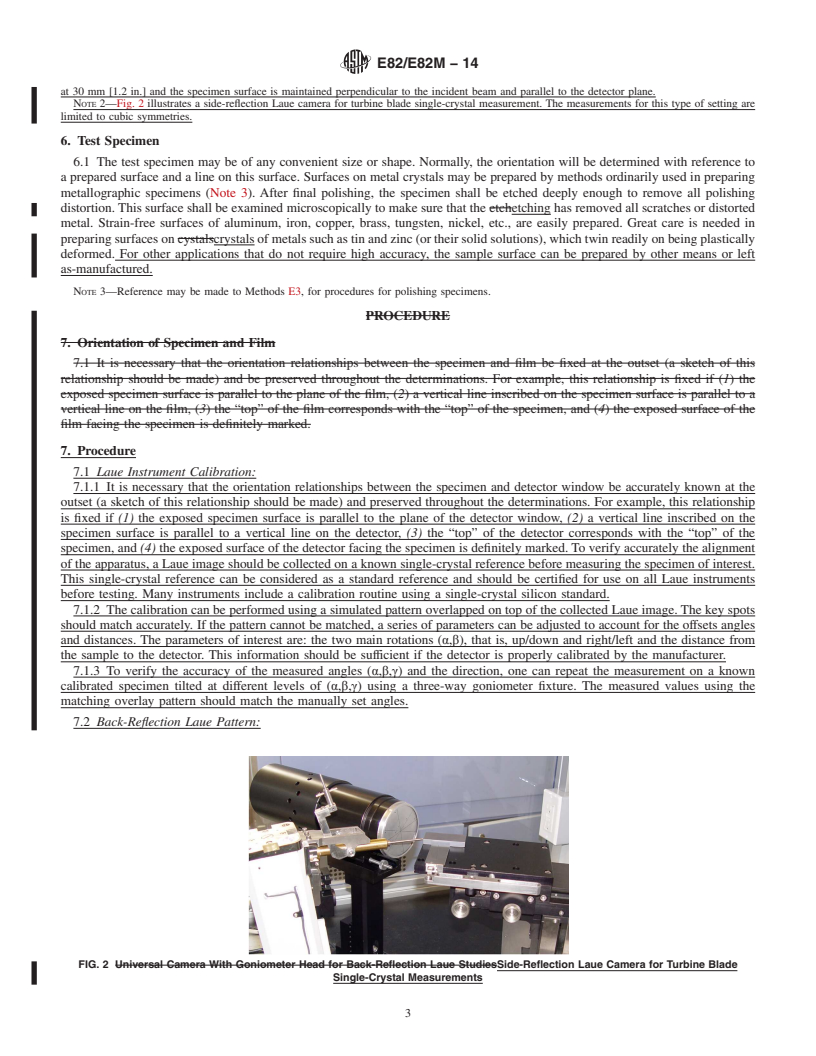

on the beam size within polycrystalline aggregates, as well as 3.1 Thearrangementoftheapparatusissimilartothatofthe

3,4

tosinglecrystalsofanysize.Thistestmethodisdescribedwith transmissionLauemethodforcrystalstructuredetermination

reference to cubic crystals and other structures such as: except that the detector is located between the X-ray source

hexagonal, tetragonal, or orthorhombic crystals. and the specimen or beside the X-ray source in the case of side

reflection geometry. The incident beam of white X-radiation

1.2 Most natural crystals have well developed external

passes through a pinhole aperture, strikes the crystal, and is

faces, and the orientation of such crystals can usually be

then diffracted back to the detector. White spots, which

determinedfrominspection.Theorientationofacrystalhaving

representX-raybeams“diffracted”bytheatomicplaneswithin

poorly developed faces or no faces at all (for example, a metal

the crystalline specimen, appear on the digital picture collected

crystal prepared in the laboratory) shall be determined by more

by the detector. The indexation of the spots and their positions

elaborate methods. The most convenient and accurate of these

in space are calculated by simulation of the Laue pattern

involves the use of X-ray diffraction. The “orientation of a

superimposed onto the digital image collected by the detector.

metal crystal” is known when the positions in space of the

Older techniques based on film technology can also be used to

crystallographic axes of the unit cell have been located with

index the spots and to calculate the orientation of the crystal.

reference to the surface geometry of the crystal specimen. This

relation between unit cell position and surface geometry is

4. Significance and Use

most conveniently expressed by stereographic or gnomonic

4.1 Thephysicalpropertiesofmetalsandothermaterialsare

projection.

often anisotropic (for example:Young’s modulus will typically

1.3 Units—The values stated in either SI units or inch-

vary in different crystallographic directions). As such, it is

pound units are to be regarded separately as standard. The

often desirable or necessary to determine the orientation of a

values stated in each system may not be exact equivalents;

single crystal to ascertain the relation of any pertinent physical

therefore,eachsystemshallbeusedindependentlyoftheother.

properties with respect to different directions in the material.

Combining values from the two systems may result in non-

4.2 This test method can be used commercially as a quality

conformance with the standard.

control test in production situations in which a desired

1.4 This standard does not purport to address all of the

orientation, within prescribed limits, is required.

safety concerns, if any, associated with its use. It is the

4.3 With the use of an adjustable, fixed holder that can later

responsibility of the user of this standard to establish appro-

be mounted on a saw, lathe, or other machine, a single crystal

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This test method is under the jurisdiction of ASTM Committee E04 on Standards volume information, refer to the standard’s Document Summary page on

Metallography and is the direct responsibility of Subcommittee E04.11 on X-Ray the ASTM website.

3

and Electron Metallography. Cullity, B. D., Elements of X-ray Diffraction, second edition, Addison-Wesley,

Current edition approved May 1, 2014. Published August 2014. Originally Reading, MA, 1978.

4

approved in 1949. Last previous edition approved in 2009 as E82–09. DOI: Barrett, C. S. and Massalski, T. B., The Structure of Metals, 3rd edition,

10.1520/E0082-14. McGraw-Hill Inc., New York, 1966, pp. 211–227.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshoho

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E82 − 09 E82/E82M − 14

Standard Test Method for

1

Determining the Orientation of a Metal Crystal

This standard is issued under the fixed designation E82;E82/E82M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the back-reflection Laue procedure for determining the orientation of a metal crystal. The

back-reflection Laue method for determining crystal orientation (1, 2)may be applied to macrograins (and3) (0.5-mm diameter or

larger) micrograins depending on the beam size within polycrystalline aggregates, as well as to single crystals of any size. The This

test method is described with reference to cubic crystals; it can be applied equally well to crystals and other structures such as:

hexagonal, tetragonal, or orthorhombic crystals.

1.2 Most natural crystals have well developed external faces, and the orientation of such crystals can usually be determined from

inspection. The orientation of a crystal having poorly developed faces,faces or no faces at all (for example, a metal crystal prepared

in the laboratory) mustshall be determined by more elaborate methods. The most convenient and accurate of these involves the

use of X-ray diffraction. The “orientation of a metal crystal” is known when the positions in space of the crystallographic axes of

the unit cell have been located with reference to the surface geometry of the crystal specimen. This relation between unit cell

position and surface geometry is most conveniently expressed by stereographic or gnomonic projection.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values given

in parentheses are mathematical conversions to SI units that are provided for information only and are not considered stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E3 Guide for Preparation of Metallographic Specimens

3. Summary of Test Method

3,4

3.1 The arrangement of the apparatus is similar to that of the transmission Laue method for crystal structure determination

except that the photographic film detector is located between the X-ray source and the specimen. The specimen or beside the X-ray

source in the case of side reflection geometry. The incident beam of white XradiationX-radiation passes through a pinhole system

and through a hole in the photographic film, aperture, strikes the crystal, and is then diffracted back ontoto the film. Darkdetector.

White spots, which represent X-ray beams “reflected”“diffracted” by the atomic planes within the crystalline specimen, appear on

the developed film. The atomic planes these spots represent are identified by crystallographic procedures and digital picture

collected by the detector. The indexation of the spots and their positions in space are calculated by simulation of the Laue pattern

superimposed onto the digital image collected by the detector. Older techniques based on film technology can also be used to index

the spots and to calculate the orientation of the metal crystal is determined.crystal.

1

This test method is under the jurisdiction of ASTM Committee E04 on Metallography and is the direct responsibility of Subcommittee E04.11 on X-Ray and Electron

Metallography.

Current edition approved Oct. 1, 2009May 1, 2014. Published October 2009August 2014. Originally approved in 1949. Last previous edition approved in 20072009 as

E82 – 91(2007).E82–09. DOI: 10.1520/E0082-09.10.1520/E0082-14.

2

The boldface numbers in parentheses refer to the list of references at the end of this method.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Cullity, B. D., Elements of X-ray D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.