ASTM D2570-96(2002)e1

(Test Method)Standard Test Method for Simulated Service Corrosion Testing of Engine Coolants

Standard Test Method for Simulated Service Corrosion Testing of Engine Coolants

SIGNIFICANCE AND USE

This test method, by a closer approach to engine cooling system conditions, provides better evaluation and selective screening of engine coolants than is possible from glassware testing (Test Method D 1384). The improvement is achieved by controlled circulation of the coolant, by the use of automotive cooling system components, and by a greater ratio of metal surface area to coolant volume.

Although this test method provides improved discrimination, it cannot conclusively predict satisfactory corrosion inhibition and service life. If greater assurance of satisfactory performance is desired, it should be obtained from full-scale engine tests (Test Method D 2758) and from field testing in actual service (Practice D 2847).

Significance and interpretation of the test and its limitations are discussed further in Appendix X1.

If this test method is used as a qualification test for Specification D 3306 and Specification D 4985, the recommended components listed in Section 5 shall be used. If it is not being used for such qualification purposes, then suitable substitution components may be used, if agreed upon between the contracting parties.

SCOPE

1.1 This test method evaluates the effect of a circulating engine coolant on metal test specimens and automotive cooling system components under controlled, essentially isothermal laboratory conditions.

1.2 This test method specifies test material, cooling system components, type of coolant, and coolant flow conditions that are considered typical of current automotive use.

1.3 The values stated in either SI or inch-pound units are to be regarded as the standard. The values given in parentheses are approximate equivalents for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D2570–96 (Reapproved 2002)

Standard Test Method for

Simulated Service Corrosion Testing of Engine Coolants

This standard is issued under the fixed designation D2570; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Adjunct references were corrected editorially in April 2006.

1. Scope D2847 Practice for Testing Engine Coolants in Car and

Light Truck Service

1.1 This test method evaluates the effect of a circulating

D3306 Specification for Glycol Base Engine Coolant for

enginecoolantonmetaltestspecimensandautomotivecooling

Automobile and Light-Duty Service

system components under controlled, essentially isothermal

D4985 Specification for Low Silicate Ethylene Glycol

laboratory conditions.

Base Engine Coolant for Heavy Duty Engines Requiring a

1.2 This test method specifies test material, cooling system

Pre-Charge of Supplemental Coolant Additive (SCA)

components, type of coolant, and coolant flow conditions that

2.2 SAE Standard:

are considered typical of current automotive use.

SAE J20e Standard for Coolant System Hoses

1.3 The values stated in either SI or inch-pound units are to

2.3 ASTM Adjuncts:

be regarded as the standard. The values given in parentheses

Coolant reservoir (1 drawing)

are approximate equivalents for information only.

Framework for test equipment (3 drawings and B/M)

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Summary of Test Method

responsibility of the user of this standard to establish appro-

3.1 An engine coolant is circulated for 1064 h at 190°F

priate safety and health practices and determine the applica-

(88°C) in a flow loop consisting of a metal reservoir, an

bility of regulatory limitations prior to use. Specific precau-

automotivecoolantpump,anautomotiveradiator,andconnect-

tionary statements are given in Section 6.

ing rubber hoses. Test specimens representative of engine

2. Referenced Documents cooling system metals are mounted inside the reservoir, which

simulates an engine cylinder block. At the end of the test

2.1 ASTM Standards:

period, the corrosion-inhibiting properties of the coolant are

D1121 Test Method for Reserve Alkalinity of Engine

determinedbymeasuringthemasslossesofthetestspecimens

Coolants and Antirusts

and by visual examination of the interior surfaces of the

D1176 Practice for Sampling and Preparing Aqueous So-

components.

lutions of Engine Coolants or Antirusts for Testing Pur-

poses

4. Significance and Use

D1177 Test Method for Freezing Point ofAqueous Engine

4.1 Thistestmethod,byacloserapproachtoenginecooling

Coolants

system conditions, provides better evaluation and selective

D1193 Specification for Reagent Water

screening of engine coolants than is possible from glassware

D1287 Test Method for pH of Engine Coolants and Anti-

testing(TestMethodD1384).Theimprovementisachievedby

rusts

controlled circulation of the coolant, by the use of automotive

D1384 TestMethodforCorrosionTestforEngineCoolants

cooling system components, and by a greater ratio of metal

in Glassware

surface area to coolant volume.

D2758 Test Method for Engine Coolants by Engine Dyna-

4.2 Although this test method provides improved discrimi-

mometer

nation, it cannot conclusively predict satisfactory corrosion

inhibition and service life. If greater assurance of satisfactory

This test method is under the jurisdiction ofASTM Committee D15 on Engine

performance is desired, it should be obtained from full-scale

Coolants and is the direct responsibility of Subcommittee D15.09 on Simulated

engine tests (Test Method D2758) and from field testing in

Service Tests.

actual service (Practice D2847).

Current edition approved April 10, 1996. Published June 1996. Originally

published as D2570–66T. Last previous edition D2570–94.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers, 400 Commonwealth Dr.,

the ASTM website. Warrendale, PA 15096.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D2570–96 (2002)

4.3 Significance and interpretation of the test and its limi- 1.6 L/s) for the General Motors 173-in. (2.8-L) V-6 engine.

tations are discussed further in Appendix X1. The flow rate may be determined by a flow measurement

4.4 If this test method is used as a qualification test for device locatedbetweenpumpdischargeandreservoirinlet,as

Specification D3306 and Specification D4985, the recom- indicatedinFig.2.Thepressuredropbetweenpumpdischarge

mendedcomponentslistedinSection5shallbeused.Ifitisnot and reservoir inlet, measured by the pressure gages shown in

being used for such qualification purposes, then suitable Fig. 2, must be maintained when the flow measurement device

substitution components may be used, if agreed upon between is removed from the system. This can be done by substituting

the contracting parties. for the flow measurement device a variable-flow restriction,

such as a valve, which can be adjusted to produce the same

5. Apparatus

pressure drop as that measured across the flow measurement

device at the specified flow rate.

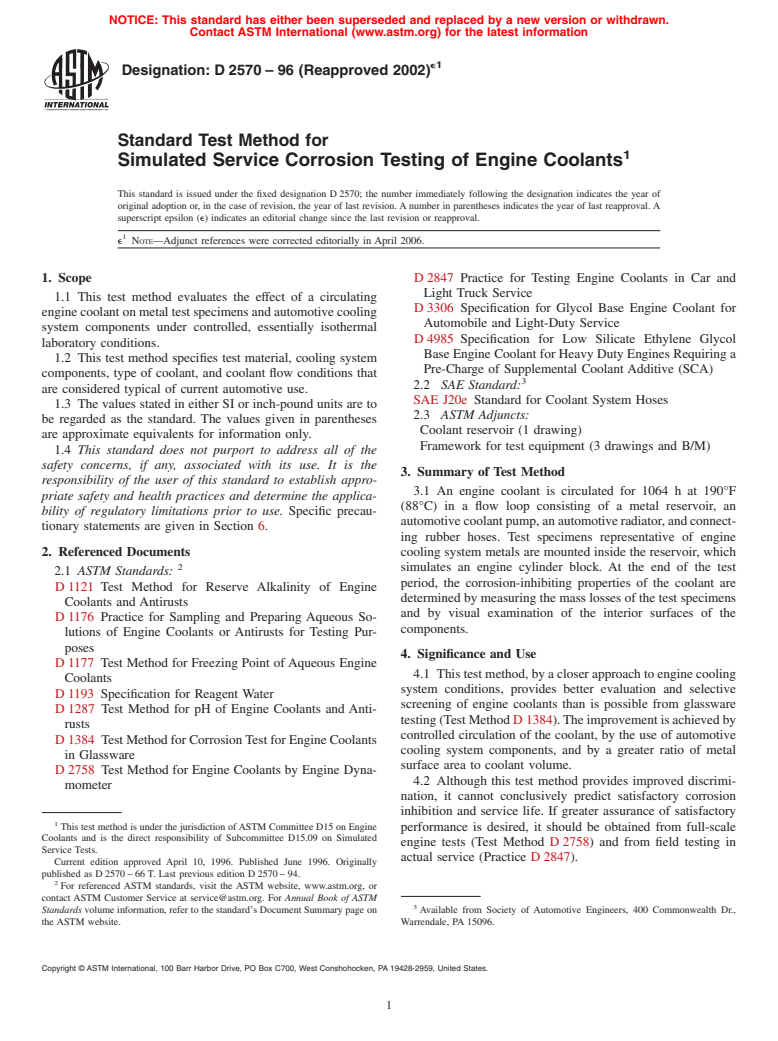

5.1 Reservoir—An assembly drawing of this component is

5.6 Electric Heater—About 2000 W, either a hot plate

showninFig.1.Thematerialofconstruction,representingthat

installed under the reservoir or a circumferential, metal-clad

oftheenginecylinderblock,shallbeSAEG3500GrayIronfor

heater band around the reservoir.

Automotive Castings. Install a right angle fitting on the top of

5.7 Thermoregulator—A suitable temperature regulator

theresevoirforattachmentofanairline.Installashutoffvalve

shall be used to maintain the coolant temperature between the

intheairlinetoavoidbackingupthesolutionintothepressure

limits specified by 9.3. The sensing unit of the regulator shall

hose.

be installed in an opening on the reservoir cover.

5.2 Automotive Components—These shall be those nor-

5.8 Thermometer—An instrument capable of indicating

mallyusedwitha4,6,or8-cylinderautomobileengineusedin

coolanttemperaturetothenearest1°For1°Cshallbeinstalled

currentautomobilesintheUnitedStates,inthe1.6to5.0-L(98

in an opening on the reservoir cover.

to 305-in. ) range of piston displacement. General character-

5.9 Framework—A suitable framework shall be used to

istics shall be as follows:

mount all the components as a unit.

5.2.1 Radiator—Brass, GMpartNo.3056740(crossflow),

with coolant recovery tank. An aluminum radiator, GM part

6. Safety Precautions

No. 3093506, may be used subject to mutual agreement of the

parties involved.

6.1 Reservoir—Protection against bursting shall be pro-

5.2.2 Radiator Pressure Cap—Normally open 12 to 15 psi vided, either by a pressure-relief valve on the cover or by a

(80 to 100 kPa), GM part No. 6410427.

safety enclosure.

5.2.3 Coolant Pump —GM part No. 14033483 (aluminum 6.2 PumpDrive—Asafetyguardforthecoolantpumpdrive

matching front end cover). GM part No. 14033526 (aluminum

belt and pulleys shall be provided.

providesbackcover),coolantdischargepartsandmountingfor 6.3 Electrical—Electrical circuits required for operation of

pump.

motor, heater, and thermoregulator shall be installed with

5.2.4 Coolant Outlet—GM part No. 14033198 (aluminum). suitable precautions against electrical shock to operating per-

5.2.5 Hoses—Reinforced elastomer, meeting the require-

sonnel in the event of accidental spills of electrically conduc-

ments of SAEJ20e. tive liquids.

5.2.6 Hose Clamps—Preferably worm-screw type (constant

6.4 Thermal—Protection of operating personnel against

tension may be used). burns from exposed metal surfaces, especially those of the

5.2.7 Hose Sight Tube—A pyrex glass sight tube shall be

heater, shall be provided.

installed in the top radiator hose.The tube should have a slight

bead on each end. (The primary purpose of the sight tube is to 7. Metal Test Specimens

see that there is entrained air in the system.)

NOTE 1—The specimens prescribed for this test method have been

5.3 Pipe Fittings—The preferred material for the fittings

accepted by automobile manufacturers and are required for Specifications

requiredinthehoseconnectionsbetweenpumpdischargeports

D3306 and D4985 qualification. Current production vehicles may have

and reservoir inlet is malleable cast iron. A satisfactory

differing alloy. Therefore, specimens other than those designated in this

alternative is steel. test method may be used by mutual agreement of the parties involved.

5.4 ElectricMotor—1 ⁄2hp(1.1kW)orlarger,drip-proofor

explosion-proof in accordance with local safety regulations.

5.5 Pulleys and Drive Belt—Sized to drive the pump at

Fischer and Porter Series 10A2235A Ratosight Flow Rate Indicator, 4 to 50

aspeed that will produce a flow rate of 20 to 25 gal/min (1.3 to

gal/min (0.3 to 3.0 L/s), of bronze construction, has been found satisfactory.

Equivalent flow measuring devices may be used.

Chromalox No. ROPH-204 has been found satisfactory. Equivalent hot plates

may be used.

4 9

Detail drawings are available from ASTM International Headquarters. Order Chromalox No. HB-8415 has been found satisfactory. Equivalent heater bands

AdjunctNo.ADJ257001.Originaladjunctproducedin1982.Reservoirsofcastiron may be used.

or cast aluminum, made in accordance with these drawings, may be obtained from Chromalox No. AR-2524P has been found satisfactory. Equivalent ther-

CommercialMachineService,1099TouhyAve.,ElkGroveVillage,IL60007,(847) moregulators may be used.

806-1901. Fischer Scientific No. 15-076D and Weston No. 2261 dial-type thermometers

Aluminum or iron may be used if mutually agreed upon between the parties have been found satisfactory. Equivalent thermometers may be used.

involved. Detail and assembly drawings of a suitable framework and arrangement of

Gates “Vulco Straight” bulk-length radiator hose, ProductType 4178, has been components thereon are available from ASTM International Headquarters. Order

found satisfactory. Equivalent radiator hoses may be used. Adjunct No. ADJ257002. Original adjunct produced in 1982.

e1

D2570–96 (2002)

FIG. 1 Reservoir

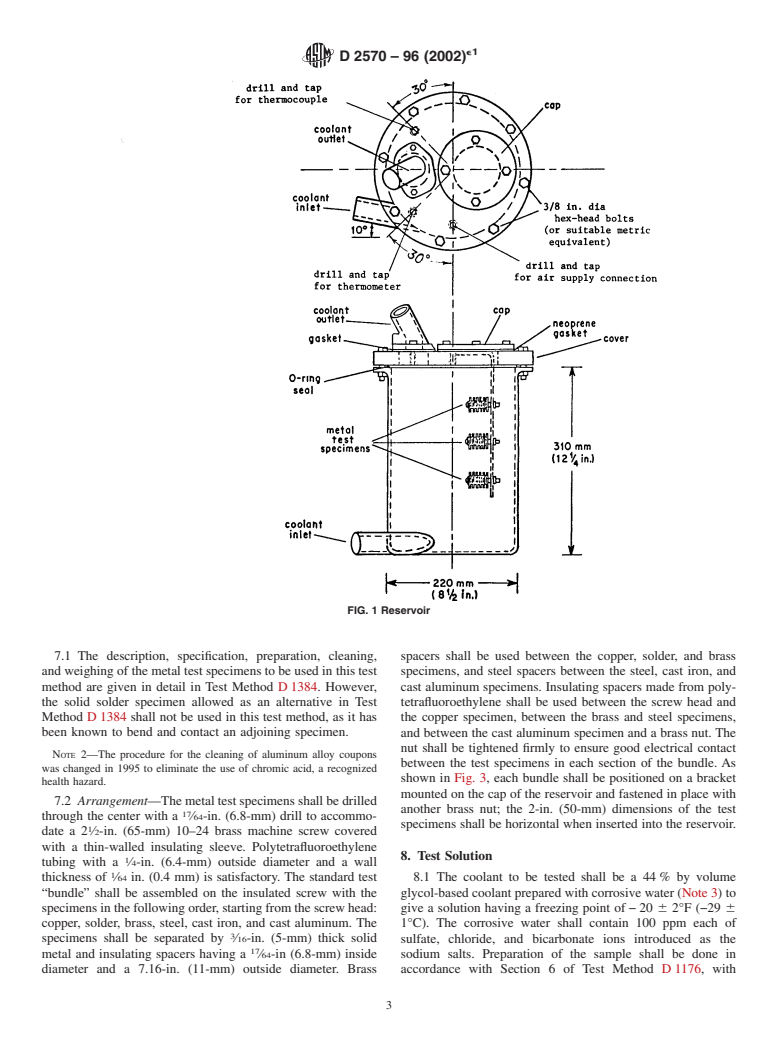

7.1 The description, specification, preparation, cleaning, spacers shall be used between the copper, solder, and brass

andweighingofthemetaltestspecimenstobeusedinthistest specimens, and steel spacers between the steel, cast iron, and

method are given in detail in Test Method D1384. However, cast aluminum specimens. Insulating spacers made from poly-

the solid solder specimen allowed as an alternative in Test

tetrafluoroethylene shall be used between the screw head and

Method D1384 shall not be used in this test method, as it has the copper specimen, between the brass and steel specimens,

been known to bend and contact an adjoining specimen.

and between the cast aluminum specimen and a brass nut. The

nut shall be tightened firmly to ensure good electrical contact

NOTE 2—The procedure for the cleaning of aluminum alloy coupons

between the test specimens in each section of the bundle. As

was changed in 1995 to eliminate the use of chromic acid, a recognized

shown in Fig. 3, each bundle shall be positioned on a bracket

health hazard.

mounted on the cap of the reservoir and fastened in place with

7.2 Arrangement—Themetaltestspecimensshallbedrilled

another brass nut; the 2-in. (50-mm) dimensions of the test

through the center with a ⁄64-in. (6.8-mm) drill to accommo-

specimens shall be horizontal when inserted into the reservoir.

date a 2 ⁄2-in. (65-mm) 10–24 brass machine screw covered

with a thin-walled insulating sleeve. Polytetrafluoroethylene

8. Test Solution

tubing with a ⁄4-in. (6.4-mm) outside diameter and a wall

thickness of ⁄64 in. (0.4 mm) is satisfactory. The standard test 8.1 The coolant to be tested shall be a 44% by volume

“bundle” shall be assembled on the insulated screw with the glycol-basedcoolantpreparedwithcorrosivewater(Note3)to

specimensinthefollowingorder,startingfromthescrewhead: give a solution having a freezing point of−20 6 2°F (−29 6

copper, solder, brass, steel, cast iron, and cast aluminum. The 1°C). The corrosive water shall contain 100 ppm each of

specimens shall be separated by ⁄16-in. (5-mm) thick solid sulfate, chloride, and bicarbonate ions introduced as the

metal and insulating spacers having a ⁄64-in (6.8-mm) inside sodium salts. Preparation of the sample shall be done in

diameter and a 7.16-in. (11-mm) outside diameter. Brass accordance with Section 6 of Test Method D1176, with

e1

D2570–96 (2002)

FIG. 2 Assembly of Test Apparatus

corrosivewaterusedfordilution.Thus,anyinsolublematerials 9. Test Conditions

will be included in the representative sample. The freezing

9.1 Assembly—The essential arrangement of the reservoir,

point of the coolant solution may be determined by Test

radiator, coolant pump, and connecting hoses is shown in Fig.

Method D1177.

2. The gasketed coolant outlet is bolted to the reservoir cover.

9.2 Coolant Flow—The coolant flow shall be maintained at

NOTE 3—The specified corrosive water can be prepared by dissolving

the following amounts of anhydrous sodium salts in a quantity of distilled 23 6 1 gal/min (1.3 to 1.6 L/s).

or deionized water:

9.3 Temperature—The test coolant shall be maintained at a

Sodium sulfate 148 mg

temperature of 190 6 5°F (88 6 3°C) throughout the test

Sodium chloride 165 mg

except during shutdown periods.

Sodium bicarbonate 138 mg

9.4 Duration—The test shall be run for 152 h/week for 7

The resulting solution should be made up to a volume of 1 L with

weeks. Operation shall be continuous, except for two 8-h

distilled or deionized water at 20°C.

shutdowns each week, until 1064 h of operation have been

If relatively large amounts of corrosive water are needed for testing, a

completed.

concentratemaybepreparedbydissolvingtentimestheaboveamountsof

the three chemicals, in distilled or deionized water, and adjusting the total

10. Preparation of Apparatus

volume to 1 L by further additions of distilled or deionized water. When

10.1 Reservoir—Sand blast or bead blast the interior sur-

needed, the corrosive water concentrate is diluted to the ratio of one part

by volume of concentrate to nine parts of distilled or deionized water. faces of the reservoir and its cover to remove all rus

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.