ASTM F1989-99

(Specification)Standard Specification for Fire Suppression Towels

Standard Specification for Fire Suppression Towels

SCOPE

1.1 This specification covers requirements for fire suppression towels intended for use by consumers in and around the home.

1.2 This specification does not apply to fire towels that: are made from asbestos; have sides of differing appearance, finish or color; have a performance that differs according to which side is used; or, are of metallic construction or component.

1.3 This specification covers fire suppression towels intended for use in extinguishing small fires in and around containers during cooking.

1.4 This specification replaces Provisional Standard Specification PS 114.

1.5 The values stated in SI units are to be regarded as the standard.

1.6 The following safety hazards caveat pertains only to the test methods portion of this specification, Section 4: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1989 – 99

Standard Specification for

1

Fire Suppression Towels

This standard is issued under the fixed designation F 1989; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.3.2 Attention shall be paid to the design of any holding

device to ensure ease of handling and hand release.

1.1 This specification covers requirements for fire suppres-

3.4 AppearanceandBi-LateralUse—Thetwosidesofafire

sion towels intended for use by consumers in and around the

towel shall be of identical appearance, finish or color and shall

home.

give the equivalent results when tested for compliance with

1.2 This specification does not apply to fire towels that: are

Section 4.

made from asbestos; have sides of differing appearance, finish

or color; have a performance that differs according to which

NOTE 1—It is important not only that either side of fire towel can be

side is used; or, are of metallic construction or component.

exposed to the fire or other hazard with equal effectiveness, but also that

no doubt be created in the mind of the user at the moment of emergency

1.3 This specification covers fire suppression towels in-

use as to which side of the fire towel to apply to the hazard.

tended for use in extinguishing small fires in and around

containers during cooking.

3.5 Resistance to Fraying or Tearing—The edges of fire

1.4 This specification replaces Provisional Standard Speci-

towels shall not fray or tear during testing for compliance with

fication PS 114.

4.3.1, 4.3.2, 4.4.4, and 4.5.1.5.

1.5 The values stated in SI units are to be regarded as the

4. Test Methods

standard.

1.6 The following safety hazards caveat pertains only to the

4.1 Sampling and Sequence of Testing:

test methods portion of this specification, Section 4: This 4.1.1 A minimum of 9 fire towels is required. Identify and

standard does not purport to address all of the safety concerns,

mark the fire towels as No. 1 to 9 and the two sides as (a) and

if any, associated with its use. It is the responsibility of the user (b).

of this standard to establish appropriate safety and health

4.1.1.1 Fire towels which contain a seam shall be tested

practices and determine the applicability of regulatory limita- both on and off the seam and, where the seam is tested, in the

tions prior to use. most unfavorable condition. Tests shall be carried out using a

single thickness of fire towels.

2. Terminology

4.1.2 Use any fire towel as required for the nondestructive

2.1 Definitions—For the purpose of this specification, the

examinations required in Section 4. Use fire towels No. 1, 2,

following definition applies:

and3fortestingto4.5.1inthesequenceof1(a),2(b),3(a).Use

2.1.1 fire towel, n—a flexible sheet(s) of material intended

firetowels4,5and6fortestingto4.4insequenceof4(a),5(b),

to be used to extinguish small fires by smothering.

and 6(a). Use fire towels 7, 8 and 9 for testing to 4.5.2 in

sequence of 7(a), 8(b), and 9(a).

3. Physical Properties

4.2 Conditioning:

3.1 Size and Shape—Fire towels shall be rectangular or

4.2.1 Condition fire towels for testing for 48 h so that they

square, with no edge less than 0.9 m or longer than 1.8 m.

are in equilibrium with air at 20 6 5°C and at a relative

3.2 Mass—Fire towels shall have a mass not exceeding 2

humidity of 50 to 70 %. After conditioning do not expose the

kg.

towel to air at different temperature or relative humidity for

3.3 Hand Holding Devices:

longerthan5minbeforetesting.Keepthefiretowelinasealed

3.3.1 Hand holding devices, if provided, shall comprise

plastic bag or other conditioning container until testing if it is

loops or pockets and shall not become detached from the towel

necessary to transport it any distance to the test site.

during testing for compliance with Section 4.

4.2.2 Store fire towel for testing in their containers, or in the

recommended storage condition for 24 h immediately prior to

the testing for conformity with the requirements of Section 4.

1

This specification is under the jurisdiction of ASTM Committee F-15 on

4.2.3 Except where otherwise specified, tests shall be car-

Consumer Products and is the direct responsibility of Subcommittee F15.46 on Fire

ried out at 20 6 10°C.

Suppression Towels.

Current edition approved Sept. 10, 1999. Published September 1999. 4.3 General Tests:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1989–99

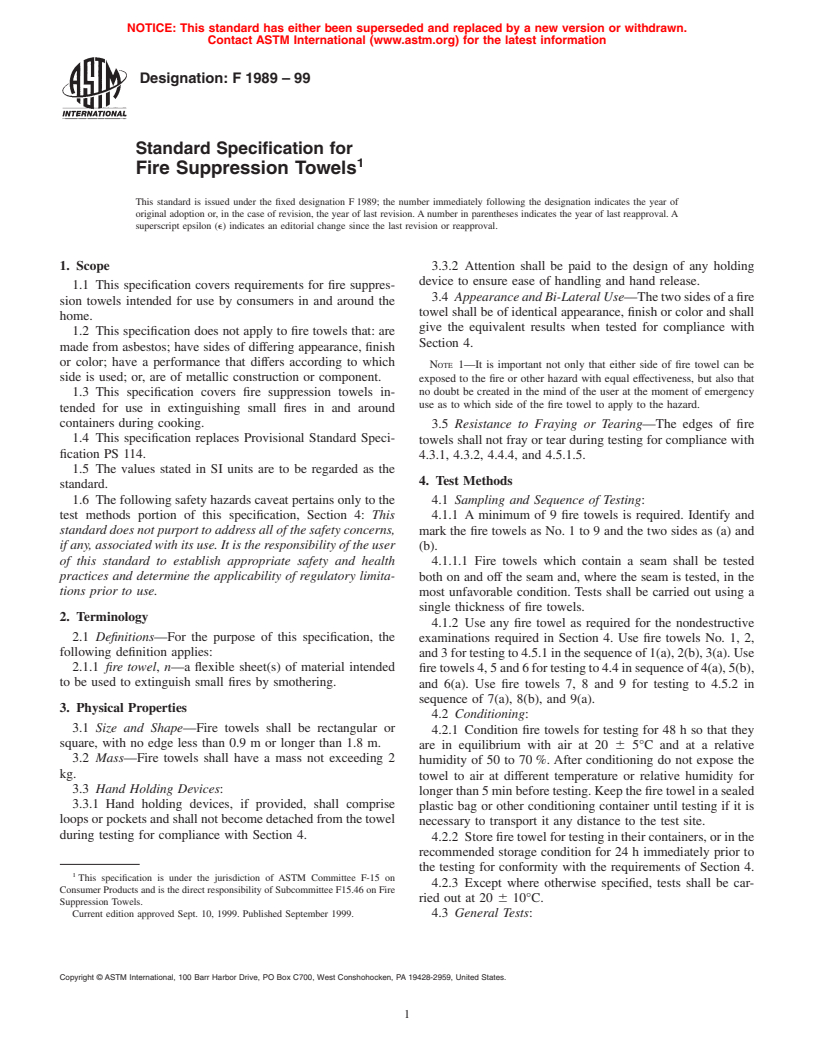

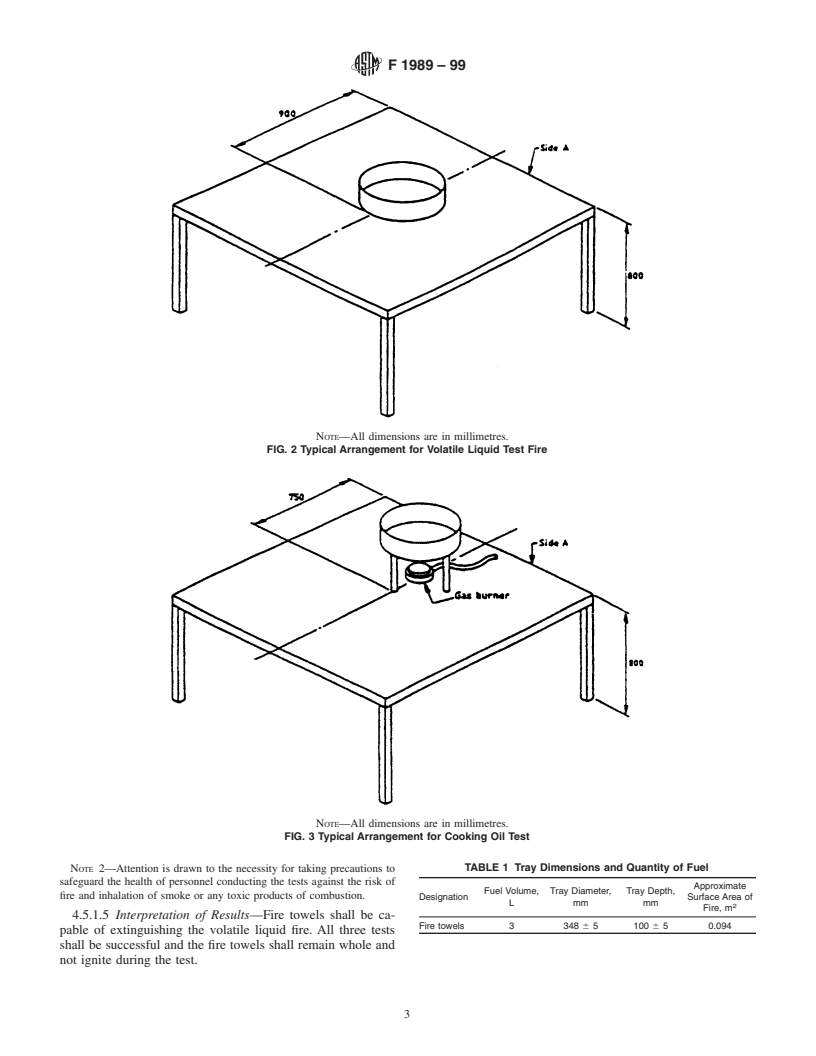

NOTE—All dimensions are in millimetres.

FIG. 1 Typical Arrangement for the Electrical Test

4.3.1 Flexibility Test—Towels shall be capable of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.